Beruflich Dokumente

Kultur Dokumente

GDFGSDF

Hochgeladen von

Eduardo Fernandez Daza0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

7 Ansichten13 Seitenggdfsgdf

Originaltitel

gdfgsdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenggdfsgdf

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

7 Ansichten13 SeitenGDFGSDF

Hochgeladen von

Eduardo Fernandez Dazaggdfsgdf

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

IAEA

0 0 000

USI

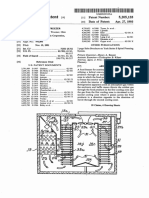

United States Patent 15 01) Patent Number: 5,460,260

Ochs et al. (45) Date of Patent: Oct. 24, 1995

[54] HELICAL CONVEYOR $,031,751 7/1991 Pahisson 198/570,

3003380 12/991 Palmaer barre

{75} Inventors: Gregory L. Ochs, Kirkland; James E. 5uts334 ‘4992 Cawley 1378

eee eee ona Susze1 W982 vin = isan

Issaquah, all of Wash ° 5214934 6/1993 Palframan etal ve 62/381

* 5,350,056 9/1994 Hager ....... 198/778,

(7) Assen: ork tterana Corporation, Ys FOREIGN PATENT DOCUMENTS

268465061993 France ers

80) 940 Germany

[21] Appl. No.: 264,058 2410392 9/1974 Germany ... 198/778

(22) Filed: Jun. 22, 1994 Primary Examiner—James R. Bidwell

[51] Int. Le . B6SG 21/18 Attorney, Agent, or Firm—Finnegan, Henderson, Farabow,

(s2] US. Cl. . 198/778 Garrett & Dunner

[58] Field of Search 198/778, 831,

198/848, 851, 841; 62/381 on Cs

‘sel stacking helical conveyor including dum supported

[56] References Cited for rotation on a vertical axis, an endless belt trained about

1S, PATE : the drum in vericaly successive beical tiers, beginning

EATEN DOCUMENTS) with a bottom tier, and having a width spanning a central

2.003270 9/937 Ginka Toad bearing porion and opposite side eige portons. Tbe

Aoakest 2/976 Aled cal. toqi26 belt includes a plurality of successive conveyor sections

4450053 5/904 Leann eta 19978 jnterconneced for pivotal and translational movement ea,

Po nage peal etal. etl tive to each other. Each of the conveyor sections includes a

sa8716 MINE non IGUTTE po ped Ustanding spp cae a he oppose

Side edge portions ofthe els each ofthe supports hang &

Sas047s 71989 Lop et “aura de ge poons ofthe bet, ech of te suppons having

4858,750 8/1989 Cawley 199/778 top detent formation teat feroetion 1 SEU

4867,301 9/1989 Roinestad etal 19@/852 Under each of said upstanding supports. A supporting assem.

{4875343101989 Jepson = ‘ote"8 x blyisassociaed withthe drum o suppor the boom te and

eseamt 21390 Ohson 08/778 the others of the helical ders ae supported by engagement

iom025 61990 Rotnad dal ist778 ofthe bottom detent formations withthe top deen forma

2arse6 11990 tevin 18778 tons on the spaced upstanding supports in an adjacent

2Si1367 71990 Olson 198778 ndariying ir of the belt. ,

253565 $7990 Singh a tours

“5aL208 17991 Jones tears

25m33 1/991 Stace al 1Bar8 22 Claims, 6 Drawing Sheets

5,460,260

Sheet 1 of 6

Oct. 24, 1995

US. Patent

‘Ob2 W 062 Q >

GZIL. (8 / 061 ‘6

fbb

be

ol

Sk

2 91

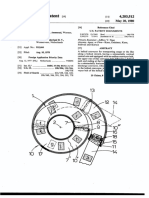

US. Patent Oct, 24, 1995 Sheet 2 of 6 5,460,260

B

2

a a, Se

>

ZS 3, =

3

8 ek B

\ AI 8 ‘As

2 PAV :

=

3 [3

© aL ———

©. 3) \\ 51 YB

NS

8 B

S

va oO

is 3

=

FIG. 2

USS. Patent Oct. 24, 1995 Sheet 3 of 6 5,460,260

FIG. 2A

- <= = 48

49- =

5 b2 Siereed

410

45

FIG. 2C

US. Patent Oct. 24, 1995 Sheet 4 of 6 5,460,260

U.S. Patent Oct, 24, 1995 Sheet 5 of 6 5,460,260

5,460,260

Sheet 6 of 6

Oct. 24, 1995

US. Patent

5,460,260

1

HELICAL CONVEYOR

BACKGROUND OF THE INVENTION

‘The present invention relates to helical conveyors, and

more particularly to self-stacking helical conveyors for use

in continuous processing of materials, such as freezing or

cooking food produets, for example.

Endless conveyors for continuous processing of materials

loaded and unloaded continuously to and from an endless

conveyor belt must have a working length adequate to

permit a required duration of time in a processing environ-

‘ment and, atthe same time, be movable at sufficiently high

‘conveying speeds for acceptable rates of processing produc-

tion, To meet these requirements, and also to reduce the

space requirements of the processing environment, helical

conveyors have been developed in which a working belt

Tength, representing a substantial portion of the overall

conveyor belt length, is carried through a continuous suc-

cession of vertically oriented helical flights or ties. In this

manner, a long working length of the conveyor belt may be

contained in a reasonably dimensioned processing enclo-

sure, such asa freezer, while loading and unloading lengths

‘of the conveyor belt may be located outside ofthe enclosure.

‘The prior art relating to helical conveyors is exemplified

by several U.S. Pat, Nos. including No. 2,093,270—Glinka,

No. 4,450,953—Le Cann et al., No. 4.982,833—Straight et

al., and No. 5,105,934—Cawley.

Giinka represents an early development in helical con-

veyors from the standpoint of recognizing the advantages of

helical conveyors for processing (ie., drying or otherwise

treating) materials by taking advantage of the reduced space

requirements of such conveyors. Le Cann et al. may be

characterized as an carly attempt at a solution to the

mechanical problems associated with driving an endless

flexible belt through a helical path, Also, Le Cann et al.

represents a self-stacking approach to helical conveyors by

using upstanding plate-like supports on opposite side edges

of the conveyor belt to support successive tiers or “spires”

of the endless belt one on the other.

Straight et al. and Cawley are representative of more

recent developments in that these latter prior art references

address mechanical details associated with clevating a

lower-most first fight or tier in an endless belt from a

horizontal run to an inclined helical turn or tier on which

successive vertical ters are supported at easton the inboard,

edge of a helical conveyor. The earlier Straight etal. patent

cites prior U.S. patents which advantageously disclose heli

cal belt systems in which both inner and outer edges of the

endless bel are self supporting. The text ofthe Straight eta.

patent points out that while prior attempts a self-support for

‘both edges of an endless helical belt were advantageous

from the standpoint of minimizing space occupied by the

working length of a helical belt, such belis suffered «

disadvantage in that the belt tier supports presented an

obstruction to circulation of a processing atmosphere, ic.

cooling air, bout products supported on the belt. Cawley

likewise discloses an endless helical belt for processing

products in which only the inboard edge of the belt is

self-supporting and the outboard edge is supported by a

hetical ramp extending throughout the length of the helical

belt length,

Both the Straight et al. and Cawley patents disclose

helical conveyor systems in which support for the bottom

tier of a vertically oriented helical belt is supported by

0

ry

25

0

45

55

2

tuolleys which travel on a circular track aligned under the

{inboard edge of the belt, Also, the disclosures of both patents

employ a transitional track section to support the belt over

a depressed ramp portion of the circular track at which the

trolleys release and engage successive bottom tiers exiting

or entering the helical belt stack.

Although the prior art relating 10 helical conveyors,

therefore, has been developed to some degree, there has

been and is need for improvement,

SUMMARY OF THE INVENTION

‘The advantages and purpose of the invention will be set

forth in part in the description which follows, and in part will

be obvious from the description, or may be leamed by

practice of the invention. The advantages and purpose of the

invention will be realized and attained by means of the

elements and combinations particularly pointed out in the

appended claims,

To attain the advantages and in accordance with the

purpose ofthe invention, as embodied and broadly described

herein, the self stacking helical conveyor of the invention

‘comprises a drum supported for rotation on a vertical axis,

an endless belt trained about the drum in vertically succes-

sive helical tiers, beginning with a bottom tier, and having

‘a width spanning a central load bearing portion and opposite

side edge portions. The belt includes a plurality of suet

sive conveyor sections interconnected for pivotal and trans-

Jational movement relative to each other. Each of the con-

‘veyor sections includes a pair of spaced upstanding supports

secured atthe opposite side edge portions of the belt, each

of the supports having 2 top detent formation. A bottom

detent formation is provided under each of said upstanding

supports. A supporting assembly is associated with the drum

{0 suppor the bottom tier as a helical wrap or convolution.

‘The others of the helical tiers are supported by an adjacent

‘underlying ter of the belt without slippage between tiers due

to engagement of the bottom detent formations with the top

Das könnte Ihnen auch gefallen

- GHFGDokument4 SeitenGHFGEduardo Fernandez DazaNoch keine Bewertungen

- HGFHDDokument13 SeitenHGFHDEduardo Fernandez DazaNoch keine Bewertungen

- NMVBNMDokument10 SeitenNMVBNMEduardo Fernandez DazaNoch keine Bewertungen

- Us 4944162Dokument14 SeitenUs 4944162Eduardo Fernandez DazaNoch keine Bewertungen

- GHDFGHFGHDokument10 SeitenGHDFGHFGHEduardo Fernandez DazaNoch keine Bewertungen

- Us 5031751Dokument9 SeitenUs 5031751Eduardo Fernandez DazaNoch keine Bewertungen

- NMVBNMDokument10 SeitenNMVBNMEduardo Fernandez DazaNoch keine Bewertungen

- GFGHFDokument8 SeitenGFGHFEduardo Fernandez DazaNoch keine Bewertungen

- GHFGHDokument15 SeitenGHFGHEduardo Fernandez DazaNoch keine Bewertungen

- DGDSFGDokument6 SeitenDGDSFGEduardo Fernandez DazaNoch keine Bewertungen

- GFDGDDokument17 SeitenGFDGDEduardo Fernandez DazaNoch keine Bewertungen

- HGFHDDokument8 SeitenHGFHDEduardo Fernandez DazaNoch keine Bewertungen

- HFGHDokument5 SeitenHFGHEduardo Fernandez DazaNoch keine Bewertungen

- FGDGDokument12 SeitenFGDGEduardo Fernandez DazaNoch keine Bewertungen

- JGHJFHDokument9 SeitenJGHJFHEduardo Fernandez DazaNoch keine Bewertungen

- FGDFGDokument3 SeitenFGDFGEduardo Fernandez DazaNoch keine Bewertungen

- GfdgsDokument10 SeitenGfdgsEduardo Fernandez DazaNoch keine Bewertungen

- BCVBCDokument10 SeitenBCVBCEduardo Fernandez DazaNoch keine Bewertungen

- European Patent Application: Vibratory Flash DryerDokument15 SeitenEuropean Patent Application: Vibratory Flash DryerEduardo Fernandez DazaNoch keine Bewertungen

- GfdgsDokument10 SeitenGfdgsEduardo Fernandez DazaNoch keine Bewertungen

- GDHFGHDokument11 SeitenGDHFGHEduardo Fernandez DazaNoch keine Bewertungen

- GHDFGHFDokument11 SeitenGHDFGHFEduardo Fernandez DazaNoch keine Bewertungen

- GDFGDFDokument8 SeitenGDFGDFEduardo Fernandez DazaNoch keine Bewertungen

- FGDFGDokument9 SeitenFGDFGEduardo Fernandez DazaNoch keine Bewertungen

- GFGFHDokument12 SeitenGFGFHEduardo Fernandez DazaNoch keine Bewertungen

- GDFGDFDokument6 SeitenGDFGDFEduardo Fernandez DazaNoch keine Bewertungen

- Us20100146814a1 PDFDokument12 SeitenUs20100146814a1 PDFEduardo Fernandez DazaNoch keine Bewertungen

- Process Description and Optimization of The Flash Dryers at Polokwane SmelterDokument6 SeitenProcess Description and Optimization of The Flash Dryers at Polokwane SmelterEduardo Fernandez DazaNoch keine Bewertungen

- Wo2007134879a1 PDFDokument19 SeitenWo2007134879a1 PDFEduardo Fernandez DazaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)