Beruflich Dokumente

Kultur Dokumente

EMX 11 G MKA - GA71 EA 012-R En-Generator Protection

Hochgeladen von

RichardLemusOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EMX 11 G MKA - GA71 EA 012-R En-Generator Protection

Hochgeladen von

RichardLemusCopyright:

Verfügbare Formate

Generator Protection

EVM II

EVM Energía del Valle de México II

Combined Cycle Power Plant

Owner Contractor

GE Global Parts & Products GmbH

General Electric Global Services GmbH, México Branch

Grid Solutions México S.A de C.V

GE POWER

Gas Power Systems

Project Document Code EMX/11/G/MKA---GA71/EA/012

Title Generator Protection

Identification Number GEK75512

Revision

Revision R 2018-04-10

Date

KKS

Information Class, if applicable, on pg. 1 et sqq

DWG Number GEK75512 Rev R Released 11/21/2017 Page 1 of 39

g

GEK 75512R

Revised, October 2017

GE Energy

Generator Protection

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to

be met in connection with installation, operation or maintenance. Should further information be desired or should particular

problems arise which are not covered sufficiently for the purchaser's purposes the matter should be referred to General Electric

Company. These instructions contain proprietary information of General Electric Company, and are furnished to its customer solely

to assist that customer in the installation, testing, operation, and/or maintenance of the equipment described. This document shall

not be reproduced in whole or in part nor shall its contents be disclosed to any third party without the written approval of General

Electric Company.

© 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 2 of 39

GEK 75512R Generator Protection

The following notices will be found throughout this publication. It is important that the

significance of each is thoroughly understood by those using this document. The definitions are

as follows:

NOTE

Highlights an essential element of a procedure to assure correctness.

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, could result in minor

or moderate injury or equipment damage.

WARNING

INDICATES A POTENTIALLY HAZARDOUS SITUATION, WHICH, IF

NOT AVOIDED, COULD RESULT IN DEATH OR SERIOUS INJURY

***DANGER***

INDICATES AN IMMINENTLY HAZARDOUS SITUATION,

WHICH, IF NOT AVOIDED WILL RESULT IN DEATH OR

SERIOUS INJURY.

2 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 3 of 39

Generator Protection GEK 75512R

TABLE OF CONTENTS

I. INTRODUCTION ....................................................................................................................................... 4

A. Standards................................................................................................................................................ 4

B. Protection Responsibility ....................................................................................................................... 4

C. Protection Equipment............................................................................................................................. 5

II. RELATIONSHIP BETWEEN OPERATION, PROTECTION AND ALARMS ................................. 6

A. Operation and Protection ....................................................................................................................... 6

B. Protection and Alarms............................................................................................................................ 6

III. ALARMS ...................................................................................................................................................... 6

IV. PROTECTION WHEN GENERATOR IS OFF LINE ........................................................................... 6

V. PROTECTION DURING STATIC START ............................................................................................. 7

VI. TRIPPING METHODS .............................................................................................................................. 7

VII. PROTECTION RECOMMENDATIONS .............................................................................................. 10

Electrical Faults ............................................................................................................................. 10

System Faults ................................................................................................................................. 16

System Operations ......................................................................................................................... 20

Mechanical or Thermal Faults ....................................................................................................... 24

VIII. REFERENCES .......................................................................................................................................... 38

LIST OF FIGURES

Figure 1: Recommended V/Hz protection............................................................................................................ 14

LIST OF TABLES

Table 1. Alarms .................................................................................................................................................... 33

Table 2. Summary of Protection Recommendations ............................................................................................ 36

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 3

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 4 of 39

GEK 75512R Generator Protection

I. INTRODUCTION

This instruction book insert was prepared to provide a summary of General Electric's recommendations

for protection of its cylindrical rotor synchronous generators. Since a wide variety of technology is

applied to machines of various size and rating, not all of the alarm and protection recommendations are

applicable for a given generator design. For example, references to hydrogen and stator water cooling

systems are not applicable to air cooled machines. The alarm and protection sections are sequenced so

that recommendations which are generally applicable appear first, ones related to hydrogen systems next,

and finally stator water cooling system alarms and protection. Recommendations for excitation system

protection are not included, but are covered in separate instructions.

This instruction book discusses the kinds of protection that are desirable, and the action that is believed to

be best for the needed protection. Specific relays and relay circuits are not discussed.

A. Standards

General Electric turbine-generators are designed and built to meet or surpass applicable industry

accepted standards. For the cylindrical rotor synchronous generators covered by these instructions,

these standards are:

1. IEEE C50.13

IEEE Standard for Cylindrical-Rotor 50 Hz and 60 Hz Synchronous Generators Rated 10 MVA

and Above

2. IEEE C50.14

Requirements for Combustion Gas Turbine Driven Cylindrical Rotor Synchronous Generators

3. IEC 60034-1

Rotating Electrical Machines - Rating and Performance

4. IEC 60034-3

Rotating Electrical Machines - Specific requirements for synchronous generators driven by

steam turbines or combustion gas turbines

B. Protection Responsibility

There are IEEE Standards covering generator protection which provide guidance material on

generator protective relaying. These include:

1. IEEE C37.101

IEEE Guide for Generator Ground Protection

2. IEEE C37.102

IEEE Guide for AC Generator Protection

3. IEEE C37.106

IEEE Guide for Abnormal Frequency Protection for Power Generating Plants

4 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 5 of 39

Generator Protection GEK 75512R

The combination of above IEEE/IEC standards are accepted by the industry today as the most

prominent standards for generator protection. At the time of the original publication of this document,

two IEEE Press Books were published which also provide a useful anthology of the background

material related to generator protection. These are:

1. Protective Relaying for Power Systems: Volume 1, IEEE Press, 1980.

2. Protective Relaying for Power Systems: Volume 2, IEEE Press, 1992.

Another useful reference is the IEEE Buff Book from the color series - IEEE Standard 242 – 2001

IEEE Recommended Practice for Protection and Coordination of Industrial and Commercial Power

Systems.

The operating limits specified by the manufacturer may be inadvertently exceeded for a number of

reasons. These include, among others:

internal generator failure

auxiliary equipment failure

operator error

abnormal system conditions

The protection methods and equipment in place should be able to safely protect the generator no

matter which of these circumstances, or combination of them, causes the abnormal operation.

Since protective relays and other devices are not immune to failure, it is recommended that

consideration be given to providing back-up protection for those faults where a device failure could

subject the generator to serious damage.

Generator protection is a large and complex subject. These instructions were written to provide

information on protection, based on our experience as designers and manufacturers that may not

always be readily available in other forms.

The recommendations contained in these instructions are based on the best available information at

the time of publication. Changes in the state of the art may result in modification of these

recommendations. Such modifications will usually be communicated to all owners of affected

turbine-generators through General Electric Technical Information Letter (TIL) series. These

modifications will be incorporated in periodic revisions to these instructions.

C. Protection Equipment

It should not be assumed that any required hardware is part of the turbine-generator supplied,

although in certain cases some protection is due to special requirements or it is integrated into the

excitation or control system.

In either case, it is the owner's or his designee’s responsibility to check, adjust, calibrate and connect

all protective equipment to suitable tripping relays or circuits in order to provide the intended

protection. The manufacturer should be consulted for specific protection application issues or

concerns.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 5

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 6 of 39

GEK 75512R Generator Protection

II. RELATIONSHIP BETWEEN OPERATION, PROTECTION AND ALARMS

A. Operation and Protection

The line between generator operation and protection is not always clear and there is inevitably an

area of overlap. These instructions cover those functions that are mainly performed by protective

relaying or similar devices or functions. A companion instruction (Ref. 1) covers those aspects of

generator operation that are mainly under control of an operator and/or electronic turbine-generator

controller. Both of these publications should be consulted during plant design and should be used in

conjunction with other parts of the instruction book for proper operation of the turbine-generator.

B. Protection and Alarms

Those protective relays or devices that trip the generator should alert an operator as to the cause of

any trip, and be able to take direct action if this should prove necessary. In addition to the tripping

relays there are other relays or devices that initiate only an alarm or data logging. In these cases, it

becomes an operator's responsibility to decide what corrective action is required and to take it.

III. ALARMS

Many of the "alarm only" devices are for temperature measurement. These are Resistance Temperature

Detectors (RTDs) and Thermocouples (TCs). Some measure other variables such as hydrogen pressure

and purity, and stator cooling water pressure, flow and conductivity (if applicable). A typical list of alarm

devices furnished with the generator is given in Table 1, including recommended alarm points and signal

ranges. If additional special instrumentation is supplied, alarm settings will be specified in the appropriate

section of the instruction book.

Table 1 contains information which may be useful when specifying signal monitoring or recording

equipment.

The table also includes typical ranges of the variable for each of the devices shown. These ranges do not

represent the actual capabilities of the generator or its auxiliary equipment and should not be used in any

way as a guide for operation.

When a protective device or function signals a trip, or when the operator trips the unit because of an

alarm or other indication of malfunction, it is most important that the cause of the problem be determined

and corrected before attempting to restart or resynchronize. Failure to do so may lead to more serious

troubles.

IV. PROTECTION WHEN GENERATOR IS OFF LINE

The need for protecting a generator while on line is well known, but the need when off line may not be as

well understood. Nevertheless, there are circumstances under which a generator could be damaged while

off line.

For this reason, it is recommended that, as a general rule, all alarms and protections be kept operative at

all times. Exceptions to this rule are those protections which would not operate properly or give false

signals when the unit is below rated speed, not excited, or not synchronized. Relaying and interlocking

circuitry that operates when the unit is off line should be reviewed to make certain it does not

inadvertently incapacitate any essential protection.

6 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 7 of 39

Generator Protection GEK 75512R

V. PROTECTION DURING STATIC START

Most GE heavy-duty gas turbines employ static starter (Load Commutated Inverter, LCI) to accelerate

the turbine to a self-sustaining rotational speed.

The LCI has a built-in DC ground fault protection scheme. Proper operation of this scheme requires that

there be no closed path to the neutral to avoid a possible damage to the power electronics in the event of a

DC ground fault. Therefore, the generator must remain ungrounded (neutral disconnect switch open) for

the duration of LCI start.

Ground fault protection schemes in protective relays that rely upon the measurement of generator neutral

voltage will not be available while the neutral disconnect switch is open. Ground fault protection

available in the LCI is generally deemed to be adequate for this short duration and the overall scheme

appropriate to protect expensive power electronics against any possible grounds during LCI operation.

Other generator protection functions that are required to be blocked prior to closing of the generator

breaker to avoid mis-operation will naturally not be available during static start. If the zone of differential

protection covers multiple regions and one of them senses the LCI current during static start, a separate

group of de-sensitized settings should be enabled during this period to avoid mis-operation of the

differential protection.

VI. TRIPPING METHODS

There are a number of ways a turbine-generator, or a generator alone, may be tripped, i.e., disconnected

from the system or shut down. Some of the factors that should be considered in determining what type of

trip to use for each fault requiring one are:

severity of fault to generator

probability of fault spreading

amount of overspeed resulting

probability of high overspeed

importance of removing excitation

need for maintaining auxiliary power

need for shutting down the unit

time required to resynchronize

effect on the power system

In recognition of the factors above, the manufacturer recommends an action that insures protection of the

generator. Unless otherwise noted, a protective action with a lower number than the recommended action

is allowable (see Table 2). Although the lower number protective action may provide faster protection,

additional danger to the turbine is incurred. These dangers include higher overspeed and worse turbine

thermal shock duty. The recommended protective actions are selected based on the manufactures

judgment with regard to providing acceptable generator protection, while minimizing unnecessarily harsh

turbine duty. The owner should select the action to be used based on the importance of the applicable

factors in his case. The number of ways a generator can be tripped from faults is categorized into the

following (trip) types with some notable differences in gas turbine vs. steam turbine driven generators.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 7

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 8 of 39

GEK 75512R Generator Protection

Note that for single shaft combined cycle applications where a gas turbine and a steam turbine share a

common generator, protection considerations can be made as if the prime mover were gas turbine. This is

because the primary danger of steam turbine overspeed is generally mitigated by the inertia from the gas

turbine compressor. Also, any interface of the protective system that need to be made with the turbine

control system will only be to that of the gas turbine controller.

1. Simultaneous trip - trips the turbine valves closed, opens generator line breakers and removes

excitation simultaneously, as with a lock-out relay. A Simultaneous trip is acceptable for all (gas

turbine or steam turbine) generator faults, and generally provides the highest degree of protection

for the turbine-generator although it does permit a small overspeed and there is a slight

probability of high overspeed.

2. Generator trip - opens the generator line breakers and removes excitation simultaneously, but

leaves the turbine running near rated speed. Where maintaining speed is not harmful, this

provides as high a degree of protection for the generator as a Simultaneous trip (Type 1). If the

plant can operate following a full load rejection, and if the cause of the trip can be identified and

rectified quickly, it may make resynchronization possible in a shorter time than Type 1. Since it

does result in a higher overspeed than Type 1, it should only be used when there is an advantage

in not tripping the turbine.

It should be noted that high overspeed events in a gas turbine, while possible, are not as likely or

as severe as in a steam turbine. As a result, tripping just excitation and the generator breaker is

acceptable in gas turbine-generator applications but should be avoided for steam

turbine-generators other than those in single shaft combined cycle applications.

3. Breaker trip - trips all generator line breakers but not the excitation or the turbine. This trip has

advantages similar to Generator trip, Type 2 when the fault permits excitation to remain applied,

and can be applied regardless of whether the prime mover is gas or steam turbine. Its advantage

over Type 2 is that it provides auxiliary power in cases where this cannot be switched to another

bus. If this is not an advantage, Types 2 or 1 should be used.

4. Sequential trip (exclusive to multi-shaft steam turbines) - trips the steam turbine first. When the

steam turbine inlet valve limit switches indicate the valves are closed, and the recommended

reverse power relay (or function) operates, normally after a three-second delay, the generator line

breakers are tripped. Opening of the breakers then trips excitation. This trip should prevent any

overspeed and thus is preferred whenever the risk from a three-second delay in tripping the

generator is slight. This is the preferred method for executing a normal shutdown of a steam

turbine generator.

Certain multiple limit-switch failures, or a reverse power relay failure, can prevent completing

the trip. Although this probability is small, a second reverse power relay, with a 10 to 30 second

time delay, connected to produce a Type 3, Breaker Trip, is recommended as a back-up. This

back-up relay also serves as the primary protection for motoring which does not occur as part of

a Sequential trip.

5. Manual trip - turbine is tripped manually. In a steam turbine, when generator power reverses,

reverse power relay trips generator line breakers. Breaker opening trips excitation. This trip is

recommended whenever an operator sees the need for a fault trip and is not certain that a

Runback and trip (Type 6) will be fast enough. Note that Type 5 is actually a manually initiated

Sequential trip.

8 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 9 of 39

Generator Protection GEK 75512R

NOTE

There are no cases for which manually tripping the generator breakers is

recommended. This is because the generator breakers should not normally be

tripped until after the turbine has been tripped and power has reversed. Then the

generator breakers should be automatically tripped by the reverse power relay. A

protected bypass switch may be used to permit manually tripping the generator

alone in case of limit-switch or reverse power relay failure. A manual generator

breaker trip should only be used with full recognition of the risk involved.

6. Manual runback and trip - manually decreases turbine output to low level or to zero, followed

by a Breaker trip in a gas turbine generator or a Sequential trip in a steam turbine generator. This

is the "normal" trip, which is preferred for all normal shutdowns. It is also recommended for

trips required by alarms when the operator judges a Type 5 Manual trip is not essential.

7. Automatic runback - reduces load (via turbine control) at a preset rate to a preset load. It is

recommended here only for loss of stator coolant (if required). It is an alternative to tripping the

unit, and permits continuing on line at a very low load. When it can be used, it has the advantage

of enabling earlier return to full load if the trouble can be quickly corrected.

8. Manual runback - manually reduces load at a rate and to a level determined by operator. This is

useful for some faults which may be load sensitive, such as local overheating, and where there is

no need to trip immediately. It also allows the generator to continue to supply reactive power to

the system.

The recommendations in these instructions are intended to provide the best-balanced protection for

the turbine-generator for generator faults. Unusual circumstances or other plant limitations must be

considered by the owner, and may require different actions. Turbine problems should be handled in

accordance with applicable turbine instructions.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 9

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 10 of 39

GEK 75512R Generator Protection

VII. PROTECTION RECOMMENDATIONS

The remainder of this instruction book comprises discussions of, and detailed recommendations for, each

of the "faults" listed in the table of contents, and summarized in Table 2.

References are listed at the end of the book.

Electrical Faults

1. Stator Overcurrent

1. Description

Generators are designed to operate continuously at rated kVA, frequency and power factor

over a range of 95 to 105% of rated voltage. Operation beyond rated kVA may result in

harmful stator overcurrent. Note that at rated kVA, 95% voltage, stator current will be

105%. This is permissible.

Normally, generator load is under the control of an operator. Situations can arise during

system disturbances, such as accompanying generator or line trip-outs, which can result in

an overcurrent condition.

For short times, it is permissible to exceed the current corresponding to rated kVA. This

capability is specified in IEEE Standard C50.13 as follows:

Time (seconds) 10 30 60 120

Armature current (percent) 226 154 130 116

2. Detection

Stator current should be monitored by an operator, and kept within rated value by

adjustment of the turbine-generator controls.

A consequence of overcurrent is stator winding overheating, which should be detected by

winding temperature detectors, usually TCs measuring stator cooling water temperature,

and/or RTD's in slots with the stator winding (if applicable). All functioning TCs and RTDs

should be continuously monitored and alarmed (see Ref. 1, and 2&3 for H2O cooled

machines). However, even though it may not result in excessive stator winding

temperatures, operating above specified currents is not an acceptable practice since

unmonitored phenomena, such as temperatures in other parts of the stator circuit, winding

forces, abnormal magnetic fields, etc., may become excessive.

3. Recommendation

Automatic tripping is not provided for protection against stator overcurrent. However, all

operators should be made aware of the importance of operating the generator within its

rated capability. In cases when a generator will operate in an unattended station, some form

of overcurrent (overload) protection should be provided. An alternative is stator

overtemperature which provides similar protection. For additional information, see Ref. 1.

10 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 11 of 39

Generator Protection GEK 75512R

2. Stator Ground Fault

1. Description

The generator stator neutral normally operates at a potential close to ground, generally

through a high impedance grounding transformer/resistor. In some cases, a reactor is used in

a resonant grounding arrangement. Should a phase winding or any equipment connected to

it fault to ground, the normally low neutral voltage could rise as high as line-to-neutral

voltage, depending on fault location.

Although a single ground fault will not necessarily cause immediate damage, the presence

of one increases the probability of a second. This is because the occurrence of such a fault is

probably the result of damage which is not confined to one spot. In fact, the existence of a

ground fault through tough, high-voltage insulation is usually a result of another, potentially

catastrophic, trouble. A second fault, even if detected by differential relays, may cause

serious damage. A second fault in the same phase will not be detected by differential relays,

and could cause serious damage as a result.

2. Detection

The usual method of detection is by a voltage relay across the grounding resistor. A current

relay is sometimes used in place of a voltage relay or as a back-up. The relay should be

insensitive to third harmonic voltage, but should have as low a pick-up level at line

frequency as is practical to reduce the unprotected zone at the neutral end of the windings.

Methods are available which are designed to protect the entire winding. These schemes

include monitoring the third harmonic voltage at the generator neutral, as well as comparing

third harmonic voltages at the generator line and neutral terminals.

Another method to detect ground faults in 100% of the stator windings is to inject a sub-

harmonic frequency voltage signal via the generator neutral. In the event of a ground fault,

the relay can measure the increased current resulting from the smaller impedance of the

ground fault path, and this sub-harmonic overcurrent and/or the sub-harmonic resistance

(calculated by the relay from the injected voltage and fault current) can be used to detect

presence of stator grounds. The injection based scheme has an advantage over the third

harmonic based schemes in that protection can be available when the generator is online as

well as offline, as long as injection is enabled. These schemes supplement the fundamental

frequency neutral voltage based protection.

WARNING

IF INJECTION BASED GROUND FAULT DETECTION SCHEME IS

EMPLOYED DURING GENERATOR OFFLINE CONDITIONS, IT

MUST BE ENSURED THAT THE INJECTION VOLTAGE SOURCE IS

DISABLED AND LOCKED OUT/TAGGED OUT PRIOR TO

PERFORMING MAINTENANCE ON THE GENERATOR OR ANY

EQUIPMENT CONNECTED TO THE GENERATOR LINE AND

NEUTRAL TERMINALS.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 11

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 12 of 39

GEK 75512R Generator Protection

3. Recommendations

The grounding impedance should limit the ground fault current to less than 25 amperes. The

usual criterion based on circuit capacitance will normally result in less than 10 amperes. The

stator ground fault relay should be connected to trip the unit within several seconds, via a

Simultaneous trip, Type 1.

For further information, see Ref. 5.

3. Stator Phase-to-Phase Fault

1. Description

A stator phase-to-phase fault is any electrical fault between two phases of the armature

winding. This type of fault is very serious because very large currents can flow and produce

large amounts of damage to the winding if allowed to persist. Because of the nature of the

construction of the armature it is very likely that this type of fault will grow to include

ground, thereby causing significant damage to the stator core.

2. Detection

It is possible to detect a phase-to-phase fault in the winding by means of a differential relay.

This method provides protection for the entire winding, and its sensitivity is limited mainly

by the degree to which the various current transformers are matched.

The differential relay method cannot protect against a fault within one phase of the winding.

Such a turn-to-turn fault can only be detected by the resulting armature current unbalance.

However, such faults are rare and will usually include ground, in which case they will be

detected by the stator ground fault relay.

3. Recommendations

Upon detection of a phase-to-phase fault in the winding, it is imperative that the unit be

tripped without delay, using a Simultaneous trip, Type 1.

4. Over-Voltage

1. Description

Permissible voltage limits under various operating conditions are given in the Generator

Operation instructions (Ref. 1). It is normally an operator's responsibility to maintain

voltage (and the corresponding kVA) within specified limits.

With turbine-generators it is unlikely that voltage will depart significantly from the preset

value. If it does, due to a regulator failure or a system disturbance, a trip signal will usually

be produced by one of the protective relays, such as volts/Hertz or maximum excitation

limit.

2. Recommended Action

Therefore, specific over-voltage protection is generally not required for the generator. In

cases where protective relays are set to provide over-voltage protection, it should be

programmed to produce a Generator trip, Type 2. However as mentioned above, such a trip

12 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 13 of 39

Generator Protection GEK 75512R

will already be available from the volts/Hertz or upper excitation limit in the Exciter.

Depending on the circumstances, it may be desirable to protect other equipment connected

to the generator. For unmanned generating stations, consideration should be given to

implementing automatic over voltage protection. For additional info, see Ref. 1.

5. Volts Per Hertz

1. Description

Per unit voltage divided by per unit frequency, commonly called volts/Hertz, is a readily

measurable quantity that is proportional to flux in the generator and step-up transformer

cores.

Moderate over fluxing (105%-110%) increases core loss, elevating core temperatures for all

generator designs and armature temperatures for generators with conventionally cooled

stator windings. Long term operation at elevated temperatures can shorten the life of the

stator insulation systems. More severe over fluxing (above 110%) further increases core

loss, and saturate portions of the core to the point that flux flows out into adjacent

structures. The resulting induced voltages can be coupled to stator punchings due to the

manner in which cores are assembled and clamped. Severe over fluxing can breakdown

interlaminar insulation, followed by rapid local core melting.

Over-volts/Hertz can be caused by regulator failure, load rejection while under control of

the dc regulator, or excessive excitation with the generator off line.

It can also result from decreasing speed while the ac regulator or the operator attempts to

maintain rated stator voltage.

2. Detection

The volts/Hertz sensor is normally included as part of the excitation system, and are this

protection is also built-into modern microprocessor based protective relays.

3. Recommendation

Even though over-volts/Hertz is more likely to occur when offline, it can also occur when

on line. For this reason, the volts/Hertz protection should be in operation whenever

excitation is applied.

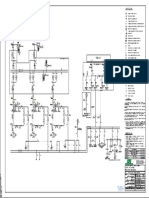

Refer to Figure 1 for a graphical representation of the recommended V/Hz protection.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 13

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 14 of 39

GEK 75512R Generator Protection

Figure 1: Recommended V/Hz protection

In view of the potential consequences it is prudent to provide as conservative protection as

possible consistent with security from false tripping. Selection of a modest maximum trip

level of above 118%, coupled with a 2 second time delay satisfies these objectives. A load

rejection from full rated KVA, rated power factor and 105% of rated voltage will not result

in tripping if an automatic voltage regulator is in service. Operation at 118% should be

limited not to exceed 45 seconds. The curve shape from 118 to 110% V/Hz approximates

the over excitation capability of many transformers (for step-up and station service power

applications). However, if the transformers require lower values, the protective relays

should be set accordingly. The excitation control limiter (if applicable) should be set to

prevent continuous operation above 109.5%.

The trip signal should produce a Generator trip, Type 2 or a Simultaneous trip, Type 1.

6. Field Over excitation

1. Description

The generator field winding is designed to operate continuously at a current equal to that

required to produce rated kVA at rated conditions. In addition, higher currents are permitted

for short times, to permit field forcing during transient conditions. These limits are specified

in terms of a curve of field voltage vs. time defined by the following points in IEEE C50.13:

Time (seconds) 10 30 60 120

Field voltage (percent) 208 146 125 112

14 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 15 of 39

Generator Protection GEK 75512R

2. Detection

Most excitation systems now being furnished include an Upper Excitation Limit function.

Its purpose is to prevent prolonged field overcurrent by recalibrating the current regulator,

transferring to another regulator, and, finally, producing a trip signal, as required.

3. Recommendation

The owner's responsibility with respect to this function is to see that the Upper Excitation

Limit is properly adjusted and maintained, and properly connected to trip the unit when

required. Protection Type 2, Generator trip, or Type 1, Simultaneous trip, is recommended.

Since loss of potential transformer signal to the voltage regulator is one cause of field

overcurrent, relaying to detect this situation and automatic transfer to another regulator is

suggested. Sensing and transfer functions are part of most modern excitation systems.

7. Field Ground

1. Description

The generator field winding is electrically isolated from ground. Therefore, the existence of

one ground fault in the winding will usually not damage the rotor. However, the presence of

two or more grounds in the winding will cause magnetic and thermal imbalances plus

localized heating and damage to the rotor forging or other metallic parts. Unfortunately, the

presence of the first ground fault makes detection of a second fault difficult, if not

impossible. In addition, modern rotor winding insulation systems have achieved a level of

quality that reduces the likelihood of a field ground except under unusual circumstances

where the probability of occurrence of a second ground or other serious problem is high.

2. Detection

The relay necessary to detect a field ground is normally supplied with the excitation system.

3. Recommendation

It is recommended that the field ground detector be connected to produce a Generator trip,

Type 2 or a Simultaneous trip, Type 1.

8. Loss of Excitation

1. Description

Loss of excitation (or loss of field) results in loss of synchronism and operation of the

generator as an induction machine. This will result in the flow of slip frequency currents in

the rotor body, wedges, and amortisseur windings (if so equipped), as well as severe torque

oscillations in the rotor shaft. The rotor is not designed to sustain such currents, nor is the

turbine-generator shaft designed to long withstand the alternating torques. The result can be

rotor overheating, coupling slippage and even rotor failure. The length of time before

serious damage occurs depends on the generator load at the time of the incident, slip

frequency, and whether the field winding is open circuited or shorted, and may be a matter

of seconds.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 15

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 16 of 39

GEK 75512R Generator Protection

A loss of excitation normally indicates a problem with the excitation system which,

depending on its nature, could be serious (e.g., collector ring flashover, if so equipped).

Because of the VARs absorbed to make up for the low or lost excitation, some systems

cannot tolerate the continued operation of a generator without excitation. Consequently, if

the generator is not disconnected immediately when it loses excitation, widespread

instability may very quickly develop, and major system shut-down may occur.

2. Detection

Since loss of excitation results in a marked change in reactive kVA, a loss of excitation

relay of the impedance or mho type is usually used (Ref. 6).

3. Recommendation

The generator should be tripped from the power system, using a Simultaneous trip (Type 1),

or a Generator trip (Type 2). It is important that all excitation power be removed. It should

not be assumed that, since there is loss of excitation, the exciter is not supplying power to an

internal fault.

System Faults

9. Unbalanced Armature Currents

1. Description

When the generator is supplying an unbalanced load, the phase currents and terminal

voltages deviate from the ideal balanced relationship, and a negative phase sequence

armature current (I2) is imposed on the generator. The negative sequence current in the

armature winding creates a magnetic flux wave in the air gap which rotates in opposition to

the rotor at synchronous speed. This flux induces currents in the rotor body iron, wedges,

retaining rings and amortisseur windings, if so equipped, at twice the line frequency.

Heating occurs in these areas and the resulting temperatures depend upon the level and

duration of the unbalanced currents. Under some conditions, it is possible to reach

temperatures at which the rotor materials no longer contain the centrifugal forces imposed

on them, resulting in serious damage to the turbine-generator set (Ref. 11).

There is always some low-level unbalance in any power system and therefore limits on the

continuous unbalance have been established. For currents above the permissible continuous

levels, a limit on the time-integral of I22 has been established for times up to 120 seconds.

Such levels will often result from faults, open lines or breaker failures.

Unless otherwise specified by the manufacturer as part of the generator design data

information, the negative sequence current limits are given in the applicable standards (Ref

31 or Ref 32), where I2 is the per unit negative sequence current on the generator base and t

is the time in seconds. See Ref 1 for further comments on unbalanced loading capability.

2. Detection

The protection scheme should be designed such that it will permit negative sequence

currents up to the continuous limit, but produce a trip signal if the level exceeds this value

long enough to reach the permissible I22t limit (Ref 13).

16 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 17 of 39

Generator Protection GEK 75512R

It is also desirable to alert an operator when I2 exceeds a normal level, which may be lower

than the permissible continuous negative sequence current. This enables the operator to

adjust load in order to prevent a trip. Ref. 1 describes in more detail the actions an operator

may take.

3. Recommendations

A negative sequence relay, similar to that described above, should be used on all units. It

should be arranged to cause a Generator trip, Type 2, or a Simultaneous trip, Type 1.

10. Loss of Synchronism

1. Description

Loss of synchronism, also referred to as out-of-step operation or pole slipping, can occur as

a result of steady-state transient or dynamic instability. It also may occur as a result of loss

of excitation or synchronizing errors.

2. Detection

The majority of users do not apply specific loss-of-synchronization relaying. However, a

skilled relay engineer can adjust impedance relaying to reliably detect loss of synchronism.

Loss of excitation relays may provide detection, but cannot be relied upon under all

conditions. If the electrical center during loss of synchronism is in the transmission system,

line relays may detect it. If they do not, specific relaying should be provided.

3. Recommendation

Out-of-step operation can result in pulsating torques and winding stresses and high rotor

iron currents that are potentially damaging to the generator. Excessive stator winding and

core end heating can also result if the out-of-step operation is caused by reduced or lost

excitation. Therefore, it is recommended that the generator be separated from the system

without delay, preferably during the first slip cycle (Ref. 14, 26, 27.). A Breaker trip, Type

3, is recommended, and permits the fastest resynchronization after conditions have

stabilized.

11. Abnormal Frequency Operation

1. Description

For a generator connected to a power system, abnormal frequency operation is a result of a

severe system disturbance. An isolated or unconnected unit could operate at low or high

frequency due to improper speed control adjustment or mis-operation of the speed control.

There are two effects to be considered. The generator can tolerate under frequency operation

for long periods, provided load and voltage are sufficiently reduced, as explained in

Generator Operation instructions (Ref. 1).

The generator can also tolerate over frequency operation provided voltage is within an

acceptable range.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 17

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 18 of 39

GEK 75512R Generator Protection

2. Recommendation

For the generator, specific protection for abnormal frequency operation is not required.

However, the turbine is very sensitive to abnormal frequencies and recommendations given

for it should be carefully studied and followed (Ref. 25). Additionally, refer to GER3620k

(Heavy Duty Gas Turbine Operating and Maintenance Considerations), GEK103801

(Turbine Off-frequency Operation (for 60Hz Modern Units)) and GEK103802 (Turbine

Off-Frequency Operation (for 50Hz Modern Units)) for guidelines on GE turbine off-

frequency operations. Detection of abnormal frequency operation may also be used to

identify system problems.

Refer further questions on unusual frequency operation to the GE Company for

recommendations.

12. Breaker Failure

1. Description

Since most faults involving the generator require tripping of the generator/line breakers,

failure of any of them to open properly results in loss of protection and/or other problems,

such as motoring. If one or two poles of a generator line breaker fail to open, the result can

be a single-phase load on the generator and negative sequence currents on the rotor.

2. Detection

Both types of failure described above will cause conditions that may be detected by other

protective devices, e.g., reverse power, loss of synchronism or negative sequence relays.

However, a more direct method is the use a dedicated Breaker Failure protection, which

uses an overcurrent relay with a set time delay.

Part of the breaker failure scheme, energizes a Breaker Failure Initiate (BFI or IBF) signal

when any breaker trip is initiated. The status of breaker is monitored using the auxiliary

breaker contacts wired to the relays. If it is determined that the breaker is still closed after

the original trip command is sent, a re-trip signal can be sent immediately as one last

attempt to open the breaker without initiating tripping of other plant breakers.

A current detector, in conjunction with the breaker auxiliary contacts, is used to monitor

continued presence of current in any one or more phases after the original trip signal was

sent to the breaker.

3. Recommendation

Industry past practice has not always recognized the need for breaker failure protection

because of the reliability of generator breakers. However, it is recommended that breaker

failure protection be used with all tripping relays that can trip a generator breaker.

If a confirmation of breaker tripping in all three phases via the current detector or from the

breaker auxiliary contacts is not received after a suitable time delay (typically not less than

the longest possible operating time of the breaker), a signal is sent to trip all breakers that

can feed current to the generator through the failed breaker (Ref 15).

18 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 19 of 39

Generator Protection GEK 75512R

13. System Back-Up

1. Description

System back-up protection is also known as external fault back-up protection. As this name

implies, it is used to protect the generator from supplying short circuit current to a fault in

an adjacent system element because of a primary relaying failure (Ref. 15, 16).

2. Detection

Either voltage restrained or current restrained inverse-time overcurrent or distance relays

may be used, depending on the kind of relaying with which the back-up relays must be

selective. Negative sequence relays, in addition to their primary protective role, are

sometimes considered for system back-up protection. However, these will not provide

protection against balanced faults.

3. Recommendation

System back-up protection is recommended. A breaker trip Type 3 is recommended, which

permits the fastest resynchronization after the system fault has been cleared. In Steam

turbines, if immediate resynchronization is not a priority, a Type 1 trip may be considered to

trip the turbine, exciter and generator breaker simultaneously.

14. Voltage Surges

1. Description

Certain abnormal conditions could occur which might subject the generator to high voltages

surges. Among these are:

Switching surges from circuit breakers at generator voltage

Positive and negative surges arriving simultaneously on two phases

Ineffective direct stroke shielding

Failure of high side surge protective equipment

Accidental connection between high and low side transformer windings, due to

internal failure, external flashover or other cause

The latter category is not a normal protective function of low voltage arrestors and would

subject them to excessive duty which could cause their failure. In view of the potential

personnel hazard in the event of surge arrestor failure, the user should consider physically

isolating the surge arrestor cubicles and limiting access to them.

2. Recommendation

To provide protection for these and similar situations, surge arrestors are recommended for

all units. Surge capacitors are generally not required for machines with single-turn coils.

They are provided on some packaged generators where optional installation of surge

capacitors close to the surge arrestors would not be convenient. Application of LCI (load

commutated inverters) for turbine-generator starting may also obviate the use of surge

capacitors on multi- turn coil machines.

Optimal protection requires surge protection be located in close proximity to the generator

terminals.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 19

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 20 of 39

GEK 75512R Generator Protection

System Operations

15. Transmission Line Switching

1. Description

The switching of transmission lines at or near generating stations for maintenance purposes,

or simply restoring a line to service after a relayed trip, are recognized as normal functions

in the course of operating a power system. In some cases, these line switching operations

can subject nearby generating units to excessive duty. The effect on the generator in severe

cases is the same as for poor synchronizing in causing possible stator winding and shaft

fatigue damage (Ref. 7).

2. Detection

A measure of the severity of a switching event is the sudden step change in power (AP) seen

by the generator at the instant of switching. As a general guide, studies have shown that

where AP does not exceed 0.5 per unit on the generator kVA base the duty will be

negligible (Ref. 17, 18). Values of AP greater than 0.5 per unit may be determined to be

non-harmful to the generator, for specific units and system switching events, but these cases

should be carefully studied and identified.

Predetermination of duties associated with line-switching operations and operating

procedures which limit these duties to acceptable values can be found from simulating these

operations, using a computer program such as that normally used for stability studies (Ref.

17, 18).

3. Recommendation

The recommended procedure for avoiding excessive duty for the normal planned line-

switching operation is to establish, where necessary, operating procedures which limit the

machine AP to either the general 0.5 per unit level or an individually determined level for

that unit.

As an adjunct to established operating procedures, phase angle check relays at key breaker

locations can prevent line closings under circumstances predetermined to be excessive.

Note, however, that such check relays should not be applied without reliable means of

overriding which would permit necessary line closing operations under emergency

circumstances.

20 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 21 of 39

Generator Protection GEK 75512R

16. High Speed Reclosing

1. Description

High speed reclosing of transmission circuits directly out of generating stations or

electrically close to the station may cause significant shaft fatigue damage to the turbine-

generator unit, particularly where high speed reclosing following severe multi-phase faults

is permitted (Ref. 7, 19). The actual fatigue duty which a unit may experience during its

lifetime from this cause depends on many factors, including both the unit's and the system's

characteristics, the frequency of fault occurrence, etc. Studies substantiate that significant

shaft damage could occur with unsuccessful reclosing for close-in three-phase faults.

2. Recommendation

In order to eliminate or reduce the potential effects of unrestricted high-speed reclosing of

lines near generating stations, an alternative reclosing practice such as one of the following

is recommended:

Delayed reclosing, with a delay of 10 seconds or longer.

Sequential reclosing, i.e., reclose initially only from the remote end of the line and

block closing at the station if the fault persists. This is recommended only if the

remote end of the line is not electrically near other turbine-generator units.

Selective reclosing, i.e., high speed reclosing only for the less severe faults such as

single line-to-ground; delayed reclosing on others. Other relaying practices

providing selectivity on the basis of fault severity would also be effective in

reducing shaft fatigue duty.

Where such alternative reclosing practices are not considered acceptable to the user, it is

recommended that either:

a. Detailed studies be performed to determine the probable lifetime fatigue damage

which might be experienced for the reclosing practice contemplated, or

b. Torsional monitoring equipment be installed to determine the accumulated fatigue

damage being incurred.

17. Subsynchronous Resonance (SSR)

1. Description

When a turbine-generator is connected to a transmission network that has series capacitor

compensation or a high voltage dc (HVDC) transmission system, it is possible to develop

subsynchronous (under line frequency) current oscillations in the lines and in the generator

armature. In the case of series compensated ac systems, these currents interact with the

synchronously rotating flux to produce torque pulsation on the generator rotor. If these

pulsations are at a frequency close to one of the torsional natural frequencies of the turbine-

generator, high levels of torsional vibration can be induced in the shafts. Torsional

instability of the turbine-generator shaft system has the potential for being extremely

damaging to the turbine-generator shafts, and resulted in two shaft failures in the early

1970s. A more recently observed phenomenon involves interaction between torsional modes

and HVDC controls (Ref. 28). This could lead to an unstable situation, resulting in

spontaneous growth of torsional vibrations and potential damage to the shaft.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 21

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 22 of 39

GEK 75512R Generator Protection

2. Detection

Unstable or high levels of torsional vibration may be detected by observing the variations in

angular velocity of the turbine-generator. A common measuring system involves a toothed

wheel, a magnetic pickup and a frequency demodulator. Strain gauge telemetry systems

have also been utilized in short-term tests to detect shaft torsional oscillations. Indirect

methods of identifying subsynchronous resonance steady-state instability problems involve

monitoring generator electrical terminal quantities. The armature current relay described in

Ref. 20 utilizes this approach.

3. Responsibility for Detection

It should be understood by those utilities that utilize series capacitor compensation, or have

HVDC transmission in their system, that the potential for damaging torsional vibrations is a

consequence of the special electrical characteristics of the transmission network. It is,

therefore, the owner's responsibility to implement devices to detect, and protect the machine

from, the influences of subsynchronous torsional interaction. In the case of HVDC

transmission lines, the potential for interaction between the HVDC controls and the turbine-

generator rotor system needs to be accounted for in HVDC control design. General Electric

has worked closely with many utilities on system studies to define the requirements for

protective devices on particular systems. The company has also manufactured and has in

service protective devices. This equipment includes (Ref. 20):

a. A static subsynchronous resonance filter (static blocking filter)

b. A supplementary excitation damping control (excitation system damper)

c. A machine frequency relay (armature current frequency relay) (Ref. 21)

d. A torsional vibration monitor (Ref. 22)

In addition, generators that are applied for use in series capacitor compensated systems or

systems containing HVDC transmission are sometimes furnished with pole-face amortisseur

windings. The addition of pole-face amortisseur windings does not necessarily enhance

negative sequence capability. The function of amortisseur windings is to reduce the machine

electrical resistance in the subsynchronous frequency range, which reduces the potential for

torsional interaction at subsynchronous frequencies.

4. Recommendation

It is vital that the electric utility work closely with the manufacturer at the planning stage to

define the need for auxiliary equipment to protect the machine. This equipment, if required,

needs to be operational when the machine is first connected to the network containing series

capacitor compensated and/or HVDC transmission lines. It needs to be highly reliable, as

mis-operation could result in major machine failure.

22 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 23 of 39

Generator Protection GEK 75512R

18. Inadvertent Energization

1. Description

When a generator is energized three-phase while at standstill or reduced speed, it will

behave and accelerate as an induction motor. The equivalent machine impedance during the

high slip interval can be represented by negative sequence reactance (X2) in series with

negative sequence resistance (R2). The machine terminal voltage and current during this

interval will be a function of generator, transformer and system impedances. If the

generator-transformer is connected to an infinite system, the machine currents will be high

(several per unit), and conversely, if the unit is connected to a weak system, the machine

current could be low (1-2 per unit). During the period the machine is accelerating, high

currents will be induced in the rotor and the time to damage may be on the order of a few

seconds.

NOTE

Negative sequence reactance of a steam turbine-generator is approximately equal to

the subtransient reactance X"dv.

A number of generators have been accidentally energized while at standstill or very

low speed. While many have survived the experience with minor damage, others

have not.

2. Detection

While there are several generator zone relays that may detect this contingency, their

performance may be marginal. Therefore, the preferred approach is to provide detection

means specifically designed for this purpose.

One such method is to use overcurrent relays that are armed by a speed relay when the

generator is offline. A more common approach today is to arm the overcurrent relays by

three-phase under voltage conditions when the generator is off line.

3. Recommendation

It is recommended that one of the detection schemes described above be used to protect

every generator. To prevent damage to the rotor, stator bearings, etc., it is desirable that

highspeed protection be provided for this contingency. The relaying should be connected to

trip the main generator breaker, and excitation, and have a breaker failure protection scheme

in place to trip any breakers which could feed current to the generator if breaker failure is

detected, and be so implemented that it is never taken out of service when the unit is shut

down for any purpose, even with the rotor removed.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 23

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 24 of 39

GEK 75512R Generator Protection

Mechanical or Thermal Faults

19. Bearing Vibration

1. Description

High vibration (as defined below) on a generator is a symptom of a problem. There are

many possible causes of vibration, including:

Unbalance

Misalignment

Thermal sensitivity

Damaged bearings

Oil Whip

Rubbing

Bent overhangs

Out-of-round journals or collectors

Stiffness dissymmetry

2. Detection

All bearings are normally provided with vibration detectors and recorders. Either velocity

probes, proximity probes, or both are used. These permit recording and monitoring of

vibration, and alarming and/or tripping at predetermined levels of vibration. The vibration

recorders do not provide the frequency spectrum information which could be useful in

determining the cause of the vibration. This information must be obtained with a portable

vibration analyzer.

GE also offers the ADRE system to more precisely analyze vibration issues. For more

information on this system, GE representatives should be contacted.

3. Recommendation

For both generator and alternator bearings provided with proximity probes, the table below

summarizes recommendations for various levels of shaft vibration. The vibration levels are

given in mils [mm], peak-to-peak, unfiltered.

For Vibration Level Exceeding Recommendations

2 Poles 4 Poles

(

(mils) (mm) (mils) mm)

10 254 12 305 Simultaneous Trip (Type1)

7 178 10 254 Runback and trip within 15 minutes (Type 6)

6 152 8 203 Correct at first opportunity

3 76 5 127 Correct when convenient

For generators provided with velocity probes which monitor endshield or pedestal

deflection in the vicinity of the bearing, the alarm level is 0.5 in/sec, and the trip level is 1

in/sec.

In some applications, the transient thermal performance of the turbine results in temporarily

elevated vibration levels on the generator bearings as well. Accordingly, alarm levels may

be raised for a specified time following start-up. See References below.

24 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 25 of 39

Generator Protection GEK 75512R

4. Reference

For more detailed information on vibration, refer to the turbine section of the instruction

book (Ref. 24).

20. Synchronizing Errors

1. Description

Improper synchronizing of units to the line may occur for a number of reasons. The most

severe of these results from incorrect connection of potential transformer or synchronizing

aids such that gross out-of-phase synchronizing, such as a 120° error, may occur. A failure

of automatic synchronizing equipment may also result in large synchronizing errors. While

turbine-generators are designed to withstand these rare occurrences without catastrophic

results, provided stator current does not exceed the three-phase short circuit value, they can

result in damage, such as slipped couplings, with resulting high vibration, loosened stator

windings, and fatigue damage to the shaft and other mechanical parts (Ref. 7).

Careless synchronizing, while generally a less severe incident, may, on an accumulated

basis, have the same result.

The following synchronizing limits are recommended to avoid damaging effects:

Breaker closing within ±10° (electrical angle)

Voltage matching within 0 to +5%

Slip slower than 10 seconds per slip cycle for manual synchronization.

Slip slower than 6 seconds per slip cycle for automatic synchronization.

2. Detection

A severe out-of-phase synchronizing incident will be evident from the physical effects of

noise and turbine-generator foundation vibration. In addition, a trip may result from the

vibration trips or from electrical protective relays. Poor synchronizing routine is less evident

but would be observable by the synchroscope and an oscillation of electrical quantities

(power, VARs) subsequent to the synchronizing.

3. Recommendations

Careful checking of circuits during initial installation or equipment changeout and the

establishment of well-adhered-to procedures for manual synchronizing are key elements in

minimizing out-of-phase synchronizing incidents.

A Synch check function should monitor manual synchronizing to prevent large errors (Ref.

8).

Automatic synchronizing relays can provide very high accuracy. Where such relays are

used, however, it is important that a check function be applied to provide an independent

back-up. Failure of the primary relays to perform should be alarmed, since this might

otherwise not be noticed.

© 2014 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part, 25

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 26 of 39

GEK 75512R Generator Protection

21. Motoring

1. Description

Motoring of a generator will occur when turbine output is reduced such that it develops less

than no-load losses while the generator is still on line. Assuming excitation is sufficient; the

generator will operate as a synchronous motor driving the turbine. The generator will not be

harmed by synchronous motoring, but, if it occurs as a result of failure to complete a

Sequential trip, protection for the fault originating that trip is lost. In addition, a steam

turbine can be harmed through overheating during synchronous motoring.

If field excitation is lost, along with turbine output, the generator will run as an induction

motor, driving the turbine. In addition to possible harm to the turbine, this will produce

slip-frequency currents in the rotor and could cause it to overheat if continued long enough.

A third type of motoring occurs when the generator is accidentally energized when at low

speed. This is discussed separately under "Accidental Energization".

2. Detection

Motoring following loss of turbine output can be detected with a reverse power relay. To

avoid false trips due to power swings, a time-delay pick-up of 10 to 30 seconds is

suggested. This is the backup relay suggested in the description of Trip 4 - Sequential trip.

Measurement of very low power levels at very low power factors will require relatively

high precision. Reduction in reactive power flow in the generator will reduce the

requirement for high precision. This may be accomplished through control action of the

excitation system or by operator action.

3. Recommendation

It is recommended that the reverse power relay referred to above be used and connected to

produce a Type 2, Generator trip or Type 3, Breaker trip. Breaker Failure Protection should

be initiated, since breaker failure may be the cause of the motoring. In addition, the turbine

section of the instruction book (Ref. 9) should be consulted and followed.

22. Stator Overtemperature

1. Description

Stator overheating may result from overcurrent operation, improper gas pressure or purity

(if applicable), gas or water cooling system malfunction, internal cooling passage blockage,

etc.

2. Detection

Armature bar temperatures are monitored by either TCs measuring stator cooling water

temperature and/or RTD's in the stator slots (if applicable). All functioning RTDs and TCs

should be constantly monitored and alarmed (see Ref 1, and 2&3 for H2O cooled machines).

As pointed out in the stator overcurrent section, these temperature detectors do not provide

complete protection against damage due to overcurrent operation, because temperatures in

other parts of the winding, winding forces, abnormal magnetic fields, etc. may become

excessive.

26 © 2017 General Electric Company. All Rights Reserved. This material may not be copied or distributed in whole or in part,

without prior permission of the copyright owner.

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number GEK75512 Rev R Released 11/21/2017 Page 27 of 39

Generator Protection GEK 75512R

3. Recommendation

Automatic shutdown is not always provided for protection against stator overheating on

generators with conventionally cooled stator windings. Section 26 describes automatic

protection recommended for liquid cooled armature windings. All operators should be made

aware of the importance of operating the generator within its rated capability. In cases

where a generator will operate in an unattended station, some form of overtemperature

protection should be provided. Implementation of an automatic stator overtemperature

protection scheme also provides some overcurrent protection, and is generally easier to

implement than overcurrent relaying.

23. Loss of Coolant to Gas Coolers (if applicable)

1. Description

Serious overheating of all generator components will occur if coolant flow to the gas

coolers is lost. Various machine temperature alarms will detect the overheating condition

prior to any damaging over temperatures. However, without human monitoring and

intervention, the condition will persist.

2. Detection

The RTD's monitoring the hot and cold gas temperatures may be used as the basis for

establishing protection against the loss of gas coolant. Refer to Table 1 for Alarm

information.

3. Recommendation

For machines which run unattended, consideration should be given to implementing an

Automatic runback (Type 6) or Simultaneous Trip (Type 1), based on the cold and hot gas

RTD's.

24. Reduced Seal Oil Pressure (if applicable)

1. Description

A floating, radial ring-type seal is used to prevent hydrogen leakage from the generator

along the shaft. Oil is supplied to the seals at a pressure slightly higher than that of the

hydrogen in the generator.

For large, liquid cooled generators, the oil is supplied by a seal oil pumping unit. The main

pump is driven by an ac motor. An emergency back-up pump is driven by a dc motor. This

pump will start automatically if the oil discharge pressure of the main pump decreases or if

ac power is lost. In addition to the main and emergency pumps, bearing header pressure is

available to maintain hydrogen pressure in the generator at a maximum of approximately 8

psig or 5 psid less than the available bearing header pressure, whichever is lower.

For most conventionally cooled hydrogen generators, seal oil is supplied from the lube oil

tank by the same pump supplying bearing oil. The main pump is driven by an ac motor. An