Beruflich Dokumente

Kultur Dokumente

Technical Service Parts: Styles 3475 Gemini™ Hydraulically Controlled Monitor Special, No Motors

Hochgeladen von

Cristián Andrés Maqueira RivasOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Technical Service Parts: Styles 3475 Gemini™ Hydraulically Controlled Monitor Special, No Motors

Hochgeladen von

Cristián Andrés Maqueira RivasCopyright:

Verfügbare Formate

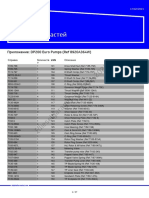

STYLES 3475

Gemini™ Hydraulically

Controlled Monitor

SPECIAL, NO MOTORS

technical service parts

MAINTENANCE INSTRUCTIONS:

Gears must be kept greased at all times

with Low-Temp Lubriplate®† or equivalent.

If O-Rings (item #4) are disassembled, silicone

grease should be applied before re-assembly.

Low-Temp Lubriplate grease should be

periodically applied to grease fittings (item #34).

Grease should be applied until visible through

swivel plugs ( item #35).

HYDRAULIC FLUID

RECOMMENDATIONS:

Temperature:

+10°F to +140°F - SAE 10W30

Temperature:

-10°F to +140°F - 1) AMSOIL ATF

-10°F to +140°F - 2) DEXTRON II ATF

-10°F to +140°F - 3) EMERY

CHEMICALS ENGARD #2802

Operating instructions:

Maximum Nozzle Flow 1000 GPM

Maximum Water Pressure 200 PSI

Maximum Hydraulic Pressure 1000 PSI

Elevation stop located at 45˚ above horizontal

to meet NFPA requirements for basket use. If

not used in basket application, set screw (#38)

can be removed to provide rotation 90˚ above

horizontal.

Hydraulic lines hook up to the base (#24) with 1/8”

NPT Connectors as follows:

Port#1—pressure for straight stream

Port #2— pressure for fog

49/ Port #3—pressure for lower nozzle

Port #4—pressure to raise nozzle

Rotational Motor requires 9/16”-18 Male

Connector with O-Ring:

*CAUTION: The hydraulic supply system must provide

the designed pressure and flow during varying climatic

conditions. Cold weather may adversely affect the

flow and pressure of the hydraulic supply system.

†® Registered Trademark of Fiske Brothers, Toledo, Ohio

123595

STYLES 3475

Gemini™ Hydraulically

Controlled Monitor

SPECIAL, NO MOTORS

technical service parts list

quantity

item part

description

no. Number

3475

1 Tube Fitting 713199 4

2 Hydraulic Hose 721211 2

3 Pipe Plug 744009 1

4 O-Ring 757017 2

5 Roll Pin *** 744084 2

6 Mounting Plate 104584 1

7 Gear Guard Bracket 704143 1

8 Upper Gear Guard 718084 1

9 Rivet 754042 3

12 Tube Fitting 713066 2

13 Stainless Steel Braided Hyd Hose 721588 2

14 Tube Fitting 713067 2

15 Hex Head Cap Screw 761017 4

16 Worm Gear *** 118528 2

17 O-Ring 757170 1

18 Hex Head Cap Screw 765097 1

19 O-Ring 757241 6

20 Mounting Bracket 104582 1

22 Socket Head Cap Screw 767043 4

23 Set Screw 765134 4

24 4” NPT Base 104581 1

25 Pipe Plug 744986 4

26 Hex Head Cap Screw 761064 6

27 Rotational Gear 104963 1

28 Self-Tapping Screw 767092 8

29 Gear Guard 718086 1

30 Ball Bearings ‡ 112

31 Nail Grip 736045 4

32 Name Plate 773252 1

33 Gear Guard 718085 2

34 Grease Fitting 713191 2

35 Swivel Plug 742023 2

36 Siamese 104585 1

37 Hex Head Cap Screw 765098 1

38 Socket Head Cap Screw* 765014 3

39 Elevation Gear**(Optional) 105659 1

39 Elevation Gear**(Standard) 107170 1

40 Outlet Tee 104586 1

41 Akromatic® 1000 Nozzle Style 5055 1

43 Socket Head Cap Screw 765030 2

3 NPT Adapter (not shown)† 104579 1

46 Bracket Stop (not shown) 704249 1

47 Spacer (not shown) 769371 2

48 Socket Head Screw (not shown) 767096 2

49 Set Screw (not shown) 765096 1

*One screw required on brass units. Two screws required on Pyrolite® units with Standard Elevation Gear (#39) to provide a stop 45˚ above horizontal as

required by NFPA 1901 for aerial application. The third screw is required when the Optional Elevation Gear (#39) is used.

**Standard Gear allows -45˚ to +90˚ travel. Optional Gear allows -45˚ to +135˚ travel. Contact Akron Brass before attempting to replace the Standard Gear

with the Optional Gear.

***Ships loose with monitor

†The 4” NPT Base (#24) must accompany optional inlets.

‡Packet of 50 ball bearings P/N 109041

PHONE: 330.264.5678 or 800.228.1161 I FAX: 330.264.2944 or 800.531.7335 I akronbrass.com

revised: 03/13

WARRANTY AND DISCLAIMER: We warrant Akron Brass products for a period of five (5) years after purchase against defects in materials or workmanship. Akron Brass will repair or replace product

which fails to satisfy this warranty. Repair or replacement shall be at the discretion of Akron Brass. Products must be promptly returned to Akron Brass for warranty service.

We will not be responsible for: wear and tear; any improper installation, use, maintenance or storage; negligence of the owner or user; repair or modification after delivery; damage; failure to follow

our instructions or recommendations; or anything else beyond our control. WE MAKE NO WARRANTIES, EXPRESS OR IMPLIED, OTHER THAN THOSE INCLUDED IN THIS WARRANTY STATEMENT,

AND WE DISCLAIM ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. Further, we will not be responsible for any consequential, incidental or

indirect damages (including, but not limited to, any loss of profits) from any cause whatsoever. No person has authority to change this warranty.

ISO 9001 REGISTERED COMPANY © Akron Brass Company. 2012 All rights reserved. No portion of this can be reproduced without the express written consent of Akron Brass Company.

Das könnte Ihnen auch gefallen

- PQM Quiz FinalDokument11 SeitenPQM Quiz FinalSyeda Sadaf ZahraNoch keine Bewertungen

- B&M Transpak Kit TH700Dokument14 SeitenB&M Transpak Kit TH700Ghostrider1100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Cracking Passwords GuideDokument45 SeitenCracking Passwords GuideKorben100% (6)

- Cut82hr Manual Parts (Cr9b-) 130712siDokument43 SeitenCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735Noch keine Bewertungen

- CTC12Dokument2 SeitenCTC12Joffre Lautaro Benavides SeminarioNoch keine Bewertungen

- G20e-5 Sb1128e05 PDFDokument808 SeitenG20e-5 Sb1128e05 PDFGORDNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- 1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Dokument11 Seiten1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Marco100% (3)

- Unpriced Proposed Renovation of Bugolobi Flat, Block C For Uganda Coffee Development AuthorityDokument39 SeitenUnpriced Proposed Renovation of Bugolobi Flat, Block C For Uganda Coffee Development AuthoritynicolasNoch keine Bewertungen

- Akira 007Dokument70 SeitenAkira 007Ocre OcreNoch keine Bewertungen

- BRH 501 Manual: Parts, Safety, Operation & MaintenanceDokument46 SeitenBRH 501 Manual: Parts, Safety, Operation & MaintenanceRomán Arturo Guerrero Uc100% (3)

- Shaira Narrative Report (Final)Dokument7 SeitenShaira Narrative Report (Final)Sheryll TamangNoch keine Bewertungen

- 08 V6 Ticking 08-017Dokument3 Seiten08 V6 Ticking 08-017Tuomas KoskinenNoch keine Bewertungen

- Critical Wear Areas & Vacuum Test Locations: 4L60-E - Valve BodyDokument4 SeitenCritical Wear Areas & Vacuum Test Locations: 4L60-E - Valve BodysuattosunNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Technical & Operation Manual (NP-180-002)Dokument105 SeitenTechnical & Operation Manual (NP-180-002)Marce Gutiérrez100% (1)

- Pompe Perkins 3340f261t PDFDokument2 SeitenPompe Perkins 3340f261t PDFKamel BelhibaNoch keine Bewertungen

- Instalación ch330Dokument4 SeitenInstalación ch330Edwing GuerreroNoch keine Bewertungen

- Generic 6d24t Spec SheetDokument2 SeitenGeneric 6d24t Spec Sheetali4299100% (2)

- Training Handout D25K D45 HydraulicDokument97 SeitenTraining Handout D25K D45 HydraulicAslam Kamal AfdhalNoch keine Bewertungen

- 31504647-Antenna System (On Tower) Installation Standard ModelDokument27 Seiten31504647-Antenna System (On Tower) Installation Standard ModelBadr AmerNoch keine Bewertungen

- Historic Trial of Ali Brothers and Shankaracharya-1921Dokument276 SeitenHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- Print CatalogDokument8 SeitenPrint Catalogamador51Noch keine Bewertungen

- Safim Power Brake Valve PDFDokument17 SeitenSafim Power Brake Valve PDFmusafirNoch keine Bewertungen

- Service-DOOSAN DL300Dokument1 SeiteService-DOOSAN DL300Mahmmod Al-Qawasmeh100% (2)

- 8920A364WDokument27 Seiten8920A364WMakar SamarskiyNoch keine Bewertungen

- Service Doosan Dl300Dokument1 SeiteService Doosan Dl300Mahmmod Al-Qawasmeh100% (1)

- R 8 PDFDokument9 SeitenR 8 PDFUriel MFNoch keine Bewertungen

- Hydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeDokument3 SeitenHydraulic Single-Acting Balanced Rotary Actuator 90° (Quarter-Turn) Fail-SafeLanceal TanNoch keine Bewertungen

- 9852 0625 01b Maintenance Schedule DHR 48 HDokument5 Seiten9852 0625 01b Maintenance Schedule DHR 48 HMood0% (1)

- RWP55 Pt. ListDokument10 SeitenRWP55 Pt. Listzul fikarNoch keine Bewertungen

- HKS Manual GT86 BRZ SuperchargerDokument41 SeitenHKS Manual GT86 BRZ SuperchargerAntonino AlduinaNoch keine Bewertungen

- Service N ValveDokument30 SeitenService N ValvesenamotoNoch keine Bewertungen

- TM55-65 Servicemanual En.2Dokument57 SeitenTM55-65 Servicemanual En.2josemanuelarmijo66Noch keine Bewertungen

- Series R1E02 General Description Technical Information: Pressure Relief ValvesDokument3 SeitenSeries R1E02 General Description Technical Information: Pressure Relief Valvesshahrol effendy rodziNoch keine Bewertungen

- V480480CCompPartsELSmith 783006060 PDFDokument10 SeitenV480480CCompPartsELSmith 783006060 PDFJames Wayne BarkerNoch keine Bewertungen

- Service InformationDokument2 SeitenService InformationMarcelo GiussaniNoch keine Bewertungen

- G300 Brake BleederDokument7 SeitenG300 Brake BleederluisNoch keine Bewertungen

- Sinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsDokument4 SeitenSinorix™: A6V10867394 - en - c2 Building Technologies 2017-06-06 Control Products and SystemsEngineering TFINoch keine Bewertungen

- 4G63 Turbo Eclipse & Talon - Twin Cam: Accessories Engineered Component KitsDokument4 Seiten4G63 Turbo Eclipse & Talon - Twin Cam: Accessories Engineered Component KitsWolim HonNoch keine Bewertungen

- TF100-53B 3900 Series QD CouplingsDokument6 SeitenTF100-53B 3900 Series QD CouplingsrrrrNoch keine Bewertungen

- Fuel Injector Cleaner: Form No. 107340Dokument4 SeitenFuel Injector Cleaner: Form No. 107340Leandro Nikko ReintarNoch keine Bewertungen

- Fuel Hose Reel Model 89010 & 102962 Series "A": SafetyDokument3 SeitenFuel Hose Reel Model 89010 & 102962 Series "A": SafetyLuis Carlos González LondoñoNoch keine Bewertungen

- Martelli Tramac PDFDokument64 SeitenMartelli Tramac PDFFastcross HondaNoch keine Bewertungen

- Generac EK130 Gas Generator Engine Parts Manual 3Dokument41 SeitenGenerac EK130 Gas Generator Engine Parts Manual 3Planejamento MegaWattNoch keine Bewertungen

- Zero Loss Drain by QPPDokument2 SeitenZero Loss Drain by QPPMod KaewdaengNoch keine Bewertungen

- Re92100 - 2023 12 04Dokument56 SeitenRe92100 - 2023 12 04josueNoch keine Bewertungen

- Performer-Plus Camshaft/Lifters/Lube Kit #2177 MODEL: 318-360 C.I.D. Chrysler V8, 1967 & Later (Not For 1985 & Later 318 V8 With Roller Lifters)Dokument6 SeitenPerformer-Plus Camshaft/Lifters/Lube Kit #2177 MODEL: 318-360 C.I.D. Chrysler V8, 1967 & Later (Not For 1985 & Later 318 V8 With Roller Lifters)v8chargeNoch keine Bewertungen

- Alltrux No Contacts 042017Dokument12 SeitenAlltrux No Contacts 042017api-359742263Noch keine Bewertungen

- LGL4 PartsDokument2 SeitenLGL4 PartsCarlos Rafael Rondon AbreuNoch keine Bewertungen

- Product Information: Air Impact WrenchDokument12 SeitenProduct Information: Air Impact WrenchkareemNoch keine Bewertungen

- Index EstabilizadorDokument12 SeitenIndex EstabilizadorRioja Chanchari PolNoch keine Bewertungen

- Sydfe1, Sydfee, Sydfec, Sydfen, Sydfed, SydfefDokument48 SeitenSydfe1, Sydfee, Sydfec, Sydfen, Sydfed, SydfefMichail ArmitageNoch keine Bewertungen

- Ficha Tecnica r9 IntertracoDokument1 SeiteFicha Tecnica r9 IntertracoIlse SaavedraNoch keine Bewertungen

- Lincoln Instruction Manual PN 1828 and 1830Dokument2 SeitenLincoln Instruction Manual PN 1828 and 1830eduardoNoch keine Bewertungen

- Troubleshooting The Fuel Priming and Primary Filter Pump GP and The Fuel Filter Base Assembly (1256, 1258, 1260, 1261, 1263) PDFDokument7 SeitenTroubleshooting The Fuel Priming and Primary Filter Pump GP and The Fuel Filter Base Assembly (1256, 1258, 1260, 1261, 1263) PDFNghiaNguyentrungNoch keine Bewertungen

- Engine CoolingDokument116 SeitenEngine Coolingmebarki aberraoufNoch keine Bewertungen

- 01 4TNV98T-ZCSTY 规格参数表-英文Dokument4 Seiten01 4TNV98T-ZCSTY 规格参数表-英文Eric CNoch keine Bewertungen

- 83.9 and 85.9 Series Engine TorquesDokument6 Seiten83.9 and 85.9 Series Engine TorquesAhmed SayedNoch keine Bewertungen

- Valvula de DiluvioDokument4 SeitenValvula de DiluvioJJ GOLE PRECIOS UNITARIOSNoch keine Bewertungen

- Fiat Barchetta: Technical DataDokument8 SeitenFiat Barchetta: Technical DatahallexNoch keine Bewertungen

- Ripper Tilt Cylinder - Remove and Install (RENR2054-04)Dokument8 SeitenRipper Tilt Cylinder - Remove and Install (RENR2054-04)connor.millsNoch keine Bewertungen

- Pilot CylindersDokument7 SeitenPilot CylindersMohsin RazaNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Content and Context Analysis of Selected Primary SourccesDokument3 SeitenContent and Context Analysis of Selected Primary SourccesToshi CodmNoch keine Bewertungen

- Budgetary Quote HPE AMD 128cores For DNDSSGDokument7 SeitenBudgetary Quote HPE AMD 128cores For DNDSSGglalit kumarNoch keine Bewertungen

- Markov Decision Processes For Path Planning in Unpredictable EnvironmentDokument8 SeitenMarkov Decision Processes For Path Planning in Unpredictable EnvironmentVartolomeiDumitruNoch keine Bewertungen

- Annex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolDokument2 SeitenAnnex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolMariel Gregore0% (1)

- Selling AIESEC To Your TargetsDokument7 SeitenSelling AIESEC To Your TargetspijoowiseNoch keine Bewertungen

- Structure of An Atom Revision PaperDokument5 SeitenStructure of An Atom Revision PaperZoe Kim ChinguwaNoch keine Bewertungen

- Healthy Body CompositionDokument18 SeitenHealthy Body CompositionSDasdaDsadsaNoch keine Bewertungen

- PTPL Ir 2018Dokument383 SeitenPTPL Ir 2018Guan WenhaiNoch keine Bewertungen

- 13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledDokument5 Seiten13-Mike Engelbrecht - Methods of Maintenance On High Voltage Fluid FilledRomany AllamNoch keine Bewertungen

- Cel2106 SCL Worksheet 6Dokument3 SeitenCel2106 SCL Worksheet 6HarryJoy JackNoch keine Bewertungen

- Lecture 7Dokument68 SeitenLecture 7Gay TonyNoch keine Bewertungen

- Scan 03-Jan-2020 PDFDokument2 SeitenScan 03-Jan-2020 PDFPavanSharmaNoch keine Bewertungen

- DBL10 - Sapporo X Schematics Document: Compal ConfidentialDokument50 SeitenDBL10 - Sapporo X Schematics Document: Compal ConfidentialEvgeniy BaranovskiyNoch keine Bewertungen

- Unit 8 Atomic Fluorescence Spectrometry PDFDokument23 SeitenUnit 8 Atomic Fluorescence Spectrometry PDFCh AswadNoch keine Bewertungen

- Sekonic L 758Dokument68 SeitenSekonic L 758mariosapereiraNoch keine Bewertungen

- Repeater Panel User GuideDokument24 SeitenRepeater Panel User Guideamartins1974Noch keine Bewertungen

- Optimizing Patient Flow: Innovation Series 2003Dokument16 SeitenOptimizing Patient Flow: Innovation Series 2003Jeff SavageNoch keine Bewertungen

- 实用多元统计分析Dokument611 Seiten实用多元统计分析foo-hoat LimNoch keine Bewertungen

- Boonton Radio Corporation - The Notebook 12Dokument8 SeitenBoonton Radio Corporation - The Notebook 12Luiz Roberto PascotteNoch keine Bewertungen

- Newsite KPI Check. - Ver2Dokument4.183 SeitenNewsite KPI Check. - Ver2nasircugaxNoch keine Bewertungen

- Research PaperDokument14 SeitenResearch PaperNeil Jhon HubillaNoch keine Bewertungen

- CNL DivisionDokument38 SeitenCNL DivisionaniketnareNoch keine Bewertungen

- Gunnar Fischer's Work On Ingmar Bergman's The Seventh Seal and Wild StrawberriesDokument6 SeitenGunnar Fischer's Work On Ingmar Bergman's The Seventh Seal and Wild StrawberriesSaso Dimoski100% (1)