Beruflich Dokumente

Kultur Dokumente

Ngp-000-Ele-15.71-0004-A Ms For Instrument & Utility Air System Test

Hochgeladen von

wqs_19Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ngp-000-Ele-15.71-0004-A Ms For Instrument & Utility Air System Test

Hochgeladen von

wqs_19Copyright:

Verfügbare Formate

NASHPA GAS PROCESSING AND LPG RECOVERY

PLANT PROC-FC-CB/NASHPA/PROJ-1247/2015

DOCUMENT NO.: MS FOR INSTRUMENT & UTILITY AIR

Page 1 of 5

NGP-000-ELE-15.71-0004-A SYSTEM TEST

METHOD STATEMENT

FOR

INSTRUMENT & UTILITY AIR SYSTEM TEST

Zealcon HBP/HH ZEL OGDCL

(Representative) (EPC contractor) (Consultant) (Owner representative)

Date: Date: Date: Date:

Signature: Signature: Signature: Signature:

NASHPA GAS PROCESSING AND LPG RECOVERY PLANT

PROC-FC-CB/NASHPA/PROJ-1247/2015

DOC. NO. NGP-000-ELE-15.71-0004-A

DESCRIPTION MS FOR INSTRUMENT & UTILITY AIR SYSTEM TEST

PAGE 2 OF 5

1. SCOPE

Main purpose of this method statement is to describe the INSTRUMENT & UTILITY AIR SYSTEM

test including activities to be carried out according to required specifications.

2. PURPOSE

To ensure INSTRUMENT & UTILITY AIR SYSTEM test.

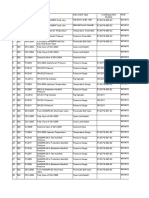

3. INSTRUMENT & UTILITY AIR SYSTEM TEST PROCEDURE

According to the overall schedule, HBP/HH is planning to INSTRUMENT & UTILITY AIR SYSTEM

at: 9:30 on 20 August 2017, details are given as below:

1) To start diesel generator Y4 as basic power source and to supply power to MDB system;

Note: external power supply is to be of alternative option.

2) After MDB receive power, close BC1-01 switchgear (PANEL AA12) ;

3) After MDB bus bar receive power, close AA17-6/12M switchgear, it is to supply power to

INSTRUMENT & UTILITY AIR system;

NASHPA GAS PROCESSING AND LPG RECOVERY PLANT

PROC-FC-CB/NASHPA/PROJ-1247/2015

DOC. NO. NGP-000-QAC-15.71-0003-A

DESCRIPTION MS FOR Y4 Diesel GENERATOR Trial Run TEST

PAGE 3 OF 5

4. INSTRUMENT & UTILITY AIR SYSTEM TEST FLOW CHART

NASHPA GAS PROCESSING AND LPG RECOVERY PLANT

PROC-FC-CB/NASHPA/PROJ-1247/2015

DOC. NO. NGP-000-ELE-15.71-0004-A

DESCRIPTION MS FOR INSTRUMENT & UTILITY AIR SYSTEM TEST

PAGE 4 OF 5

5. Electrical isolation scheme

NASHPA GAS PROCESSING AND LPG RECOVERY PLANT

PROC-FC-CB/NASHPA/PROJ-1247/2015

DOC. NO. NGP-000-ELE-15.71-0004-A

DESCRIPTION MS FOR INSTRUMENT & UTILITY AIR SYSTEM TEST

PAGE 5 OF 5

6. SAFETY PRE-CAUTIONS AND MEASURES

1). Procedural: Approved Standard Operating Procedure should be prepared / developed and

Operating staff by Commissioning Team

2). Procedural: Shift Inspection Checklist to be developed by commissioning team (including

leakages, dozing details, and as per Vendor recommended checklist)

3). Procedural: Work instructions for operator shall be installed

4). Equipment Safety: Direction or indication of live piping should be done to aware all workforce

about live lines

5). Equipment Safety: Leakages of gas/diesel should be rectified and Missing bolts and screws

shall be installed

6). Equipment Safety: CO2 Fire extinguishers shall be placed

7). Personnel Safety: Work area should be well barricaded to avoid unauthorized entry

8). Personnel Safety: Proper grounding / earthling of equipment should be ensured and checked

as per standard

9). Personnel Safety: Warning sign/instruction sign shall be installed for graphical communication

10). Personnel Safety: Trained and competent personnel should be deployed

11). Personnel Safety: Proper illumination should be ensured within the facility as per standard

guidelines

12). Personnel Safety: entrance slope should be prepared properly to avoid tripping hazards

13). Personnel Safety: Tagging of all valves should be done as per Standards

14). Environmental Compliance: Drainage/leakage should be checked before start up.

Das könnte Ihnen auch gefallen

- Recovery Plus Operating ManualDokument136 SeitenRecovery Plus Operating Manualkishoreprithika100% (4)

- J24B EngineDokument196 SeitenJ24B EngineLeonel Dominguez100% (2)

- Sat Practice Answer SheetDokument5 SeitenSat Practice Answer SheetJasonNoch keine Bewertungen

- B-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)Dokument39 SeitenB-63.888 - B - Operational Test Procedure For Lifting Stations (Ls 1-5)onome ohwerhiNoch keine Bewertungen

- IOCL Report 2011Dokument56 SeitenIOCL Report 2011Ajay ShekhawatNoch keine Bewertungen

- NGP 001 PCS 15.03 0002 04B - 00 - Specification For Turbo Expander RecompressorDokument31 SeitenNGP 001 PCS 15.03 0002 04B - 00 - Specification For Turbo Expander Recompressorm.shehreyar.khanNoch keine Bewertungen

- Method Statement OF Air Blowing / Water Flushing of PipesDokument19 SeitenMethod Statement OF Air Blowing / Water Flushing of Pipesarun kumar100% (1)

- Compressed Gas Cylinders and Related SystemsDokument26 SeitenCompressed Gas Cylinders and Related SystemsPassmore DubeNoch keine Bewertungen

- Logic Check Function Check ProcedureDokument15 SeitenLogic Check Function Check ProcedureArjun Shantaram Zope100% (1)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsVon EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsBewertung: 4 von 5 Sternen4/5 (9)

- Key Lessons Successful HydrorcakerDokument24 SeitenKey Lessons Successful HydrorcakerMohamed RefaatNoch keine Bewertungen

- CA LiberationDokument2 SeitenCA Liberationwqs_19Noch keine Bewertungen

- Wagon Airbrake System, Indian Railways.Dokument75 SeitenWagon Airbrake System, Indian Railways.Srinivas Avutapalli82% (11)

- TM9-732B M8 Howitzer Motor CarriageDokument321 SeitenTM9-732B M8 Howitzer Motor CarriagedieudecafeNoch keine Bewertungen

- Turbo Expander PDFDokument105 SeitenTurbo Expander PDFwqs_1960% (5)

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDokument110 SeitenHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- Thermal Power Plant: Pre-Operational ActivitiesVon EverandThermal Power Plant: Pre-Operational ActivitiesBewertung: 4 von 5 Sternen4/5 (4)

- GGCP-00-P0-ES-010-PP - Procedure and Preparation For Hazop Study - Rev 3Dokument105 SeitenGGCP-00-P0-ES-010-PP - Procedure and Preparation For Hazop Study - Rev 3wahyu100% (3)

- SMP For Silica Hach 5500scDokument7 SeitenSMP For Silica Hach 5500scPrince MaheshNoch keine Bewertungen

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDokument32 SeitenHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- P6076b PrattWhitney FT8MobilePac PowerPlant Estimated Performance and Emi2Dokument10 SeitenP6076b PrattWhitney FT8MobilePac PowerPlant Estimated Performance and Emi2lifemillion2847100% (1)

- SNO R DB 100 005 - Start Up and Operating Manual Rev B1Dokument61 SeitenSNO R DB 100 005 - Start Up and Operating Manual Rev B1Muhamad Fadli Arsyada100% (2)

- Clean Air Flow TestDokument13 SeitenClean Air Flow Testsrigirisetty20880% (5)

- Hazop ReportDokument78 SeitenHazop ReportFarinde Tosin100% (1)

- Gdtest of EspDokument13 SeitenGdtest of Espsrigirisetty208Noch keine Bewertungen

- 3100b BrochureDokument12 Seiten3100b BrochurealexNoch keine Bewertungen

- 1 - Method Statement For Ventilation FanDokument9 Seiten1 - Method Statement For Ventilation FanASHWANI100% (2)

- Performance Test & UncertaintyDokument30 SeitenPerformance Test & UncertaintyEnrique Javier González HenríquezNoch keine Bewertungen

- Closed Drain Transfer Pump Root Cause Failure AnalysisDokument11 SeitenClosed Drain Transfer Pump Root Cause Failure AnalysisMd. Sumon AhmedNoch keine Bewertungen

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Dokument7 SeitenS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராNoch keine Bewertungen

- Borescope Inspection Management For EngineDokument7 SeitenBorescope Inspection Management For EngineThanapaet RittirutNoch keine Bewertungen

- Handbook of Thermal&NuclearEngineeringDokument402 SeitenHandbook of Thermal&NuclearEngineeringNino V. Nieves100% (2)

- 0708 R RE 001 Design BasisDokument11 Seiten0708 R RE 001 Design BasisHimawan Sigit NugrohoNoch keine Bewertungen

- Manitou 200 AtjDokument2 SeitenManitou 200 AtjNeil Desai100% (1)

- PROGRAM UPLOAD FROM AC500 (Upload Programming AC500 Programs)Dokument2 SeitenPROGRAM UPLOAD FROM AC500 (Upload Programming AC500 Programs)wqs_19Noch keine Bewertungen

- NGP-000-INS-15.02-0001-00-00-Instrument IndexDokument267 SeitenNGP-000-INS-15.02-0001-00-00-Instrument Indexwqs_19Noch keine Bewertungen

- PCAM-200-HD-K-002 (Rev. L.T.M.)Dokument5 SeitenPCAM-200-HD-K-002 (Rev. L.T.M.)Augusto CamposNoch keine Bewertungen

- Basic OF HEV & EVDokument24 SeitenBasic OF HEV & EVMayukh MajumderNoch keine Bewertungen

- Fuel Gas System Operation ProcedureDokument11 SeitenFuel Gas System Operation Procedurehai dang maiNoch keine Bewertungen

- NGP-001-PCS-15.09-2001!15!00 PID Hot Oil Expansion Vessel and Circulation PumpDokument1 SeiteNGP-001-PCS-15.09-2001!15!00 PID Hot Oil Expansion Vessel and Circulation Pumpwqs_19Noch keine Bewertungen

- 8474L 013 ML 001 ADokument217 Seiten8474L 013 ML 001 ANguyễn Tiến Dũng0% (1)

- 8474L 013 ML 002 ADokument338 Seiten8474L 013 ML 002 ANinhHoàngHảiNoch keine Bewertungen

- Flow Calibration Procedure PDFDokument32 SeitenFlow Calibration Procedure PDFkfathi55100% (1)

- Turbine Generator Set 1Dokument21 SeitenTurbine Generator Set 1dedy yuliantoNoch keine Bewertungen

- Pnumatic Test Procedure R0Dokument7 SeitenPnumatic Test Procedure R0faizanAkhtarNoch keine Bewertungen

- Air Pre-Heater 600mwDokument15 SeitenAir Pre-Heater 600mwAmit BiswasNoch keine Bewertungen

- Testing Schedule For Commissioning of Condensate Extraction PumpsDokument13 SeitenTesting Schedule For Commissioning of Condensate Extraction PumpsJackSparrow86100% (1)

- Advanced Temperature Measurement and Control, Second EditionVon EverandAdvanced Temperature Measurement and Control, Second EditionNoch keine Bewertungen

- Natural Gas Processing from Midstream to DownstreamVon EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNoch keine Bewertungen

- Pollution Control Handbook for Oil and Gas EngineeringVon EverandPollution Control Handbook for Oil and Gas EngineeringNoch keine Bewertungen

- Ngp-001-Pcs-15.71-0009!17!001 Sat For Instrument & Utility Air and Nitrogen Generation System-EndDokument5 SeitenNgp-001-Pcs-15.71-0009!17!001 Sat For Instrument & Utility Air and Nitrogen Generation System-Endwqs_19Noch keine Bewertungen

- Ensuring Healthiness and Availability of Black Start System of Gas StationsDokument12 SeitenEnsuring Healthiness and Availability of Black Start System of Gas StationsAbhiroop AwasthiNoch keine Bewertungen

- A Prognostic Modeling Approach For Predicting Recurring Maintenance For Shipboard Propulsion Systems PDFDokument8 SeitenA Prognostic Modeling Approach For Predicting Recurring Maintenance For Shipboard Propulsion Systems PDFMuhammad Fahmi MahmudNoch keine Bewertungen

- GT2014 26443Dokument43 SeitenGT2014 26443abbkr48Noch keine Bewertungen

- B11PA-X-300-MS-7880-1102-0002-02D Technical Requisition Package (TRP) For Gas Auto SamplerDokument113 SeitenB11PA-X-300-MS-7880-1102-0002-02D Technical Requisition Package (TRP) For Gas Auto Samplera_zulkiflyNoch keine Bewertungen

- NEWAC OverviewDokument64 SeitenNEWAC OverviewjoseantoniolopezsanchezNoch keine Bewertungen

- 6107 - 08 - r0 - Comp BDokument67 Seiten6107 - 08 - r0 - Comp BMohammad MohseniNoch keine Bewertungen

- 1220 0017 PDFDokument45 Seiten1220 0017 PDFeko handoyoNoch keine Bewertungen

- Application of Roms To Aeroengines Health Monitoring: April 2019Dokument20 SeitenApplication of Roms To Aeroengines Health Monitoring: April 2019tadele10Noch keine Bewertungen

- ESA-TECMSP-TN-007384 Rev2 - Process Verification of Altenative Chemical Conv Coating - SurtecDokument6 SeitenESA-TECMSP-TN-007384 Rev2 - Process Verification of Altenative Chemical Conv Coating - Surtecgoooga299Noch keine Bewertungen

- Performance Degradation Prediction by GADokument10 SeitenPerformance Degradation Prediction by GAMukhtiar AliNoch keine Bewertungen

- Andrew Pravin - Field OperatorDokument6 SeitenAndrew Pravin - Field OperatorVenkatesh VaradarajanNoch keine Bewertungen

- Ravi 2015 IOP Conf. Ser. - Mater. Sci. Eng. 90 012042 2Dokument11 SeitenRavi 2015 IOP Conf. Ser. - Mater. Sci. Eng. 90 012042 2hasantapNoch keine Bewertungen

- Pneumatic TestDokument6 SeitenPneumatic TestShrichand G. BathvNoch keine Bewertungen

- Eqix Sg4 2 Mech Cx3 002 r0 Air Balancing MV FansDokument19 SeitenEqix Sg4 2 Mech Cx3 002 r0 Air Balancing MV FansLâm trầnNoch keine Bewertungen

- Pneumatic ProcedureDokument5 SeitenPneumatic ProcedurekumaraguruNoch keine Bewertungen

- Career Episode 1 De-Bottlenecking of Fuel Gas Circuit CE 1.1Dokument7 SeitenCareer Episode 1 De-Bottlenecking of Fuel Gas Circuit CE 1.1zeeshanNoch keine Bewertungen

- Mechanical Cleaning - Wire Brushing & Air Cleaning For Pipes & FittingsDokument10 SeitenMechanical Cleaning - Wire Brushing & Air Cleaning For Pipes & FittingsraviNoch keine Bewertungen

- 0014 HAZOP Automate The BRA & BRD Hydrocyclone Backflush Valves Rev.00 - SignedDokument25 Seiten0014 HAZOP Automate The BRA & BRD Hydrocyclone Backflush Valves Rev.00 - SignedMohd HisammudinNoch keine Bewertungen

- Gas Turbine EngDokument11 SeitenGas Turbine EngRodriguez ArthursNoch keine Bewertungen

- WGQ bps100605w2Dokument15 SeitenWGQ bps100605w2Sanjay KumarNoch keine Bewertungen

- CMAS Training Plan: BP Tangguh LNGDokument17 SeitenCMAS Training Plan: BP Tangguh LNGAenur RofiiqNoch keine Bewertungen

- Gral 100 Ei X 100 CDokument9 SeitenGral 100 Ei X 100 CAldo FernandezNoch keine Bewertungen

- Supervisión Tremendo Ii - PCPDokument12 SeitenSupervisión Tremendo Ii - PCPmanuel cabarcasNoch keine Bewertungen

- S.No. Tasks 1 Make Sales Gas Compressor Logs 2 Make Turbo Expander Indent 3 Update Indent/ Approval Statuses 4 Working On Indents 5 Instrument Air Compressor Package UnderstandingDokument1 SeiteS.No. Tasks 1 Make Sales Gas Compressor Logs 2 Make Turbo Expander Indent 3 Update Indent/ Approval Statuses 4 Working On Indents 5 Instrument Air Compressor Package Understandingwqs_19Noch keine Bewertungen

- NOF Plant Softwares ListDokument3 SeitenNOF Plant Softwares Listwqs_19Noch keine Bewertungen

- NOF Plant Softwares ListDokument3 SeitenNOF Plant Softwares Listwqs_19Noch keine Bewertungen

- Muhammad Ibrar - ResumeDokument4 SeitenMuhammad Ibrar - Resumewqs_19Noch keine Bewertungen

- Control Valves (Fisher)Dokument6 SeitenControl Valves (Fisher)wqs_19Noch keine Bewertungen

- Load List of EquipmentDokument2 SeitenLoad List of Equipmentwqs_19Noch keine Bewertungen

- FACP Fire Alarm System Cabinet DrawingDokument8 SeitenFACP Fire Alarm System Cabinet Drawingwqs_19Noch keine Bewertungen

- Cover Letter For Turbo Expander Indent - InstrumentDokument1 SeiteCover Letter For Turbo Expander Indent - Instrumentwqs_19Noch keine Bewertungen

- Control Philosophy ACDokument10 SeitenControl Philosophy ACwqs_19Noch keine Bewertungen

- Solenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBDokument8 SeitenSolenoid Valves 3 - 2 5 - 2 Stainless Steel Body 551 553 CAT 80114GBwqs_19Noch keine Bewertungen

- 118 4417593 D03Dokument106 Seiten118 4417593 D03wqs_19Noch keine Bewertungen

- S.No. Tagnames Description Type Old NameDokument2 SeitenS.No. Tagnames Description Type Old Namewqs_19Noch keine Bewertungen

- This Feeder Marked in Red Is Not Working in Link 1 and Link 2Dokument2 SeitenThis Feeder Marked in Red Is Not Working in Link 1 and Link 2wqs_19Noch keine Bewertungen

- HMC Separator Analog SignalsDokument1 SeiteHMC Separator Analog Signalswqs_19Noch keine Bewertungen

- Zishan Engineers (PVT.) LTD.: Instrument List For HP, MP & LP SeparatorDokument9 SeitenZishan Engineers (PVT.) LTD.: Instrument List For HP, MP & LP Separatorwqs_19Noch keine Bewertungen

- Steam Boiler - Fluidized BedDokument10 SeitenSteam Boiler - Fluidized BedEdhi SutantoNoch keine Bewertungen

- Pipeline - The Best & Most Efficient Mode of Transport of HydrocarbonDokument3 SeitenPipeline - The Best & Most Efficient Mode of Transport of HydrocarbonsdmaityNoch keine Bewertungen

- Reasearch Paper - OilDokument18 SeitenReasearch Paper - OilAmr Abou HusseinNoch keine Bewertungen

- Transport Trailers: Pressure Transfer UnitDokument2 SeitenTransport Trailers: Pressure Transfer UnitT. LimNoch keine Bewertungen

- Oxygen Sensor 2Dokument2 SeitenOxygen Sensor 2Kevin Strong100% (1)

- Bhilai Cement Coal Tar Chemical Naphthalene Creosote IndiaDokument7 SeitenBhilai Cement Coal Tar Chemical Naphthalene Creosote Indiaabhibansal2001Noch keine Bewertungen

- Sonihull DuoDokument7 SeitenSonihull DuoAliasgar PatrawalaNoch keine Bewertungen

- Ansari Shanawaz Ayaz S-Class ProjectDokument93 SeitenAnsari Shanawaz Ayaz S-Class ProjectAli Ahmed KhanNoch keine Bewertungen

- Energy Integration of A HydrotreatmentDokument43 SeitenEnergy Integration of A Hydrotreatmentvarun kumarNoch keine Bewertungen

- STIHL FS 70 Strimmer Instruction ManualDokument40 SeitenSTIHL FS 70 Strimmer Instruction Manualcbx78Noch keine Bewertungen

- Service Bulletin 32343Dokument5 SeitenService Bulletin 32343YAMA� YENERNoch keine Bewertungen

- High Pressure Pump Sprocket Remover: Hyundai - KIADokument2 SeitenHigh Pressure Pump Sprocket Remover: Hyundai - KIAAdrian HernandezNoch keine Bewertungen

- Motor WartsilaDokument12 SeitenMotor WartsilaPabloVarela18Noch keine Bewertungen

- Diesel Heavy Equipment TechnicianDokument3 SeitenDiesel Heavy Equipment Technicianeng_ahmed_1500Noch keine Bewertungen

- Low Alloy Steels Part2Dokument1 SeiteLow Alloy Steels Part2fedaquiNoch keine Bewertungen

- Diesel Engine Trouble ShootingDokument3 SeitenDiesel Engine Trouble ShootingAnonymous wxL9DSuYk100% (1)

- Jan Trocki Pres EngDokument28 SeitenJan Trocki Pres Engdie_1Noch keine Bewertungen

- Gas Space HeaterDokument4 SeitenGas Space HeaterŞinasi ALTINELNoch keine Bewertungen

- Lava Heat Italia - Opus Patio Heater - Owners ManualDokument16 SeitenLava Heat Italia - Opus Patio Heater - Owners ManuallavaheatitaliaNoch keine Bewertungen

- Oil Gas Operations Consultant in Houston Texas Resume David HuntingtonDokument4 SeitenOil Gas Operations Consultant in Houston Texas Resume David HuntingtonDavid HuntingtonNoch keine Bewertungen

- Bapco Terminal Info - GAC BahrainDokument3 SeitenBapco Terminal Info - GAC Bahrainchris chazNoch keine Bewertungen