Beruflich Dokumente

Kultur Dokumente

Production Test Certificate

Hochgeladen von

Solomon MacwanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Production Test Certificate

Hochgeladen von

Solomon MacwanCopyright:

Verfügbare Formate

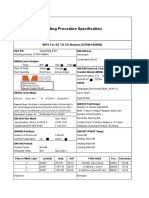

Format No: F-C-08-07-16

Production Test Certificate Rev-0

Product Description Type IV Composite LPG cylinder with non-load bearing plastic liner

Approved Inspection Body TUV Rhineland

Approved Inspection Body’s Mark

Certificate No. SIL/16/04/10kg/14 Date 21/04/2016

Manufacturer Name& The Supreme Industries Limited- Composite Division, 188/1 & 189/1, Village Chandrapura,

Address Taluka-Halol-389350,Dist.Panchmahal,Gujarat-India

Hindustan Petroleum Corporation

Client Name &Address

17, Jamshedji Tata Road, Mumbai 400020

Material Grade HDPE Resin Hardener Glass Rovings

Lupolen 4261 Owens

HDPE AG BD

Manufacturer Basell Manufacturer Dow Manufacturer Dow Manufacturer

Corning

Pallet No. /

Resin TW 103 Batch No. PE3045102H Batch No. 3E2719JD06 Batch No. D553F4D006

Invoice No.

204410159951

Whether Whether Whether

Whether meeting Yes/

Hardener TW 152 meeting Yes/ No meeting Yes/ No

specifications No

meeting Yes/ No

specifications specifications specifications

Liner Tensile

Glass 158 B Fiber Tensile

strength at 17.689 2715.874

Roving SE 1200 Tex strength (MPa)

yield (MPa)

Liner Elongation

12.194

at yield (%)

Test Standard Date of Production

Serial numbers Quantity

1604G02014001 to

ISO 11119-3:2002 18/04/2016 194

1604G02014200

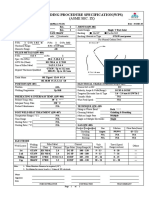

Ambient cycle test Burst Pressure test Mode of failure

Serial No. Cycle frequency

Test Pressure No. of Cycles Min Burst Press. Actual Burst Pr.

1604G02014040 30 12000 15 cycle/min. ----- ----- N.A

Burst through

1604G02014005 ----- ----- 5 bar/sec. 60 bar 129.12 bar

Shell area

Date of Production 04/2016 Next Inspection Date 03/2021

Water Capacity (L) 24.5 Drawing No 24.5/AS/1/16/00

Test Pressure (bar) 30

Tare weight with valve (kg) 5.9

Each liner was produced by over-wrapping a seamless liner with resin-impregnated filament reinforcement.

Liner material designated as HDPE was supplied by LyondellBasell and the analysis was within the required limits.

Each liner was produced by an approved process.

The results of the mechanical test have been found satisfactory.

Overwrap was applied by winding under controlled tension.

Glass fiber roving supplied by Owens Corning impregnated with resin designated as Epoxy manufactured by Dow Chemicals.

Identified by pallet number and cured after wrapping to the manufacturer’s standard.

Filaments strand strength and reinforcement were verified and found satisfactory.

Calculated stress levels on the reinforcement filaments satisfy design requirements.

Each cylinder was subjected to a hydraulic proof pressure test at the test pressure stated above.

The results of Ambient cycle test and burst tests were satisfactory.

Each cylinder has been marked as required by ISO 11119-3 clause -10 and customer requirement.

WE HEREBY CERTIFY that each of the above cylinders meets, in full, the requirements of ISO 11119-3:2002

For and on behalf of the manufacturer

Date HarmenTrivedi Manager QA/QC Company Seal

For and on behalf of the approved

inspection body

Date Name& Signature Designation Company Seal

Format No: F-C-08-07-16

Production Test Certificate Rev-0

Das könnte Ihnen auch gefallen

- TechnipFMC Project MobilizationDokument9 SeitenTechnipFMC Project MobilizationJobJob100% (8)

- Sample BQ For TNBDokument30 SeitenSample BQ For TNBKar Keh Kelly67% (6)

- MAG General Business Mill Test CertificateDokument1 SeiteMAG General Business Mill Test CertificateRaul Sebastiam67% (3)

- Essential Rubber Formulary: Formulas for PractitionersVon EverandEssential Rubber Formulary: Formulas for PractitionersBewertung: 3 von 5 Sternen3/5 (1)

- Welder ID CardDokument4 SeitenWelder ID CardTanpreet Singh100% (1)

- ITP Piping Stainless Steel (REV2.0)Dokument3 SeitenITP Piping Stainless Steel (REV2.0)mohd as shahiddin jafriNoch keine Bewertungen

- Mill Test Certificate for Safety Relief ValvesDokument1 SeiteMill Test Certificate for Safety Relief ValvesAlejandro Martinez100% (4)

- Proposed WPSDokument2 SeitenProposed WPSChisom Ikengwu100% (2)

- Volzhsky Pipe Plant, JSC: Revision 1. QTK-3-141Dokument3 SeitenVolzhsky Pipe Plant, JSC: Revision 1. QTK-3-14111tkt11100% (3)

- Welder Identification Card: Reference Code: ASME SEC IX Company Name - TESCODokument4 SeitenWelder Identification Card: Reference Code: ASME SEC IX Company Name - TESCOibrahim100% (2)

- Test CertificateDokument1 SeiteTest CertificateAvinash JadhavNoch keine Bewertungen

- Quality Assurance PlanDokument3 SeitenQuality Assurance PlanVicky Gautam100% (1)

- Ferrite Content ReportDokument2 SeitenFerrite Content ReportJawad MunirNoch keine Bewertungen

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Dokument5 SeitenWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Sample For Painting ReportDokument1 SeiteSample For Painting ReportSơn Nguyễn TháiNoch keine Bewertungen

- 694Dokument1 Seite694Mauricio Ramirez100% (1)

- Calculation of Longitudinal Forces in BridgesDokument155 SeitenCalculation of Longitudinal Forces in BridgesamirNoch keine Bewertungen

- Prevent Negative Volume in Foam ModelsDokument9 SeitenPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNoch keine Bewertungen

- DLS 11 14 18 27 36 60 TOUCH Parts ManualDokument35 SeitenDLS 11 14 18 27 36 60 TOUCH Parts ManualJose Manuel Castro0% (1)

- Assure Solutions: Hydro Test ReportDokument1 SeiteAssure Solutions: Hydro Test ReportKailas NimbalkarNoch keine Bewertungen

- 2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14Dokument8 Seiten2 in Check Valve 2 X 300 Neway Astm A216 WCB RF S-N 61035-250-14JORGE BAENA100% (1)

- Mill Test Certificate: Zibo Camel Material Co., LTDDokument1 SeiteMill Test Certificate: Zibo Camel Material Co., LTDJoseph Arturo SolisNoch keine Bewertungen

- MTC 4500528257 Iii - 210209Dokument3 SeitenMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNoch keine Bewertungen

- Material TCDokument1 SeiteMaterial TCgmbakshiNoch keine Bewertungen

- MILL TEST CERTIFICATE FOR H.F.W. STEEL PIPEDokument2 SeitenMILL TEST CERTIFICATE FOR H.F.W. STEEL PIPEClarkFedele27100% (1)

- WPQ Formats NEWDokument4 SeitenWPQ Formats NEWMANABENDRA MAITRANoch keine Bewertungen

- 08.05.2019 Npu 400Dokument2 Seiten08.05.2019 Npu 400Yasin BaturNoch keine Bewertungen

- Welder Id Card DhavalDokument18 SeitenWelder Id Card DhavalDhaval engineeringNoch keine Bewertungen

- MTC - Plate 2mx12m - 8mmDokument4 SeitenMTC - Plate 2mx12m - 8mmValesh Monis100% (1)

- Mill Test Certificate Certificate Conform To: EN 10204/3.1Dokument1 SeiteMill Test Certificate Certificate Conform To: EN 10204/3.1GLORIA MONSALVE SALAZARNoch keine Bewertungen

- Flange 10 & 12 InchDokument2 SeitenFlange 10 & 12 InchreniNoch keine Bewertungen

- Test CertificateDokument2 SeitenTest CertificatePRITESHNoch keine Bewertungen

- Wps Aws d1.1 NEWDokument2 SeitenWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokument2 SeitenElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Mag General Business: Mill Test CertificateDokument1 SeiteMag General Business: Mill Test CertificateRaul Sebastiam100% (1)

- Liquid Penetrant Examination Report: PO No.&Dokument2 SeitenLiquid Penetrant Examination Report: PO No.&Samir Chaudhary100% (2)

- QC FORMDokument3 SeitenQC FORMRicardo LourençoNoch keine Bewertungen

- Welder Qualification Test Certificate for Mohan ReddyDokument2 SeitenWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- Mill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateDokument1 SeiteMill Mill Mill Mill Test Test Test Test Certificate Certificate Certificate CertificateNurzamain AdiNoch keine Bewertungen

- Qualified Welder List Valid Until - 03-12-2019Dokument2 SeitenQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Aws d1.1 WPS, PQR & WQTDokument4 SeitenAws d1.1 WPS, PQR & WQTWeld Bro SandeepNoch keine Bewertungen

- Quality Certificated 123Dokument1 SeiteQuality Certificated 123Zaid Raslan Ayoub100% (1)

- WPS for SS to CS WeldingDokument1 SeiteWPS for SS to CS WeldingLipika GayenNoch keine Bewertungen

- Material Test Report: ISO EN 10204 2004-3.1Dokument4 SeitenMaterial Test Report: ISO EN 10204 2004-3.1Johan Sebastian C. SNoch keine Bewertungen

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Dokument1 SeiteMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- QD62-H-103 DocumentationDokument16 SeitenQD62-H-103 DocumentationAlam MD SazidNoch keine Bewertungen

- MTR's PO# 2113-06-12 PDFDokument14 SeitenMTR's PO# 2113-06-12 PDFAgustinaDeWinneNoch keine Bewertungen

- Inc 800 MTC - FlangeDokument1 SeiteInc 800 MTC - Flangeranjith_007100% (1)

- L.P.T Reports.Dokument12 SeitenL.P.T Reports.Shaikh AdilNoch keine Bewertungen

- Welding Procedure Specification: ST NDDokument1 SeiteWelding Procedure Specification: ST NDMaung SleeperNoch keine Bewertungen

- SLA Mill Test Certificate for 316/316 Stainless Steel PlatesDokument4 SeitenSLA Mill Test Certificate for 316/316 Stainless Steel PlatesSurajPandey33% (3)

- Customer Report Dimensions Visual InspectionDokument9 SeitenCustomer Report Dimensions Visual Inspectioniftekhar ahmedNoch keine Bewertungen

- Pro PWHT 006 Rev 1 - Procedure For PWHTDokument6 SeitenPro PWHT 006 Rev 1 - Procedure For PWHTsugumar100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Dokument3 SeitenWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Painting & Sand Blasting ReportDokument41 SeitenPainting & Sand Blasting ReportAshwani Dogra89% (9)

- Ball Valve MTCDokument1 SeiteBall Valve MTCAdnanAtifNoch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- Val Caraig WPQTDokument1 SeiteVal Caraig WPQTMark Jason M. BrualNoch keine Bewertungen

- Tube S2 HFS MTCDokument1 SeiteTube S2 HFS MTCunnamed90Noch keine Bewertungen

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDokument5 SeitenWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Dokument3 SeitenHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNoch keine Bewertungen

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDokument39 SeitenNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNoch keine Bewertungen

- Technical Data Ig ArgoniteDokument2 SeitenTechnical Data Ig ArgoniteTun JebatNoch keine Bewertungen

- c19846 2 PDFDokument2 Seitenc19846 2 PDFnaser712Noch keine Bewertungen

- From To: Selection Screen Material: Plant: Date: OutputDokument2 SeitenFrom To: Selection Screen Material: Plant: Date: OutputSolomon MacwanNoch keine Bewertungen

- MD81Dokument1 SeiteMD81Solomon MacwanNoch keine Bewertungen

- CTM EvaluationDokument1 SeiteCTM EvaluationSolomon MacwanNoch keine Bewertungen

- MD81 Customer ReqDokument1 SeiteMD81 Customer ReqSolomon MacwanNoch keine Bewertungen

- Master Recipe ScenariosDokument13 SeitenMaster Recipe ScenariosSolomon MacwanNoch keine Bewertungen

- Material Quota ArrangementDokument5 SeitenMaterial Quota ArrangementSolomon MacwanNoch keine Bewertungen

- PP Ecm01 - Create EcnDokument5 SeitenPP Ecm01 - Create EcnSolomon MacwanNoch keine Bewertungen

- ABAP Query User Groups User Groups Queries Queries Functional Areas User Groups QueriesDokument29 SeitenABAP Query User Groups User Groups Queries Queries Functional Areas User Groups QueriesSolomon MacwanNoch keine Bewertungen

- SAP Production Planning TableDokument97 SeitenSAP Production Planning Tablesam96% (23)

- Work Method Statement - Fireproofing PaintDokument4 SeitenWork Method Statement - Fireproofing Paintarrojak maksumNoch keine Bewertungen

- Curing in ConstructionDokument7 SeitenCuring in ConstructionNgissah NketiahNoch keine Bewertungen

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesDokument12 SeitenMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokNoch keine Bewertungen

- Dual Phase SteelsDokument26 SeitenDual Phase SteelsharieduidNoch keine Bewertungen

- Seismic Retrofit of RC Frame Buildings With Masonry Infill Walls: Literature Review and Preliminary Case StudyDokument83 SeitenSeismic Retrofit of RC Frame Buildings With Masonry Infill Walls: Literature Review and Preliminary Case Studybasabi12Noch keine Bewertungen

- Bar STDDokument8 SeitenBar STDtushk20100% (1)

- How To Control The Warping of Parts in Thin SheetDokument6 SeitenHow To Control The Warping of Parts in Thin SheetNeil WayneNoch keine Bewertungen

- En-353GF Head & Lower HalfDokument22 SeitenEn-353GF Head & Lower HalfVaeco Đoàn Tncs HcmNoch keine Bewertungen

- MaxxShot & MaxxShot Plus Extend Die LifeDokument4 SeitenMaxxShot & MaxxShot Plus Extend Die LifeDhinesh DftNoch keine Bewertungen

- Rehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadDokument2 SeitenRehabilitation of Sindangan-Siayan-Dumingag-Mahayag RoadAljie CañeteNoch keine Bewertungen

- Pump (English) TemplateDokument1 SeitePump (English) TemplateMichael HaiseNoch keine Bewertungen

- Introduction To Prestressing CE 572: Purdue University School of Civil EngineeringDokument21 SeitenIntroduction To Prestressing CE 572: Purdue University School of Civil EngineeringNatarajan SaravananNoch keine Bewertungen

- Seismic Rules Masonry Walls Eurocode 6Dokument8 SeitenSeismic Rules Masonry Walls Eurocode 6Nikolai BogdanovNoch keine Bewertungen

- Ventilation & Indoor Climate NoteDokument65 SeitenVentilation & Indoor Climate NotenervozaurNoch keine Bewertungen

- Method Statement For Site OfficeDokument18 SeitenMethod Statement For Site OfficeAdrianus Hindradjaja100% (2)

- Parts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherDokument12 SeitenParts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherMARTIN CABRERANoch keine Bewertungen

- As 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PDokument8 SeitenAs 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PSAI Global - APACNoch keine Bewertungen

- Steel Column Buckling Axial and Transverse LoadingDokument31 SeitenSteel Column Buckling Axial and Transverse LoadingTor GrimlundNoch keine Bewertungen

- Machine Design - Introduction PDFDokument13 SeitenMachine Design - Introduction PDFDida KhalingNoch keine Bewertungen

- Steel Fibers For Fiber-Reinforced ConcreteDokument4 SeitenSteel Fibers For Fiber-Reinforced ConcreteIvan TapiaNoch keine Bewertungen

- VIBR.ROLLER DRUM PARTS LIST BW 212-2Dokument9 SeitenVIBR.ROLLER DRUM PARTS LIST BW 212-2Nidya Wardah JuhanaNoch keine Bewertungen

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDokument1 SeiteThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamNoch keine Bewertungen

- Concrete Shell ElementDokument25 SeitenConcrete Shell ElementRudranath BhattacharyaNoch keine Bewertungen

- PIP PCECV001 Guidelines For Application of Control ValvesDokument39 SeitenPIP PCECV001 Guidelines For Application of Control ValvesAndresNoch keine Bewertungen

- 1way and 2way SlabsDokument7 Seiten1way and 2way Slabslance lancelottiNoch keine Bewertungen