Beruflich Dokumente

Kultur Dokumente

Pilot-to-close check valve technical details

Hochgeladen von

cesar5984Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pilot-to-close check valve technical details

Hochgeladen von

cesar5984Copyright:

Verfügbare Formate

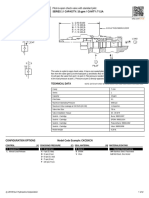

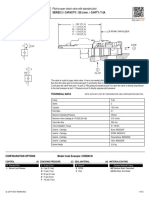

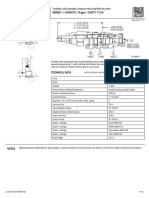

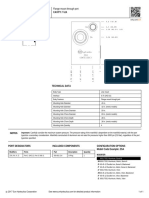

MODEL Pilot-to-close check valve

CODA SERIES 1 / CAPACITY: 20 gpm / CAVITY: T-11A

snhy.com/CODA

This valve is a spring biased closed, pilot-to-close check cartridge that has a 1.8:1 pilot ratio. The valve allows flow

from port 1 to port 2 and blocks reverse flow. Pressure at the pilot port opposes pressure at port 1 at a ratio of

1.8:1. This valve is most often used in regeneration circuits.

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-11A

Series 1

Capacity 20 gpm

Pilot Ratio 1.8:1

Maximum Operating Pressure 5000 psi

Maximum Valve Leakage at 110 SUS (24 cSt) 1 drops/min.

Valve Hex Size 7/8 in.

Valve Installation Torque 30 - 35 lbf ft

Seal kit - Cartridge Buna: 990011007

Seal kit - Cartridge EPDM: 990011014

Seal kit - Cartridge Polyurethane: 990011002

Seal kit - Cartridge Viton: 990011006

Model Weight 0.28 lb.

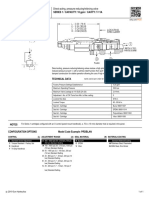

CONFIGURATION OPTIONS Model Code Example: CODAXCN

CONTROL (X) CRACKING PRESSURE (C) SEAL MATERIAL (N) MATERIAL/COATING

X Standard Pilot C 30 psi (2 bar) N Buna-N Standard Material/Coating

A 4 psi (0,3 bar) E EPDM /AP Stainless Steel, Passivated

B 15 psi (1 bar) V Viton /LH Mild Steel, Zinc-Nickel

D 50 psi (3,5 bar)

E 75 psi (5 bar)

F 100 psi (7 bar)

G 150 psi (10,5 bar)

c 2017 Sun Hydraulics Corporation

See www.sunhydraulics.com for detailed product information 1 of 2

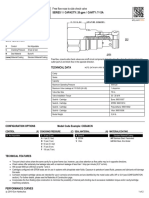

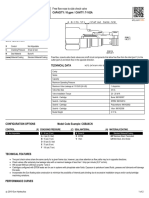

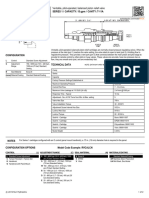

TECHNICAL FEATURES

Minimum clearances between the spool and sleeve and a seal on the pilot piston diameter significantly reduce the potential for silting.

Nominal pilot ratio is 1.8:1. This means that a pressure of 1000 psi (70 bar) at the pilot port will close a valve against a pressure of 1800 psi (125 bar) at port 1. Any

decay or loss of pilot pressure could allow the valve to open, even if it is a momentary decay or loss.

Pressure at the port 2 area directly opposes pilot pressure.

Reverse flow through the valve from port 2 to port 1 is not possible under any condition.

With equal pressures at all ports the valve is closed.

In the begining the CO*A's did not have a positive seal on the pilot pistons and the CO*B's did. Now the CO*A's are positively sealed and the 2 valves are

mechanically identical. CO*A's are more readily available and cost less.

Cartridges configured with EPDM seals are for use in systems with phosphate ester fluids. Exposure to petroleum based fluids, greases and lubricants will damage

the seals.

Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP or /LH (see CONFIGURATION

section). For further details, please see the Materials of Construction page under TECHNICAL RESOURCES.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

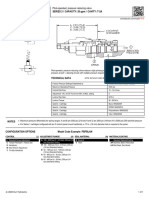

PERFORMANCE CURVES

c 2017 Sun Hydraulics Corporation

See www.sunhydraulics.com for detailed product information 2 of 2

Das könnte Ihnen auch gefallen

- Pilot-to-close check valve technical detailsDokument2 SeitenPilot-to-close check valve technical detailsErasmo LimaNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AVignesh PandiyanNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AAnurag JainNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Sealed Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADokument2 SeitenModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNoch keine Bewertungen

- Pilot-to-open check valve technical detailsDokument2 SeitenPilot-to-open check valve technical detailsVEERAMANINoch keine Bewertungen

- Model 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotDokument2 SeitenModel 5:1 Pilot Ratio, Pilot-To-Open Check Valve With Standard PilotVignesh PandiyanNoch keine Bewertungen

- CKEB_full_en_metric_letterDokument2 SeitenCKEB_full_en_metric_letterRafalNoch keine Bewertungen

- CVCV Full en Metric A4Dokument2 SeitenCVCV Full en Metric A4Ηρακλης ΤσαπραζηςNoch keine Bewertungen

- Sun Cartridge CXDA-XCNDokument2 SeitenSun Cartridge CXDA-XCNJustinNoch keine Bewertungen

- Free-flow nose-to-side check valve technical detailsDokument2 SeitenFree-flow nose-to-side check valve technical detailssnsnagarajanNoch keine Bewertungen

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADokument2 SeitenModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNoch keine Bewertungen

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 3 / Capacity: 60 GPM / Cavity: T-17ADokument1 SeiteModel Pilot-To-Open Check Valve With Standard Pilot: Series 3 / Capacity: 60 GPM / Cavity: T-17Acorsini999Noch keine Bewertungen

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDokument2 SeitenLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNoch keine Bewertungen

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Dokument2 SeitenModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNoch keine Bewertungen

- PVDB Full en Us LetterDokument2 SeitenPVDB Full en Us LetterIsrael RuizNoch keine Bewertungen

- CSAD Full en Us LetterDokument2 SeitenCSAD Full en Us LetterService - Anda Hydraulics Asia Pte LtdNoch keine Bewertungen

- Sun Hydraulics FDBA-LANDokument2 SeitenSun Hydraulics FDBA-LANJustinNoch keine Bewertungen

- Model Vented Pilot-To-Open Check Valve: Series 3 / Capacity: 60 GPM / Cavity: T-23ADokument2 SeitenModel Vented Pilot-To-Open Check Valve: Series 3 / Capacity: 60 GPM / Cavity: T-23ANguyễn Thị Ngọc HòaNoch keine Bewertungen

- PRDBOEN Full en Us LetterDokument3 SeitenPRDBOEN Full en Us LetterPartagon PowNoch keine Bewertungen

- RGFA Full en Metric LetterDokument4 SeitenRGFA Full en Metric LetteressamNoch keine Bewertungen

- Direct-Acting Solenoid Poppet Valve GuideDokument3 SeitenDirect-Acting Solenoid Poppet Valve GuideAnurag JainNoch keine Bewertungen

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDokument2 SeitenModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNoch keine Bewertungen

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoDokument2 SeitenModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaNoch keine Bewertungen

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850Noch keine Bewertungen

- CXDA-80 L/min check valveDokument2 SeitenCXDA-80 L/min check valveSara SaritaNoch keine Bewertungen

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Dokument2 SeitenModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNoch keine Bewertungen

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDokument2 SeitenModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNoch keine Bewertungen

- Normally closed balanced poppet valveDokument2 SeitenNormally closed balanced poppet valvejuampacervantesNoch keine Bewertungen

- Model Ventable, Pilot-Operated, Balanced Piston Relief ValveDokument2 SeitenModel Ventable, Pilot-Operated, Balanced Piston Relief ValveGamal El Deen KamalNoch keine Bewertungen

- FDBA en Metric LetterDokument1 SeiteFDBA en Metric LetterY.EbadiNoch keine Bewertungen

- 10:1 pilot ratio counterbalance valveDokument2 Seiten10:1 pilot ratio counterbalance valveVignesh PandiyanNoch keine Bewertungen

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainNoch keine Bewertungen

- Dkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpenDokument2 SeitenDkdr8: Model Normally Closed, Balanced Poppet, Logic Element With Integral T-8A Control Cavity - Vent-To-OpensnsnagarajanNoch keine Bewertungen

- CBCALHN-EAC Full en Us LetterDokument5 SeitenCBCALHN-EAC Full en Us LetterVentas Control HidráulicoNoch keine Bewertungen

- DRBCLBN Full Es Us A4Dokument2 SeitenDRBCLBN Full Es Us A4Erasmo LimaNoch keine Bewertungen

- RPGC Full en Us A4Dokument2 SeitenRPGC Full en Us A4zapchasty29Noch keine Bewertungen

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNoch keine Bewertungen

- Sun Hydraulics NFCC-KCNDokument2 SeitenSun Hydraulics NFCC-KCNJustinNoch keine Bewertungen

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanNoch keine Bewertungen

- CVGV Full en Metric LetterDokument2 SeitenCVGV Full en Metric LetterRonaldNoch keine Bewertungen

- FREA Full en Us A4Dokument2 SeitenFREA Full en Us A4Rodrigo LisboaNoch keine Bewertungen

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADokument1 SeiteModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNoch keine Bewertungen

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaNoch keine Bewertungen

- Sun Hydraulics-Cbca Lan EccDokument5 SeitenSun Hydraulics-Cbca Lan EcchendntdNoch keine Bewertungen

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADokument2 SeitenModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNoch keine Bewertungen

- RDFALWN-CAM S Full en Us LetterDokument5 SeitenRDFALWN-CAM S Full en Us LetterJustinNoch keine Bewertungen

- FDBALAN en Us LetterDokument1 SeiteFDBALAN en Us LetterDAGNoch keine Bewertungen

- Pump Unload Pilot Valve SUN QPABDokument2 SeitenPump Unload Pilot Valve SUN QPABankesh_ghoghariNoch keine Bewertungen

- RVCALCN Full en Us A4Dokument2 SeitenRVCALCN Full en Us A4Felipe DiazNoch keine Bewertungen

- CXHAXAN - Full - en - Metric - Letter BorbetDokument2 SeitenCXHAXAN - Full - en - Metric - Letter BorbetRonaldNoch keine Bewertungen

- PBFB en Us A4Dokument1 SeitePBFB en Us A4operacion hydratekNoch keine Bewertungen

- Normally open modulating LPFC series 2 elementDokument2 SeitenNormally open modulating LPFC series 2 elementDhrubajyoti BoraNoch keine Bewertungen

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityDokument2 SeitenModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareNoch keine Bewertungen

- Control counterbalance valve performanceDokument2 SeitenControl counterbalance valve performanceதமிழன் இராமசாமிNoch keine Bewertungen

- Model Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32ADokument2 SeitenModel Closed Center, Flow Divider-Combiner Valve: Series 2 / Capacity: 3 - 15 GPM / Cavity: T-32AAnurag JainNoch keine Bewertungen

- CBCY_full_en_us_letter (1)Dokument2 SeitenCBCY_full_en_us_letter (1)Ventas Control HidráulicoNoch keine Bewertungen

- Solenoid-operated pressure reducing/relieving assemblyDokument7 SeitenSolenoid-operated pressure reducing/relieving assemblyMay Perez RNoch keine Bewertungen

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDokument2 SeitenModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidNoch keine Bewertungen

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileVon EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNoch keine Bewertungen

- Datasheet SMT Ha0019 enDokument23 SeitenDatasheet SMT Ha0019 enДима ПолищукNoch keine Bewertungen

- Oxbo 2460 18Dokument6 SeitenOxbo 2460 18cesar5984Noch keine Bewertungen

- Pressure Relief Valve, Direct-Operated Type DBD: RE 25402, Edition: 2020-03, Bosch Rexroth AGDokument24 SeitenPressure Relief Valve, Direct-Operated Type DBD: RE 25402, Edition: 2020-03, Bosch Rexroth AGcesar5984Noch keine Bewertungen

- Pressure SwitchDokument60 SeitenPressure SwitchMohammed RayanNoch keine Bewertungen

- Pressure SwitchDokument60 SeitenPressure SwitchMohammed RayanNoch keine Bewertungen

- Cartridge Pressure Relief Valves Sp-Cart: Screw-In MountingDokument6 SeitenCartridge Pressure Relief Valves Sp-Cart: Screw-In Mountingcesar5984Noch keine Bewertungen

- Cartridge Check Valves DB, DR: Screw-In Mounting - From G1/4" To G1/2"Dokument2 SeitenCartridge Check Valves DB, DR: Screw-In Mounting - From G1/4" To G1/2"cesar5984Noch keine Bewertungen

- Pressure Control Valves Agir, Agis, Agiu: Two Stage, Subplate Mounting, ISO 5781 Sizes 10, 20 and 32Dokument4 SeitenPressure Control Valves Agir, Agis, Agiu: Two Stage, Subplate Mounting, ISO 5781 Sizes 10, 20 and 32cesar5984Noch keine Bewertungen

- Pilot Operated Check Valves Adrl, Agrl, AgrleDokument4 SeitenPilot Operated Check Valves Adrl, Agrl, Agrlecesar5984Noch keine Bewertungen

- Pressure relief valves type AGAMDokument5 SeitenPressure relief valves type AGAMcesar5984Noch keine Bewertungen

- Pressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded PortsDokument3 SeitenPressure Relief Valves ARE: Direct Operated, in Line Mounting - G 1/4" and G 1/2" Threaded Portscesar5984Noch keine Bewertungen

- Flange mount through port hydraulic manifoldDokument1 SeiteFlange mount through port hydraulic manifoldcesar5984Noch keine Bewertungen

- DHE Dhe-E015Dokument4 SeitenDHE Dhe-E015cesar5984Noch keine Bewertungen

- Untitled Build-Grand Vitara-8N3WJO157215062023220458Dokument4 SeitenUntitled Build-Grand Vitara-8N3WJO157215062023220458mc wanadongriNoch keine Bewertungen

- Bhutan Yoga RetreatDokument4 SeitenBhutan Yoga RetreatSadhwi SondhiNoch keine Bewertungen

- Bagaimana LAN BerfungsiDokument5 SeitenBagaimana LAN BerfungsiZarina Abdul RahimNoch keine Bewertungen

- Piña Colada CheesecakeDokument2 SeitenPiña Colada CheesecakejhNoch keine Bewertungen

- 42MF130A-37 Mp1.1u - Aa - 312278515691 - enDokument89 Seiten42MF130A-37 Mp1.1u - Aa - 312278515691 - enNorman TranNoch keine Bewertungen

- Philippine Traditional Costumes To High Fashion Couture Feature ArticleDokument3 SeitenPhilippine Traditional Costumes To High Fashion Couture Feature ArticleLee-Yoo Improgo Tan IIINoch keine Bewertungen

- IMSLP319806-PMLP517398-Twenty-four Preludes and Fugues USDokument84 SeitenIMSLP319806-PMLP517398-Twenty-four Preludes and Fugues USTuput AmadreNoch keine Bewertungen

- Palawan Sample BrochureDokument2 SeitenPalawan Sample BrochureJosef Jiao100% (1)

- Wenger UltraStor Cabinets SpecificationsDokument4 SeitenWenger UltraStor Cabinets SpecificationskittlesonaNoch keine Bewertungen

- GameAnalytics Benchmarks Report 2018Dokument27 SeitenGameAnalytics Benchmarks Report 2018Стас БабаевNoch keine Bewertungen

- Female Protagonists and Gender Roles in Nosferatu and DraculaDokument6 SeitenFemale Protagonists and Gender Roles in Nosferatu and DraculaKTNoch keine Bewertungen

- Carlton Mellick III-Zombies and Shit - Deadite Press (2010) PDFDokument242 SeitenCarlton Mellick III-Zombies and Shit - Deadite Press (2010) PDFSzonja Kadar100% (2)

- 2015 Music Teaching and Learning Syllabus (Primary and Lower Secondary)Dokument24 Seiten2015 Music Teaching and Learning Syllabus (Primary and Lower Secondary)Peiwen SohNoch keine Bewertungen

- WORKSHEET 3 - Present Perfect TenseDokument8 SeitenWORKSHEET 3 - Present Perfect TenseAlanPoloMartinezHernandezNoch keine Bewertungen

- Age of Fantasy Regiments Full Rulebook PDFDokument33 SeitenAge of Fantasy Regiments Full Rulebook PDFjure dolenc100% (1)

- Plasma Tweeter - Final PaperDokument24 SeitenPlasma Tweeter - Final PaperZihan Zang100% (1)

- Modern Drama: Course Code:9070Dokument122 SeitenModern Drama: Course Code:9070Maryam BatoolNoch keine Bewertungen

- CRICKET 2007 CheatDokument17 SeitenCRICKET 2007 Cheatdeivendran_dmeNoch keine Bewertungen

- CRUSH 1: Lauren's Beach Crush - ExcerptDokument29 SeitenCRUSH 1: Lauren's Beach Crush - ExcerptSimon and SchusterNoch keine Bewertungen

- BPM023062 NetworkManageSvcsDokument148 SeitenBPM023062 NetworkManageSvcsDeny SuhartanaNoch keine Bewertungen

- Nouns - Answer KeyDokument2 SeitenNouns - Answer KeyHuyền TrangNoch keine Bewertungen

- New Titles List 2010, Issue 4Dokument76 SeitenNew Titles List 2010, Issue 4Worldwide Books CorporationNoch keine Bewertungen

- Bella CiaoDokument5 SeitenBella CiaoAdelina MNoch keine Bewertungen

- Lesson 1 Subject - Object PronounsDokument3 SeitenLesson 1 Subject - Object PronounsOng Ern HweeNoch keine Bewertungen

- OTP2 Level-1 Extra-Practice-Wkshts U4 PDFDokument3 SeitenOTP2 Level-1 Extra-Practice-Wkshts U4 PDFB.AcostaNoch keine Bewertungen

- Intro To Humanities ArtsDokument10 SeitenIntro To Humanities ArtschurvaloooNoch keine Bewertungen

- Let's Learn About Music NotesDokument15 SeitenLet's Learn About Music Notessimianchan0% (1)

- Holmes - Clark - Apr 3 - 23Dokument87 SeitenHolmes - Clark - Apr 3 - 23George Louis CostanzaNoch keine Bewertungen

- Reading and Writing-11-16Dokument6 SeitenReading and Writing-11-16Laura MoraNoch keine Bewertungen

- Bai Tap Va Dap An Cau Dieu KienDokument3 SeitenBai Tap Va Dap An Cau Dieu Kienanhlabugo2Noch keine Bewertungen