Beruflich Dokumente

Kultur Dokumente

Fluid Analysis Services: Call 131 228

Hochgeladen von

RasoolKhadibi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten1 SeiteGrease

Originaltitel

Grease

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenGrease

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten1 SeiteFluid Analysis Services: Call 131 228

Hochgeladen von

RasoolKhadibiGrease

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

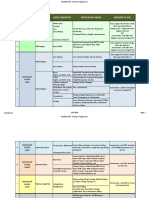

Fluid Analysis Services

GREASE ANALYSIS Contamination

• PQ Index

• Water

Incorrect grease selection can lead to • Filter Patch

costly downtime and repairs. Analysis • Moisture content by Karl Fischer

from the Hastings Deering Condition Coulometer

Monitoring Centre ensures the grease Elemental composition

is suitable for application and in good • Sulphur

condition. Contamination and wear • Iron

levels are easily identified and reported • Silicon

along with a photograph of the debris • Aluminium

and a wear severity graph to highlight • Vanadium

compartment condition. • Sodium

• Phosphorous

• Lithium

Grease samples can be collected in • Copper

S.O.S sample bottles (Part # SOS011)

SM

• Chromium

and forwarded to the laboratory. • Tin

• Nickel

Inherent characteristics and

quality indicators.

• Drop Point

• Cone Penetration

• NLGI Classification

For more about fluid analysis

call 131 228

© 2011 Caterpillar. All rights reserved. CAT, CATERPILLAR, their respective logos, ‘Caterpillar Yellow’, the POWER EDGE trade dress,

as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

Das könnte Ihnen auch gefallen

- Aq-710 PDSDokument3 SeitenAq-710 PDSMufaddal HazariNoch keine Bewertungen

- Mud DF SystemDokument83 SeitenMud DF Systemayman mohamed100% (1)

- Analytical Portfolio For Mining ApplicationsDokument35 SeitenAnalytical Portfolio For Mining ApplicationsLud PasNoch keine Bewertungen

- Magna Site Magnetic Level Gauge 10.18Dokument16 SeitenMagna Site Magnetic Level Gauge 10.18Srimathi VijayakumarNoch keine Bewertungen

- Superior Mining Chemic Al Technologies For Improved Miner Al GR Ade & RecoveryDokument2 SeitenSuperior Mining Chemic Al Technologies For Improved Miner Al GR Ade & Recoveryxibs2009Noch keine Bewertungen

- Valorisation of Refractory Waste: Latest Developments & ProgressDokument40 SeitenValorisation of Refractory Waste: Latest Developments & ProgressĐức MạnhNoch keine Bewertungen

- DF Systems160108Dokument57 SeitenDF Systems160108Long Nhật PhanNoch keine Bewertungen

- Industry - Minerals Processing 2022Dokument23 SeitenIndustry - Minerals Processing 2022Prabhat MishraNoch keine Bewertungen

- D'Ox Customer Presention: Excellence With SpeedDokument29 SeitenD'Ox Customer Presention: Excellence With SpeedShashank Shekhar100% (1)

- Unitex: Mechanical Seals - Mechanical Seals For Pumps - Standard Cartridge SealsDokument4 SeitenUnitex: Mechanical Seals - Mechanical Seals For Pumps - Standard Cartridge SealsserdarNoch keine Bewertungen

- SSC825 Spec SheetDokument2 SeitenSSC825 Spec SheetShankar RajNoch keine Bewertungen

- Indirect Restoration: Reconstructions Using Alloys and Ce-RamicsDokument20 SeitenIndirect Restoration: Reconstructions Using Alloys and Ce-RamicsTasya Citra KiranaNoch keine Bewertungen

- Longcliffe Diagram FinalDokument1 SeiteLongcliffe Diagram FinalDian Mia TaufikusumoNoch keine Bewertungen

- 1072 - Ppo Noryl gfn1720Dokument4 Seiten1072 - Ppo Noryl gfn1720pava16230.meNoch keine Bewertungen

- Metals and Non-MetalsDokument24 SeitenMetals and Non-MetalsLoca1 Th3rapistNoch keine Bewertungen

- IKM Testing Brochure Pipeline-Mechanical Completion-Commissiong 2018Dokument16 SeitenIKM Testing Brochure Pipeline-Mechanical Completion-Commissiong 2018Aprilia NatasyaNoch keine Bewertungen

- Oil-Analysis Cause EfectDokument8 SeitenOil-Analysis Cause EfectRohmanNoch keine Bewertungen

- Molla ProposalDokument15 SeitenMolla Proposalandualem nigussieNoch keine Bewertungen

- Surface Coating Selection GuideDokument2 SeitenSurface Coating Selection GuideRestu SihotangNoch keine Bewertungen

- Webinar Power PointDokument12 SeitenWebinar Power Pointmara2proleta100% (1)

- 3 Decalcification and DehydrationDokument5 Seiten3 Decalcification and DehydrationAngel RamosNoch keine Bewertungen

- ST Diaphragm Valve Rubber LinedDokument2 SeitenST Diaphragm Valve Rubber Linedsaroat moongwattanaNoch keine Bewertungen

- SGS MIN WA013 Flotation EN 11 PDFDokument3 SeitenSGS MIN WA013 Flotation EN 11 PDFPaul Acosta MamaniNoch keine Bewertungen

- Solutions: For Float and Tempered Glass ManufacturingDokument6 SeitenSolutions: For Float and Tempered Glass ManufacturingjagadeeshyogiNoch keine Bewertungen

- WM Dry Lubricants GB Fiche A4 R0120 BDDokument2 SeitenWM Dry Lubricants GB Fiche A4 R0120 BDDr ZoggNoch keine Bewertungen

- Tube Failure and RLA - Shamsul, RinojDokument67 SeitenTube Failure and RLA - Shamsul, RinojShamsul HuthaNoch keine Bewertungen

- Solvay O&G PortfolioDokument18 SeitenSolvay O&G PortfolioJHOTORRES100% (1)

- CBL Basics - KondurDokument24 SeitenCBL Basics - KondurReza RamadhanNoch keine Bewertungen

- 12 200 Tech Taylor ValveDokument2 Seiten12 200 Tech Taylor ValvevsubhramaniyunNoch keine Bewertungen

- Crown Check Valves: Leading The Way in Pipeline TechnologyDokument4 SeitenCrown Check Valves: Leading The Way in Pipeline TechnologyJosé Daniel ArenasNoch keine Bewertungen

- Plumbing Market SurveyDokument5 SeitenPlumbing Market SurveyYashashreeNoch keine Bewertungen

- Diamond Coatings Customer PresentationDokument51 SeitenDiamond Coatings Customer PresentationChérif GrabaNoch keine Bewertungen

- Drilling Fluids PresentationDokument81 SeitenDrilling Fluids PresentationNamwangala Rashid Natindu100% (1)

- Illium Alloy 8 For Non-Galling, Corosion-Resistant Alloy SolutionsDokument2 SeitenIllium Alloy 8 For Non-Galling, Corosion-Resistant Alloy Solutionsdouglas guedezNoch keine Bewertungen

- Background To ICOLD Tailings Committee Last ICOLD Bulletin On Tailings Dam Safety (1989) & Improving Tailings Dam Safety (2011)Dokument25 SeitenBackground To ICOLD Tailings Committee Last ICOLD Bulletin On Tailings Dam Safety (1989) & Improving Tailings Dam Safety (2011)valeriaarmi4854Noch keine Bewertungen

- Product - Line RustrolDokument2 SeitenProduct - Line RustrolomarNoch keine Bewertungen

- Yugo Parker P2Dokument2 SeitenYugo Parker P2Francisco javierNoch keine Bewertungen

- Ds.37.din .RBR .LN .NRHW .25.v1.1Dokument2 SeitenDs.37.din .RBR .LN .NRHW .25.v1.1Marketing RNSNoch keine Bewertungen

- 1.what Is Cement ? 2.history. 3.overveiw of Cement Manufacturing Process. 4.overveiw of Kiln Process. 5.why Burn Wastes ?Dokument43 Seiten1.what Is Cement ? 2.history. 3.overveiw of Cement Manufacturing Process. 4.overveiw of Kiln Process. 5.why Burn Wastes ?HABIB UR REHMANNoch keine Bewertungen

- Manufacturing Processes and Technology (Mem360) 2Dokument13 SeitenManufacturing Processes and Technology (Mem360) 2Azhar HafiqNoch keine Bewertungen

- Mechanical Seals - Mechanical Seals For Pumps - Pusher SealsDokument4 SeitenMechanical Seals - Mechanical Seals For Pumps - Pusher SealsAndré Silva RibeiroNoch keine Bewertungen

- Melting Temperature MetalsDokument2 SeitenMelting Temperature MetalsMari selvamNoch keine Bewertungen

- 06-Zone CoverageDokument40 Seiten06-Zone CoverageJesus Ponce GNoch keine Bewertungen

- Cement FactoryDokument20 SeitenCement FactorySabbir KhanNoch keine Bewertungen

- Lorbrand Composite RollsDokument6 SeitenLorbrand Composite RollsIgor San Martín PeñalozaNoch keine Bewertungen

- AURUM Habermann Pumpen ENGDokument24 SeitenAURUM Habermann Pumpen ENGpartoNoch keine Bewertungen

- Mechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDokument6 SeitenMechanical Seals - Agitator Seals - Liquid-Lubricated Seals: Rely On ExcellenceDikaAnindyajatiNoch keine Bewertungen

- Ferrite Testing: Accurate Measurement of Stainless SteelsDokument2 SeitenFerrite Testing: Accurate Measurement of Stainless SteelsalphadingNoch keine Bewertungen

- Section 9 PRM AluminiumDokument10 SeitenSection 9 PRM Aluminiumprasanth cpNoch keine Bewertungen

- Aslan 100Dokument20 SeitenAslan 100Héctor PinzónNoch keine Bewertungen

- DE Module 4Dokument15 SeitenDE Module 4AVERAGENoch keine Bewertungen

- Diager Catalogue English 2022 d00375 1Dokument2 SeitenDiager Catalogue English 2022 d00375 1AdrianoTavaresNoch keine Bewertungen

- Week 2 - Basic Log AnalysesDokument9 SeitenWeek 2 - Basic Log AnalysesMuhammad ShahrukhNoch keine Bewertungen

- Matrox ENDokument18 SeitenMatrox ENjhax90Noch keine Bewertungen

- Full Brochure PDFDokument15 SeitenFull Brochure PDFFrancia LugoNoch keine Bewertungen

- Matrox Family e PDFDokument18 SeitenMatrox Family e PDFrajanarenderNoch keine Bewertungen

- E CatalogueDokument12 SeitenE CatalogueMikku KattaNoch keine Bewertungen

- TEFC Vertical Pump Motors: Innovation and QualityDokument2 SeitenTEFC Vertical Pump Motors: Innovation and QualityDinalpinNoch keine Bewertungen

- Oil & Gas Industry Cycle: Where Are The Hydrocarbons?Dokument38 SeitenOil & Gas Industry Cycle: Where Are The Hydrocarbons?ahza hanifNoch keine Bewertungen

- XL As11437bm en UsDokument20 SeitenXL As11437bm en UsRasoolKhadibiNoch keine Bewertungen

- Atlas Copco Portable Air Compressors: XA (T, V) S 375 JD6 T3Dokument2 SeitenAtlas Copco Portable Air Compressors: XA (T, V) S 375 JD6 T3RasoolKhadibiNoch keine Bewertungen

- 150 CadDokument154 Seiten150 CadRafael Quevedo Mogollon100% (4)

- 3 C 6896Dokument2 Seiten3 C 6896RasoolKhadibiNoch keine Bewertungen

- Daewoo Excavators Spec 89bb26Dokument6 SeitenDaewoo Excavators Spec 89bb26RasoolKhadibiNoch keine Bewertungen

- Fuel Injection Systems Diesel Fuel InjecDokument39 SeitenFuel Injection Systems Diesel Fuel InjecRasoolKhadibiNoch keine Bewertungen

- Cylinder Liners and Pistons, Replace (All) PDFDokument14 SeitenCylinder Liners and Pistons, Replace (All) PDFEsam PhlipeNoch keine Bewertungen

- 23717945Dokument36 Seiten23717945RasoolKhadibiNoch keine Bewertungen

- 3040359Dokument1 Seite3040359RasoolKhadibiNoch keine Bewertungen

- Transmission Glycol TestDokument1 SeiteTransmission Glycol TestRasoolKhadibiNoch keine Bewertungen

- Transmission Glycol TestDokument2 SeitenTransmission Glycol TestRasoolKhadibiNoch keine Bewertungen

- Caterpillar D11Dokument3 SeitenCaterpillar D11RasoolKhadibiNoch keine Bewertungen

- 4769663Dokument24 Seiten4769663RasoolKhadibiNoch keine Bewertungen

- Baldwin Fuel Filters PDFDokument20 SeitenBaldwin Fuel Filters PDFheartofdixieNoch keine Bewertungen

- Caterpillar D6Dokument3 SeitenCaterpillar D6RasoolKhadibi100% (1)

- M EthanethiolDokument4 SeitenM EthanethiolRasoolKhadibiNoch keine Bewertungen

- Mercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesDokument11 SeitenMercaptans in Crude Oil: Larry Kremer & Weldon Cappel Baker HughesRasoolKhadibiNoch keine Bewertungen

- Torque ConverterDokument6 SeitenTorque ConverterRasoolKhadibiNoch keine Bewertungen

- Variable Vane Pumps PV7Dokument32 SeitenVariable Vane Pumps PV7RasoolKhadibi100% (1)

- New Holland AgricultureDokument14 SeitenNew Holland AgricultureRasoolKhadibiNoch keine Bewertungen

- Caterpillar D9Dokument4 SeitenCaterpillar D9RasoolKhadibiNoch keine Bewertungen

- Wheel Tractor ScraperDokument2 SeitenWheel Tractor ScraperRasoolKhadibi0% (1)

- Paver (Vehicle)Dokument3 SeitenPaver (Vehicle)RasoolKhadibiNoch keine Bewertungen

- EthanethiolDokument3 SeitenEthanethiolRasoolKhadibiNoch keine Bewertungen

- Caterpillar 797Dokument7 SeitenCaterpillar 797RasoolKhadibiNoch keine Bewertungen

- DYNA4 Car ProfessionalDokument4 SeitenDYNA4 Car ProfessionalRasoolKhadibiNoch keine Bewertungen

- Claas Kgaa MBHDokument3 SeitenClaas Kgaa MBHRasoolKhadibiNoch keine Bewertungen

- TerexDokument5 SeitenTerexRasoolKhadibiNoch keine Bewertungen

- Komatsu D575ADokument4 SeitenKomatsu D575ARasoolKhadibiNoch keine Bewertungen

- ABC Organic Gardener - MagazineDokument86 SeitenABC Organic Gardener - Magazinealexe012Noch keine Bewertungen

- Philosophy For Management and DisciplineDokument8 SeitenPhilosophy For Management and Disciplineapi-300120362Noch keine Bewertungen

- International Trade Law: AssignmentDokument2 SeitenInternational Trade Law: AssignmentQuỳnh PhạmmNoch keine Bewertungen

- Dna Recombinant TechnologyDokument20 SeitenDna Recombinant TechnologyJuliet Ileto Villaruel - AlmonacidNoch keine Bewertungen

- 2014 EN AdvancedBootkitTechniquesOnAndroid ChenZhangqiShendiDokument66 Seiten2014 EN AdvancedBootkitTechniquesOnAndroid ChenZhangqiShendihombre pocilgaNoch keine Bewertungen

- B1 SpeakingDokument5 SeitenB1 SpeakingHoàng Nam Thắng100% (2)

- YuzurtDokument2 SeitenYuzurtFranco Ascari100% (1)

- Switching Power Supply Design: A Concise Practical Handbook: February 2022Dokument5 SeitenSwitching Power Supply Design: A Concise Practical Handbook: February 2022Juan Gil RocaNoch keine Bewertungen

- 4Dx - Series B Capital Raising IMDokument42 Seiten4Dx - Series B Capital Raising IMsamNoch keine Bewertungen

- JAMB Biology Past Questions 1983 - 2004Dokument55 SeitenJAMB Biology Past Questions 1983 - 2004Keith MooreNoch keine Bewertungen

- PAP and PAPE ReviewDokument9 SeitenPAP and PAPE ReviewYG1Noch keine Bewertungen

- Performantele MTADokument5 SeitenPerformantele MTAana aNoch keine Bewertungen

- New-DLP Phase2 Assignment-3 Module-B Final-9.8.18Dokument6 SeitenNew-DLP Phase2 Assignment-3 Module-B Final-9.8.18PNoch keine Bewertungen

- Types of Shops Shopping: 1. Chemist's 2. Grocer's 3. Butcher's 4. Baker'sDokument1 SeiteTypes of Shops Shopping: 1. Chemist's 2. Grocer's 3. Butcher's 4. Baker'sMonik IonelaNoch keine Bewertungen

- Teoria Do Campo Ligante - Part IIDokument25 SeitenTeoria Do Campo Ligante - Part IIArthurGrafdeSousaNoch keine Bewertungen

- Intelligent: - 60 AMP - 80 AMPDokument8 SeitenIntelligent: - 60 AMP - 80 AMPHayson NuñezNoch keine Bewertungen

- Ws - Mea Millennium Ecosystem AssessmentDokument3 SeitenWs - Mea Millennium Ecosystem Assessmentapi-305791685Noch keine Bewertungen

- Rodents and Sectional Title ComplexDokument2 SeitenRodents and Sectional Title ComplexFredSmith777Noch keine Bewertungen

- Remote Control RC902V1 ManualDokument3 SeitenRemote Control RC902V1 ManualdezdoNoch keine Bewertungen

- Critique PaperDokument1 SeiteCritique PapernicolealerNoch keine Bewertungen

- X FEDEX EIDokument13 SeitenX FEDEX EINISREEN WAYANoch keine Bewertungen

- NANOGUARD - Products and ApplicationsDokument2 SeitenNANOGUARD - Products and ApplicationsSunrise VenturesNoch keine Bewertungen

- Plumber PDFDokument68 SeitenPlumber PDFshehanNoch keine Bewertungen

- Rotorcraft-Flight-Manual 5ab11c331723dd329c63732fDokument12 SeitenRotorcraft-Flight-Manual 5ab11c331723dd329c63732fpilot digitalNoch keine Bewertungen

- PU-133AB - 規格GMXa spc 2022Dokument5 SeitenPU-133AB - 規格GMXa spc 2022Ý TrầnNoch keine Bewertungen

- O o o O: (Approval and Adoption of BCPC AWFP) (Approval and Adoption of BCPC AWFP)Dokument2 SeitenO o o O: (Approval and Adoption of BCPC AWFP) (Approval and Adoption of BCPC AWFP)Villanueva YuriNoch keine Bewertungen

- FALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewDokument51 SeitenFALLSEM2021-22 EEE3004 ETH VL2021220100810 Reference Material I 16-Aug-2021 7 Controlled Rectifier NewVAHEESNoch keine Bewertungen

- Geographical Perspective On Selected Issues and Problems #ToppersnotesDokument16 SeitenGeographical Perspective On Selected Issues and Problems #ToppersnotesParidhi JainNoch keine Bewertungen

- MS Fresher HR DocumentDokument4 SeitenMS Fresher HR DocumentJahanvi KambojNoch keine Bewertungen

- Health and Illness Answer-8Dokument2 SeitenHealth and Illness Answer-8June DumdumayaNoch keine Bewertungen