Beruflich Dokumente

Kultur Dokumente

p103 Stts Gec Asi Ms Ele 006 - Method Statement For Underground Cable Laying

Hochgeladen von

Anandu AshokanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

p103 Stts Gec Asi Ms Ele 006 - Method Statement For Underground Cable Laying

Hochgeladen von

Anandu AshokanCopyright:

Verfügbare Formate

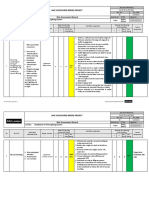

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

Document No: P103-STTS-GEC-ASI-MS-ELE-006

REV. DATE DESCRIPTION GENFOCUS ASI/WSP

PREPARED APPROVED

000 27-05-18 Issued for Approval QA/QC PM

DOCUMENT No. REV DATE

Page 1 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

1.0 PURPOSE

1.1 The purpose of this Method Statement is to describe in details the method of underground cable

laying.

2.0 SCOPE

2.1 The purpose of this Method statement is to define the procedure to be adopted for cable and to

ensure that the jobs are carried out strictly in accordance with the requirements specified in the

relevant specifications as attached

3.0 TOOLS AND RESOURCES

3.1 Cable Winch

3.2 Hydraulic jack

3.3 Cable rollers

3.4 Tools (Hydraulic cutting machine, spanners)

3.5 Drum supports.

3.6 Multi-meter. ( valid calibration certificate will be provide before use )

4.0 RESPONSIBILITIES

4.1 PROJECT MANAGER

4.1.1 Project manager shall be responsible overall to complete all MEP works as per specifications,

budget, time, & quality.

4.2 MEP SITE ENGINEERS

4.2.1 MEP Site Engineers shall be responsible for but not limited to the following important

activities:

4.2.1.1 To ensure that all the preparation and application works are carried out according to the

contract specification and manufacturer’s data sheet(s).

DOCUMENT No. REV DATE

Page 2 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

4.2.1.2 To ensure that the progressing of works is carried out according to the planned program,

and as per the approved Method statement.

4.2.1.3 To ensure that all the equipment’s and materials required in executing the works are

available according to the planned constriction program.

4.2.1.4 To coordinate with the main contractor’s MEP coordinator and safety officer for all safe

and proper execution of the work in accordance with the risk assessment.

4.2.1.5 To coordinate with the civil team for any area preparation, access, clearance.

4.3 QA/QC ENGINEERS

4.4.1 Quality control engineers shall be responsible for but not limited to the following important

activities:

4.3.1.1 Inspecting the materials on site as per approved materials submittal and raise MIR

within 24 hrs prior to installation on site.

4.3.1.2 Inspection for the installation as per approved drawings and approved test plans and

checklists.

4.3.1.3 Preparing test forms for testing on site and updating results accomplished.

4.3.1.4 Issuing inspection request within 24 hrs before the actual inspection.

4.3.1.5 Responsible for the assurance of Quality control, method statement and inspection

test plan.

4.3.1.6 Controlling the shop drawings flow on site.

4.4 HSE OFFICER

4.5.1 H& S Officer shall be responsible for but not limited to the following important activities:

4.4.1.1 Ensure health and safety of the site personnel.

4.4.1.2 Ensuring PPE available with site personnel.

4.4.1.3 Good housekeeping on site.

4.4.1.4 Environmental concerns are addressed.

DOCUMENT No. REV DATE

Page 3 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

4.4.1.5 Responsible for implementation and assurance of the safety and environmental

requirements (JHA).

5.0 PROCEDURE

5.1 OFF-LOADING AND HANDLING OF CABLE

5.1.1 Load tested/certified lifting tackles/cranes will be used to unload cable drums.

5.1.2 Ensure that the lifting equipment (Mobile cranes, Boom Loader, Fork lift) is adequately rated

for the specified weight (shown on the rating plate) and fit for purpose.

5.1.3 Off-loading of the cable shall be made in open area and the equipment should be covered with

polythene sheets to protect against external elements and make hard barricading to avoid the

damages.

5.1.4 Verify that the bracing & supports are provided to prevent damage during transit, lifting or

unloading.

5.1.5 Use only the fixtures provided (transport eyebolts, bugles, lifting points) while lifting or pulling

the cable drums.

5.1.6 Pulling or pushing shall be done using cable trailers and forklift for safe moving.

5.1.7 Lifting and pulling of the cable drums shall be as per the manufacture recommendation (see the

attachment).

5.1.8 Use only lifting slings of sufficient length to obtain an angle of 450 between the cable drums.

5.1.9 The cable drums shall be offloaded at an open area in an upright position.

5.1.10 Avoid standing directly underneath the cable drums, when lifted, unless absolutely necessary.

5.1.11 The storage base must be smooth and horizontal.

5.1.12 Lower the cable drums slowly and place it gently on the ground.

5.1.13 Cable drums shall be shifted from the store to respective site by using cable trailer.

DOCUMENT No. REV DATE

Page 4 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

5.2 SEQUENCE OF WORKS

5.2.1 Drawings and approved method statement should be available necessary permits shall be

obtained for the trench work and approved by the engineer before excavation.

5.2.2 Excavation plan should be prepared

5.2.3 Excavation plan should be approved by engineer/appropriate authority and prior Approval from

authority shall be taken before the commencement of the work.

5.2.4

5.2.5 Layout, Alignment, Size of Excavation and depth should be marked on the ground as per

approved Excavation plan.

5.2.6 All trail pits shall be done with hand excavation for identifying the underground services prior

to proceeding with any mechanical excavation works. Underground utilities, sewers, water

pipeline, cables, if any etc. should be checked and brought to the notice of site in-charge.

According to the site condition services should be coordinate and rectify any clashes with

approval of all concern.

5.2.7 The excavated pits should be adequately sloped/shored/timbered and should be properly

barricaded for working and trial pits shall be kept open until finish the work at that area.

5.2.8 Barricading & caution signs should be provided for trench excavations.

5.2.9 The excavated material should be kept away from the edge of trench.

5.2.10 Heavy equipment such as cranes, shovels, ladders should be at least 6m from the edge of

excavated trench.

5.2.11 Danger sign should be provided near the excavated area.

5.2.12 Ramp shall be provided at both ends to trench for easy access and exit from the work area.

5.2.13 All road crossing shall be provided with concrete duct bank.

5.2.14 All concrete duct bank shall be constructed as per the approved shop drawing and approved

sections.

5.2.15 Trench base shall be coved with 5cm thick sand bed

DOCUMENT No. REV DATE

Page 5 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

5.2.16 All materials received at site shall be inspected. MIR to be raised for material verification and

rejected material should be removed from site.

5.2.17 The work area should be inspected for safety prior to start the installation.

5.2.18 Obtain relevant work and excavation permits from the authorities.

5.2.19 Pre-installation Testing of cables for continuity & insulation resistance will be carried out as

per specification and ITP

5.2.20 All relevant approved shop drawings are available at site for the execution of job.

5.2.21 Ensure all control measures stated in the corresponding risk assessment are adhered to when

carrying out the job.

5.2.22 Use the cable jacks and bars that are of sufficient size to carry the weight of cable drum.

5.2.23 The cables shall be laid as per the approved load schedules.

5.2.24 The cable shall leave from bottom of the drum while pulling.

5.2.25 The pulling tension does not exceed the safe pulling tension of 12 kN allowable force of the

cable and it can measured from cable winch information digital display.

5.2.26 The winch rope will be pulled into the trench from the winch position to the cable position

using the draw rope.

5.2.27 Check that the wire-pulling sock will be fitted to the cable end and the winch rope will be

attached to the sock eye.

5.2.28 Lubricate the cable, if necessary from the drum end prior to its entry into the trench with the

approved pulling compound.

5.2.29 Every cable ends should be provide end cap to avoid any corrosion and rust.

5.2.30 Proper care shall be taken while pulling the cables through sleeves, by using bell mouth rollers,

lubricants and sufficient monitoring to avoid damages

5.2.31 After cable pulling is completed, inspection to proceed for cable laying, 5cm thick soft sand

coverage around the cable will be provided cable tiles and backfilling as per approved method

statement

DOCUMENT No. REV DATE

Page 6 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR UNDERGROUND CABLE LAYING

5.2.32 As per approved shop drawing warning tape shall be provided 300mm below the ground level

along the cable route.

5.2.33 Identify the cable route by placing the concrete cable route marker at every 25m and every

change of direction.

DOCUMENT No. REV DATE

Page 7 of 8

P103-STTS-GEC-ASI-MS-ELE-006 000 27-05-2018

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Method Statement For Drainage Pipes InstallationDokument11 SeitenMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Method Statement For Earthing and Lightning ProtectionDokument12 SeitenMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Wiring Accessories InstallationDokument9 SeitenMethod Statement For Wiring Accessories InstallationAnandu AshokanNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Method Statement For Water Heaters InstallationDokument9 SeitenMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Method Statement For Structured Cabling System InstallationDokument9 SeitenMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Risk Assessment For Installation of Water Supply PipeDokument18 SeitenRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Sanitary WaresDokument14 SeitenRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Drainage PipesDokument17 SeitenRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Toilet Exhaust FanDokument11 SeitenRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Method Statement For PPR Pipes and Fittings InstallationDokument9 SeitenMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNoch keine Bewertungen

- VentilationDokument92 SeitenVentilationRobert Nixon100% (1)

- Risk Assessment For Installation of Fire Fighting SystemDokument20 SeitenRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan93% (30)

- Risk Assessment For Installation of Ducts and AccessoriesDokument17 SeitenRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan82% (11)

- The Pentester BlueprintDokument27 SeitenThe Pentester Blueprintjames smith100% (1)

- Method Statement For PEX Pipes and Fittings InstallationDokument9 SeitenMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For Cable Tray and Truncking InstallationDokument9 SeitenMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDokument11 SeitenMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Risk Assessment For Installation of Grill, Diffuser and LouversDokument13 SeitenRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- 3000 CalorieDokument10 Seiten3000 CalorieNIKHILNoch keine Bewertungen

- Method Statement LV Distribution Boards InstallationDokument9 SeitenMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For PVC Conduits InstallationDokument9 SeitenMethod Statement For PVC Conduits InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For Fire Alarm and Emergency System InstallationDokument9 SeitenMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- MS For Installation of Drainage PipesDokument20 SeitenMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS Cover SheetDokument1 SeiteMS Cover SheetAnandu AshokanNoch keine Bewertungen

- MS For Installation of Duct & AccessariesDokument21 SeitenMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS Comments SheetDokument1 SeiteMS Comments SheetAnandu AshokanNoch keine Bewertungen

- S6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Dokument26 SeitenS6MT 1Q w1 3 MELC1 SLM MIXTURES FinalCopy09082020Rona Dindang100% (1)

- Method Statement For GI Conduits InstallationDokument9 SeitenMethod Statement For GI Conduits InstallationAnandu AshokanNoch keine Bewertungen

- MS For Installation of Sanitary WaresDokument22 SeitenMS For Installation of Sanitary WaresAnandu AshokanNoch keine Bewertungen

- MS - Installation of Water Supply PipeDokument20 SeitenMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- RAMS EvaluationDokument3 SeitenRAMS EvaluationAnandu AshokanNoch keine Bewertungen

- MS For Installation of FF Pipes FittingsDokument23 SeitenMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- MS For Installation of Grills, Diffuser & LouversDokument21 SeitenMS For Installation of Grills, Diffuser & LouversAnandu AshokanNoch keine Bewertungen

- MS For Installation of Toilet Exhaust FanDokument20 SeitenMS For Installation of Toilet Exhaust FanAnandu AshokanNoch keine Bewertungen

- Consider Recycled Water PDFDokument0 SeitenConsider Recycled Water PDFAnonymous 1XHScfCINoch keine Bewertungen

- Break Free - Nathaniel BrandenDokument16 SeitenBreak Free - Nathaniel Brandennbckudxtkudkuf50% (2)

- 4 6051111060339957657Dokument361 Seiten4 6051111060339957657Oviedo OviedoNoch keine Bewertungen

- Hydropad InstructionsDokument2 SeitenHydropad Instructionsmohamed hindawiNoch keine Bewertungen

- RJ Bensingh Pub Composites CoatingsDokument5 SeitenRJ Bensingh Pub Composites CoatingsFakkir MohamedNoch keine Bewertungen

- PhilLife claims process ECQDokument18 SeitenPhilLife claims process ECQNoel EboniaNoch keine Bewertungen

- ZP Series Silicon Rectifier: Standard Recovery DiodesDokument1 SeiteZP Series Silicon Rectifier: Standard Recovery DiodesJocemar ParizziNoch keine Bewertungen

- Secondary AssessmentsDokument12 SeitenSecondary Assessmentsapi-338389967Noch keine Bewertungen

- Understanding Empathy and SympathyDokument2 SeitenUnderstanding Empathy and SympathyFrinces MarvidaNoch keine Bewertungen

- Kidde Ads Fm200 Design Maintenance Manual Sept 2004Dokument142 SeitenKidde Ads Fm200 Design Maintenance Manual Sept 2004José AravenaNoch keine Bewertungen

- Steps of Repertorization - 5e097dab9ad98Dokument18 SeitenSteps of Repertorization - 5e097dab9ad98Sowjanya JyothsnaNoch keine Bewertungen

- Chemistry CHM 1311C 2012 Test 1 BlankDokument6 SeitenChemistry CHM 1311C 2012 Test 1 BlankSimon HagosNoch keine Bewertungen

- CSK - W - My - Mother - at - Sixty - Six 2Dokument2 SeitenCSK - W - My - Mother - at - Sixty - Six 2Aaron JoshiNoch keine Bewertungen

- No.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10Dokument9 SeitenNo.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10William DaslerNoch keine Bewertungen

- Undas Deployment PadsDokument15 SeitenUndas Deployment PadsVic NairaNoch keine Bewertungen

- Bibie Evana OsmanDokument6 SeitenBibie Evana OsmanStabat Jaya TrademarkNoch keine Bewertungen

- Overhead Set (OBC)Dokument19 SeitenOverhead Set (OBC)MohamedNoch keine Bewertungen

- Joyforce SDS - PVA Pellet - r2.ENDokument3 SeitenJoyforce SDS - PVA Pellet - r2.ENjituniNoch keine Bewertungen

- GDCR Final PDFDokument311 SeitenGDCR Final PDFHrushikesh PatelNoch keine Bewertungen

- 1 The Fifth CommandmentDokument10 Seiten1 The Fifth CommandmentSoleil MiroNoch keine Bewertungen

- Research PaperDokument12 SeitenResearch PapershreyanshNoch keine Bewertungen

- GEH-6680LCI FaultsDokument76 SeitenGEH-6680LCI FaultsMuhammad IdreesarainNoch keine Bewertungen

- Chin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous DentitionsDokument6 SeitenChin Cup Therapy An Effective Tool For The Correction of Class III Malocclusion in Mixed and Late Deciduous Dentitionschic organizerNoch keine Bewertungen

- Environmental Product Declaration: PU EuropeDokument6 SeitenEnvironmental Product Declaration: PU EuropeIngeniero Mac DonnellNoch keine Bewertungen

- Deadline Anchors BrochureDokument3 SeitenDeadline Anchors Brochurejlmunozv100% (2)

- Methodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsDokument16 SeitenMethodology For The Validation of Fuel Consumption in Diesel Engines Installed On Board Military Ships, Using Diesel Oil and Biodiesel BlendsErick RodriguesNoch keine Bewertungen