Beruflich Dokumente

Kultur Dokumente

Heat Treatment Labrotary

Hochgeladen von

Venkadeshwaran Kuthalingam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

43 Ansichten4 SeitenHeat Treatment Lab

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHeat Treatment Lab

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

43 Ansichten4 SeitenHeat Treatment Labrotary

Hochgeladen von

Venkadeshwaran KuthalingamHeat Treatment Lab

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

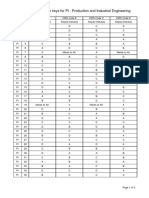

HEAT TREATMENT LABORATORY [2 Credits [0-0-4]]

1. Preparation of Metallographic Specimens.

2. Study of Microstructure of Pure Metals.

3. Study of Microstructure of Two-phase alloys

Muntry Metal

Al-Bronze

Q/T steel.

4. The microstructure of Eutectic & Eutectoid Alloys.

5. Comparison of Microstructures of 0.2, 0.6 & 1.1% C Steel in annealed

condition.

6. Primary calibration of Thermo – Couple.

7. Hardening & Tempering of Rail Steel.

8. Carburizing of Low – Carbon Steel.

9. The microstructure of Gray, White, Malleable & Ductile Cast Iron.

10. Joining End – Quench Test.

Course Outcomes:

Scheme of Evaluation (100 marks)

Continuous Internal Evaluation [CIE] (maximum 60+10=70 marks)

Do minimum eight experiments carrying 10 marks each.

Reduce 80 marks to 60 marks.

Two internal tests conducted for (5+5=10) marks in-between the

semester.

Semester End Examination [SEE] (maximum 30 marks)

One semester end examination will be conducted at the end of semester

carrying 30 marks.

PHASE TRANSFORMATION LABORATORY [2 Credits [0-0-4]]

1. Study of pearlitic transformation in mild

2. rail and file steels; Study of Martensitic transformation in steel ;

3. Study of Bainitic transformation in Austempered Ductile Iron ;

4. Phase transformation in Brass ;

5. Phase transformation in Aluminium Bronze ;

6. X-ray analysis of phases ;

7. Thermal analysis to study phase transformation ;

8. Quantitative estimation of phases

Course Outcomes:

Scheme of Evaluation (100 marks)

Continuous Internal Evaluation [CIE] (maximum 60+10=70 marks)

Do minimum 8 experiments carrying 10 marks each.

Reduce 80 marks to 60 marks.

Two internal tests conducted for (5+5=10) marks in-between the

semester.

Semester End Examination [SEE] (maximum 30 marks)

One semester end examination will be conducted at the end of semester

carrying 30 marks.

COMPOSITE FABRICATION LABORATORY [2 CREDITS [0-0-4]]

1. Introduction to Lab, Safety procedures

2. Overview of Composites Theory, with applications

3. Fibre & Matrix types. Overview of manufacturing processes.

4. Hand lay-ups.

5. Hand lay-ups, room-temp cures / Hand lay-ups, oven cures of

preparation / wet-lay ups.

6. Filament winding.

7. Applications to Marine, Aerospace, and Chemical Structures. Tours of

CCAD.

8. Other fabrication techniques such as SCRIMP, RTM.

9. Retrofit and Repair of Civil Structures With Composites

10. Basic Joining Concepts. Designing Composite Structures.

Course Outcomes:

Scheme of Evaluation (100 marks)

Continuous Internal Evaluation [CIE] (maximum 60+10=70 marks)

Do minimum 8 experiments carrying 10 marks each.

Reduce 80 marks to 60 marks.

Two internal tests conducted for (5+5=10) marks in-between the

semester.

Semester End Examination [SEE] (maximum 30 marks)

One semester end examination will be conducted at the end of semester

carrying 30 marks.

Material Testing & Characterization Lab [2 CREDITS [0-0-4]]

1. Preparation and examination of metallography specimens.

2. Primary calibration of the thermocouple.

3. Measurement of the melting point of the metal.

3. Theory and practice of thermal analysis.

4. Scanning calorimeter & Dilatometer.

5. Thermo gravitometer.

6. High-temperature microscopic study of Ceramic material.

7. High-temperature microscopic study of the Metallic material.

8. Topological and elemental analysis of the metallic sample by SEM.

9. Theory and practice of XRD technique

Course Outcomes:

Scheme of Evaluation (100 marks)

Continuous Internal Evaluation [CIE] (maximum 60+10=70 marks)

Do minimum 8 experiments carrying 10 marks each.

Reduce 80 marks to 60 marks.

Two internal tests conducted for (5+5=10) marks in-between the

semester.

Semester End Examination [SEE] (maximum 30 marks)

One semester end examination will be conducted at the end of semester

carrying 30 marks.

Das könnte Ihnen auch gefallen

- Material Science and MetallurgyDokument10 SeitenMaterial Science and MetallurgysrujankalaNoch keine Bewertungen

- EMM Syllabus - 2019 Patt - 06.072020Dokument3 SeitenEMM Syllabus - 2019 Patt - 06.072020prashant patilNoch keine Bewertungen

- Final PPT On ProjectDokument26 SeitenFinal PPT On ProjectartikscindianNoch keine Bewertungen

- Tajuk 1 SKMM2921 Metalografi by NhayatiDokument7 SeitenTajuk 1 SKMM2921 Metalografi by NhayatiNader MohammedNoch keine Bewertungen

- Effect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelDokument5 SeitenEffect of Tempering Temperature On Microstructure and Mechanical Properties of AISI 6150 SteelCường BéoNoch keine Bewertungen

- Lab Material 3Dokument11 SeitenLab Material 3Faiz AmeeriNoch keine Bewertungen

- 430459.A005-RIM 09 - 031 - Stefanija Klaric PDFDokument6 Seiten430459.A005-RIM 09 - 031 - Stefanija Klaric PDFGizachew HeleboNoch keine Bewertungen

- Lab I - Metallography-RevisedDokument9 SeitenLab I - Metallography-RevisedNgọc Phạm VănNoch keine Bewertungen

- JIS G5131ï š2008 High Manganese Steel Castings PDFDokument14 SeitenJIS G5131ï š2008 High Manganese Steel Castings PDFsupendiNoch keine Bewertungen

- Manual As On 10-1-22Dokument40 SeitenManual As On 10-1-22MADHAV AGARWALNoch keine Bewertungen

- B4 Heat Treatment and MetallographyDokument19 SeitenB4 Heat Treatment and MetallographyIrfan FadzailahNoch keine Bewertungen

- Ta 201 A Laboratory ManualDokument22 SeitenTa 201 A Laboratory ManualSunitNoch keine Bewertungen

- 2009-2010 Midsem QADokument5 Seiten2009-2010 Midsem QAMugesh RanjanendranNoch keine Bewertungen

- 3rd SEMDokument19 Seiten3rd SEMAnjali BaghNoch keine Bewertungen

- Heat Treatment & Phase Transformations: Laboratory Manual Cum Observation BookDokument45 SeitenHeat Treatment & Phase Transformations: Laboratory Manual Cum Observation Book035K Ayush ChoudharyNoch keine Bewertungen

- Assessment of Metal Condition and Remaining Life of In-Service Power Plant Components Operating at High TemperatureDokument119 SeitenAssessment of Metal Condition and Remaining Life of In-Service Power Plant Components Operating at High TemperatureAlok SinghNoch keine Bewertungen

- The Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelDokument7 SeitenThe Effect of Microstructure On Tensile Behaviour of X80 Microalloyed SteelMarcelo Varejão CasarinNoch keine Bewertungen

- Materials Testing LabDokument3 SeitenMaterials Testing LabBenNoch keine Bewertungen

- EXP8Dokument8 SeitenEXP8alolqigoNoch keine Bewertungen

- Pertemuan 1.1Dokument15 SeitenPertemuan 1.1Ika Bayu RamadhanaNoch keine Bewertungen

- Production EngineeringDokument39 SeitenProduction EngineeringkeepingbusyNoch keine Bewertungen

- The Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelDokument8 SeitenThe Influence of Niobium and Aging Treatment in The 18% Ni Maraging SteelGopala Rao ThellaputtaNoch keine Bewertungen

- KEN BangaloreDokument2 SeitenKEN BangaloreWell WisherNoch keine Bewertungen

- Experiment 4: The Effects of Heat Treatment On The Microstructure of SteelDokument3 SeitenExperiment 4: The Effects of Heat Treatment On The Microstructure of Steelkano100% (1)

- Diploma Work Shop TechnologyDokument10 SeitenDiploma Work Shop TechnologyadarshNoch keine Bewertungen

- Mechanical PDFDokument144 SeitenMechanical PDFPrad UpNoch keine Bewertungen

- Heat Treatment of SteelDokument11 SeitenHeat Treatment of Steel12babonNoch keine Bewertungen

- 4.32 & 4.33 TE & BE - Mech Engg 106Dokument1 Seite4.32 & 4.33 TE & BE - Mech Engg 106Honey SinghNoch keine Bewertungen

- Ilkgul TezDokument21 SeitenIlkgul TezJohn WaitNoch keine Bewertungen

- Study Module SubjectwiseDokument38 SeitenStudy Module SubjectwiseKiran HadaNoch keine Bewertungen

- Characterisation of Al Cu Fe Quasicrystal Alloy Synthesised Via In-Situ Casting Under Standard Room Ambient and Argon Enriched AtmosphereDokument7 SeitenCharacterisation of Al Cu Fe Quasicrystal Alloy Synthesised Via In-Situ Casting Under Standard Room Ambient and Argon Enriched AtmosphereTan Chee WayneNoch keine Bewertungen

- Obiukwu Osita, Udeani Henry, Ubani ProgressDokument12 SeitenObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarNoch keine Bewertungen

- Swaminathan 2008Dokument13 SeitenSwaminathan 2008Primawati RahmaniyahNoch keine Bewertungen

- Hardenability of SteelDokument9 SeitenHardenability of SteelUmitjan PirnepesowNoch keine Bewertungen

- Mechanical Properties Analysis of Medium Carbon Steel Heated at 850°C by Quenching in Naoh SolutionDokument3 SeitenMechanical Properties Analysis of Medium Carbon Steel Heated at 850°C by Quenching in Naoh SolutionNoval RedaNoch keine Bewertungen

- EMLABDokument7 SeitenEMLABputri nur shahidaNoch keine Bewertungen

- 6252 8377 1 PB PDFDokument5 Seiten6252 8377 1 PB PDFBillyAdhityaNoch keine Bewertungen

- Revision Structure of SE (Mechanical)Dokument30 SeitenRevision Structure of SE (Mechanical)vdchaudhariNoch keine Bewertungen

- Metals-09-00939 OKDokument14 SeitenMetals-09-00939 OKRebeca Francis Moran CamposNoch keine Bewertungen

- Ojay 1ST Publication PDFDokument16 SeitenOjay 1ST Publication PDFvenkatrangan2003Noch keine Bewertungen

- MSE-227 Lecture 1 IntroductionDokument18 SeitenMSE-227 Lecture 1 IntroductionsamNoch keine Bewertungen

- Midterm Exam Odd Semester 2020-2021-HSTDokument5 SeitenMidterm Exam Odd Semester 2020-2021-HSTArraafi FadhillahNoch keine Bewertungen

- BE Syllabus of Mumbai Uni3Dokument10 SeitenBE Syllabus of Mumbai Uni3Rajendra B PawarNoch keine Bewertungen

- W.e.f.-July-2010 Academic Session-2010-11 1Dokument24 SeitenW.e.f.-July-2010 Academic Session-2010-11 1piyushmalviaNoch keine Bewertungen

- School of Mechanical EngineeringDokument4 SeitenSchool of Mechanical EngineeringHitesh KumarNoch keine Bewertungen

- TADILODokument15 SeitenTADILOSamiMasreshaNoch keine Bewertungen

- PDFDokument3 SeitenPDFJoaquin UreñaNoch keine Bewertungen

- Manual Mould and Tool SteelsDokument38 SeitenManual Mould and Tool Steelsodhiles1Noch keine Bewertungen

- Libroduplex PDFDokument183 SeitenLibroduplex PDFHugo PeñaNoch keine Bewertungen

- Characteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceDokument5 SeitenCharacteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceAbolfazl HabibiNoch keine Bewertungen

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelDokument7 SeitenEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanNoch keine Bewertungen

- CHT307 - Ktu QbankDokument3 SeitenCHT307 - Ktu QbankYuxin CasioNoch keine Bewertungen

- Heat Treatment Experiments PDFDokument6 SeitenHeat Treatment Experiments PDFPawan Kumar Sapra100% (1)

- TA-201 Lab MannualDokument19 SeitenTA-201 Lab MannualAnujNagpalNoch keine Bewertungen

- Escala de Dureza MetalogDokument28 SeitenEscala de Dureza MetalogrosamelNoch keine Bewertungen

- Computer Integrated ManufacturingDokument51 SeitenComputer Integrated ManufacturingAnonymous VDnLHNG7QQNoch keine Bewertungen

- Metallurgy & Materials Engineering: Lecture # 1: MME#1aV1.0 3/10/2015Dokument11 SeitenMetallurgy & Materials Engineering: Lecture # 1: MME#1aV1.0 3/10/2015SINCERITY777Noch keine Bewertungen

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Von EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Noch keine Bewertungen

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIVon EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNoch keine Bewertungen

- UNIT 3 Condition MonitoringDokument32 SeitenUNIT 3 Condition MonitoringVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit V Reliability Apr 06 2020Dokument56 SeitenUnit V Reliability Apr 06 2020Venkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 1 Principles and Practices of Maintenance Planning KVNDokument23 SeitenUnit 1 Principles and Practices of Maintenance Planning KVNVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 2 Maintenance EnggDokument46 SeitenUnit 2 Maintenance EnggVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 3 Wear Debris AnalysisDokument4 SeitenUnit 3 Wear Debris AnalysisVenkadeshwaran KuthalingamNoch keine Bewertungen

- UNIT 3 Condition MonitoringDokument32 SeitenUNIT 3 Condition MonitoringVenkadeshwaran KuthalingamNoch keine Bewertungen

- Maintainability Questions - Vskills Practice TestsDokument7 SeitenMaintainability Questions - Vskills Practice TestsVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 3 Wear Debris AnalysisDokument4 SeitenUnit 3 Wear Debris AnalysisVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 2 Maintenance EnggDokument46 SeitenUnit 2 Maintenance EnggVenkadeshwaran KuthalingamNoch keine Bewertungen

- Reliability Management Questions - Vskills Practice Tests PDFDokument7 SeitenReliability Management Questions - Vskills Practice Tests PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- Reliability Modeling Questions Questions - Vskills Practice Tests PDFDokument5 SeitenReliability Modeling Questions Questions - Vskills Practice Tests PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- RE-sample MCQ For XQPDokument11 SeitenRE-sample MCQ For XQPVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 1 Principles and Practices of Maintenance Planning KVNDokument23 SeitenUnit 1 Principles and Practices of Maintenance Planning KVNVenkadeshwaran KuthalingamNoch keine Bewertungen

- Maintenance and Reliability Mock Test - Vskills Practice Tests PDFDokument26 SeitenMaintenance and Reliability Mock Test - Vskills Practice Tests PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- Pi 2014Dokument18 SeitenPi 2014udaygwlNoch keine Bewertungen

- Machine DesignDokument97 SeitenMachine DesignGourav Kapoor100% (4)

- Heat Transfer IES GATE IAS 20 Years Question and Answers by S K MondalDokument97 SeitenHeat Transfer IES GATE IAS 20 Years Question and Answers by S K Mondalpriyampatel2185% (13)

- Unit V Assignment Apr 07 2020 Casestudy Based ANSWERDokument3 SeitenUnit V Assignment Apr 07 2020 Casestudy Based ANSWERVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit V Assignment Apr 07 2020 Casestudy BasedDokument2 SeitenUnit V Assignment Apr 07 2020 Casestudy BasedVenkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 4 Event Tree AnalysisDokument21 SeitenUnit 4 Event Tree AnalysisVenkadeshwaran KuthalingamNoch keine Bewertungen

- GATE 2014 Answer Key Download - PI Production and Industrial Engineering PDFDokument1 SeiteGATE 2014 Answer Key Download - PI Production and Industrial Engineering PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- PiDokument16 SeitenPiSaurabh TiwariNoch keine Bewertungen

- GATE 2013 Exam Answer Key PI - Production and Industrial Engineering PDFDokument2 SeitenGATE 2013 Exam Answer Key PI - Production and Industrial Engineering PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- Materials Question From My BookDokument54 SeitenMaterials Question From My BookRavinder Antil100% (6)

- MCQ Collection Ap 2020Dokument7 SeitenMCQ Collection Ap 2020Venkadeshwaran KuthalingamNoch keine Bewertungen

- Unit 4 Event Tree AnalysisDokument21 SeitenUnit 4 Event Tree AnalysisVenkadeshwaran KuthalingamNoch keine Bewertungen

- Maintenance and Reliability Mock Test - Skills Practice TestsDokument18 SeitenMaintenance and Reliability Mock Test - Skills Practice TestsVenkadeshwaran KuthalingamNoch keine Bewertungen

- UNIT 4 Energy StorageDokument1 SeiteUNIT 4 Energy StorageVenkadeshwaran KuthalingamNoch keine Bewertungen

- Wear Debris Analysis Case Study Mar 23 2020Dokument2 SeitenWear Debris Analysis Case Study Mar 23 2020Venkadeshwaran KuthalingamNoch keine Bewertungen

- Easwari Engineering College B.E ECE Solar & Energy Storage Systems Question Paper PDF Download - ENTRANCEINDIA PDFDokument4 SeitenEaswari Engineering College B.E ECE Solar & Energy Storage Systems Question Paper PDF Download - ENTRANCEINDIA PDFVenkadeshwaran KuthalingamNoch keine Bewertungen

- Fassi Marine SerieDokument32 SeitenFassi Marine SerieArnulfo ArriagaNoch keine Bewertungen

- Dissimilar WeldingDokument24 SeitenDissimilar WeldingVishnupriya SunilNoch keine Bewertungen

- A 960 PDFDokument9 SeitenA 960 PDFEnrique L BlancoNoch keine Bewertungen

- Uddeholm Qro90supremeDokument12 SeitenUddeholm Qro90supremeDarwin Anderson GNoch keine Bewertungen

- Case Study On Corrosion Assessment of Infield Pipelines byDokument10 SeitenCase Study On Corrosion Assessment of Infield Pipelines byHazim NaharNoch keine Bewertungen

- 630 2005 Reff2021Dokument11 Seiten630 2005 Reff2021Yoginder SainiNoch keine Bewertungen

- Properties of A 55 % Aluminium Zinc Coating On Steel Sheeting PDFDokument4 SeitenProperties of A 55 % Aluminium Zinc Coating On Steel Sheeting PDFing_fernandogalvez2015Noch keine Bewertungen

- A276a276m 2023Dokument8 SeitenA276a276m 20237620383tlNoch keine Bewertungen

- BHMA Finish ChartDokument5 SeitenBHMA Finish ChartRey Eduard Q. UmelNoch keine Bewertungen

- Etag 032 Part 7 May 2013Dokument65 SeitenEtag 032 Part 7 May 2013coolkaisyNoch keine Bewertungen

- Sa 179Dokument3 SeitenSa 179Raju SkNoch keine Bewertungen

- Quality Casting ManualDokument27 SeitenQuality Casting ManualvisitabhinavNoch keine Bewertungen

- Weld Selector GuideDokument32 SeitenWeld Selector Guidegechaves1Noch keine Bewertungen

- U1. T2. Activity 1. Heat Treatments of SteelDokument11 SeitenU1. T2. Activity 1. Heat Treatments of SteelTygaNoch keine Bewertungen

- Catalog Grounding Lightning 2019Dokument126 SeitenCatalog Grounding Lightning 2019nikhom_dk1565Noch keine Bewertungen

- Tank Power PDFDokument22 SeitenTank Power PDFstctoolNoch keine Bewertungen

- Astm A194 A194m 23Dokument7 SeitenAstm A194 A194m 23Kalanithi GKNoch keine Bewertungen

- 20 Astm A672 A672m-2014Dokument7 Seiten20 Astm A672 A672m-2014FYNoch keine Bewertungen

- A1020A1020M-02 (2012) Standard Specification For SteeDokument4 SeitenA1020A1020M-02 (2012) Standard Specification For SteeRony YudaNoch keine Bewertungen

- Brochure-FIS EM PlusDokument8 SeitenBrochure-FIS EM PlusnurulapriliashNoch keine Bewertungen

- Welding of Stainless Steels & Duplex: Roshan RampureDokument74 SeitenWelding of Stainless Steels & Duplex: Roshan Rampureapurva karleNoch keine Bewertungen

- World's Largest Science, Technology & Medicine Open Access Book PublisherDokument25 SeitenWorld's Largest Science, Technology & Medicine Open Access Book Publishermhd efriyansyahNoch keine Bewertungen

- Metal Solid IronDokument48 SeitenMetal Solid IronVinoth SangNoch keine Bewertungen

- Hulamin Extrusions Design Manual 2016 Low WebDokument71 SeitenHulamin Extrusions Design Manual 2016 Low WebramonaNoch keine Bewertungen

- 1) Fitting HammersDokument2 Seiten1) Fitting HammersKrako TramNoch keine Bewertungen

- Recent Developments in High Temperature Heat Exchangers: A ReviewDokument15 SeitenRecent Developments in High Temperature Heat Exchangers: A Reviewnantha kumarNoch keine Bewertungen

- Asme Section II A Sa-216 Sa-216mDokument4 SeitenAsme Section II A Sa-216 Sa-216mAnonymous GhPzn1xNoch keine Bewertungen

- 173 13 12 Steel Degassing USDokument8 Seiten173 13 12 Steel Degassing USAl M JamilNoch keine Bewertungen

- Cutting Edge BrochureDokument2 SeitenCutting Edge BrochureKen SmithNoch keine Bewertungen

- Underwater Welding Code: D3.6M:2017 An American National StandardDokument14 SeitenUnderwater Welding Code: D3.6M:2017 An American National StandardSatendra kumar33% (3)