Beruflich Dokumente

Kultur Dokumente

040 Workshops 2016 - 04 - 01

Hochgeladen von

Anonymous sId0uhkEIVOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

040 Workshops 2016 - 04 - 01

Hochgeladen von

Anonymous sId0uhkEIVCopyright:

Verfügbare Formate

FEEDLOT DESIGN AND CONSTRUCTION

40. Machinery

workshops

AUTHORS: Rod Davis and Ross Stafford

FEEDLOT DESIGN AND CONSTRUCTION

Introduction

Any feedlot needs a properly designed and equipped workshop for the

repair and maintenance of machinery and for light engineering. Part of

the building may also serve as a store for spare parts and consumables.

The workshop is generally a rectangular shed with an entrance at

one end – either open or with doors which provide shelter from the

elements. Its design and construction will depend on the size and

location of the feedlot.

Design objectives

Machinery workshops should be designed, constructed and

maintained to

• have sufficient space for undercover accommodation of feedlot

machinery during maintenance and repairs

• have functional space for maintenance and repair activities

• have well lit and well ventilated space for maintenance and

repair activities

• have sufficient space for spare parts for the repair and

maintenance of on-site machinery

• be compliant with respective state building codes and relevant

Australian standards

• provide a safe working environment.

Mandatory requirements

The building elements such as concrete footings, floor slabs and

steel structures should meet the structural provisions of the Building

Code of Australia (BCA) and local building regulations, and be

designed in accordance with the relevant Australian standards.

Design choices

Site selection

Site selection is often difficult when planning a workshop, but the site

should be well drained to allow access to the shed at all times and be

accessible to vehicles and other items of plant. Topography and soil

type will impact on earthworks and the design of foundations; on some

Machinery workshop at large feedlot with

drive through design and external storage clay soils, road base may be needed to ensure access in wet weather.

area for steel.

Accessibility, proximity to the feedlot and on-site traffic management

are also considerations when selecting a suitable workshop site. See

Section 2 – Feedlot site layout for overall site layout.

Sufficient distance should be allowed from other existing buildings

to allow for future expansion, reduce fire hazard and allow room for

machinery manoeuvring and parking.

The workshop should be orientated so that the main entrance is

away from prevailing weather. Where possible, locate large doors in

end walls so that roof water does not fall inside the shed, or provide

adequate gutters.

2 40. Machinery workshops

FEEDLOT DESIGN AND CONSTRUCTION

Floor plan

A workshop area may be added to an existing machinery storage

building or a separate building constructed. An attached workshop

may increase the fire potential of the machinery storage area, but

having both areas combined in one building or close to each other is

more convenient.

The workshop area required will depend on the size of the feedlot,

the equipment to be maintained and repaired and the type of

equipment to be used. Machines should be able to be moved easily

into and out of the workshop.

The workshop should be able to accommodate the largest machine A large machinery workshop with double

on the site with space to manoeuvre equipment inside the building if sliding doors and entry from both ends

required. Service space around the perimeter of the machine should

be at least two metres wide for manoeuvring lifting equipment

(e.g. forklifts).

One or more work benches and a machinery area 1–1.2 m wide

will be needed along the walls, along with room for storage of

equipment, tools, spare parts and consumables (e.g. nuts and bolts)

and some additional space for new tools and equipment.

The interior layout should be planned to provide maximum

convenience for doing maintenance and repair work. For example,

welding units (gas and electric) located immediately inside the

access doors will allow their use inside or outside the building.

Location of personnel access doors will depend upon the choice of

floor plan and on the type of construction.

Steel or timber construction

Australia is well serviced by companies that design and construct

all types of farm buildings. Cost will depend on geographic location,

source of supply, span and length of the building and the way in

which the project is undertaken.

The shed frame may be made from steel, timber or a combination of

these two materials. Timber may need to be protected from termite

attack while poor construction or inadequate maintenance may lead A large machinery workshop with an open

to corrosion problems with steel. Galvanised steel sheeting is the side offering good access, good ventilation

and natural lighting — but little protection

most common and most economical form of cladding. from the weather.

Steel framed sheds may use three types of construction – portal

frame, structural steel frame and stud frame. The cladding and

flashings are common to all types.

Portal frame

The basic principle is that all the purlins (both rafters and columns)

consist of cold-rolled C section joined by fabricated brackets that

bolt each assembly together. The main structure is called the portal

frame (Figure 1). The roof and wall members are added once all the

portal frames have been stood.

The span width of portal frame sheds can be limited by the length of

roof cladding. Steel roof cladding is usually limited to 12 m lengths,

which is the length that can be transported on a semi-trailer. Wider

spans would require multiple roof sheets or roll forming on site.

40. Machinery workshops 3

FEEDLOT DESIGN AND CONSTRUCTION

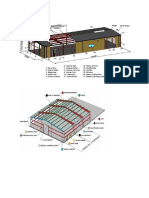

Figure 1. Typical cross section of a steel portal frame shed

Structural steel frame

With the structural steel frame, all the columns and rafters are

from hot-rolled section such as H section, I beam, or C channels

with welded cleats and joiners on all ends. The roof and wall

members are normally the same as the portal frame (see Figure 2).

The advantage of this type of design is that it allows larger spans,

normally over 18 metres in width. The structural steel is heavy to

transport but does allow faster erection and has an extremely high

strength joining system.

As with portal frame sheds, the span width of structural steel sheds

can be limited by the length of roof cladding. Spans greater than

12 m require multiple roof sheets or roll forming on site. Also a

floor area greater than 500 m2 requires additional services to comply

with BCA requirements.

Figure 2. Typical cross section of a structural steel frame shed

4 40. Machinery workshops

FEEDLOT DESIGN AND CONSTRUCTION

Steel stud frame

This is identical to the steel stud framing used in housing and

results in a very strong overall construction. The walls and trusses

are all prefabricated in sections and simply stood on site and then

clad. The advantage of this system is the ease of finishing the

sheeting internally.

Structural design

Most shed companies provide a holistic design, structural design and

manufacture service. Alternatively, structural design requirements

may be obtained from a consulting structural engineer.

The structural design requirements include

• selection of appropriate member sizes and joint details

• erection of steelwork or concrete frameworks

• temporary fragility or instability of structure

• load-bearing requirements for overhead cranes

• stability and integrity of structure

• foundations/footing design for columns

• design of slab.

The design of the footings for a shed should take into account the

bearing capacity of the soil and movement of soil due to wetting

and drying.

Figure 3. Typical cross section of a colourbond steel sheeted shed

Flooring

The floor of the workshop should be elevated at least 100–300 mm

above the natural outside grade to provide good drainage and to

stop water entering. The ground around the shed should be graded

to channel water away.

A concrete floor in the workshop area will promote cleanliness,

withstand the weight of machinery and provide a durable working

surface. The floor should be sloped at a grade of 1% (1 mm per 100

mm) to the access doors for drainage.

Concrete shed floors are usually laid over a gravel-based subgrade

before the shed frame is put up. Typically, the minimum thickness

is 170 mm on a medium to good subgrade (200 mm on a poor

subgrade) and is reinforced with square mesh.

40. Machinery workshops 5

FEEDLOT DESIGN AND CONSTRUCTION

Doors

The height and width of access doors should be 600 mm wider and

150 mm higher than the largest machine on the site.

Where practical, large access doors should be located on the end

walls. One machinery access door may be adequate, but having

doors in both the front and back will offer drive through ease in

handling large machines.

There are various arrangements for workshop doors. These

include sliding (bypass, bi-parting, single) hinged or roller. Each

arrangement has its own advantages and disadvantages. The key

considerations are space utilisation and cost.

Workshop with space for vehicle and

machinery repairs, and with fluorescent Overhead roller type doors take less space and are easier to open

and halogen strips for good lighting. Note

the wall mounted swing-away jib boom for than sliding doors, but are more costly.

welder on the left.

Sliding and hinged doors require space to the sides of the opening

and may limit access to the sides of the building. They are durable

and cheaper.

At least one personnel door must be provided for safety and in

accordance with relevant building codes.

Services

Electrical

Electric power will be required for various activities and services

with generally single phase 10A and 15A outlets and 32A 3-phase

outlets. The electrical service should have some reserve capacity for

future expansion.

Electrical installation must comply with the current electrical

standards including all subsequent amendments, and all applicable

regulations and bylaws of statutory authorities. Work not covered by

the requirements of statutory authorities must comply with the latest

edition of the appropriate publication from the Standards Australia.

Lighting

It is impractical to install enough windows to provide sufficient

light for working. Clear polycarbonate sheeting may be installed

on the roof but degrades over time and is prone to damage from

hail. Irrespective of windows, the primary source of light should be

artificial.

The positioning and illumination level should be sufficient to

eliminate shadowing and allow activities to be completed safely.

The following Australian Standards provide guidance on minimum

illumination levels.

• AS1680.1-2006, ‘Interior and workplace lighting – general

principles and recommendations’

• AS/NZS 1680.2 series, ‘Interior and workplace lighting –

specific applications’

6 40. Machinery workshops

FEEDLOT DESIGN AND CONSTRUCTION

Ventilation

Workshops should be naturally or artificially ventilated. Gases and

fumes from various activities need to be removed from a safety

perspective. Exhaust fans may be installed for rapid air removal.

Windows provide some natural ventilation and entrance of fresh air

when exhaust fans are operating.

Essential safety measures

The Building Code of Australia (BCA) outlines the essential safety

measures that apply to the various classes of buildings defined by

the BCA. Refer to Section 26 – Office and amenities.

Machinery buildings would be classed as Class 10a (a non-habitable

building or shed) according to the BCA. The essential safety Australian Standard AS4084–2012 sets out the

requirements are stipulated in the Building Code of Australia, minimum requirements for steel storage and pallet

racking systems.

respective State Building Fire Safety Regulations and the relevant

Australian Standards.

For example, a fire hydrant system or fire hose reels are not required

in a building having a total floor area of less than 500 m2. For

Class 10 buildings, no point on the workshop floor must be more

than 20 m from an exit, or a point from which travel in different

directions to two exits is available, in which case the maximum

distance to one of those exits must not exceed 40 m.

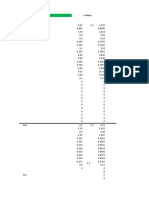

Hence, a workshop of 20 m by 24 m (Figure 4) complies with the

BCA requirements for floor area and travel distance and no fire

hydrant and hose reel system is required.

Portable fire extinguishers and electrical isolation of machinery are

the bare minimum provision for a machinery workshop.

Figure 4. Class 10 buildings have a floor area of less than 500 m2

40. Machinery workshops 7

FEEDLOT DESIGN AND CONSTRUCTION

Hoists

A hoist should never be attached to the roof trusses since this would place

an unsafe concentrated load on that portion of the building. A chain

hoist should be attached to a portable beam supported at both ends with

A-frames on casters. Alternatively it could be attached to a steel beam

across the width of the workshop with the beam separately supported at

each wall as a permanent part of the building. A permanent steel beam

support is less versatile than a mobile A-frame unit.

Vehicle lift hoists

Vehicle lift hoists are an alternative to inspection pits for inspecting the

undercarriage of vehicles, but they do need constant maintenance. With

lift hoists, it is easier to walk to other parts of the workshop for tools

but work cannot also be done above the vehicle when it is raised. Hoists

are safer for servicing petrol vehicles because of fumes and the ability

to escape in the event of fire.

In a feedlot workshop, a heavy truck lift needed to service the size

of vehicles operating (trucks, tractors, earthmoving machinery)

would be extremely expensive. As the number of vehicles to be

serviced is low, an inspection pit offers a more practical and cost

effective solution.

Inspection pits

Inspection pits are commonly used to inspect the underside and

suspension of vehicles, to replace oil and filters and for servicing

and minor repairs.

Inspection pit with stairs for access. Pit From a safety perspective, inspection pits are preferred for servicing

should have temporary fencing when not diesel vehicles and vehicles with air bag suspension but not for

in use. petrol vehicles.

Inspection pits require safe means of entry and exit, usually

stairways. At least one fixed entry/exit point should be provided

with a separate means of escape where a risk assessment identifies

the need e.g. where escape from the pit may be blocked by the

parked vehicle or long pits. The surface around the inspection pit

should be slip-resistant.

Typically inspection pits are along the workshop bay. The depth of

the inspection pit is optional but its width depends on the vehicles

to be serviced. The width is about 150–200 mm on each side less

that the width between the vehicle tyres.

Inspection pits provide a safe working environment but they do present

particular hazards. They are a common cause of accidents, not only to

those unfamiliar with the premises but also to staff who momentarily

forget the presence of an unfenced pit, or who slip or trip into them.

Inspection pit edges should be painted so that the pit opening can be

clearly seen. Temporary fencing needs to be provided when the pit is

Access to pits should comply with not in use, or a steel or wooden cover put in place.

the relevant WHS requirements, with

fixed handrails. Prefabricated steel inspection pits are also available.

8 40. Machinery workshops

FEEDLOT DESIGN AND CONSTRUCTION

Signage

Machinery workshops should have appropriate signage, including

• Personal protection equipment to be worn – eye or hearing

protection and footwear

• Evacuation procedure

• Emergency assembly point

• Emergency contact details

• No smoking

• Flammable gas

• First Aid station

Workshops should have signage and

Waste management portable fire extinguishers.

Wastes generated at machinery workshops include regulated wastes

(hydrocarbon waste such as oils and tyres, solvents and batteries), general

waste (damaged parts, air filters, hydraulic hoses, rags, cardboard and

paper) and scrap steel. Some paint solvents are highly flammable.

The appropriate management and storage of all wastes, in particular

regulated wastes, will prevent potential on site and off site

environmental harm to livestock, land, surface water or groundwater.

Workshops should have the provision for storage, handling and

spill containment equipment and materials for each category of

waste generated.

Waste management – large oil drip trays

(above) and aggregation tank (below)

A cluttered workshop with insufficient bench space for small repairs.

Clear area for small vehicle repairs, but

poor type of drip trays under the oil drums.

40. Machinery workshops 9

FEEDLOT DESIGN AND CONSTRUCTION

Quick tips

• Sufficient distance should be allowed from existing buildings to allow for future expansion,

to reduce fire hazard and allow room for manoeuvring and parking machinery.

• Consider space for manoeuvring repair equipment around the perimeter of the machine when

sizing the workshop floor area.

• The correct structural design of a workshop should be carried out by a reputable manufacturer

or by a structural engineer.

• Dimensions, member sizes or construction details must never be changed without the approval

of appropriate authorities.

• Keep records of building approvals for future reference.

• Ensure adequate safety and fire protection measures.

Further reading

Local Authority Planning Scheme for local requirements for buildings.

Australian Building Codes Board (ABCB), 2013, Volumes One and Two of the National Construction Code

of Australia.

Standards Australia (1998). Steel structures, AS 4100-1998, Sydney, NSW, Standards Australia.

Standards Australia (2002). Dead and live load combinations, AS/NZS 1170.1-2002, Sydney, NSW, Standards

Australia.

Standards Australia (2005). Cold formed steel structures, AS/NZS 4600-2005, Sydney, NSW, Standards

Australia.

Standards Australia (2005). Emergency Escape Lighting and Exit Signs for Building – Inspection and

Maintenance, (AS 2293.2-2005), Sydney, NSW, Standards Australia.

Standards Australia (2009). Concrete construction (including reinforced and prestressed concrete),

AS 3600-2009, Sydney, NSW, Standards Australia.

Standards Australia (2011). Masonry (including masonry-veneer, unreinforced masonry and reinforced

masonry), AS 3700-2011, Sydney, NSW, Standards Australia.

Standards Australia (2011). Wind Loads, AS 1170.2-2011, Sydney, NSW, Standards Australia.

Standards Australia (2012). Routine service of fire protection systems and equipment, AS 1851-2012, Sydney,

NSW, Standards Australia.

Standards Australia (2012), Steel Storage Racking, AS4084-2012 – Sydney, NSW, Standards Australia.

Standards Australia (2004), Cranes, hoists and winches – Guided storing and retrieving appliances,

AS1418.6-2012 – Sydney, NSW, Standards Australia.

10 40. Machinery workshops

Das könnte Ihnen auch gefallen

- Micro Concrete - ROOFDokument4 SeitenMicro Concrete - ROOFRajesh ChowhanNoch keine Bewertungen

- Guide to Performance-Based Road Maintenance ContractsVon EverandGuide to Performance-Based Road Maintenance ContractsNoch keine Bewertungen

- REID Hangars PDFDokument20 SeitenREID Hangars PDFSyed RaziuddinNoch keine Bewertungen

- Ultratech Xtralite Autoclaved Aerated Concrete Aac BlockDokument9 SeitenUltratech Xtralite Autoclaved Aerated Concrete Aac BlockkhajahusNoch keine Bewertungen

- Caissons Cofferdams ReportDokument24 SeitenCaissons Cofferdams ReportTrudeep Dave100% (1)

- Pre-Engineered BuildingsDokument6 SeitenPre-Engineered BuildingsJenna VargasNoch keine Bewertungen

- Dam Safety Guidelines - 4Dokument178 SeitenDam Safety Guidelines - 4OngeriJNoch keine Bewertungen

- Detailing StairsDokument7 SeitenDetailing Stairselmerbarreras100% (1)

- Managing Hangar Construction From Start To FinishDokument17 SeitenManaging Hangar Construction From Start To FinishArvindSinghNoch keine Bewertungen

- Shaft Design and Construction ArticleDokument4 SeitenShaft Design and Construction ArticleIzam FatimaNoch keine Bewertungen

- 19mine HoistingDokument52 Seiten19mine Hoistingtridev kant tripathiNoch keine Bewertungen

- Brochure Remu Big Float Eng 2019Dokument9 SeitenBrochure Remu Big Float Eng 2019Atiqur RahmanNoch keine Bewertungen

- Study On Fly Ash BricksDokument66 SeitenStudy On Fly Ash BricksKiran Kumar100% (2)

- Metal Building Parts NameDokument8 SeitenMetal Building Parts Name11 Sqn RER100% (1)

- Vetiver System For Improvement of Water QualityDokument79 SeitenVetiver System For Improvement of Water Qualityapi-3714517Noch keine Bewertungen

- Geoplast Slabs Solution English BrochureDokument52 SeitenGeoplast Slabs Solution English BrochureMohamedNoch keine Bewertungen

- Micro-Concrete Roofing Tile ProductionDokument6 SeitenMicro-Concrete Roofing Tile ProductionzulizwxnNoch keine Bewertungen

- The Boral Book of ConcreteDokument44 SeitenThe Boral Book of ConcreteGustavo SteffenNoch keine Bewertungen

- OZ-8794 - Planning Justification ReportDokument24 SeitenOZ-8794 - Planning Justification ReportThe London Free PressNoch keine Bewertungen

- Roof TrussesDokument19 SeitenRoof TrussesShantanuShahNoch keine Bewertungen

- Make Your Own Concrete CountertopDokument6 SeitenMake Your Own Concrete CountertopFirefox24Noch keine Bewertungen

- Adding Value To ConcreteDokument16 SeitenAdding Value To ConcreteFrancois KokNoch keine Bewertungen

- Hollowcore Plant Design ManualDokument59 SeitenHollowcore Plant Design Manualnfaayed100% (1)

- Tara Machines BrochureDokument8 SeitenTara Machines BrochureBaba Jee Shiva ShankarNoch keine Bewertungen

- Rubble MasonryDokument10 SeitenRubble MasonrySahithi MagantiNoch keine Bewertungen

- Indianapolis Airport StructuralDokument3 SeitenIndianapolis Airport Structuralrorobinhoodiee100% (1)

- 3D Precast System TechnologyDokument16 Seiten3D Precast System TechnologyDhirubhai PatelNoch keine Bewertungen

- Vetiver System For Slope StabilizationDokument51 SeitenVetiver System For Slope Stabilizationzulkifli1220Noch keine Bewertungen

- Modular FormworkDokument10 SeitenModular Formworkfeihrb100% (1)

- Reengineering Construction EquipmentDokument62 SeitenReengineering Construction EquipmentVinod YbNoch keine Bewertungen

- 2018 NBC Book PreviewDokument70 Seiten2018 NBC Book PreviewRonald KahoraNoch keine Bewertungen

- Calculating Grease Quantity, FrequencyDokument2 SeitenCalculating Grease Quantity, FrequencyAnonymous F2TxS3YoaNoch keine Bewertungen

- Construction Equipment 10708Dokument22 SeitenConstruction Equipment 10708mukesh516Noch keine Bewertungen

- Cbs CatalogueDokument195 SeitenCbs Cataloguemadaboutalfa8168Noch keine Bewertungen

- Instalación de Tendones en Post-TensadoDokument80 SeitenInstalación de Tendones en Post-TensadoJorge Fernando Loaiza VergaraNoch keine Bewertungen

- Materi PPT Secondary EngDokument5 SeitenMateri PPT Secondary EngFanya arifantiNoch keine Bewertungen

- Goals: I. II. Iii.Dokument68 SeitenGoals: I. II. Iii.ganeshlalkumawatNoch keine Bewertungen

- Water From Rock OutcropsDokument63 SeitenWater From Rock OutcropsShiitakeNoch keine Bewertungen

- Large Pipes For Pipe Jacking and Open Trench InstallationDokument4 SeitenLarge Pipes For Pipe Jacking and Open Trench Installationvtsh100Noch keine Bewertungen

- Sika Roof Detail Membrane v1Dokument2 SeitenSika Roof Detail Membrane v1NinaNoch keine Bewertungen

- The Basic Clay Brick Making PlantDokument6 SeitenThe Basic Clay Brick Making PlantSubhashree Bhattacharya0% (1)

- PDF Burj KhalifaDokument18 SeitenPDF Burj Khalifajohncena777100% (1)

- Defender 130 en INTDokument52 SeitenDefender 130 en INTAndrea Evans Khosasih100% (1)

- Anupam Stainless Steel Kitchen SinksDokument93 SeitenAnupam Stainless Steel Kitchen SinksAnkit JainNoch keine Bewertungen

- The Future Outlook of Desalination in The GulfDokument63 SeitenThe Future Outlook of Desalination in The GulfChristian D. OrbeNoch keine Bewertungen

- Brochure Solutions For StadiumsDokument20 SeitenBrochure Solutions For StadiumsBambangShrNoch keine Bewertungen

- Tata Solar BrochureDokument6 SeitenTata Solar BrochurekalpanaadhiNoch keine Bewertungen

- Clay Brick Making Machine Mew CB 3000Dokument5 SeitenClay Brick Making Machine Mew CB 3000Aakansh NigamNoch keine Bewertungen

- Guide To Thatch Construction in South Africa1Dokument97 SeitenGuide To Thatch Construction in South Africa1sebby_s20100% (1)

- Motor Grader Circle Drive Help Info Customer 27feb2014Dokument10 SeitenMotor Grader Circle Drive Help Info Customer 27feb2014Roger Mendoza CaceresNoch keine Bewertungen

- CT Dredging Soil Lecture1a 2012Dokument13 SeitenCT Dredging Soil Lecture1a 2012rme11maNoch keine Bewertungen

- Building Construction AssignmentDokument26 SeitenBuilding Construction AssignmentCharlesNoch keine Bewertungen

- Dsi Info 22 en PDFDokument172 SeitenDsi Info 22 en PDFMauricio GutierrezNoch keine Bewertungen

- Prefabricated Building TechnologyDokument45 SeitenPrefabricated Building TechnologySyed Ashique Hussain HamdaniNoch keine Bewertungen

- BridgesDokument26 SeitenBridgesFaJane CallojellasNoch keine Bewertungen

- CompactadoraDokument16 SeitenCompactadoraGustavo VargasNoch keine Bewertungen

- Structural Analysis and Design of An Industrial Building: @seismicisolationDokument54 SeitenStructural Analysis and Design of An Industrial Building: @seismicisolationTeme man of TNoch keine Bewertungen

- PEBDokument17 SeitenPEBTanuj Bhardwaj100% (1)

- Pre Engineered BuildingsDokument20 SeitenPre Engineered BuildingsGyandeep Jaiswal100% (3)

- The Law Society Conditions of Sale 2015 PDFDokument39 SeitenThe Law Society Conditions of Sale 2015 PDFAnonymous sId0uhkEIV50% (2)

- DS 63 Drawing ListDokument3 SeitenDS 63 Drawing ListAnonymous sId0uhkEIVNoch keine Bewertungen

- Pressed PDFDokument143 SeitenPressed PDFAnonymous sId0uhkEIVNoch keine Bewertungen

- Agreement PDFDokument3 SeitenAgreement PDFAnonymous sId0uhkEIVNoch keine Bewertungen

- DS 63 Drawing ListDokument3 SeitenDS 63 Drawing ListAnonymous sId0uhkEIVNoch keine Bewertungen

- Att 2699Dokument189 SeitenAtt 2699LukasPodolskiNoch keine Bewertungen

- PDFDokument8 SeitenPDFAdrianNoch keine Bewertungen

- Aq71 003 001 01JDokument1 SeiteAq71 003 001 01JAnonymous sId0uhkEIVNoch keine Bewertungen

- Harris Amunga Anyangu ProjectDokument91 SeitenHarris Amunga Anyangu ProjectsaravananNoch keine Bewertungen

- Tesla Automobile Repair and Service: Project Description Vicinity Map Symbol Legend General NotesDokument12 SeitenTesla Automobile Repair and Service: Project Description Vicinity Map Symbol Legend General NotesAnonymous sId0uhkEIVNoch keine Bewertungen

- ODeL Programs PDFDokument1 SeiteODeL Programs PDFAnonymous sId0uhkEIVNoch keine Bewertungen

- Aq71 001 003 01HDokument1 SeiteAq71 001 003 01HAnonymous sId0uhkEIVNoch keine Bewertungen

- Types of DrawingsDokument16 SeitenTypes of Drawingskash30Noch keine Bewertungen

- Design BookDokument320 SeitenDesign BookMarko67% (3)

- Creating Large Building Models: Graphisoft Aug 2003Dokument26 SeitenCreating Large Building Models: Graphisoft Aug 2003hary123Noch keine Bewertungen

- Tender For Fuel Pump Station Petrol Station Tender No Mcidc t01 2015 2016Dokument88 SeitenTender For Fuel Pump Station Petrol Station Tender No Mcidc t01 2015 2016Anonymous sId0uhkEIV71% (7)

- ConsumptionDokument3 SeitenConsumptionAnonymous sId0uhkEIVNoch keine Bewertungen

- 04 Office and Laundry BlockDokument1 Seite04 Office and Laundry BlockAnonymous sId0uhkEIVNoch keine Bewertungen

- Zasady Vykreslovani enDokument12 SeitenZasady Vykreslovani enMarvin MessiNoch keine Bewertungen

- NCA Regulations 2014Dokument16 SeitenNCA Regulations 2014Lucas AdweraNoch keine Bewertungen

- Design GuideDokument27 SeitenDesign GuideHranean Gore-gabriel100% (1)

- (Jim Forrest, Peter Jennings) Workshop Constructio PDFDokument72 Seiten(Jim Forrest, Peter Jennings) Workshop Constructio PDFAnonymous sId0uhkEIVNoch keine Bewertungen

- 03 Typical Staff HouseDokument1 Seite03 Typical Staff HouseAnonymous sId0uhkEIVNoch keine Bewertungen

- Book of Drawings: Construction of Storm Water Drainage at Icpak Offices, Thika RoadDokument9 SeitenBook of Drawings: Construction of Storm Water Drainage at Icpak Offices, Thika RoadAnonymous sId0uhkEIVNoch keine Bewertungen

- Creating Large Building Models: Graphisoft Aug 2003Dokument26 SeitenCreating Large Building Models: Graphisoft Aug 2003hary123Noch keine Bewertungen

- Zasady Vykreslovani enDokument12 SeitenZasady Vykreslovani enMarvin MessiNoch keine Bewertungen

- Gas Station GuidelinesDokument16 SeitenGas Station GuidelinesAnonymous sId0uhkEIVNoch keine Bewertungen

- Frewq PDFDokument5 SeitenFrewq PDFpsn1234567890Noch keine Bewertungen

- Checklist of Library Building Design ConsiderationsDokument192 SeitenChecklist of Library Building Design ConsiderationsRifka Rifiana100% (2)

- HVAC ProductsDokument10 SeitenHVAC ProductsMihai ConstantinescuNoch keine Bewertungen

- Specification of WorkDokument21 SeitenSpecification of Workhusnain611Noch keine Bewertungen

- 2C08 Advanced Design of Steel and Composite StructuresDokument4 Seiten2C08 Advanced Design of Steel and Composite StructuresqutabshNoch keine Bewertungen

- Bill of Quntity Ato Alem Meles As CorrectedDokument194 SeitenBill of Quntity Ato Alem Meles As Correctedhabtamu tadesseNoch keine Bewertungen

- Building Construction Technology QuestionsDokument9 SeitenBuilding Construction Technology QuestionsBipul PoudelNoch keine Bewertungen

- What Is Natural Ventilation ?Dokument26 SeitenWhat Is Natural Ventilation ?subhashini soundarNoch keine Bewertungen

- Hot and Humid ClimateDokument30 SeitenHot and Humid Climatebhumika mehtaNoch keine Bewertungen

- Trussform Tech GuideDokument21 SeitenTrussform Tech GuidePierre CamusNoch keine Bewertungen

- Model Checklist For Bim CollaborationDokument1 SeiteModel Checklist For Bim CollaborationWunNaNoch keine Bewertungen

- Sample-Bq 1Dokument60 SeitenSample-Bq 1Shirly Ee Shek LiNoch keine Bewertungen

- 3 Proposed Work Programe and Completion Schedule - Report As Per 05 05 21 Based On Rev 03 Dated 30 04 21 - Rev00Dokument2 Seiten3 Proposed Work Programe and Completion Schedule - Report As Per 05 05 21 Based On Rev 03 Dated 30 04 21 - Rev00NethiyaaRajendranNoch keine Bewertungen

- Hota Cu Inductie de Perete INOX Tangra CK A 1000x700mm Fisa TehnicaDokument4 SeitenHota Cu Inductie de Perete INOX Tangra CK A 1000x700mm Fisa TehnicaDana LoreNoch keine Bewertungen

- Lecture 4 - Ground Floors, Frames & Upper FloorsDokument185 SeitenLecture 4 - Ground Floors, Frames & Upper FloorsWong Yi RenNoch keine Bewertungen

- PL - Drain EstimateDokument5 SeitenPL - Drain EstimatejaninevargasNoch keine Bewertungen

- MODULE - 3, Lesson - 3.1 and ACTIVITYDokument33 SeitenMODULE - 3, Lesson - 3.1 and ACTIVITYParth AgarwalNoch keine Bewertungen

- Internship ReportDokument32 SeitenInternship ReportNaman DwivediNoch keine Bewertungen

- BCM Report 222Dokument4 SeitenBCM Report 222Shipra AnandNoch keine Bewertungen

- Revised Building Byelaws GMDADokument119 SeitenRevised Building Byelaws GMDABaharulHussainNoch keine Bewertungen

- Fresh Fruit: HVAC StudyDokument17 SeitenFresh Fruit: HVAC StudyAmer GaladNoch keine Bewertungen

- Concrete Construction Article PDF - Dry - and Wet-Mix Process ShotcreteDokument2 SeitenConcrete Construction Article PDF - Dry - and Wet-Mix Process ShotcretelenanaNoch keine Bewertungen

- Fire Safety Audit ReportDokument9 SeitenFire Safety Audit ReportSheikh Nouman Mohsin RamziNoch keine Bewertungen

- The Design of A 3 Bedroom One Storey Building and Its Cost ImplicationDokument4 SeitenThe Design of A 3 Bedroom One Storey Building and Its Cost ImplicationsentaljohnNoch keine Bewertungen

- Neufert 4th Edition 180 240Dokument61 SeitenNeufert 4th Edition 180 240dharavathdamodhar24Noch keine Bewertungen

- Building Construction and Materials Notes - Civilenggforall PDFDokument254 SeitenBuilding Construction and Materials Notes - Civilenggforall PDFDebrahanath100% (2)

- Mark Publishing PG 2Dokument1 SeiteMark Publishing PG 2Mark MuzindaNoch keine Bewertungen

- Hap Calculations - Etr-1Dokument10 SeitenHap Calculations - Etr-1jobees7850Noch keine Bewertungen

- DO - 057 - S2015 - Item 706 Conc, Clay, Plastic Fiber PipesDokument5 SeitenDO - 057 - S2015 - Item 706 Conc, Clay, Plastic Fiber PipesRay RamiloNoch keine Bewertungen

- Classification of AggregatesDokument3 SeitenClassification of Aggregatespaddy11234Noch keine Bewertungen

- Cob Project ReportDokument8 SeitenCob Project ReportrituNoch keine Bewertungen

- Tenshin Dorms SummaryDokument71 SeitenTenshin Dorms Summarythethird20Noch keine Bewertungen