Beruflich Dokumente

Kultur Dokumente

GDFGDF

Hochgeladen von

Eduardo Fernandez Daza0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

53 Ansichten6 Seitengdfgsdfgd

Originaltitel

gdfgdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengdfgsdfgd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

53 Ansichten6 SeitenGDFGDF

Hochgeladen von

Eduardo Fernandez Dazagdfgsdfgd

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

US 2017007458681

cu») United States

«2 Patent Application Publication co Pub. No.: US 2017/0074586 AI

ENSEN et al.

oy

oy

~

ey

@y

(86)

G0)

Mat. 15,

ASPIN

POWDER BY SPIN FLASH DRYING

Applicant: SPX FLOW TI

DANMARK AV

NOLOGY

bora (DK)

Inventors: Michael CHRISTENSEN, Smerum

(DK): Per NIE

Appl. No: 18/122,837

PCT Filed: Mar, 13, 2018

PCT No,

$371 (eX),

(2) Date

pcre

"2015/055283

Aug. 30, 2016

Foreign Application Priority Data

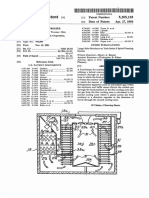

2014 (DK)

100

SEN, Bogsverd (DK)

PA201400139

R

(43) Pub. Date: Mar. 16, 2017

Publication Classification

GI) Ime,

4268 2804 (2006.01)

F268 17710 (200501),

1268 37002 2006.01),

(2) US. C1,

cr F268 25/04 2013.01); F26B 3/0924

(2013.01); #268 17/103 (2013.01), F268

17/104 (2013.01); F26B 2200/02 (201301)

6 ABSTRACT

Herein is diselosod a spin flash deyer further comprising 9

‘waste outlet arranged ina ehamber hortom of the spin Bash

Ayer for removal ofa residual organic waste material from

spin fash dryer during spin flash operation and a method

‘of operating a such spin fish dryer to remove residual

fonganie waste material from suid spin Mash dryer during

‘operation.

=f

40

200

Patent Application Publication Mar, 16, 2017 US 2017/0074586 AI

100

“\

>) FE

1

2

4

5 2 ie

1 T

fa f17-8 of 410 4

L— =)

1-7

: <200

&

Figure 1

US 2017/0074586 AI

ASPIN FLASH DRYER FOR PRODUCING 4

POWDER BY SPIN FLASH DR}

REF

[0001] This application isthe US. national stage of Inter

national Application No, PCT/EP2015(085283, filed Mar

13, 2015, which elaims priority to Danish Application No.

PA201400139, filed Mar. 13, 2014, the disclosures of which

‘are ineorporated herein by reference in their entirey.

RENCE TO RELATED APPLICATIONS

FIELD

10002] The present disclosure relates to a spin fash dryer

Jor producing a powder by spin flash drying, in particular for

tse inthe field of food waste disposal.

BACKGROUND

10003] The present disclosure relates to a spin flash dryer

Jor prodoeing a powder by spin lsh drying in partielar for

use i the Field of food waste disposal.

10004] The disclosure specifically relates w spin Bash

dryer for drying of a material in particular from the food

processing industry, in the form ofa paste or filler ake,

‘witha verical, eylindrial, dryer chamber having a rotating

counially placed strer, wth a variable speed drive serew

feeder and with apertures for supply of hot drying gas and

or removal ofthe spent drying yas and removal of the dried

material

[0005] Feed material preferably dried according to the

invention are organic materials, preferably organic waste

materials such as eg. food waste products, fruit and best

alps, distiller’ residues, waste products compesing animal

blood such as e slaughterhouse animal wast, proteins,

‘carbolydrates such as ex. sugars and starches, fey waste,

and non-caking permeates. Preferred organie waste materi

als are waste produets comprising blood. The feed material

‘can eg. bea liquid suspension comprising a solids fraction,

‘8 paste, or a Mller cake material, wherein a vetion of the

liquid suspension comprising a solids fraction, the paste, oF

the filter cake material has a particulate size which is Too

Jarge to undergo spin flash drying. i. which density is larger

than the lifting power ofthe uidization medium of the spi

flash dryer, or altematively wherein the solids fraction is

ormed during operation of the spa. flash deyer by agare-

gation or agglomeration,

[0006] itis well known, eg. fom BP 0 141 403 t0 dry

materials in the form of a paste or fiter cake t0 obtain a

powder. In this apparatus the produced powder particles

sizes are all under a given cut size andthe residual drying

js furthermore emitted tothe environment. Likewise itis

Well-known eg, rom WO 97/19307 to spin fash dey

powder with a desired mean panicle size and a narow

particle size distribution

[0007] As spin Mash drying has gained popularity the

materials which have been tied in these dryers have

increased in complexity and today itis not uncommon (©

tempt to dry materials, wherein the material to be dried can

be formed into a paste or a filler cake, but wherein this

material nevertheless comprises a fraction of the paste oF

filter cake material that has @ partieulate size which is 100

large to undergo spin flash drying, or wherein a fraction of

the material to be dried undergoes insufficient particulation

during drying thereby forming agglomerates which cannot

be lifed by the drying air and out of the spin flash dyer.

Mar. 16, 2017,

[0008] uct a situation is particulaely often observed

the food processing indusiry, where the residual organi

‘material supplied to the spn ash dryer often agareyates and

‘agglomerates during spin flash cluing, thereby” fonning

‘agglomerates which accumulate at the bortom of the spin

Tash dryer. This is highly unwanted and bas several unde-

sired consequences, stich as eg. increasing residence time of

the material inthe spin flash dryer, reducing the spin flash

Aiyer’s capacity as well as decreasing the intervals between

‘mainlenance stops

[0009] This situation in particular i often observed in the

‘eat processing industry. Waste materials from meat pro-

cessing often contain useful onic components, whieh

faot he separated from the carcass of the animal body in

the noma process of cutting and parting the animal. How-

ever, such waste materials from meat processing can be

uslized in further industrialized process steps. For example

st processing by-products comprising an animal blood

fraction are useful by-products of the meat processing

industry which advantageously can be spin fash dried to

‘obtain powders enriched in blood.

[0010] However, in pastes or filter cakes comprising

‘eal processing by-product comprising an animal blood

faction itis often the situation that the by-product also

comprises a fraction of material eg. crushed bones from the

fnimtl carcass, which cannot undergo spin-flash drying and

therefore aocumlates atthe bottom ofthe spin fish dryer,

fr, which is more common, particles of ligaments and

sinews together with the ever present blood, coagulate and

become gluey under the processing conditions of the spin

slash dryer, and start forming very large, keseale, conglo

feraes of spin lash waste which eannot undergo spin lash

‘drying, However, by authorities, and for economic reasons,

the ability to cometly teat by-products of the mest pro”

‘essing industry comprising blood and crushed bones mate-

ial is considered essential for health and environmeatal

[0011] In general, accumulation of materia, in particular

‘of waste materials buildup, atthe bottom of. spin flash dryer

fs cumbersome to handle as removal of this material gen-

cally requires the processing line to be shut dovsn during

‘maintenance, which may entail dissssembling the spin lash

dyer and long waiting times in onder for the dryer (© cool

to Temperatures which permit operator access to the drying

chamber. Also, when food products is concerned, operator

access is highly unwanted as it wil disturb (or eontaminate)

the biological integrity ofthe spin Mash deying system,

[0012] There exists, therefore, the need for a spin Dash

‘dryer which can handle such agglomerating materials with-

‘out requiring an increased number of maintenance stops.

[0013] WO 031018954 discloses a cuitings. processing

system inching a steam atmosphere spia fish deying

chamber able to process oil-eniched rock cuitings in an

inert atmosphere for direct installation on an off-shore oil

platform. The spin flash unit included in the eutings pro-

‘essing system of WO 03018954 inches a drain and overs

ischarge for access to the spin flash unit during operation

down time. Spin fash drying of oib-enriched material is 4

particular dangerous process and the cuttings processing

system is designed to stay closed during operation to prevent

for reduce the risk of fire on the oil platform. Due to the

‘manner in which ol is drilled, mek cuttings have uniform

size distributions with only a minor fraction having a size

soo large to undergo spin fash dying, Fuser, rock

US 2017/0074586 AI

‘does not undergo agglomeration. Rather, the rock facto

will accumulate, but not aggregate, atthe bottom of the spi

flash dryer and for safety reasons must be removed during

intermission for maintenance in the production line.

[0014] In the context of the present disclosure, waste

‘alerial ito be understood a any matter contained ina feed

material fora spin flash dryer, typically a paste or filer cake

material, fed to a spin flash dryer, which waste material

‘cannot undergo particuation andlor loecuation to become

a dred spin flash product in a spin fash dryer and be lifted

by the deying airflow against the gravitational force to exit

the spin flash drying chamber through an aperture for

removal of a dried spin fash product from the drying

‘chamber ofthe spin Nash deyer.

[0015] Such waste materials are routinely observed 10

Torm in many spin fash drying processes as residuals stil

‘contained in the drying chamber (1) after an interval of

‘drying time otherwise cosidered sulicent for particuatio

and flocculation of the feed materia.

[0016] In CN 202562247 (U) there is disclosed a drying

‘unit, in patcular a spin Rash dryer, comprising a spin ash

drying oom, a dispersing device, a driving device, a evolv-

ing shat nai inlet anda feed inlet. The revolving sha is

‘connected with the driving device, the dispersing device is

‘connected with the revolving shafl, and the dispersing

‘device and the revolving shall are arranged inside the spi

flash drying room. The dispersing device comprises more

than three dispersing vanes, and one end of the dispersing

vanes is connected with the revolving shaft to form an

‘annular dispersing surface. The spin flash dryer of the

described invention is directed to effective avoidance of

materials buildup on the bottom of a dryer through the

dispersing device.

10017] The present inventors have now realized the need

Tor further improvements in spin fash deyers to evercome

unwanted effeets on the drying process and spin fish

‘chamber due to residual orzanie waste material buildup on.

the bottom of sich a spin flash dryer, in paricularin the fed

‘of food processing, ind most in particular in the Held of

‘waste products from the food processing industry comprise

ing blood,

SUMMARY OF 1

IE INVENTION

[0018] ‘The invention is disclosed in the present deserip-

Vion and drawings and in the claims.

10019] As according to a fist aspect and embodiment

there is disclosed a spin flash dryer comprising a drying

‘chamber enclosed by atleast a chumber wall anda chamber

bottom: a rotating ster, said rotating stir arranged in

said drying chamber near said chamber bottom, sid rotating

btimor being provided with a plurality of string Blas:

members for the supply of a material to be dried, said

members arranged in said chamber vwall to permit the

passage of a material to be dried from the exterior of said

‘drying chamber to the interior of said drying chamber:

apertures for supply and removal of a medium for Muiiza

tion and drying and for removal of a dried produc, sad

aperture for supply of the Quidization and drying medium

being positioned in said drying chamber wall between said

‘chamber bottom and said aperture for removal of a dried

product in said drying chamber; sid spin flash dryer further

‘comprising a waste outlet arranged in ssid chamber bottom,

fof said spin flash dryer, and whercin said waste outlet is

‘ranged! for continvous removal of residual omzanic Waste

Mar. 16, 2017,

nial, which residual omaie want material cannot be

in Rash ded de to deity of sid eid organic

waste mateal being higher thn @ illing power os

‘edu for fidzation nd dying of si spin Nash dyer

‘vein ai west ole save which can fora sie

fn een removal is cased by sa rong ier

roving sid rsa organic waste materi ino said waste

Cutlet rng spin fh dryer operation upon which sa

real onanie waste material is removed via sid waste

butlet ina sicing operation.

[0020] As accotin wo an cmhodinent theres scone

‘pin fash dryer whecin sai wane outs arranged ator

fer the ovens point, fine, plane of sd caer

‘estom

[0021] As according to an embodiment there is disclosed

2 spin ash dryer wherein sad waste outlets aap lor

Connecting wo an arrangement for tansporting waste mate-

fal fom te intrior of sid drying chamber to the exterior

Sr sid dying chamber

[0022] As according to an embodiment there is disclosed

{pin Mash diner, wherein said avangement Fr teanspeting

Sate mtr from the inferior of sid drying camber

the exer of sid ying chamber compres #reatoch-

ale fd for covering sid waste outlet ding operation of

Seid spin fash dyer, which fd con be detched rom sok

seat ute ring an intemisson of operation of sed spin

Tash dyer to emove any waste mater screed a neat

Seid wane cule on said chamber betom manvaly

[0023] As according to an embodiment there slosed

2 spin hash dryer wierein sid sue comprises rating

arrangement of openings ad losres apd o mais

an evsetally fd tight seal benwon the nto of sak

drying chamber and the exterior of sid dying chamber

dhring operation of said she and said spin ash dyer

Preferably, said rotating arrangement of openings and lo-

Sires arn valve oa sling valve

[W024] As accoting to an embwiment theres closed

Spin Mash dyer, wherein sid arrangement fr rasp

frase material Ip spaced below sak waste outlet By an

Intersoction, idimerseeton eg, being length ofa eondit

ee

{0028} _As according to an embodiment there is disclosed

{pin fah dryer wherin si chamber boom conical

chamber httom which extends conical tapering upwards

Soside ssid devin chamber

[0026] As according to an embodiment there is disclosed

$epin Mash dyer sad spin fh cyer further comping an

aml dsinbtor for ditboting said foiation and

dying md, eid annular distor srcunding ower

‘ation of sid chamber wall, whereby sai ation and

Giying media i ed nto the drying shamber in an evenly

[0027] As acconing to an embnent theres dsclosed

a spin sh deer wherein the omanie materials fod mate-

fal are seecod from onganie se caters compas

food waste product, rit and bot pp, cistillers resis,

tase pmdocts comprising animal blood, slaughterhouse

‘nim waste, protein, earboydrats, soars, Saree, ay

sete, anor ning permesten

[0028] As according to an embodiment there is disclosed

! method of remving residual organic waste mater fom

the interior of a spin fash yer ding spin flesh dryer

tperation, wherein removal i cased hy ating ster

moving sid endl organic waste material ino @ waste

US 2017/0074586 AI

‘outlet during spin flash dryer operation upon which seid

residual omganie waste material is removed via said waste

‘outlet ina slicing operation.

10029] FIG. 1: Exemplary spin fash dryer with waste

ote,

DETAILED DESCRIPTION

10020] Spin fash dryers for fd bed drying, particularly

for simullancous drying and disintegration of terial in

the form of paste ora iter cake ae commonly known

[0031] An exemplary spin flash dryer according tw the

invention is shown in FIG. 1, wherein prior a spin ash

diver (100) as Been mounted with a waste out (200)

secording 1 the invention

[0032] In FIG. 1.2 spin flash dryer (100) of the prior artis

shown, wherein the spin flash dryer further comprises a

tanto (200) ofthe vention. Spin fash dryers (100)

Of the prior art are in general consnited wilh a dying

‘chamber (1) eoelsed by ciber wall 2), ad having

‘hnber bottom (in fxed conection therewlh, A roating

Stier (9, 10) wil sully be arranged coil inthe dying

‘hmber (1) nea its chamber bottom (3) ona shaf (7) which

teanfers a rotation fom a oor (6) the ster) Usa,

the sliver (9) provided with x plurality of sing blades

{Ao}. Thebiades (10) ofthe stirrer) are wormaly arranged

in parle to the charter botiom (3), but depending on

junetion, modifications to stirrer (9) and sttrer blades (10)

are koa,

0033] Further the deying chamber (1) will eomprise mem-

bers (14, 18) for the supply of a material to be dried,

spertures (6, 16) for supply (S) and removal (16) of

medium for uidization and drying and for removal (16) of

1 dried product

10034] In many spin flash dryers of the prior art the

‘chamber bottom (3) i a conical chamber bottom (3) which

‘extends conically tapering upwards inside the chamber (1,

10035] Usually, dhe aperture for supply of the Budization

snd drying medium (8) is positioned inthe deying chamber

wall (2) between the chamber bottom (3) and the aperture

(16) for removal of a dried product in the drying chamber

(A), Also customarily, an annular distebutor (4) foe distib-

‘utng the fidization and drying medium is surrounding the

Tower region of the chamber wall (2) whereby the fiiza-

tion and drying medium is le into the drying chamber (1)

in an evenly manner.

10036] Usually in spin Mash dryers of the proe art the

blades (10) of the ster (9) are positioned ata relatively

small distance from the chamber bottom (3). It is well

known to add farther stirer elements (11, 12, 13) coaxially

‘on the rotating shaft (7).

10037] Likewise itis commonly known inte prorat for

the dying chamber (1) and the annular distributor (4) to

have a stretch of common wall, which is heat insulated (17)

‘on the side facing the distributor (4).

0038] Likewise commonly known in the prior artis foe

the deying chamber (1) to inelude at least one panicle size

classifier positioned inside the drying chamber (1) above the

sizrer(®) hut below the aperture (16) for removal ofa dried

product. Thereby the particle size ofthe dried! precuet may

advantageously be controlled. In such embodiments of the

Mar. 16, 2017,

prior art comprising particle size classifiers, « plurality of

fpertures (16) may be comprised in the spin ach dryer of

the prior at (100),

[0039] To a spin Mash dryer of the prior art (100), the

resent inventors sugges the addition ofa waste outlet (200)

positioned in the chamber bottom (3) of the spin ash dryer

(100), A waste outlet (200) of the invention will be dimen-

sionod according to the particular needs of the individval

Spin flash dryer into which it wil be installed, but will often

hhave a-dimensioa between 30 mm to 1000 mm, usually

between 100 mn to 300 mm.

[040] 1 is advantageous if a waste outlet (200) of the

invention is positioned a or near the bottommost point, fine,

or plane of the chumber bottom (3). Thereby itis secured

‘that gravitation and forces exerted by the stirer (9) and

blades (10) on the paste or iter cake mass contained in the

dgyng chamber will drive any waste material towards and

the waste outlet (200), from where it may be removed

at a time of an operator's choice. Proferentially. waste

‘material ean be removed coatiauously during operation of

the spin Mash dryer.

[041] Advantageously, the waste outlet (200) is adapted

{or connecting to an amangement for transporting. waste

‘matecal fom the interior ofthe drying chamber (H) to the

exterior ofthe drying chamber (1). Such an adaptation cole

eg, be by a flange section on said waste outlet (200) and

secured using nuts snd bots

[042] In one embodiment ofthe waste outlet (200), said

frangement for transporting waste material comprises @

reatlachable lid for covering the waste outlet 200) during

‘operation of the spin ash dryer (100), which fid ean be

{detached from the waste ourlet (200) during an intermission

fof operation of the spin flash dryer (100) to remove any

waste material accreted aor near the waste outlet (200) on

the chamber bottom (3) of the spin flash dryer (100) man-

ally

[0043] In another embodiment of dhe waste outlet (200),

suid arrangement for transporting waste material comprises

‘sluice adapted to permit dhe passage of waste material rom

the interior of the drying chamber (1) during operation ofthe

spin lash dryer (100) in a shicing operation, The sluice can

eg, bea check valve or any other type of non-return valves

such as eg. buttelly valves, double butterily valves, or

‘olating valves. In prefered embodiment the sluice com-

prises @ revolving emangement of openings and closures

Adapted 10 maintain an essentially fui tight seal berwoon

the drying chamber (1) and the exterior of said drying

chambee during operation of sluice and spin fash dryer

Preferably, said revolving arrangement of openings and

closutes isa rotating valve o sliding valve.

0044} Ina further embodiment of the waste outlet (200),

suid amangement for transporting waste material is spaced

below said waste outlet by an intersection, suid intersection

eg. being a length ofa conduit or pipe. Thereby a calm zone

js created helow the chamber bottom which will facilitate

ficient removal of waste material during operation without

interfering with the deying peosess

CLOSING COMMENTS

[045] ‘The term “comprising” as used in the claims does

‘ot exclude oiler elements or steps. The tem “a” or “an” as

vsed in the claims does not exclude « plurality

[0046] Although the present invention has been described

in detail for purpose of llusteion, itis understood that sue

US 2017/0074586 AI

‘detail is solely for that purpose, and variations can be made

therein by those skilled in the ar without departing from the

scope of the iaventon,

1-10, (canceled)

11. A spin fash dryer comprising

‘drying chamber enclosed by a least a ebamber wall and

chamber bottom: thereby defining an exterior and an

interior of said drying chamber,

rotating stirrer, sid rotating slimer arranged in said

dying chamber near said chamber bottom, said roat-

ing strer being provided with a plurality of siting

blades

rmomibers forthe supply of a material to be dried, said

‘members aminged in ssid chamber wall to pent

passage of @ material to be dried from the exterior of

‘tid drying. chamber 10 the interior of said: drying

chamber;

apertures for supply and removal of a medium for Mu

zation and drying and for removal ofa dried prosiuct,

‘Said aperture for supply of said Nuidization aod deying

‘medium being positioned in said drying chamber wall

hheween said chamber hotiom and said aperture for

removal ofa dried product in said drying chamber,

said spin fash dryer further comprising

a waste outlet arranged in said chamber bottom of seid

spin fash dryer; and

wherein said waste outlet is arranged for contimons

removal of residual omginie waste material, which

residual organic waste material cannot be spin flash

dried due to a density of said residual onganic waste

‘material being higher than a Titing power of said

‘medium for Buidization and drying of said spin fash

dyer, wherein said waste outlet sa valve whieh forms

fa sluice: and

wherein removal is caused by said rotating stirer moving

‘said residoal organic waste material into said waste

‘outlet during spin lash dryer operation upon which said

residual organic waste material is removed via said

‘waste outlet in a sluicing operation,

wherein said sluice comprises rotating arrangement of

‘openings and closures adapted fo maintain an essen=

tilly uid tight seal Between the interior of said drying

chamber and the exterior of sid drying chamber daring.

‘operon of said shuice and said spin lsh dryer.

Mar. 16, 2017,

12. A spin fash deyer aecording to claim 11, wherein said

waste cutlets arranged at or near the bottommost point,

Tine, or plane of said chamber bottom

13. Aspin Bash dryer according to claim 11, wherein sad

waste outlet is adapted for connecting to an arrangement for

transporting waste material from the interior of sil drying

chaher to the exterior of said drying chamber,

14, Aspin fash dryer according fo claim 13, wherein sad

‘arrangement for transporting waste material trom the ine-

rior of said drying chamber to the exterior of said drying

chamber comprises a restachable lid for covering said

‘waste outlet ring operation af said spin flash dryer, which

Tid can be detaches from said waste outlet during an inter

mission of operation of said spin flash dryer to remove any

‘waste material accreted at or near sid Waste outlet on said

chamber bortom manually

18, Asp fash dryer according to claim 14, wherein said

arrangement for transporting waste material is spaced below

Said waste outlet by an intersection, said intersection eg,

being a length of @ conduit or pipe

16. A spin flash dryer ecording to claim 11, wherein said

‘chaiber bottom sa eonial chamber bottom which extends

conically tapering upwards inside sad drying chamber.

17. A spin Mash diyer acconding to claim 11, further

comprising an annular distibutor for distributing said the

‘ization and drying medium, said annular distributor sur-

rounding a Jower region of sid chamber wall, whereby said

‘uidization and drying medium is ld ino the drying cham-

ber in an evenly manner

18. A spin flash dryer according to elaim 11, wherein the

‘onganie materials feed materials are selected from orga

‘waste materials comprising food waste products, fuit and

beet pulps, disillers” residues, waste products comprising

animal blood, slaughterhouse animal waste, proteins, car

Dohiydrates, sugars, starches, fatty waste, and/or non-caking

pemeates.

19, A method of removing residual organie waste material

from the interior ofa spin flash dryer during spin flash dryer

‘operation, wherein removal is caused by'a rotating stimer

‘moving ssid residual organic waste material into a waste

‘outlet during spin flash dryer operation upon whieh said

residual onganic waste material is removed via sid waste

outlet in a sluicing operation,

Das könnte Ihnen auch gefallen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- GHDFGHFGHDokument10 SeitenGHDFGHFGHEduardo Fernandez DazaNoch keine Bewertungen

- FGDFGDokument3 SeitenFGDFGEduardo Fernandez DazaNoch keine Bewertungen

- Us 5031751Dokument9 SeitenUs 5031751Eduardo Fernandez DazaNoch keine Bewertungen

- GHFGDokument4 SeitenGHFGEduardo Fernandez DazaNoch keine Bewertungen

- GfdgsDokument10 SeitenGfdgsEduardo Fernandez DazaNoch keine Bewertungen

- HFGHDokument5 SeitenHFGHEduardo Fernandez DazaNoch keine Bewertungen

- NMVBNMDokument10 SeitenNMVBNMEduardo Fernandez DazaNoch keine Bewertungen

- HGFHDDokument13 SeitenHGFHDEduardo Fernandez DazaNoch keine Bewertungen

- Us 4944162Dokument14 SeitenUs 4944162Eduardo Fernandez DazaNoch keine Bewertungen

- GHFGHDokument15 SeitenGHFGHEduardo Fernandez DazaNoch keine Bewertungen

- GFGHFDokument8 SeitenGFGHFEduardo Fernandez DazaNoch keine Bewertungen

- GfdgsDokument10 SeitenGfdgsEduardo Fernandez DazaNoch keine Bewertungen

- NMVBNMDokument10 SeitenNMVBNMEduardo Fernandez DazaNoch keine Bewertungen

- GFDGDDokument17 SeitenGFDGDEduardo Fernandez DazaNoch keine Bewertungen

- HGFHDDokument8 SeitenHGFHDEduardo Fernandez DazaNoch keine Bewertungen

- DGDSFGDokument6 SeitenDGDSFGEduardo Fernandez DazaNoch keine Bewertungen

- JGHJFHDokument9 SeitenJGHJFHEduardo Fernandez DazaNoch keine Bewertungen

- BCVBCDokument10 SeitenBCVBCEduardo Fernandez DazaNoch keine Bewertungen

- GDFGDFDokument8 SeitenGDFGDFEduardo Fernandez DazaNoch keine Bewertungen

- GDFGSDFDokument13 SeitenGDFGSDFEduardo Fernandez DazaNoch keine Bewertungen

- FGDGDokument12 SeitenFGDGEduardo Fernandez DazaNoch keine Bewertungen

- GDHFGHDokument11 SeitenGDHFGHEduardo Fernandez DazaNoch keine Bewertungen

- GHDFGHFDokument11 SeitenGHDFGHFEduardo Fernandez DazaNoch keine Bewertungen

- FGDFGDokument9 SeitenFGDFGEduardo Fernandez DazaNoch keine Bewertungen

- European Patent Application: Vibratory Flash DryerDokument15 SeitenEuropean Patent Application: Vibratory Flash DryerEduardo Fernandez DazaNoch keine Bewertungen

- Process Description and Optimization of The Flash Dryers at Polokwane SmelterDokument6 SeitenProcess Description and Optimization of The Flash Dryers at Polokwane SmelterEduardo Fernandez DazaNoch keine Bewertungen

- Us20100146814a1 PDFDokument12 SeitenUs20100146814a1 PDFEduardo Fernandez DazaNoch keine Bewertungen

- Wo2007134879a1 PDFDokument19 SeitenWo2007134879a1 PDFEduardo Fernandez DazaNoch keine Bewertungen

- GFGFHDokument12 SeitenGFGFHEduardo Fernandez DazaNoch keine Bewertungen