Beruflich Dokumente

Kultur Dokumente

5.15.1 Winkler Heated Sample Line

Hochgeladen von

Marleny Lindo CajusolCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5.15.1 Winkler Heated Sample Line

Hochgeladen von

Marleny Lindo CajusolCopyright:

Verfügbare Formate

Heated sample gas lines

Temperature-controlled, heated sample gas lines

Non-replaceable Teflon core, max. 200 °C

L ■ Ordering data Order No.

N

Note: The complete Ordering data for a heated sample gas line must

PE include both items I and II

Pt 100 Item I

Preassembled pack for 7MB1 943-2BA00

l = 1,5 m

temperature-controlled, heated

sample gas line for operating

Pt 100 109 temperatures up to 200 °C

Æ 47

Æ 42

(delivery unit 1 line)

Non-replaceable Teflon core,

Æ 6 or 8

with 1 Pt 100 temperature sensor

Type of fitting: ferrule,

25 Mat. No. 1.4571,

both sides straight

1000

Item II

Length-dependent data

l =_____ m (delivery unit 1 m)

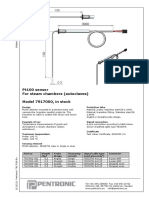

Fig. 3/2 Temperature-controlled, heated sample gas line for operating Outer sheath

temperatures up to max. 200 °C, non-replaceable Teflon core Polyamide corrugated hose

Hose

■ Design PTFE hose 4/6 mm

PTFE hose 6/8 mm

7MB1 943-2AA01

7MB1 943-2AA02

Internal hose (type) Hose with Teflon (PTFE) core,

stainless steel braiding Temperature sensor mounting Sensor 1:1 m

point

Connection fittings at inlet and outlet Connecting sleeves RSL at both

ends, mat. No. 1.4571

Ferrule

Measured from the electrical con-

nection side (standard) or

specified in plain text: Sensor 1: ..... m

3

Hose connection and termination Silicone end cap 2nd temperature sensor On request

2nd heating circuit On request

Heat conductor Moisture-proof, braided by

PE conductor Temperature controller See page Seite 5

Thermal insulation Thermo-fleece (CFC-free, flame

retardant)

Outer sheath Polyamide corrugated hose,

black, waterproof, flame retar-

dant to UL94 HB, Example for ordering

thermally stable from The following is required:

-40 to +80 °C,

short-term +120 °C Temperature-controlled, heated sample gas line

Temperature sensor Pt 100 in 2-wire system (Pt 100 for operating temperatures up to 200 ºC,

resistance thermometer) with straight connection fittings on both sides,

outer sheath made of polyamide corrugated hose,

Power supply connection Power supply and sensor cables

with common outlet, connector

PTFE hose 4/6 mm,

sleeves, L = 1500 mm 10 m long

Tests complied with VDE 0721 Part 1 Order as follows:

• High-voltage test 7MB1 943-2BA00 + 10 x 7MB1 943-2AA01

• Insulation resistance test

■ Technical data

Max. permissible operating 200 °C

temperature

Max. length of heating circuit 50 m

Max. production length 100 m

Protection class I

Smallest bending radius

• Not crush-proof 200 mm

• Crush-proof 500 mm

Max. permissible operating 30 bar

pressure

Power supply 230 V AC, 50 Hz

Rated power 100 VA/m

Weight (heating hose) Approx. 0.5 kg/m

Siemens PA 11 · 2006 3/3

T E C H N O L O G I E S

Guidelines for the installation of heated hoses

With your winkler heated hose you have acquired a high quality product.

Please read the following instructions carefully to ensure a long service life of this product.

General information Thermal stability

The central element of the heated hose is the inner tube through which Please observe the maximum operating temperature stated on the type

the fluid flows. It is normally made of high-grade PTFE with a smooth plate. The product may be severely damaged if the temperature is ex-

surface, or corrugated stainless steel, or smooth-surfaced stainless steel. ceeded.

Correspondingly, care should also be taken when bundling lines or

The inner tube is covered with braiding - i.e., provided with one armouring laying a hose along machine parts with higher temperatures.

of stainless steel for medium pressure and two such armourings for As a rule, temperature sensors should always be installed, so that the

high pressure - so as to increase the tube’s ressistance to pressure. line can be kept at an even temperature by means of a temperature

controller. Lines with fixed heating must be equipped with sensors to

Where fittings are installed, they are moulded into the entire hose struc- prevent overheating.

ture with a defined pressure and time period.

It is possible to integrate any special type of fitting. Mounting of temperature sensors

The heating system consists of high-grade heat conductor alloys combined The temperature sensors are mounted in such a way that they can

with different insulating materials depending on temperature: register the temperature between heating and hose or pipe. With certain

designs, they can also be arranged on the heat conductor.

Silicone with protective conductor braiding In standard products, the sensor is positioned at a distance of 250 mm

from the electrical connection side. The sensor position can also be spe-

PTFE with protective conductor braiding cified by the customer after consultation with our experts.

Glass silk with protective conductor braiding Please note: The ambient temperature at the sensor location will

determine the internal temperature.

Mineral insulation with stainless steel jacket

The entire hose heating is designed according to VDE guidelines in such Temperatures

a way that the high flexibility of the pressure hose or the bending poten-

tial is hardly affected. The stated operating temperatures are obtained under ideal conditions

(unvarying -20 °C in a climatic cabinet). The actual temperature in

Depending on design, the lines can be supplied TÜV-tested or SEV- different hose areas can differ considerably from these values due to

tested. external influences:

The thermal insulation is adapted to temperature range and type. Wind exposure will result in a great loss of heat at the outer jacket.

Mechanically, the line is protected by an XCVB outer jacket. The hoses The hose should therefore be laid in a manner providing protection

are furnished with thermostable connection caps at both ends. against wind.

Different ambient temperatures along the route of the hose will result

Resistance to different substances in different internal temperatures. Decisive for temperature control is

the ambient temperature at the location of the sensor, which - to avoid

The various materials coming into contact with the fluid are described overheating - should be positioned in the area with the highest ambient

in the relevant brochure or in our offer. The resistance to attack must temperatures.

be checked by the user. Consequently, the internal hose temperature will lie below the regulated

temperature value in areas with lower ambient temperature, but will

be above in areas with higher ambient temperature.

Version 09/2003 Wi Eng _01

T E C H N O L O G I E S

Guidelines for the installation of heated hoses continued

Putting into operation During operation Applications

1. Check type plate to see if type, mains 1.Have you read the Guidelines for Installation? Our heating systems are designed by experts

voltage, power or working temperatures according to the principle that

correspond to your specifications. 2.Don’t hold on to the fitting when pulling

the hose. The fittings are all resistant to »heat should be applied

2. Check visually if the hose design cor- pressure but not so much to tension. directly where it is required«.

responds to the one ordered by you.

3.It can happen that hardening of the fluid We manufacture heating systems of all sizes,

3. Always follow the guidelines for installation. will lead to clogging up of a fitting, which for straight or curved surfaces, or exactly

will then only be unblocked again after a adapted to the heated object.

4. If you use clamps, banding or similar for certain heating period. Do not try to shorten

supporting the hose, please make sure that this waiting period by external heating (e.g. Heating systems for:

pressing does not reduce the external dia- using a burner). This will often damage the

meter by more than 10 % at the most. hose - and the replacement delivery will Columns Tops of bunkers/bins

Above this 10 % limit, heat conductors, take longer, despite the winkler Hotline Valves Conveyor installations

control leads or sensor wires could be Service. Pumps Distributors

damaged. Flanges Moulding equipment

Mirrors Operating tables

5. If there are control cores running through We can supply suitable heating sleeves for Funnels Photocopiers

the hose, please observe the electrical load the heating of fittings, valves and other plant Freezers Electronic equipment

capability of these cores. Their standard components. Hot plates Vessels and containers

cross-section amounts to 0.75 mm2. Hot plates Parabolic reflectors

They may be loaded with a maximum of In some cases, the fluid at the inlet or inflow Refrigerators Plates and panels

8 A at 230 V. point is hotter than the maximum hose Barrels Shipping containers

temperature. You should then try to establish Filters Kitchen containers

6. Please ensure that you are using the correct a temperature gradient by means of a transition Antennae Vacuum facilities

type of controller. Controller rating, sensor element. Sampling tubes Meat containers

type and temperature range must be com- ....

patible.

7. Is the controller properly connected to the By observing all the guidelines you will be

hose? An accidentally reversed thermo- able to use your winkler heated hose for a

couple, for example, will result in heating long time and to your full satisfaction.

up the hose until it is completely destroyed.

There will be no such problems if you em-

ploy the existing winkler hose controller

systems.

8. Have you observed the regulations for

electrical installation valid in your country?

9. If the hose is laid outdoors it must be suit-

ably protected against wind. Accessories

10.Lines with PVC outer jacket should not be Information on our wide range of accessories

laid when the outside temperature is below can be found in our catalogues or obtained

-5 °C unless they are preheated. from our specialists.

Version 09/2003 Wi Eng _02

T E C H N O L O G I E S

Technical data of standard hose lines

Important: The measured internal diameters of the nipples are not identical with the nominal diameter (DN) of the hose.

Pressure resistance Pressure resistance of medium-pressure

The pressure resistance of the flexible heated DN Burstpressure* Operating pressure...

hoses changes according to the different

24°C 100°C 150°C 200°C

working temperatures. Please observe the

mm bar bar bar bar bar

table on the right!

4 1000 250 225 212 200

6 900 225 202 191 180

In the range up to 200 °C the pressure

8 800 200 180 170 160

resistance can still be defined, but this drops

10 600 150 135 127 120

down to 0 bar as from 250°C. In between,

13 500 125 112 106 100

the pressure should be carefully calculated,

16 400 100 90 85 80

depending on the type of loading, with a

20 280 70 63 59 56

correction factor of 0.7 related to 24 °C.

25 220 55 49 47 44

Watch out for pressure peaks! They can be

very high and are not registered by normal Pressure resistance of PTFE-pipe

pressure indicators.

The operating pressure must never be ex- 4 60 20 11 9 6

ceeded. 6 39 13 7 6 4

8 33 11 6 5 3

Pressure resistance of low-pressure hoses: *At room temperature and pressure increasep max. / 5 + 10 sec.

operating pressure up to 15 bar Pressure resistance for high pressure: op.pressure approx. 25 % above the values of medium-pressure hoses.

Vacuum Bending radius Tolerances

Hoses and PTFE-pipes up to DN 8 (nominal Your heated hose has been designed to with- Wattage : ± 10 %

diameter) have been tested at temperatures stand a certain bending stress. However, the Diameter : ± 10 %

up to 250 °C with approx. 8 mbar. stated bending radii should not be reduced Length :± 5%

any further. Kinks or strong twisting will lead

to the destruction of the heated hose. Pressure load variations may lead to changes

Please follow the guidelines for installation. in length up to + 2 % during operation.

Protective braiding Bending radius fordifferent braid Measurements

The protective braiding normally consists of DN Plastic Metal up to DN 16 up to DN 25

thin wires that are braided to form a hose. mm mm mm D1 40 mm 59 mm

Please take care to avoid projecting nails, 4 160 200 D2 45 mm 65 mm

sharp edges or similar objects which could 6 160 200 D3 65 mm 81 mm

damage the individual wires. 8 160 200

10 250 290 D3 D2 D1

The protective braiding is employed for dif- 13 250 290

ferent temperatures, depending on the type 16 250 290

of hose. 20 450 500

25 500 550

Plastic : 160 °C L

Galvanized metal : 250 °C Special design:

Stainless steel : 250 °C -“Crush-resistant” design up to DN 8: 500 mm L = Lenght

Version 09/2003 Wi Eng _03

T E C H N O L O G I E S

WRONG RIGHT

If the heated hoses are too short, the hose is

bent at the connection ends.

Remedy: Include a straight section - measuring

about 5 x hose diameter - at each connection

end. A large bending radius will increase the

service life of your hose.

Hose is laid with a sagging part.

Remedy: Supports or rollers with counterweight.

Pulling at the end of a rolled up hose will lead

to twisting (torsional stress) as well as a

bending radius smaller than permissible.

Remedy: Unroll the hose ring without pulling

at the hose.

Version 09/2003 Wi Eng _04

T E C H N O L O G I E S

WRONG RIGHT

Compression along the longitudinal axis due

to wrong installation or during movement will

reduce the pressure resistance.

Stretch compensation by fixed hoses leads to

their destruction.

Remedy: Bends at connection points.

Torsional movements will damage the heated

hose. This is often due to wrong installation,

particularly to turning in the wrong direction

when connecting the hose.

Remedy: Ensure that the hose axes run parallel

and that the direction of motion is in one

plane.

Use a counter-wrench during installation to

prevent twisting the hose.

Version 09/2003 Wi Eng _05

T E C H N O L O G I E S

WRONG RIGHT

Corners are danger spots because of the risk

of kinks and bending stress.

Remedy: Saddle support or roller with cor-

responding diameter.

Excessive bending stress near the connection

points is damaging.

Remedy: Pipe bends

With hand-held equipment, the risk of kinks is

particularly great.

Remedy: Depending on working position, fit

bend or anti-kink system (e.g., wire spiral).

Version 09/2003 Wi Eng _06

T E C H N O L O G I E S

WRONG RIGHT

If powdery substances, adhesives or other

materials with thermal insulation properties

are spilt onto the heated hose, it will lead

to overheating at these points.

Remedy: Constant cleaning and removing of

such materials.

If heated hoses are laid in a closed channel

or duct, this will result in heat concentration.

Remedy: The hoses must not be in contact

with each other. Additionally, it will be ne-

cessary to provide adequate ventilation.

Bundling of hoses or laying hoses next to each

other will lead to overheating at the points

of contact.

Remedy: Always leave sufficient space bet-

ween the hoses.

Heat concentration with overheating can also

be caused by wrapping other materials around

the heated hose. If the sensor area is wrapped

up, the remaining hose section will cool down.

When fixing the hose with clamps or similar

it must be ensured that the outer structure is

not squeezed.

Version 09/2003 Wi Eng _07

T E C H N O L O G I E S

Winkler GmbH

Englerstraße 24

D-69126 Heidelberg

Phone : +49 (0) 62 21 - 36 46 - 0

Fax : +49 (0) 62 21 - 36 46 - 40

email : info@winkler-waerme.de

internet : www.winkler-waerme.de

Version 09/2003 Wi Eng _08

Das könnte Ihnen auch gefallen

- International Business ManagementDokument3 SeitenInternational Business Managementkalaiselvi_velusamyNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Electrical Heat Tracing: in Hazardous AreasDokument44 SeitenElectrical Heat Tracing: in Hazardous AreasZevaNoch keine Bewertungen

- Handbook of Heating, Ventilating and Air ConditioningVon EverandHandbook of Heating, Ventilating and Air ConditioningBewertung: 4 von 5 Sternen4/5 (6)

- Deloitte - Introduction To TS&A - CloudDokument2 SeitenDeloitte - Introduction To TS&A - Cloudsatyam100% (1)

- 8D & 7QC ToolsDokument117 Seiten8D & 7QC ToolsAshok Kumar100% (1)

- Retail Operations ManualDokument44 SeitenRetail Operations ManualKamran Siddiqui100% (2)

- Earth and Life Science, Grade 11Dokument6 SeitenEarth and Life Science, Grade 11Gregorio RizaldyNoch keine Bewertungen

- Mongodb TutorialDokument106 SeitenMongodb TutorialRahul VashishthaNoch keine Bewertungen

- Necromunda CatalogDokument35 SeitenNecromunda Catalogzafnequin8494100% (1)

- (QII-L2) Decorate and Present Pastry ProductsDokument30 Seiten(QII-L2) Decorate and Present Pastry ProductsLD 07100% (1)

- Gics-In-India Getting Ready For The Digital WaveDokument81 SeitenGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- NCPDokument6 SeitenNCPJoni Lyn Ba-as BayengNoch keine Bewertungen

- Combining Wavelet and Kalman Filters For Financial Time Series PredictionDokument17 SeitenCombining Wavelet and Kalman Filters For Financial Time Series PredictionLuis OliveiraNoch keine Bewertungen

- Watt Density & Heater SelectionDokument2 SeitenWatt Density & Heater Selectionferperez90Noch keine Bewertungen

- WellaPlex Technical 2017Dokument2 SeitenWellaPlex Technical 2017Rinita BhattacharyaNoch keine Bewertungen

- OPTITEMP TRA-TW59 - KROHNE GroupDokument3 SeitenOPTITEMP TRA-TW59 - KROHNE GroupalicardozoNoch keine Bewertungen

- Optitemp Tca-Ts53 - Krohne GroupDokument3 SeitenOptitemp Tca-Ts53 - Krohne GroupalicardozoNoch keine Bewertungen

- Mill Ol 0to150Dokument4 SeitenMill Ol 0to150Kumar AmbujNoch keine Bewertungen

- 2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2Dokument4 Seiten2/2-Way Solenoid Valve With Servo-Diaphragm, G 1/2 - G 2 1/2MacakafkaNoch keine Bewertungen

- Sanitary Diaphragm Valve: Type 612Dokument6 SeitenSanitary Diaphragm Valve: Type 612Hilux PabloNoch keine Bewertungen

- TT 30Dokument2 SeitenTT 30fabianrico2Noch keine Bewertungen

- Instrumentation Design BasicsDokument28 SeitenInstrumentation Design BasicsCharles ChettiarNoch keine Bewertungen

- Pentronic 7917000 enDokument2 SeitenPentronic 7917000 ensalahNoch keine Bewertungen

- Air Heater E-Heater-Alfred-Nolte-GmbhDokument4 SeitenAir Heater E-Heater-Alfred-Nolte-GmbhJohan ConradieNoch keine Bewertungen

- Omnigrad TST410: RTD ThermometerDokument4 SeitenOmnigrad TST410: RTD ThermometerTCP.MT.2014 TCP.MT.2014Noch keine Bewertungen

- Omnigrad M TR 11: RTD Temperature SensorDokument16 SeitenOmnigrad M TR 11: RTD Temperature SensorRudin Fahrudin RahmanNoch keine Bewertungen

- Pt100 &thermocouple Assemblies: For Industrial ApplicationsDokument3 SeitenPt100 &thermocouple Assemblies: For Industrial ApplicationsRicardo KharisNoch keine Bewertungen

- 9884 - Duct Temperature Sensor FK-TP - 200 - enDokument4 Seiten9884 - Duct Temperature Sensor FK-TP - 200 - enMinh nhut LưuNoch keine Bewertungen

- Omnnigrad S - TR61Dokument12 SeitenOmnnigrad S - TR61GiuseppeNoch keine Bewertungen

- 9898 - Immersion Temperature Sensor FT-TP - 100 FT-TP - 400 - enDokument4 Seiten9898 - Immersion Temperature Sensor FT-TP - 100 FT-TP - 400 - enurangtengakNoch keine Bewertungen

- 5658 Electric Actuated 3-Way Ball Valves: FeaturesDokument6 Seiten5658 Electric Actuated 3-Way Ball Valves: FeaturesRADHAKRISHNANNoch keine Bewertungen

- hpr2 Regulator For Model 933 Analyzer PN 300-9478Dokument7 Seitenhpr2 Regulator For Model 933 Analyzer PN 300-9478Jose JohnNoch keine Bewertungen

- Na16643a H 4000 TPLDokument17 SeitenNa16643a H 4000 TPLMiroslav LuladžićNoch keine Bewertungen

- DE400015 Heated Sample Gas LineDokument3 SeitenDE400015 Heated Sample Gas Lineseve1Noch keine Bewertungen

- GB PetroTraceOilfieldheatingsystemsNAM SB H58453 Tcm432 26180Dokument12 SeitenGB PetroTraceOilfieldheatingsystemsNAM SB H58453 Tcm432 26180turboconchNoch keine Bewertungen

- HFCF CatalogueDokument12 SeitenHFCF CatalogueHồ ĐạtNoch keine Bewertungen

- Omnigrad TST410: RTD ThermometerDokument4 SeitenOmnigrad TST410: RTD Thermometermetanoia88Noch keine Bewertungen

- Pos 0,5 DatasheetDokument7 SeitenPos 0,5 DatasheetDoğa Tuğçe DurmuşNoch keine Bewertungen

- Datasheet - Live: Thermocouple and RTD SensorsDokument2 SeitenDatasheet - Live: Thermocouple and RTD SensorsManuel HTNoch keine Bewertungen

- ExPro-TT enDokument1 SeiteExPro-TT enTato MayoNoch keine Bewertungen

- TR95, TC95Dokument8 SeitenTR95, TC95greatNoch keine Bewertungen

- RTD 800.pdftermometro DigitalDokument2 SeitenRTD 800.pdftermometro DigitalnikNoch keine Bewertungen

- PT100 Detail and Resistance Temperature Chart PDFDokument4 SeitenPT100 Detail and Resistance Temperature Chart PDFanurag_jay12464Noch keine Bewertungen

- TCNet Design ReportDokument2 SeitenTCNet Design Reportanon_478154411Noch keine Bewertungen

- Sensör ProbuDokument8 SeitenSensör Probuekazkayasi6810Noch keine Bewertungen

- RDokument21 SeitenRMiroslav LuladžićNoch keine Bewertungen

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionDokument10 SeitenServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineNoch keine Bewertungen

- Tempco Sensors PI 160 - High-Temp - PrintDokument4 SeitenTempco Sensors PI 160 - High-Temp - PrintsrikannthNoch keine Bewertungen

- 2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmDokument5 Seiten2/2 or 3/2-Way Solenoid Valve, With Pivoted Armature and Isolating DiaphragmSohail AhmedNoch keine Bewertungen

- Catalogo de Producto HFCF PDFDokument12 SeitenCatalogo de Producto HFCF PDFJhon Edinson Blanco GomezNoch keine Bewertungen

- Sanitary Diaphragm Valve: Type 672Dokument7 SeitenSanitary Diaphragm Valve: Type 672Hilux PabloNoch keine Bewertungen

- Across STF Tube Furnace ManualDokument33 SeitenAcross STF Tube Furnace Manualys710924Noch keine Bewertungen

- What Is A Thermocouple Sensor?: Room-Temperature Insulation Resistance Ungrounded ThermocoupleDokument3 SeitenWhat Is A Thermocouple Sensor?: Room-Temperature Insulation Resistance Ungrounded ThermocoupletbmariNoch keine Bewertungen

- Pt100 RTD & Thermocouple Probes For Industrial ApplicationsDokument2 SeitenPt100 RTD & Thermocouple Probes For Industrial ApplicationsTrung DũngNoch keine Bewertungen

- CP MULTITHERM C Electric Heater: 1 ApplicationDokument2 SeitenCP MULTITHERM C Electric Heater: 1 Applicationmaria caipaNoch keine Bewertungen

- 12 Peter Baen ThermonDokument31 Seiten12 Peter Baen ThermonHafeez AhmadNoch keine Bewertungen

- ELECTRIC DUCT HEATERS Catalogue EnglishDokument8 SeitenELECTRIC DUCT HEATERS Catalogue EnglishHewa AkreyNoch keine Bewertungen

- Endress-Hauser RTD-Assembly U S Style T14 ENDokument4 SeitenEndress-Hauser RTD-Assembly U S Style T14 ENangel uscangaNoch keine Bewertungen

- Doc348350573022 PDFDokument24 SeitenDoc348350573022 PDFZahir KhiraNoch keine Bewertungen

- 5) Hd651enCP VarithermDokument3 Seiten5) Hd651enCP VarithermAnish KarthikeyanNoch keine Bewertungen

- Manguera Calefactora Tempco PDFDokument2 SeitenManguera Calefactora Tempco PDFErick MüllerNoch keine Bewertungen

- kjl-6000ss OperatorsmanualDokument4 Seitenkjl-6000ss OperatorsmanualSantiago MatuteNoch keine Bewertungen

- Murphy - RTDs - Termocuplas Acero InoxidableDokument2 SeitenMurphy - RTDs - Termocuplas Acero InoxidableJohn Jairo Simanca CastilloNoch keine Bewertungen

- Product Category 00-TMT Thermocouple Assemblies With Metal Protective TubeDokument4 SeitenProduct Category 00-TMT Thermocouple Assemblies With Metal Protective TubeNami Atta AssadiNoch keine Bewertungen

- Nabertherm - RD 3020011 Tube FurnaceDokument1 SeiteNabertherm - RD 3020011 Tube FurnaceVesna AnticNoch keine Bewertungen

- CP SLIMTHERM D Electric Heater: 1 ApplicationDokument2 SeitenCP SLIMTHERM D Electric Heater: 1 ApplicationRatheesh KumarNoch keine Bewertungen

- RS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Dokument13 SeitenRS1075 - Modelling of The BP 6MW Burner Test Rig With FIHR V 2.0Ian MannNoch keine Bewertungen

- DE420009 P2.x ATEXDokument7 SeitenDE420009 P2.x ATEXseve1Noch keine Bewertungen

- (I S S U e D 1 D e C - 1 9 6 5) C R D - C 4 5 - 6 5 Method of Test For Thermal Conductivity of Lightweight Insulating ConcreteDokument5 Seiten(I S S U e D 1 D e C - 1 9 6 5) C R D - C 4 5 - 6 5 Method of Test For Thermal Conductivity of Lightweight Insulating ConcreteFritz Gerald JimenoNoch keine Bewertungen

- Vibration Analysis of Heat Exchangers of A Nitric Acid PlantDokument8 SeitenVibration Analysis of Heat Exchangers of A Nitric Acid PlantAdrian García MoyanoNoch keine Bewertungen

- Thermocouple TC, Sensor High TempDokument1 SeiteThermocouple TC, Sensor High TempGuenidi Sif EddineNoch keine Bewertungen

- Arbol GeneologicoDokument4 SeitenArbol GeneologicoMarleny Lindo CajusolNoch keine Bewertungen

- Acta de Pruebas de Medición de Laresistencia Eléctrica de La Puesta AtierraDokument4 SeitenActa de Pruebas de Medición de Laresistencia Eléctrica de La Puesta AtierraMarleny Lindo CajusolNoch keine Bewertungen

- List of Contents - Preheater 2Dokument1 SeiteList of Contents - Preheater 2Marleny Lindo CajusolNoch keine Bewertungen

- 5.14.1 Norgren Pneumatic Pressure SwitchDokument4 Seiten5.14.1 Norgren Pneumatic Pressure SwitchMarleny Lindo CajusolNoch keine Bewertungen

- En IGBT FW E (No Tienen Instalado)Dokument108 SeitenEn IGBT FW E (No Tienen Instalado)Marleny Lindo CajusolNoch keine Bewertungen

- En Rpba01 Um F A4Dokument116 SeitenEn Rpba01 Um F A4Franco SotoNoch keine Bewertungen

- ES ACS800 FW H With Updaten PDFDokument278 SeitenES ACS800 FW H With Updaten PDFMarleny Lindo CajusolNoch keine Bewertungen

- ES ACS800 FW H With Updaten PDFDokument278 SeitenES ACS800 FW H With Updaten PDFMarleny Lindo CajusolNoch keine Bewertungen

- En SysCtrlProg FW G LowresDokument338 SeitenEn SysCtrlProg FW G LowresMarleny Lindo CajusolNoch keine Bewertungen

- En IGBT FW E (No Tienen Instalado)Dokument108 SeitenEn IGBT FW E (No Tienen Instalado)Marleny Lindo CajusolNoch keine Bewertungen

- En IGBT FW E (No Tienen Instalado)Dokument108 SeitenEn IGBT FW E (No Tienen Instalado)Marleny Lindo CajusolNoch keine Bewertungen

- Paper 4 Material Management Question BankDokument3 SeitenPaper 4 Material Management Question BankDr. Rakshit Solanki100% (2)

- Face Detection and Recognition Using Opencv and PythonDokument3 SeitenFace Detection and Recognition Using Opencv and PythonGeo SeptianNoch keine Bewertungen

- Manual TV Hyundai HYLED3239iNTMDokument40 SeitenManual TV Hyundai HYLED3239iNTMReinaldo TorresNoch keine Bewertungen

- Technical DescriptionDokument2 SeitenTechnical Descriptioncocis_alexandru04995Noch keine Bewertungen

- Small Data, Big Decisions: Model Selection in The Small-Data RegimeDokument10 SeitenSmall Data, Big Decisions: Model Selection in The Small-Data Regimejuan carlos monasterio saezNoch keine Bewertungen

- Coefficient of Restitution - Center of MassDokument3 SeitenCoefficient of Restitution - Center of MassMannyCesNoch keine Bewertungen

- S P99 41000099DisplayVendorListDokument31 SeitenS P99 41000099DisplayVendorListMazen Sanad100% (1)

- OracleCarrierManifestingPartnerIntegration PDFDokument40 SeitenOracleCarrierManifestingPartnerIntegration PDFvishal_vishnu11Noch keine Bewertungen

- BBAG MPR and STR LISTSDokument25 SeitenBBAG MPR and STR LISTShimanshu ranjanNoch keine Bewertungen

- RseDokument60 SeitenRseH S Vishwanath ShastryNoch keine Bewertungen

- 2008 Kershaw CatalogDokument38 Seiten2008 Kershaw CatalogDANILA MARECHEKNoch keine Bewertungen

- H.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeDokument108 SeitenH.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeeswariNoch keine Bewertungen

- Group 4&5 Activity Syntax AnalyzerDokument6 SeitenGroup 4&5 Activity Syntax AnalyzerJuan PransiskoNoch keine Bewertungen

- Turnbull CV OnlineDokument7 SeitenTurnbull CV Onlineapi-294951257Noch keine Bewertungen

- Mahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportDokument5 SeitenMahindra First Choice Wheels LTD: 4-Wheeler Inspection ReportRavi LoveNoch keine Bewertungen

- Southern California International Gateway Final Environmental Impact ReportDokument40 SeitenSouthern California International Gateway Final Environmental Impact ReportLong Beach PostNoch keine Bewertungen

- General Characteristics of Phonemes: Aspects of Speech SoundsDokument8 SeitenGeneral Characteristics of Phonemes: Aspects of Speech SoundsElina EkimovaNoch keine Bewertungen

- Assignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Dokument8 SeitenAssignment & Case Marketing Week 1: Max Van Neerven: 1664172 Mounir Trabelsi: 1705839 Renaldas Zlatkus: 1701775Ren ZkNoch keine Bewertungen