Beruflich Dokumente

Kultur Dokumente

Deep Sea Electronics PLC: Model 606 Comprehensive Amf Module

Hochgeladen von

mohammedalathwaryOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Deep Sea Electronics PLC: Model 606 Comprehensive Amf Module

Hochgeladen von

mohammedalathwaryCopyright:

Verfügbare Formate

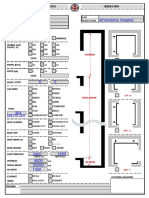

Deep Sea Electronics Plc

600 Series CONTROL MODULES

MODEL 606 COMPREHENSIVE AMF MODULE

DESCRIPTION

The Model 606 is an Automatic Mains Failure and Engine

FEATURES

Control Module, which has been designed to allow the

OEM to meet most of the industry’s complex

specifications.

The module is used to automatically start the generator in

the event of a mains failure, and transfer the load when

the engines operating criteria are met, then stop the

engine on mains restoration, indicating the operational

status and fault conditions, automatically shutting down

the engine and indicating the engine failure by means of

an LCD display and flashing LED’s on the front panel.

Selected operational sequences, timers and alarms can

be altered by the customer (with suitable security

passwords entered). Alterations to the system are made

by using the RS232 interface and a PC or in a more

limited way via the front panel pushbuttons.

This interface also provides real time diagnostic and

(optional) telemetry facilities to monitor the operation of

the system either locally or remotely via a modem. Full

remote PC controlled operation of the module is also

featured.

Operation of the module is via pushbutton controls (with

security locking facility) mounted on the front panel with

STOP/RESET, AUTO, TEST, ALARM MUTE, MANUAL and

START pushbuttons. The pushbuttons feature ‘selected’

þ Advanced Micro-processor based Design

LED indications. Further pushbuttons provide LAMP þ Automatic Engine Starting and Stopping

TEST, LCD PAGE SELECT and DISPLAY SCROLL þ Automatic Shutdown on Fault Condition

functions. Alterations to the module configuration can be

made to limited degree using the front panel push- þ Back-lit LCD Display

buttons in the absence of a PC in the field. þ PC Configurable via MS-Windows based software

The 606 module provides metering and alarm facilities

via the LCD display with the following instrumentation

þ Provides Engine Instrumentation Gauges

displays, access via the LCD PAGE SELECT push- þ Provides Generator Output Instrumentation

button:- þ Provides Alarm and Status Information

Generator Volts L1-N, L2-N, L3-N

Generator Volts L1-L2, L2-L3, L3-L1 þ Simple Push-button Controlled Operation

Generator Amps L1,L2,L3 þ Remote telemetry and control via MS-Windows

Generator Frequency Hz

Engine Speed RPM

þ Modem Communications

Engine Oil Pressure þ Configurable Digital Inputs

Engine Oil Temperature þ Configurable Relay Outputs

Engine Temperature

Plant battery Volts þ Configurable Timer Settings

Fuel Level þ Configurable Alarm Trip Points

Engine Hours Run

Mains Volts L1-N, L2-N, L3-N

þ Full Event logging and data capture facilities

Mains Volts L1-L2, L2-L3, L3-L1 þ Audible and LED Alarm indication

Mains Frequency Hz þ Pre-Alarm facility on monitored values

Generator kVA L1,L2,L3, Total

Real Time Clock and Current Scheduled Exercise þ Built in configurable Exercise Scheduler

settings þ Mimic Diagram Status Display Panel

Description continues overleaf...

11/3/00 606sales_leaflet.doc Issue 2 MR

DESCRIPTION - CONTINUED

SPECIFICATION

The metering displays are supplemented further by LCD DC Supply:

display pages covering operating status and alarms. The 8 to 35 V Continuous.

selected page is displayed :- Cranking Dropouts:

Status Page Able to survive 0 V for 50 mS, providing supply was at least

Instruments Page (INS) 10 V before dropout and supply recovers to 5V. This is

Alarm Page achieved without the need for internal batteries.

Event Log Page Max. Operating Current:

LED indication is provided for Telemetry Active, Remote 800 mA at 12 V. 390 mA at 24 V.

Start, System Lock, Mains out of limits, Safety on, Fault Typical Standby Current:

warning, Electrical trip, Fault shutdown, Fail to start, Low 500 mA at 12 V. 260 mA at 24 V.

oil pressure, High engine temperature, Under/Overspeed, Typical Running Current:

Generator Under/Over volts and Emergency stop alarm. 580 mA at 12 V. 300 mA at 24 V.

Microprocessor control allows for enhanced operation, Typical Sleep Current:

the module features a comprehensive list of timers and <1mA with no Datalog hardware fitted

pre-configured sequences. This allows complex 12mA with Datalog hardware fitted

specifications to be easily met. Configurable expansion Alternator Input Range:

facilities are also provided . 15 - 300 V ac RMS (Phase to Neutral)

The module accepts the following digital inputs; Alternator Input Frequency:

16 Fully configurable warning or shutdown inputs 50 - 60 Hz at rated engine speed.

4 Analogue inputs re-configurable to read digital switches Magnetic Pick-up Voltage Input Range:

Emergency Stop Input - A N/C DC positive input 0.5 V to 70 V Peak to Peak

With the exception of the Emergency Stop Input, these are Magnetic Input Frequency:62Hz to 10,000 Hz at rated

configurable to be either N/C or N/O contacts connected engine speed.

the -Ve DC. The fully configurable auxiliary inputs are Start Relay Output:

provided to give protection expansion or control extra 16 Amp DC at supply voltage.

functions. These can be selected to be warning or Fuel Relay Output:

shutdown inputs either immediate or held off during start 16 Amp DC at supply voltage.

up. Auxiliary Relay Outputs:

Multiple alarm channels are provided to monitor the Relays 5-8: 8 Amp DC at supply voltage

system including the following:- Relays 1-4,9&10: 5 Amp DC at supply voltage

Under/Over Generator Volts Dimensions:

Over-current 298 X 216 X 105

Under/Over Generator Frequency Charge Fail / Excitation Range:

Under/Overspeed 0 V to 35 V

Charge Fail Operating Temperature Range:

Emergency Stop -15 to +55°C

Low oil pressure

High engine temperature The 600 series modules have been designed for front

High oil temperature panel mounting. The module is fitted into the cut-out with

High/Low Fuel with transfer pump control the fixing clips removed. These are then fitted from the

Fail to Start rear. Connection is via locking plug and socket connectors.

Low/High DC Battery Volts

Fail to stop

Reverse Power

Earth Fault

Mains out of limits

Loss of speed sensing and programmable inputs as

selected.

First up alarm is indicated by an LCD Message, LED

indication and Audible Alarm. Pre-alarms of the above

shutdowns are also provided to give advance warning of

faults.

Relay outputs are provided for Fuel Solenoid Output, Start

Output, Load Transfer Control Outputs and eight

configurable outputs. The configurable relay functions

can be selected from a range of different functions,

conditions or alarms. Six of the relays are N/O contact

type, two are C/O contact type.

TELEMETRY BUILT-IN FUNCTIONS

The 606 module provides the user with the option of full

þ 1 or 3 Phase Mains Under/Over Volts Detection

telemetry facilities via the Link 600 Software (optional). þ 1 or 3 Phase Mains Under/Over Frequency Detection

The module is accessed via it’s RS232 port (No.2), this is þ Alternator Under/Over Volts Warning/Shutdown

either connected to the PC directly or via a suitable

modem. þ Alternator Under/Over Freq. Warning/Shutdown

þ Under/Over Speed Warning/Shutdown

The optional PC software is MS-windows based and

allows the operator to control the module from a remote

þ Low Oil Pressure Warning/Shutdown

location, operating the push-buttons and viewing the LCD þ High Coolant Temp Warning/Shutdown

and LED’s in the same manner as a local operator. þ High Oil Temp Warning/Shutdown

The remote operator can also view the instrumentation, þ Low Battery Volts Warning/Pre-warning

Alarm and Data log details, and the relay and input status. þ High Battery Volts Warning/Pre-warning

All access is password controlled so un-authorised

operators cannot log onto the system.

þ Over-current Warning/Electrical Trip/Shutdown

þ Reverse Power Warning/Electrical Trip/Shutdown

The PC software also contains the off-line configuration þ Earth Fault Warning/Shutdown

editing software, this allow the user to change

configuration parameters affecting the operation of the þ Low Fuel Level Warning/Transfer Pump On

module with-out even leaving the office (via a suitable þ High Fuel Level Warning/Transfer Pump Off

RS232/Modem link).

þ Start Delay and Mains Return Timer

Additionally in the event of the module detecting an alarm þ Pre-heat/Oil Pre-lube and Safety on timers

condition, it will initiate a modem dial out to the host PC to þ Adjustable crank cycle/attempts

inform the remote operator of the problem; giving

identification of the module followed by the alarm event þ Warm up and cooling Timers

and the time and date of occurrence. þ Contactor transfer delay and pulse timers

þ In-built logic for Smoke Limit and Governor Gain

þ External remote start input (On load/Off load)

DATA LOG & EVENT CAPTURE þ Manual Restore to mains function

þ Auto start inhibit function

While the standard module features event capture

facilities, accessing the module via the Telemetry link can þ System lock security function

provide the operator with a detailed data log. This allows þ Alternator Volts/Freq. Trip Inhibit function

the operator to closely monitor the performance of the

generator and create trend logs etc.

þ Immediate Mains Drop-out Function

þ Alternator Load inhibit Function

Event Log:- þ Analogue Sender Fault Alarm

þ Louvre and Air-flap control output

19

þ Circuit Breaker or Contactor control capability

Apr9814:34:14

þ Magnetic Pick-up or Alternator speed monitoring

þ PC configuration (On-line or Off-Line)

Data-Log:- þ Event and Data Logging

þ Full Remote Control and Telemetry via RS232

244

242 Mains Voltages þ Engine Instrumentation

240 þ Alternator Output Instrumentation

238 þ Mains Supply Instrumentation

236

234

50

:00

:30

:10

:40

:00

:20

0:

:30

:30

:30

:30

:31

:30

:3

14

14

14

14

14

14

14

11/3/00 606sales_leaflet.doc Issue 2 MR

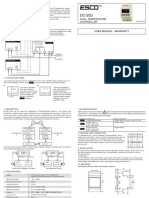

CASE DIMENSIONS

A B

C

F

216.0mm

194mm

E

1 2

EARTH

105.0mm

298.0mm

9.0mm Panel Cut-out: 276mmx194mm

TYPICAL CONNECTIONS

P1

S1

P1

S1

P1

S1

P1

S1

F F F F F F

F F

Deep Sea Electronics Plc

Mountside Park, Queen Margarets Road,

Scarborough, YO11 2RH. ENGLAND

Tel:- +44 (0)1723 377566 Fax:- +44 (0)1723 354453 E-Mail:- sales@deepseaplc.com

Das könnte Ihnen auch gefallen

- Blow MoldingDokument46 SeitenBlow MoldingShashank ChauhanNoch keine Bewertungen

- AGC-3 Parameter List 4189340705 UK PDFDokument168 SeitenAGC-3 Parameter List 4189340705 UK PDFHugo DNoch keine Bewertungen

- WEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual EnglishDokument78 SeitenWEG Automatic Voltage Regulator Grt7 Th4 r2 10001284109 Manual Englisht8823pcNoch keine Bewertungen

- Sky301-V3 User ManualDokument16 SeitenSky301-V3 User Manualمحمدحماد100% (1)

- Elevator Control ManualDokument29 SeitenElevator Control ManualJouny Wael100% (4)

- Elevator Control ManualDokument29 SeitenElevator Control ManualJouny Wael100% (4)

- 7000 Series ATS Operator's ManualDokument11 Seiten7000 Series ATS Operator's ManualJimNoch keine Bewertungen

- Optimize Refinery Product BlendingDokument15 SeitenOptimize Refinery Product BlendingRohit Kalyan50% (2)

- 32.37.20.10 Instrument Signal LinesDokument36 Seiten32.37.20.10 Instrument Signal LinesJohn Rangel50% (2)

- EWD-RL-J2 Elevator Device ManualDokument12 SeitenEWD-RL-J2 Elevator Device Manualmohammedalathwary100% (4)

- Easytronic Micro II (2012 Revision15) ControllerDokument11 SeitenEasytronic Micro II (2012 Revision15) Controllermohammedalathwary56% (9)

- Precision Escalator Parts CatalogDokument10 SeitenPrecision Escalator Parts CatalogmohammedalathwaryNoch keine Bewertungen

- EasyGen 2000 Configuration Manual 37427 PDFDokument339 SeitenEasyGen 2000 Configuration Manual 37427 PDFmalamal1Noch keine Bewertungen

- 350-28700-to-SX440-to - AS440 AVR Conversion InstructionsDokument6 Seiten350-28700-to-SX440-to - AS440 AVR Conversion InstructionsRamon Pujol PerramonNoch keine Bewertungen

- Types of BricksDokument5 SeitenTypes of BricksMian M KhurramNoch keine Bewertungen

- SJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9Dokument16 SeitenSJT-WVF-V Group Control User Manual (Version 2018) : Shenyang Bluelight 2018.7.9mohammedalathwary100% (2)

- 909 User Manual Rev H PDFDokument354 Seiten909 User Manual Rev H PDFRemiel Zapata GNoch keine Bewertungen

- Inteligen-Nt Sevice Manual1Dokument21 SeitenInteligen-Nt Sevice Manual1Duy Kha100% (1)

- GBA 26800 H IV OVF 20 Service - ToolDokument31 SeitenGBA 26800 H IV OVF 20 Service - ToolIvcha80% (15)

- Online System, Functions, and PlatformsDokument28 SeitenOnline System, Functions, and PlatformsJules Gajes80% (5)

- 15A Universal 1/2 Wave Self Excited AVRDokument2 Seiten15A Universal 1/2 Wave Self Excited AVRHerbertNoch keine Bewertungen

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDokument7 SeitenTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaNoch keine Bewertungen

- GU3303 GU3304Genset Controller Operation ManualDokument44 SeitenGU3303 GU3304Genset Controller Operation ManualArc Hie100% (4)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Dokument7 Seiten标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- 标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相Dokument7 Seiten标准版供电装置hcyd22 Xx Ag2说明书4.70 Tdgk Vr1.1板子英文 单相mohammedalathwary100% (1)

- LV System SiemenDokument1.468 SeitenLV System SiemenputrasejahtraNoch keine Bewertungen

- 24/7 Power Protection PanelDokument5 Seiten24/7 Power Protection PanelErwan Shidiq FathoniNoch keine Bewertungen

- Powercommand 2.3 Control System: Specification SheetDokument7 SeitenPowercommand 2.3 Control System: Specification SheetJoseLunaNoch keine Bewertungen

- EG-3000 Governor Controller Operation ManualDokument7 SeitenEG-3000 Governor Controller Operation ManualrepelindNoch keine Bewertungen

- st3td 210 MW PDFDokument203 Seitenst3td 210 MW PDFDevesh BadsiwalNoch keine Bewertungen

- Dse 8610Dokument119 SeitenDse 8610Akhmad FatoniNoch keine Bewertungen

- WEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRDokument50 SeitenWEG Regulador de Tensao Grt7 Th4 10040217 Manual Portugues BRJuan I. Meza Lozano100% (1)

- Guide to Automatic Mains Failure Unit User ManualDokument69 SeitenGuide to Automatic Mains Failure Unit User ManualRahmat Nur IlhamNoch keine Bewertungen

- Cummins pcc1301 Manual DDokument6 SeitenCummins pcc1301 Manual DAnonymous vqsuRy100% (1)

- Compound ManualDokument28 SeitenCompound ManualoveladoNoch keine Bewertungen

- CD Deluxe New PDFDokument109 SeitenCD Deluxe New PDFSANTOSH KUMAR100% (3)

- PC3.3 Parallel-ApplicationDokument39 SeitenPC3.3 Parallel-ApplicationVivek AwasthiNoch keine Bewertungen

- GDKDokument30 SeitenGDKRobert Aguilar100% (4)

- InteliLite AMF20-25Dokument2 SeitenInteliLite AMF20-25albertooliveira100% (2)

- PV On Buildings and Fire Safety: Recommendation For DRRG Solar PV SystemsDokument17 SeitenPV On Buildings and Fire Safety: Recommendation For DRRG Solar PV SystemsAbhinav SinhaNoch keine Bewertungen

- Behaviour and Strength of Fully Encased Composite Columns PDFDokument198 SeitenBehaviour and Strength of Fully Encased Composite Columns PDFdxzaberNoch keine Bewertungen

- Datasheet Sdmo Nexys2 Control PanelDokument4 SeitenDatasheet Sdmo Nexys2 Control PanelRomulo GomesNoch keine Bewertungen

- SG2D Governador de VelocidadeDokument4 SeitenSG2D Governador de VelocidadealbertooliveiraNoch keine Bewertungen

- EGCP-2 Application ManualDokument188 SeitenEGCP-2 Application Manualharis khanNoch keine Bewertungen

- Triple 10 Sun Oil Gasoline Station Company ProfileDokument5 SeitenTriple 10 Sun Oil Gasoline Station Company ProfileWendy May Villapa67% (3)

- Selection, Installation and Maintenance of Electrical Apparatus for Hazardous LocationsDokument29 SeitenSelection, Installation and Maintenance of Electrical Apparatus for Hazardous Locationskieran43100% (1)

- 1 .Power Command PCC1300Dokument16 Seiten1 .Power Command PCC1300Waqar AhmedNoch keine Bewertungen

- Exploring Cusco Peter Frost PDFDokument2 SeitenExploring Cusco Peter Frost PDFLiz0% (2)

- Power Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Dokument2 SeitenPower Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Javier MongeNoch keine Bewertungen

- DIAGRAMA COMPLETO USCA e QTA Maq SdmoDokument11 SeitenDIAGRAMA COMPLETO USCA e QTA Maq SdmoAllanMouraNoch keine Bewertungen

- AGC 200 Manual de Instalação PDFDokument67 SeitenAGC 200 Manual de Instalação PDFMarco Olivetto100% (1)

- Zenith ZTG SeriesDokument8 SeitenZenith ZTG SeriesFlo MircaNoch keine Bewertungen

- DG SPEC C110D5 With 6BT5.9G2Dokument4 SeitenDG SPEC C110D5 With 6BT5.9G2Anonymous tXzjQAJttH100% (1)

- A400 PDFDokument25 SeitenA400 PDFArturo FuentesNoch keine Bewertungen

- Gu301 ADokument3 SeitenGu301 AJosé Da Silva MataNoch keine Bewertungen

- AGC-4 Parameter List 4189340688 UKDokument210 SeitenAGC-4 Parameter List 4189340688 UKAnonymous 7Gtw5rwZbNoch keine Bewertungen

- Dse 704-4120Dokument3 SeitenDse 704-4120Jose Daniel Garcia RodriguezNoch keine Bewertungen

- DC-20D Dual Temperature Controller Wiring DiagramDokument4 SeitenDC-20D Dual Temperature Controller Wiring DiagramWaqar AhmedNoch keine Bewertungen

- DER1 User Manual PDFDokument40 SeitenDER1 User Manual PDFCris_eu09Noch keine Bewertungen

- Eaam0199 enDokument36 SeitenEaam0199 enRaymund SanoneNoch keine Bewertungen

- DPG-2201-00X Digital Controllers: User ManualDokument50 SeitenDPG-2201-00X Digital Controllers: User ManualPatrick CreighNoch keine Bewertungen

- Technical Manual: ATS115-ATS115PlusDokument113 SeitenTechnical Manual: ATS115-ATS115PlusMarcos BrandãoNoch keine Bewertungen

- TWD1643GE: Volvo Penta Genset EngineDokument2 SeitenTWD1643GE: Volvo Penta Genset Enginemohsen_cumminsNoch keine Bewertungen

- Amf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control SystemsDokument20 SeitenAmf 4.0 Automatic Mains Failure Unit User Manual V1.3: EN-KO Electronic Control Systemsمحمد فرحات100% (1)

- Setup AlarmsDokument8 SeitenSetup AlarmsbacNoch keine Bewertungen

- DKG-114 User Manual GuideDokument9 SeitenDKG-114 User Manual Guideangel aguilarNoch keine Bewertungen

- SG128V07EDokument2 SeitenSG128V07EAngel Danubio Medina PerezNoch keine Bewertungen

- Gu601a En0507 PDFDokument30 SeitenGu601a En0507 PDFChhoan Nhun100% (2)

- Der2 Digital Regulator: Technical GuideDokument36 SeitenDer2 Digital Regulator: Technical GuideNatan Hernandez100% (1)

- GOB EG1065x Manual en PDFDokument8 SeitenGOB EG1065x Manual en PDFRonaldCarrasquelNoch keine Bewertungen

- ME-AGS-N wiring diagram for Hardy Diesel HDYW Series generatorDokument1 SeiteME-AGS-N wiring diagram for Hardy Diesel HDYW Series generatorAyub WaskitoNoch keine Bewertungen

- QC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTODokument2 SeitenQC4003 ESF Zaragoza Application Datasheet EN 2954567001 LTOmoises100% (1)

- Software RgamDokument24 SeitenSoftware RgammasanmartinfNoch keine Bewertungen

- Gac Esd5500Dokument7 SeitenGac Esd5500christramNoch keine Bewertungen

- Catalogue Cummins 6LTAA8.9 G3Dokument5 SeitenCatalogue Cummins 6LTAA8.9 G3José Diaz100% (2)

- EG2000 Manual PDFDokument620 SeitenEG2000 Manual PDFHendra WibowoNoch keine Bewertungen

- FY Operation Manual V200602Dokument48 SeitenFY Operation Manual V200602Vicente ChinchillaNoch keine Bewertungen

- DSE560datasheetDokument4 SeitenDSE560datasheetHalit Yalçınkaya100% (1)

- Deep Sea 5110 Automatic Engine Control ModuleDokument2 SeitenDeep Sea 5110 Automatic Engine Control ModuleÁlvaro 2.0Noch keine Bewertungen

- Generator Controller DSE520 Instruction ManualDokument3 SeitenGenerator Controller DSE520 Instruction Manualabuzer1981Noch keine Bewertungen

- DKG 705Dokument4 SeitenDKG 705taleb 6269Noch keine Bewertungen

- DATAKOM DKG109 DatasheetDokument2 SeitenDATAKOM DKG109 DatasheetWilliam FlorezNoch keine Bewertungen

- 5110UL EngDokument2 Seiten5110UL EngAhmed Elsayed Abdel GhanyNoch keine Bewertungen

- Dkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionDokument2 SeitenDkg-517-J Manual and Remote Start Unit With J1939 Interface: DescriptionJorge Omar ToroNoch keine Bewertungen

- Dkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionDokument2 SeitenDkg-507-J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanNoch keine Bewertungen

- Bernini OverviewDokument7 SeitenBernini Overviewaberardo1Noch keine Bewertungen

- Break Reless Chapter 1 IntroDokument1 SeiteBreak Reless Chapter 1 IntromohammedalathwaryNoch keine Bewertungen

- Smart Home Automation Using AndroidDokument8 SeitenSmart Home Automation Using Androidultimatekp144100% (1)

- Break SpecificationsDokument1 SeiteBreak SpecificationsmohammedalathwaryNoch keine Bewertungen

- Lift Control Panels & Push ButtonsDokument1 SeiteLift Control Panels & Push ButtonsmohammedalathwaryNoch keine Bewertungen

- Chapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnDokument1 SeiteChapt Er2Wi Ri NG: 2. 1termi Naldefi Ni T I OnmohammedalathwaryNoch keine Bewertungen

- VanderGraaf INSTALL-MANUAL PDFDokument18 SeitenVanderGraaf INSTALL-MANUAL PDFJonathan Omar Martinez HernandezNoch keine Bewertungen

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Dokument1 SeiteSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNoch keine Bewertungen

- Car Operating Panels & Landing Push Stations: Lift ComponetsDokument1 SeiteCar Operating Panels & Landing Push Stations: Lift ComponetsmohammedalathwaryNoch keine Bewertungen

- 07Dokument4 Seiten07mohammedalathwaryNoch keine Bewertungen

- Electronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200Dokument31 SeitenElectronics Prom Programmer Series Ii User Manual MODELS 160 170 180 200mohammedalathwaryNoch keine Bewertungen

- P Ja 51687 Av TF32 VDDokument3 SeitenP Ja 51687 Av TF32 VDrabreyNoch keine Bewertungen

- Alhamdany Hospital: Partner Asansör FormDokument1 SeiteAlhamdany Hospital: Partner Asansör FormmohammedalathwaryNoch keine Bewertungen

- De DP016Dokument14 SeitenDe DP016mohammedalathwaryNoch keine Bewertungen

- HGL10 Operation Service ManualDokument49 SeitenHGL10 Operation Service ManualmohammedalathwaryNoch keine Bewertungen

- Manual For EncoderDokument2 SeitenManual For EncodermohammedalathwaryNoch keine Bewertungen

- Warnings: Device Usage and Operation SequenceDokument9 SeitenWarnings: Device Usage and Operation Sequencemohammedalathwary100% (1)

- Sec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186Dokument1 SeiteSec Electronics: Exchange Safety Circuit 185 With Safety Circuit 186mohammedalathwaryNoch keine Bewertungen

- ICsoftware quick start guide: add elevators, controllers & assign access cardsDokument5 SeitenICsoftware quick start guide: add elevators, controllers & assign access cardsmohammedalathwaryNoch keine Bewertungen

- 275 Reflux 819 Fo mt103 e PDFDokument93 Seiten275 Reflux 819 Fo mt103 e PDFsilver lauNoch keine Bewertungen

- Furniture Design ProposalDokument46 SeitenFurniture Design ProposalIvneet VohraNoch keine Bewertungen

- EurocodesNews 07 - 10.2008 - 0139Dokument10 SeitenEurocodesNews 07 - 10.2008 - 0139nebojsadj6411Noch keine Bewertungen

- Brochure For York ChillerDokument8 SeitenBrochure For York ChillervenkatearNoch keine Bewertungen

- Cse 26Dokument13 SeitenCse 26rs_paliwalNoch keine Bewertungen

- Apple Watch Series 2Dokument8 SeitenApple Watch Series 2dorian451Noch keine Bewertungen

- Cable Laying ProductsDokument36 SeitenCable Laying ProductsSoul BladeNoch keine Bewertungen

- LF IntroductiontoCircuitProtectionDokument27 SeitenLF IntroductiontoCircuitProtectionAnun SumookNoch keine Bewertungen

- Jaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyDokument1 SeiteJaw & Jaw: - Turnbuckles Recommended For Straight or In-Line Pull OnlyErwin EleserioNoch keine Bewertungen

- Testing of Sand Quality at Construction Site For ConcreteDokument6 SeitenTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNoch keine Bewertungen

- ENGR 313: Introduction To Materials Science and EngineeringDokument7 SeitenENGR 313: Introduction To Materials Science and EngineeringTracey HowardNoch keine Bewertungen

- Selection of Antifriction BearingsDokument22 SeitenSelection of Antifriction BearingsSunil MandoreNoch keine Bewertungen

- Astm C 76 - 99Dokument11 SeitenAstm C 76 - 99LNoch keine Bewertungen

- Technical Guide Solar 2007Dokument100 SeitenTechnical Guide Solar 2007sanitermNoch keine Bewertungen

- PS-103 AAH PharmaceuticalsDokument1 SeitePS-103 AAH PharmaceuticalsJohn ShaneNoch keine Bewertungen