Beruflich Dokumente

Kultur Dokumente

Determining F Floor Flatness and Floor Levelness Numbers: Standard Test Method For

Hochgeladen von

Pavimentos Industriales Pavirat SLOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Determining F Floor Flatness and Floor Levelness Numbers: Standard Test Method For

Hochgeladen von

Pavimentos Industriales Pavirat SLCopyright:

Verfügbare Formate

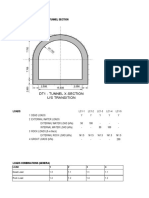

Standard Test Method for

Determining F F Floor Flatness and

F L Floor Levelness

Numbers

Based on the

ASTM International Designation

E 1155 M - 96 (Reapproved 2001)

Excel Sheet Developed

April 2003

Stanford Linear Accelerator Center

Alignment Engineering Group

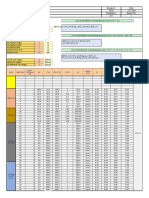

Type I Flatness Raw Data

(height units = mm)

Test Sample j=0 Test Sample j=1

Reading Points Elevation Reading Points Elevation

Name hi Name hi

P 0 418.617 P 0 418.592

P 1 419.938 P 1 421.081

P 2 421.894 P 2 422.072

P 3 423.748 P 3 421.513

P 4 425.221 P 4 420.040

P 5 424.739 P 5 421.132

P 6 423.799 P 6 420.675

P 7 424.307 P 7 421.640

P 8 425.425 P 8 421.894

P 9 424.688 P 9 421.538

P 10 423.164 P 10 421.183

P 11 422.758 P 11 421.894

P 12 420.472 P 12 419.684

P 13 416.738 P 13 420.040

P 14 P 14 417.982

P 15 P 15

P 16 P 16

P 17 P 17

P 18 P 18

P 19 P 19

Test Sample j=2 Test Sample j=3

Reading Points Elevation Reading Points Elevation

Name hi Name hi

P 0 418.338 P 0 418.617

P 1 419.659 P 1 418.973

P 2 419.227 P 2 419.100

P 3 419.227 P 3 420.878

P 4 418.668 P 4 419.989

P 5 418.186 P 5 419.227

P 6 418.973 P 6 419.684

P 7 419.379 P 7 420.751

P 8 420.141 P 8 420.065

P 9 419.532 P 9 421.259

P 10 418.643 P 10 421.386

P 11 418.719 P 11 418.846

P 12 416.763 P 12 419.887

P 13 414.782 P 13 418.363

P 14 P 14

P 15 P 15

P 16 P 16

P 17 P 17

P 18 P 18

P 19 P 19

Type I Raw Data

5/15/2003 2:35 PM ASTM E 1155M Section 9.1.1 Page 1 of 2

Type I Raw Data Continued

(height units = mm)

Test Sample j=4 Test Sample j=5

Reading Points Elevation Reading Points Elevation

Name hi Name hi

P 0 418.846 P 0 419.735

P 1 418.135 P 1 420.370

P 2 418.998 P 2 421.640

P 3 419.405 P 3 422.199

P 4 420.294 P 4 423.342

P 5 420.370 P 5 423.748

P 6 421.640 P 6 423.875

P 7 421.259 P 7 424.688

P 8 422.910 P 8 423.672

P 9 423.926 P 9 423.672

P 10 424.053 P 10 424.282

P 11 423.164 P 11 422.148

P 12 422.732 P 12 420.624

P 13 422.834 P 13

P 14 421.513 P 14

P 15 P 15

P 16 P 16

P 17 P 17

P 18 P 18

P 19 P 19

Test Sample j=6 Test Sample j=7

Reading Points Elevation Reading Points Elevation

Name hi Name hi

P 0 P 0

P 1 P 1

P 2 P 2

P 3 P 3

P 4 P 4

P 5 P 5

P 6 P 6

P 7 P 7

P 8 P 8

P 9 P 9

P 10 P 10

P 11 P 11

P 12 P 12

P 13 P 13

P 14 P 14

P 15 P 15

P 16 P 16

P 17 P 17

P 18 P 18

P 19 P 19

Type I Raw Data

5/15/2003 2:35 PM ASTM E 1155M Section 9.1.1 Page 2 of 2

Type I or II Flatness: Procedure and Calculations

(Height Units = mm)

Data Entry Field

Section 7 Tests: (See ASTM E 1155M for details)

Slab Dimensions

Width (m) 3.36 Pass 7.2.1 Area (m2): 20.53 Pass 7.2.1

Length (m) 6.11 Pass 7.2.1

Applicable Tests and Warnings

Section Comment Calcs

7.3.1 Make sure no sample line < 3.3 meters in length

7.3.2.2 NO 600 mm edge restriction <= Area excluded (m2) => 15.21

7.3.3 Make sure no sample lines closer than 1.2 meters to each other

7.4, 7.5 Slab is large enough <= Max # points on longest diag => 16

7.6 Minimum number of zi values has been met <= (Nmin): => 10

7.7 Construction joints are not presently accounted for

Section 8 Procedure and Tests: (See ASTM E 1155M for details)

8.1 Name of Subject Building

SPEAR3 Concrete Test Pad

Building Location

Behind Fort Apache on hill top

Installation Date of Subject Floor (MM/DD/YY)

04/04/03

Floors Specified F f and F l Values

Composite Values for Entire Floor Minimum Values For Any Section

Ff 30 Ff 15

Fl 20 Fl 10

Instrument Make, Model and Serial Number

K+E Site Level, PC14688, SN 71-1111 with K+E 40 Rod

Date of Test (MM/DD/YY)

05/05/03

Note 5: Ref. ACI 117-90 requires

Crew tolerances be check within 72 hours

Banuelos, Griffin, Gaudreault of concrete pour.

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 1 of 6

Section 8 Procedure and Tests: (continued)

8.2 Lay out the test surface.

8.2.1 Divide entire test surface into test sections. (i.e. divide large area into sub-areas)

Assign unique ID number to each test section and note locations

ID Number Location Details

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

- - - if more rows are needed, continue entering values on the "Overall F-Numbers" TAB section - - -

8.2.2 Determine number and location of all sample measurement lines

Assign different number for each line in test area starting with j = 0

Record locations of all line starting and stopping points and mark on surface

8.2.3 Test section width < 7.5 so orient sample lines 45° to longest const. joint

Do NOT orient sample lines corner to corner

8.3 Collected Type I or Type II raw data ===> Type: I

Type I: Instruments that measure point elevations (see 6.1.1)

Type II: Instruments that measure change in elevations (see 6.1.2)

8.3.1 Ensure each sample measurement line subdivided into 300 mm intervals

Starting point is designated as P0 for each line

8.3.2 TYPE I Data Entered: Measure and record in sequence the elevations (mm) of all points

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 2 of 6

Section 9 Calculations: (See ASTM E 1155M for details)

9.2 The chart below is a subjective quality control check for gross anomalies

Check each profile to ensure it really represents the actual floor

0 1 2 3 4 5

ASTM E 1155 M Section 9.2 Straight Line Graph

425.000

420.000

Height (mm)

415.000

0 1

2 3 4

4 5

6 7 2

8 9 10 Sample Line

Point (Pi)

11 12 0

13

14

9.4 For each test sample line j the profile curvatures are calculated pos = trough

neg = crest

0 1 2 3 4 5

q2 0.635 -1.499 -1.753 -0.229 1.575 0.635

q3 -0.102 -1.549 0.432 1.651 -0.457 -0.711

q4 -0.381 -0.914 -0.559 -2.667 0.483 0.584

q5 -1.956 2.565 0.076 0.127 -0.813 -0.737

q6 -0.457 -1.549 1.270 1.219 1.194 -0.279

q7 1.448 1.422 -0.381 0.610 -1.651 0.686

q8 0.610 -0.711 0.356 -1.753 2.032 -1.829

q9 -1.854 -0.610 -1.372 1.880 -0.635 1.016

q10 -0.787 0.000 -0.279 -1.067 -0.889 0.610

q11 1.118 1.067 0.965 -2.667 -1.016 -2.743

q12 -1.880 -2.921 -2.032 3.581 0.457 0.610

q13 -1.448 2.565 -0.025 -2.565 0.533

q14 -2.413 -1.422

q15

q16

q17

q18

q19

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 3 of 6

Section 9 Calculations: (continued)

9.5 For each test sample line j the elevation differences zi are calculated. Points are

separated by 3 meters

Positive = uphill change in elevation Negative = downhill change in elevation

0 1 2 3 4 5

z10 4.547 2.591 0.305 2.769 5.207 4.547

z11 2.819 0.813 -0.940 -0.127 5.029 1.778

z12 -1.422 -2.388 -2.464 0.787 3.734 -1.016

z13 -7.010 -1.473 -4.445 -2.515 3.429

z14 -2.057 1.219

z15

z16

z17

z18

z19

9.6 For each test sample line j the mean qij is calculated (from section 9.4)

9.7 For each test sample line j the standard deviation S q j is calculated (from section 9.4)

0 1 2 3 4 5

qij (mm) -0.421 -0.350 -0.275 -0.157 -0.047 -0.196

2

Sq j (mm ) 1.201 1.776 1.026 2.039 1.175 1.207

9.8 For each test sample line j the mean zij is calculated (from section 9.5)

9.9 For each test sample line j the standard deviation S z j is calculated (from section 9.5)

0 1 2 3 4 5

zij (mm) -0.267 -0.503 -1.886 0.229 3.724 1.770

2

Sz j (mm ) 5.148 2.134 2.048 2.192 1.602 2.781

9.10 For each test sample line j the F f j Flatness Number is calculated (sec. 9.6 and 9.7)

0 1 2 3 4 5

FF j 28.8 20.4 34.6 18.5 32.4 30.4

r 12 13 12 12 13 11

9.11 Calculation of the COMPOSITE F F Flatness Number estimate

Based upon 73 readings of 600 mm profile curvatures, the test section

has an estimated Flatness F -Number of =====> F F 25.2

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 4 of 6

Section 9 Calculations: (continued)

9.12 For each test sample line j the F L j Levelness Number is calculated (sec. 9.8 and 9.9)

0 1 2 3 4 5

FL j 20.0 45.6 39.2 46.2 36.9 31.1

r 4 5 4 4 5 3

9.13 Calculation of the COMPOSITE F L Levelness Number estimate

Based upon 25 readings of 3 m elevation differences, the test section

has an estimated Levelness F -Number of ====> F L 32.5

9.14 Calculation of the 90% confidence intervals, CI90%

CI90% ==> 14.6

FFj

F -Number 90% Confidence Interval ===> 21.5 to 28.8

CI90% ==> 25.3

FLj

F -Number 90% Confidence Interval ===> 24.3 to 40.8

9.15 Enter all test section (sub-section) area and F values on "Overall F-Numbers"

TAB page to compute the overall F F and F L Numbers for the entire test surface

Overall F F ====>

Overall F L ====>

Section 10 Report: (See ASTM E 1155M for details)

10.1 Summary of each test section results: (Namely 9.1, 9.3, 9.4 and 9.10 to 9.14)

To satisfy this condition, print all TAB pages in this report for this concrete test

section and all TAB pages in every other sectional report

10.2 Final F -Numbers for this particular test section at 90% confidence

F f 25.2 ( 21.5 - 28.8 )

F l 32.5 ( 24.3 - 40.8 )

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 5 of 6

Section 10 Report: (continued)

10.3 Maximum qi for each straight section (choose construction joints if applicable)

0 1 2 3 4 5

qmax 1.448 2.565 1.270 3.581 2.032 1.016

10.4 Overall F-Number results for entire test surface

Warning: The values below may not include all test surfaces. See "Overall F-Numbers"

Overall FF =>

Overall FL =>

Sections 11 and 12 Precision and Bias Factors: (See ASTM E 1155M for details)

11.2 On very level floors the F -Numbers could be computed as functions of only the

standard deviations if the sample size is large enough. For interest only all test

sample lines are computed using this criteria in the following table:

11.3 99.73% of all q i and z i readings have absolute max q and z values less than of

equal to:

DO NOT USE THESE VALUES ! !

0 1 2 3 4 5

FF 32.1 21.7 37.6 18.9 32.8 32.0

FL 7.5 18.1 18.9 17.6 24.1 13.9

qmax (mm) 3.605 5.330 3.078 6.119 3.527 3.622

zmax (mm) 15.450 6.404 6.145 6.579 4.808 8.347

12.1 The repeatability standard deviation for both F F and F L is less than 0.25

12.2 ASTM Test Method E 1155 has no bias by definition

Procedure and Calculations

5/15/2003 2:37 PM ASTM E 1155M - 96 (Reapproved 2001) Page 6 of 6

Das könnte Ihnen auch gefallen

- "Self Reporting" Letter of Ethical Violations by Kansas Assistant Attorney General - Stephen Phillips, (May 11th, 2016)Dokument45 Seiten"Self Reporting" Letter of Ethical Violations by Kansas Assistant Attorney General - Stephen Phillips, (May 11th, 2016)Conflict GateNoch keine Bewertungen

- Calculations: Beam Design-Ultimate Strength Design: (Aci 318)Dokument10 SeitenCalculations: Beam Design-Ultimate Strength Design: (Aci 318)Anass SoubraNoch keine Bewertungen

- Astm A496-02Dokument6 SeitenAstm A496-02AlbertoNoch keine Bewertungen

- BS en 14891Dokument29 SeitenBS en 14891namNoch keine Bewertungen

- Rebars Splice and Column RebarDokument11 SeitenRebars Splice and Column RebarIrfan KhanNoch keine Bewertungen

- Reinforcing Bar Development and Splice Lengths Per ACI 318-05Dokument8 SeitenReinforcing Bar Development and Splice Lengths Per ACI 318-05cengizNoch keine Bewertungen

- Pile Group AnalysisDokument4 SeitenPile Group AnalysisrahimNoch keine Bewertungen

- Design & Const. of A 20.5m High Innovative Nehemiah Wall Near Cameron Highlands, Pahang (LCH & Dr. Nimal)Dokument4 SeitenDesign & Const. of A 20.5m High Innovative Nehemiah Wall Near Cameron Highlands, Pahang (LCH & Dr. Nimal)sutiknohung69970% (1)

- Calculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateDokument9 SeitenCalculation Report For Fence Foundation Model HP3000: REV Description Engineering Approval Boss DateGerardo JoseNoch keine Bewertungen

- Vibration Standards For Different CountriesDokument7 SeitenVibration Standards For Different CountriesNalla PerumalNoch keine Bewertungen

- Concrete Column Design Based On ACI 318-19: Input Data & Design SummaryDokument1 SeiteConcrete Column Design Based On ACI 318-19: Input Data & Design SummaryManuel Mendoza JaraNoch keine Bewertungen

- Seismic Loads For Liquid-Containing Rectangular RC Tank, According ACI 350.3-06, Appendix B Method Based On 1997 Uniform Building CodeDokument17 SeitenSeismic Loads For Liquid-Containing Rectangular RC Tank, According ACI 350.3-06, Appendix B Method Based On 1997 Uniform Building CodeEnger AlingasaNoch keine Bewertungen

- Base Plate For Tensile LoadsDokument96 SeitenBase Plate For Tensile Loadsfaizan ashiqueNoch keine Bewertungen

- Beggs Deformeter CalculationsDokument5 SeitenBeggs Deformeter CalculationsCivil EngineerNoch keine Bewertungen

- BA 001 R0A (Without Mezzanine)Dokument1 SeiteBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNoch keine Bewertungen

- Structural Analysis Report 9-11-2019 - MEC2019Dokument39 SeitenStructural Analysis Report 9-11-2019 - MEC2019仁俊李Noch keine Bewertungen

- Seismic DesignDokument1 SeiteSeismic Designجميل عبد الله الحماطيNoch keine Bewertungen

- Section 6 - Torque - TensionDokument23 SeitenSection 6 - Torque - TensionChris MedeirosNoch keine Bewertungen

- HILTI RE-500 Rebar ConnectionDokument7 SeitenHILTI RE-500 Rebar ConnectionAlma M. LaraNoch keine Bewertungen

- Simple Composite Beam DesignDokument6 SeitenSimple Composite Beam DesignandreashendiNoch keine Bewertungen

- Norma Aisc-Asd89 Sap2000Dokument29 SeitenNorma Aisc-Asd89 Sap2000IVAN SAAVEDRA TNoch keine Bewertungen

- Hilti - Profis Anchor Design Report 594Dokument5 SeitenHilti - Profis Anchor Design Report 594Madhu GuptaNoch keine Bewertungen

- Bolt Depot - Bolt Grade Markings and Strength ChartDokument2 SeitenBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- Settlement AnalysisDokument11 SeitenSettlement Analysishossam khashabaNoch keine Bewertungen

- Tutorial 4Dokument13 SeitenTutorial 4shalvinNoch keine Bewertungen

- Metal Roof Deck - VercoDokument87 SeitenMetal Roof Deck - VercoEduardo De Castro Cruz Jr.Noch keine Bewertungen

- Concrete T BeamDokument3 SeitenConcrete T BeamfreddielistoNoch keine Bewertungen

- Columna CirculDokument16 SeitenColumna Circulp_ignatiusNoch keine Bewertungen

- Concrete Shear: Tank SupportDokument12 SeitenConcrete Shear: Tank SupportfostbarrNoch keine Bewertungen

- Publication Hilti RebarDokument234 SeitenPublication Hilti RebarRedwan HendiNoch keine Bewertungen

- 0.5 Ton-CraneDokument20 Seiten0.5 Ton-CraneILYAS HUSSAINNoch keine Bewertungen

- Types of Ties For and Placement of Reinforcing SteelDokument8 SeitenTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवार100% (1)

- Fully Restrained - Moment Connection PDFDokument19 SeitenFully Restrained - Moment Connection PDFMauricio RiquelmeNoch keine Bewertungen

- TSS 35 205Dokument1 SeiteTSS 35 205Akhil VNNoch keine Bewertungen

- Strongwell Gridform Design GuideDokument352 SeitenStrongwell Gridform Design GuideBintee PanchalNoch keine Bewertungen

- Wall DesignDokument10 SeitenWall DesignJames WilliamsNoch keine Bewertungen

- For Maximum Load (Normal Case) : From Staad From STAAD With ImpactDokument4 SeitenFor Maximum Load (Normal Case) : From Staad From STAAD With ImpactVasu Deva Rao ChilukuriNoch keine Bewertungen

- Load Combination Generation MatrixDokument6 SeitenLoad Combination Generation Matrixvirat_daveNoch keine Bewertungen

- Soil NailDokument4 SeitenSoil NailnephembaniNoch keine Bewertungen

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014Dokument19 SeitenACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev1.1 - 09-Nov-2014manoj_mousamNoch keine Bewertungen

- Laboratory Test Frequency LGEDDokument6 SeitenLaboratory Test Frequency LGEDmohammed nusrot hossanNoch keine Bewertungen

- Pipe Concrete AnchorDokument6 SeitenPipe Concrete AnchorRahmat RiskiNoch keine Bewertungen

- Software Verification: AISC-360-10 Example 001Dokument9 SeitenSoftware Verification: AISC-360-10 Example 001Davico HernandezNoch keine Bewertungen

- IS 3370 Part 2 - 2009-Readable PDFDokument14 SeitenIS 3370 Part 2 - 2009-Readable PDFpradip ghodeswarNoch keine Bewertungen

- ASTM A 496 - 01 - Steel Wire For Concrete ReinforcementDokument5 SeitenASTM A 496 - 01 - Steel Wire For Concrete ReinforcementAsif HameedNoch keine Bewertungen

- ACI 350R Vs 318 - RevisedDokument76 SeitenACI 350R Vs 318 - RevisedtroyscribdNoch keine Bewertungen

- Pipe Friction Loss Spreadsheet - Hazen Williams Apr17Dokument6 SeitenPipe Friction Loss Spreadsheet - Hazen Williams Apr17Kapil BairagiNoch keine Bewertungen

- Physical Properties Strand PDFDokument1 SeitePhysical Properties Strand PDFlilik riyantiNoch keine Bewertungen

- Slab Foundation-Refer To Section 4.1 of ACI 360R: Project Job RefDokument2 SeitenSlab Foundation-Refer To Section 4.1 of ACI 360R: Project Job Refmpj1998Noch keine Bewertungen

- Anchor Bolt Design As Per American CodeDokument1 SeiteAnchor Bolt Design As Per American CodeS A K ClostreNoch keine Bewertungen

- Advanced Structural Steel Design Advanced Structural Steel DesignDokument10 SeitenAdvanced Structural Steel Design Advanced Structural Steel DesignMasudNoch keine Bewertungen

- Manta Ray DesignDokument6 SeitenManta Ray DesignJose Alfredo Perez MartinezNoch keine Bewertungen

- Astm D2729 PDFDokument2 SeitenAstm D2729 PDFShan Adrias100% (1)

- Life-365 Service Life Prediction Model Version 2.0Dokument2 SeitenLife-365 Service Life Prediction Model Version 2.0Fernando RosalesNoch keine Bewertungen

- Design of Axial Members - WoodDokument41 SeitenDesign of Axial Members - WoodRyan5443Noch keine Bewertungen

- Tally SheetDokument2 SeitenTally SheetReyzalyn LagrimasNoch keine Bewertungen

- Wa0024.Dokument1 SeiteWa0024.adit nugrahaNoch keine Bewertungen

- Operator 1 Operator 2 Cus-Operator 1 Operator 2 TomerDokument6 SeitenOperator 1 Operator 2 Cus-Operator 1 Operator 2 Tomersunita choudharyNoch keine Bewertungen

- Converting Radians To Degrees and Vice VersaDokument4 SeitenConverting Radians To Degrees and Vice VersaChristine Angelie GranadaNoch keine Bewertungen

- Sawtooth Waveform: P P P P PDokument8 SeitenSawtooth Waveform: P P P P PnyquistukNoch keine Bewertungen

- Camcor Coriolis Meter User ManualDokument140 SeitenCamcor Coriolis Meter User ManualGerardo OrtigozaNoch keine Bewertungen

- Hope Therapy PDFDokument18 SeitenHope Therapy PDFalexNoch keine Bewertungen

- Determinants of Income InequalityDokument30 SeitenDeterminants of Income InequalityKorawit Booranakit100% (1)

- SMS SRH-2D SedimentTransportDokument19 SeitenSMS SRH-2D SedimentTransportthendyNoch keine Bewertungen

- Handwritten English Alphabet RecognitionDokument8 SeitenHandwritten English Alphabet RecognitionIJRASETPublicationsNoch keine Bewertungen

- 2018 06 OnlineDokument12 Seiten2018 06 OnlineMohamed HasikNoch keine Bewertungen

- Fiat Barchetta: EngineDokument20 SeitenFiat Barchetta: EngineHallex OliveiraNoch keine Bewertungen

- HyperMILL Readme enDokument20 SeitenHyperMILL Readme enjimNoch keine Bewertungen

- Crane Wheels-General InformationDokument3 SeitenCrane Wheels-General InformationArvind VaishNoch keine Bewertungen

- Viscosity Measurements On Oligoesters From Terephthalic Acid and GlycoDokument7 SeitenViscosity Measurements On Oligoesters From Terephthalic Acid and GlycoMaria RincondeNoch keine Bewertungen

- Sensor Gaurd Installation and Maintenance ManualDokument57 SeitenSensor Gaurd Installation and Maintenance ManualCapacitacion TodocatNoch keine Bewertungen

- Unit Iv Ce 6405Dokument13 SeitenUnit Iv Ce 6405HanafiahHamzahNoch keine Bewertungen

- C 13Dokument33 SeitenC 13rgerwwaaNoch keine Bewertungen

- 截屏 2021-08-05 17.02.20Dokument98 Seiten截屏 2021-08-05 17.02.204WEM GTNoch keine Bewertungen

- LTTS Corporate BrochureDokument20 SeitenLTTS Corporate BrochureshountyNoch keine Bewertungen

- Simulation Tool ComparisonDokument8 SeitenSimulation Tool ComparisonsmautifNoch keine Bewertungen

- 04 Extended Graphics DesignDokument34 Seiten04 Extended Graphics DesignEngenheiro AmoedoNoch keine Bewertungen

- Transmission Line TowersDokument3 SeitenTransmission Line TowersSoumik Dandapat100% (2)

- NDT VTL-3-3Dokument2 SeitenNDT VTL-3-3Priyesh MauryaNoch keine Bewertungen

- The C Puzzle BookDokument93 SeitenThe C Puzzle Bookabhijeetnayak67% (3)

- Yohimbine InjectionDokument1 SeiteYohimbine InjectionKasidit SornchaiNoch keine Bewertungen

- Net Work Survey VehicleDokument26 SeitenNet Work Survey VehiclegurvinderkumarNoch keine Bewertungen

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteDokument4 SeitenStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniNoch keine Bewertungen

- B28 VivaDokument27 SeitenB28 VivashubhamNoch keine Bewertungen

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionDokument4 SeitenDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileNoch keine Bewertungen

- Math 9 Textbook AnswersDokument43 SeitenMath 9 Textbook AnswersMehak GillNoch keine Bewertungen

- Mha Mca Cet SyllabusDokument20 SeitenMha Mca Cet Syllabusm kumarNoch keine Bewertungen

- Grade 9 Cells and Cell Movements Formative WorksheetDokument8 SeitenGrade 9 Cells and Cell Movements Formative WorksheetHari PatelNoch keine Bewertungen

- Maharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified) Winter - 2022 Examination Model Answer Subject: 22619Dokument22 SeitenMaharashtra State Board of Technical Education (Autonomous) (ISO/IEC - 27001 - 2005 Certified) Winter - 2022 Examination Model Answer Subject: 22619Pratiksha JadhavNoch keine Bewertungen

- Caliper Xy MemoryDokument6 SeitenCaliper Xy MemoryA MuNoch keine Bewertungen