Beruflich Dokumente

Kultur Dokumente

US3002206 - Tapping Attachment With Adjustable Clutch PDF

Hochgeladen von

devheadbot0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

42 Ansichten3 SeitenOriginaltitel

US3002206 - Tapping Attachment with Adjustable Clutch.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

42 Ansichten3 SeitenUS3002206 - Tapping Attachment With Adjustable Clutch PDF

Hochgeladen von

devheadbotCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

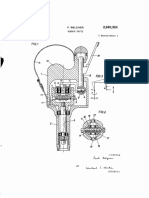

Oct. 3, 1961 A. S. JOHNSON 3,002,206

TAPPING ATTACHMENT WITH ADJUSTABLY YIELDABLE CLUTCH MEANS

Filed Aug, 25, 1958

INVENTOR.

Asan 8. Tonnson

Mees ¢ issue

Sareouees

ie

we

United States Patent Office

3,002,206

Patented Oct. 3, 1961

3,002,206

TAPPING ATTACHMENT WITH ADJUSTABLY

YIELDABLE CLUICH MEANS

Allan, Johnson, Newport Bench, Calif asignor to Tp.

ofCatfonia yee 8 eeepc

Filed Aug. 25, 1958, Ser. No. 756,831.

2 Claims, (Cl. 10—135)

This invention relates to thread-cutting or tapping at-

tachments for use with drilling machines, lathes and bor-

ing machines in association with the spindle of said de-

‘The object of the invention is to provide an improved

tapping attachment.

‘Another object is to provide a tapping attachment hav-

ing a positive torque adjustment means limiting the

torque force applied to the tapping tool.

Another object is to provide a tapping attachment

having a free axial float means limiting the power ap-

plied fo the tapping tool to rotative forces.

A further object is to provide a tapping attachment

having a depth control means limiting the depth to which

the tapping tool penetrates the work piece,

‘Still another object is to provide a tapping attachment

having in combination the features of an adjustable means

providing positive torque limit, means providing free

axial float thereby to limit the force applied to the tool

to rotative forces, and means providing depth control

thereby to limit the extent to which the tool engages the

work piece, which attachment is of simple design and

inexpensive to produce.

Other objects will be apparent as the invention is more

fully hereinafter disclosed.

Tn accordance with these objects I have designed and

devised a tapping attachment having the above noted

features and advantages which is simple in design and

inexpensive to manufacture, one specific embodiment of

which is illustrated in the accompanying drawings and

will be hereinafter described by way of example but not

by way of limitation of the present invention.

In the drawings:

FIG. 1 is a vertical cross-sectional view of a capping

attachment improved in accordance with the present

invention; and

FIG. 2 is a horizontal cross-sectional view taken along

plane 2—2 of FIG. 1.

‘Referring to the drawings, the tapping attachment

shown therein is one designed for general utility in the

art in the tapping of drill holes up to a diameter of about

‘two inches.

‘The attachment is provided with the usual mechanical

‘elements of such devices such as a member A adapted

to be mounted onto a spindle to be rotatively driven

thereby, a member B adapted to be rotatively driven by

‘the member A, a clutch means C to engage the mem-

ber B to the member A for driving the member B, and

a tool-holding chuck means D mounted on the member

B to be rotatively driven thereby.

In this basic combination of mechanical elements,

common to all such tapping attachments, I have provided

‘a means T providing a positive torque adjustment limit-

ing the power to be applied to the member B thereby to

prevent tap breakage; 2 means F providing a free axial

float for the member B thereby limiting the forces ap-

plied to the member B to rotative forces and thus per-

sitting the tsp to determine its own lead to insure that the

thread produced will conform to the thread on the tap;

anda depth control means H permitting tapping to a

predetermined depth in the work piece. The three said

‘means are incorporated in the basic combination in such

0

aw

20

25

20

35

40

4

50

55

60

cc)

2

manner as to provide a simple, rugged construction

adapted for inexpensive production and providing a pro-

longed operating and efficient service life for the tapping

attachment.

Referring more specifically to these said improve-

ments:

‘The means T providing a positive torque adjustment for

the tapping attachment limiting the maximum torque

applicable to the member B comprises in combination a

cap 10 mounted on the rotatably driven member A to

‘be movable therealong to a plurality of pre-set positions,

as by engaging threaded sections 11—11’. The interior

of the cap 10 is provided with a plurality of annularly

spaced pins 12 seating in complementary annularly spaced

ore passegeways 13 in the base 14 of the rotatably

driven member A. ‘The axes of said bore passageways

13 lic substantially parallel to the axis of the member A.

Driving balls 18 are disposed in each said bore passage

‘way 13 and 2 compression spring means 16 is provided

in each said bore passageway U3 to spring load the driv-

ing balls 15 into engagement with concave recesses 17 on

the abutting surface of the clutch means C. It can be

seen that by this arcangement the cap 10 when rotated

fon the engaging threads 1111’ upwardly lessens the

spring load on the balls 18 and when rotated on the

threads 1111" downwardly increases the spring load

‘on the balls 45 thereby to control and limit the torque

applied to drive the clutch means C. By this means the

‘maximum torque force applied to the member B may be

preset.

Various other and substantially equivalent means and

mechanisms may be substituted for the threaded cap

‘means 10 without essential departure from the invention,

2s one skilled in the art will recognize.

‘The clutch means C is rotatably mounted within a de-

pending sleeve portion of the base 14 of the driven mem-

ber A by means of roller bearing 18 and means, such

as an oil passageway 19, is provided to lubricate the

abutting surfaces of the member A and the clutch C.

With this arrangement it may be seen that when the

torque applied to the clutch C by the member A exceeds

the spring load applied to the driving balls 1S, with result-

tant displacement of the driving balls 45 out of the con-

eave recesses 17 in the clutch C, the member A con-

‘tinues to rotate without rotating the clutch C on the roller

bearing 18.

‘The clutch means C is secured by a plurality of an-

ularly spaced roller pins 20 to drive driven member B,

the said roller pins 20 being fixedly mounted at one end

in the momber B adjacent its upper end with the opposite

‘end of the roller pin 20 riding free in longitudinal slots

21, each of said slots 24 terminating at its bottom end

{in ‘annular groove 22.

Tae member B is mounted for axial rotation on de-

pending axle 25 secured at its upper end for axial rotation

‘with member A and is sustained for axial rotation about

the axis of the member A by spaced bearings 26—27. By

this arrangement it may be recognized that the axle 25

is free to rotate by means of the bearings 26—27 inde-

pendently of the member B and that when the clutch

‘means C is being driven by the member A, the roller pins

20 transmit the rotary movement of the clutch means

C to the member B. It will also be recognized that the

member B is slidably mounted on the axle 25 by means

of the roller pins 20.

To control and regulate the sliding movement of the

‘member B on the axle 25, opposing compression springs

28-29 are provided above and below the bearing 26.

‘The upper spring 28 is a cushioning spring and is of

sufficient strength to limit the sliding movement of the

‘member B upwardly on the axle 25 to a position short of

8,002,206

3

contact with the member A. The lower spring 29 is a

relatively light spring with a spring strength adapted to

retura the member B to the position show in FIG. 1 from.

any sliding position below this position.

‘The member B is mounted in the clutch C for sliding

‘movernent therein by means of sleeve bearing 30 disposed

adjacent the bottom end of the clutch C, the upper end of

the sleeve bearing 30 forming the bottom wall or shoulder

(ofthe annular slot 21.

Chuck means D dependingly mounted on the bottom

end of the member B for rotation therewith is a chuck

‘means typical in the art in that it has the usual type of

jaws 30, collet 31 and thimble 32 for actuating the chuck

‘means D to engage a tapping tool for axial rotation there

with,

‘The depth control meaus H of the present invention

‘comprises a collar 35 dependingly and adjustably mounted

‘on the bottom end of the clutch means C, the said collar

38 being provided with an internal shoulder 36 thereon

adjacent the bottom end thereof adapted to engage an

outstanding shoulder 37 on the member B, thereby to limit

the sliding movement of the member B'on the axle 25

AAs indicated in the drawings the collar 35 is adjustably

‘mounted on the bottom end of the clutch means C by

‘means of engaging threaded sections 38-39. Other

substantially equivalent means for adjustably mounting

the collar 38 on the bottom end of the clutch means C

may be employed without departure from the invention,

as may also various other types of means for limiting the

extent of sliding movement of member B on the axle 25

be employed without essential departure from the inven-

ton, as one skilled in the art will recognize.

Its believed appatent from the specific embodiment of

the present invention illustrated in the drawings and here-

inabove described that the improved tapping attachment

Of the present invention provides an attachment which by

the means T controls and regulates to a precise degree the

‘maximum torque to be applied to the driven member B

by the driving member A; and that by the means F therein

provided the only force applied to the tapping tool secured

in the chuck D is the precise maximum rotating or torque

force pre-set by the means T. This leaves the tapping

tool freo to determine its own Iead in the tap hole and

adapts the tool for pulling itself and the driven member

B to which it is operatively connected into the hole being

tapped against the relatively light spring resistance of

the spring 29.

‘When the tapping operation is completed as may be

limited by the depth control means H, the spring means

29 operates to gently spring urge the member B upwardly,

‘on reversely driving the member A, thereby to withdraw

the tapping tool from the tapped hole, during which re-

‘verse movement the tool is as free to determine its own

lead in the reverse direction as in the forward direction,

the force applied thereto being only rotary.

‘The improved tapping attachment of the present inven-

tion permits the repeated insertion of the tapping tool into

and out of a tapped hole without in any way distorting the

tapped threads thereof, a feature which other tapping at-

tachments heretofore provided in the art failed to provide.

Having hereinabove disclosed the present invention

‘generically and specifically and having described and il

Iustrated the same in one specific embodiment thereof, it

is believed spparent that the invention may be widely

varied without substantial or essential departure there

from and all modifications, departures, changes and altera-

tions of the specific embodiment as herein described and

illustrated are contemplated by me as may fall within the

scope of the following claims.

‘What is claimed is:

1. Ina tapping attachment having a first member adapt-

4

ed to be secured to a rotatable spindle for rotation there-

‘with, a second member having a tool-holding means

‘mounted on one end thereof and a clutch means mounted

‘on the opposite end thereof for engaging the second mem-

5 ber to the first member for rotation therewith, the im-

provement which comprises an adjustable means for en-

‘paging said clutch means to said first member for rotation

‘therewith, said adjustable means limiting the torque force

applied by said first member to said second “member

10 through said clutch means to 2 selected maximum torque

force, means slidably mounting the second member on

said first member and in and to said clutch means for

relative sliding movement therebetween thereby to limit

the force applied to the tool to rotary forces, said means

16 for slidably mounting the second member on said first

member and in and to said clutch means comprising an

axle dependingly mounted for axial rotation with said

first member about the same axis of rotation, an annular

clutch means rotatively and dependingly sustained from

20 said first member in end abutting relation thereto 10

rotate about the axis of rotation of said axle in spaced

relation thereto, a substantially tubular second member,

the inside and outside diameters thereof permitting the

said tubular second member to be seated in the space gap

25 between the clutch means and axle, a plurality of longi-

‘udinally extending roller trackways on the inner face of

said clutch means, a plurality of rollers mounted at one

end to said tubular second member adjacent the upper end

thereof with the roller element thereof seated in and en-

80 gaging said roller trackways, spaced-apart slide bearings

‘maintaining the axle, tubular second member and cluich

‘means in concentric spaced relation, a strong compression

spring means limiting the movement of said tubular sec~

ond member inwardly along said trackways, a weaker

385 compression spring means for urging the ubular second

‘member inwardly to said limited position, and an annular

trackway connecting the bottom end of said trackways.

Ina tapping attachment having a first_member

adapted to be secured to a rotatable spindle for rotation

40 therewith, a second member having a tool-holding means

‘mounted on one end thereof and a clutch means mounted

‘on the opposite end thereof for engaging the second mem

ber to the first member for rotation therewith, the im-

provement which comprises an adjustable means for en-

45 gaging said clutch means to said first member for rota~

tion therewith, said adjustable means limiting the torque

force applied by said first member to said second member

through said clutch means to a selected maximum torque

force, means slidably mounting the second member on said

50 frst member and in and to said clutch means for rela-

tive sliding movement therebetween thereby to limit the

force applied to the tool to rotary forces, means limiting

and controlling the extent of sliding movement of said

second member relative to said first member and said

clutch means thereby to limit the depth of penetration of

the tool in 2 work piece, and said means limiting and con-

tuolling the extent of sliding movement of said second

member relative to the first member comprising a stop

extension on ssid second member and an engaging stop

60 extension on ssid first member, said engaging stop ex-

tension being movable toward and away from the first

stop extension to provide a determined space gap there-

between,

fe References Cited in the file of this patent

UNITED STATES PATENTS

2723406 Angst = Nov. 15, 1955

2,881,454 Moneymaker ~ Apr. 14, 1959

0 FOREIGN PATENTS

153,133 Sweden Jan. 17, 1956

Das könnte Ihnen auch gefallen

- Pen TurningDokument2 SeitenPen TurningdevheadbotNoch keine Bewertungen

- US6953298 - Pinstripe Painting Device, 2005Dokument8 SeitenUS6953298 - Pinstripe Painting Device, 2005devheadbotNoch keine Bewertungen

- Anodising - Aluminium Anodising DyesDokument4 SeitenAnodising - Aluminium Anodising DyesdevheadbotNoch keine Bewertungen

- US1994497 - Indicator - Winters For Gladwin, 1935Dokument5 SeitenUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotNoch keine Bewertungen

- @341 A É'Wqkammm: Filed July 28-, 1944Dokument3 Seiten@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNoch keine Bewertungen

- US2466380 - Precision Centering Device - Leland Clark, 1949Dokument5 SeitenUS2466380 - Precision Centering Device - Leland Clark, 1949devheadbotNoch keine Bewertungen

- US1157800 - Universal Test-Indicator - Oslund, 1915Dokument3 SeitenUS1157800 - Universal Test-Indicator - Oslund, 1915devheadbotNoch keine Bewertungen

- US3230631 - Optical Center PunchDokument6 SeitenUS3230631 - Optical Center PunchdevheadbotNoch keine Bewertungen

- @341 A É'Wqkammm: Filed July 28-, 1944Dokument3 Seiten@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNoch keine Bewertungen

- US2940324 - Wobble Mechanism (Scraper)Dokument4 SeitenUS2940324 - Wobble Mechanism (Scraper)devheadbotNoch keine Bewertungen

- US2579903 - Periscopic Sextant - Kollsman, 1951Dokument9 SeitenUS2579903 - Periscopic Sextant - Kollsman, 1951devheadbot100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)