Beruflich Dokumente

Kultur Dokumente

Structural Washer

Hochgeladen von

HARDEEP SINGH0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

50 Ansichten1 Seitegood f

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengood f

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

50 Ansichten1 SeiteStructural Washer

Hochgeladen von

HARDEEP SINGHgood f

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

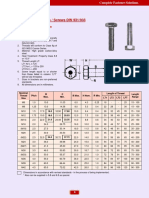

Table 5: 'UNILOK' High Strength Structural Washers - Dimensions

Bolt Size M16 M20 M22 M24 M27 M30 M36

Min. 18.00 22.00 24.00 26.00 30.00 33.00 39.00

d

Max. 18.43 22.52 24.52 26.52 30.52 33.62 39.62

Max. 34.00 42.00 44.00 50.00 56.00 60.00 72.00

D

Min. 32.40 40.40 42.40 48.40 54.10 58.10 70.10

Max. 4.60 4.60 4.60 4.60 4.60 4.60 4.60

H

Min. 3.10 3.10 3.40 3.40 3.40 3.40 3.40

Weight

Kg/1000pcs 20.3 31.3 33.2 44.7 54.8 61.4 89.7

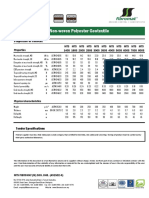

Table 6: Mechanical Properties of H.S.S. Bolts

Property Class 8.8 Property Class 10.9

Stress

Thread Ultimate Proof Load Ultimate Proof Load

Area Hardness Hardness

Size Load (Min) (Min) Load (Min) (Min)

2

mm Newtons Newtons HRC Newtons Newtons HRC

M16 157 125600 91060 22-32 163280 130310

M20 245 203350 147000 254800 203350

(M22) 303 251490 181800 315120 251490

M24 353 292990 211800 367120 292990 32-39

23-34

(M27) 459 380970 275400 477360 380970

M30 561 465630 336600 583440 465630

M36 817 678110 490200 849680 678110

Table 7: Mechanical Properties of H.S.S. Nuts

Property Class 8 Property Class 10

Thread Size Proof Load Proof Load

Hardness Hardness

Newtons Newtons

M16 168900 195500

M20 263400 305000

(M22) 325700 HRB89 377200 HRC 26

M24 379500 To 439500 to

(M27) 493400 HRC 38 571500 HRC 38

M30 603100 698400

M36 878300 1017200

ASSEMBLY paint or any other foreign material or placed in position.

Calculation of Bolt length : any defect. A clean, as rolled surface Driving of bolts should not be

The length of bolt required to be used with light mill scale is acceptable. permitted as it will damage the

in the assembly will depend on the All bolts, nuts and washers should be threads.

Grip Length (Clamping Length). Table identified as being the correct type Each bolt and nut should be

4 gives range of Grip Lengths for H.S.S. Fasteners while drawing from assembled with flat washer under the

individual Bolt Lengths. In deciding the stores. The holes will be lined up with nut or bolt head, whichever is to be

ranges, allowances have been made sufficient drift pins to maintain the rotated during tightening, preferably

for the thickness of nut, one flat round dimensions and plumbness of the tightening will be done by nut rotation.

washer and sufficient thread protrusion structure until bolts in the remaining Taper washers are used under nuts or

beyond nut. Adequate allowances holes have been fully tightened - well bolt heads where I angular seatings are

should be made for additional aligned holes will permit bolts to be necessary.

washers or taper washers, if used. freely

Holes in Members:

All holes should preferably be drilled,

burrs should be removed. Nominal

hole diameters are given in Table 8.

Operation:

All contact sufaces should be free of

oil, dirt, loose scales, rust, burrs,

Das könnte Ihnen auch gefallen

- Principles and Applications of Tribology: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series in Materials Science and TechnologyVon EverandPrinciples and Applications of Tribology: Pergamon International Library of Science, Technology, Engineering and Social Studies: International Series in Materials Science and TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Wear: Materials, Mechanisms and PracticeVon EverandWear: Materials, Mechanisms and PracticeGwidon W. StachowiakNoch keine Bewertungen

- RITZ Screw Specification PDFDokument12 SeitenRITZ Screw Specification PDFThawatchai DanwangkhawNoch keine Bewertungen

- Din 934Dokument1 SeiteDin 934Chuan ChuNoch keine Bewertungen

- Din 933Dokument2 SeitenDin 933Sugumar0% (1)

- Astm A325m PDFDokument1 SeiteAstm A325m PDFFrose KhanNoch keine Bewertungen

- Metric Hex Bolt DimensionsDokument7 SeitenMetric Hex Bolt DimensionsVishal MistryNoch keine Bewertungen

- Hex NutsDokument10 SeitenHex Nutsjaskaran singhNoch keine Bewertungen

- Complete Fastener Solutions Hexagon BoltsDokument2 SeitenComplete Fastener Solutions Hexagon Boltscoolkaisy100% (2)

- Hdpe Twisted TwineDokument2 SeitenHdpe Twisted TwineUmesh ThakareNoch keine Bewertungen

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Dokument2 SeitenHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNoch keine Bewertungen

- Torque ChartDokument1 SeiteTorque Chartjyoti prakash singhNoch keine Bewertungen

- Conveyor Calculation IS 11592Dokument2 SeitenConveyor Calculation IS 11592Maknan SteelNoch keine Bewertungen

- High Tensile Bolts TechnicalDokument6 SeitenHigh Tensile Bolts Technicalventhan_kalaiNoch keine Bewertungen

- MIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9Dokument2 SeitenMIDLAND FASTENERS LTD BOLT STANDARDS BS EN 14399-3 8.8 & 10.9Hüseyin VarolNoch keine Bewertungen

- TITAN Datasheet EN 2015 PDFDokument4 SeitenTITAN Datasheet EN 2015 PDFMarleneNoch keine Bewertungen

- Torque SettingsDokument3 SeitenTorque Settingsgamedbk002Noch keine Bewertungen

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDokument2 SeitenHeavy Hex Structural Bolts - ASTM A325M: Metric Series - Dimensionskptl6185Noch keine Bewertungen

- Astm A325 Grade 8.8 PDFDokument2 SeitenAstm A325 Grade 8.8 PDFWisnu AjiNoch keine Bewertungen

- Heavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsDokument2 SeitenHeavy Hex Structural Bolts - ASTM A325M: Metric Series - DimensionsSuresh BabuNoch keine Bewertungen

- Non-Pre Load Hexagon Nut Bs 3692: Standards BS3692 (British Standard)Dokument2 SeitenNon-Pre Load Hexagon Nut Bs 3692: Standards BS3692 (British Standard)Mahfuz AlamNoch keine Bewertungen

- Design and Stress Analysis of Perforated Plates Under Uni-Axial CompressionDokument14 SeitenDesign and Stress Analysis of Perforated Plates Under Uni-Axial CompressionNaveenprakashNoch keine Bewertungen

- Calculationof The RC Pile From JianhuaDokument5 SeitenCalculationof The RC Pile From JianhuaDier K-riboNoch keine Bewertungen

- Bapp Astm A490m AssemblyDokument4 SeitenBapp Astm A490m Assemblyparcia90Noch keine Bewertungen

- FibrotexDokument2 SeitenFibrotexMan ChupingNoch keine Bewertungen

- Bridge rules for load assessmentDokument1 SeiteBridge rules for load assessmentJaganath MallikNoch keine Bewertungen

- MTC Spec 1916Dokument3 SeitenMTC Spec 1916Indwell RaigarhNoch keine Bewertungen

- Mechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelDokument1 SeiteMechanical Properties of Fasteners Made of Carbon Steel and Alloy SteelVarun KumarNoch keine Bewertungen

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDokument1 Seite024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaNoch keine Bewertungen

- Singly Reinforced Beam: Design For ShearDokument16 SeitenSingly Reinforced Beam: Design For ShearArbaz AhmedNoch keine Bewertungen

- Kokamthan Pipe Culverts BBSDokument3 SeitenKokamthan Pipe Culverts BBSSreekanth SattirajuNoch keine Bewertungen

- Repot k2Dokument3 SeitenRepot k2Mahendra AdiNoch keine Bewertungen

- Socket Head Cap Screws Dimensions and Torque SpecsDokument4 SeitenSocket Head Cap Screws Dimensions and Torque SpecssarbiniNoch keine Bewertungen

- Bolt CalculationDokument2 SeitenBolt CalculationTuanren Wu100% (2)

- Cyclic Behaviour of Glued-In-Joints Under Bending Moments: Natalino Gattesco, Alessandra Gubana, Manuela ButtazziDokument8 SeitenCyclic Behaviour of Glued-In-Joints Under Bending Moments: Natalino Gattesco, Alessandra Gubana, Manuela Buttazzipacman922Noch keine Bewertungen

- Koneg Instruction Manual - Mackintosh - JKR Probe Set (Colour)Dokument10 SeitenKoneg Instruction Manual - Mackintosh - JKR Probe Set (Colour)Bumi BinadayaNoch keine Bewertungen

- High Tensile: Hexagon Nuts EN ISO 4032 (DIN 934)Dokument2 SeitenHigh Tensile: Hexagon Nuts EN ISO 4032 (DIN 934)plex015Noch keine Bewertungen

- Presentation On Helical Spring: Dhaka University of Engineering & Technology, GAZIPUR-1700Dokument19 SeitenPresentation On Helical Spring: Dhaka University of Engineering & Technology, GAZIPUR-1700Md saydul islamNoch keine Bewertungen

- Laboratorium Metalurgi Fisik Dep. T. Mesin Ft-Uh: TensileDokument7 SeitenLaboratorium Metalurgi Fisik Dep. T. Mesin Ft-Uh: Tensilesham mulsyNoch keine Bewertungen

- Estimation SummaryDokument7 SeitenEstimation SummaryLily QuiNoch keine Bewertungen

- BAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFDokument4 SeitenBAPP-Preload-Assem-BS EN 14399HR-3-HRASS PDFrjtcostaNoch keine Bewertungen

- Bapp Preload Assem Bsen14399hr 3 HrassDokument4 SeitenBapp Preload Assem Bsen14399hr 3 HrasspolpositionNoch keine Bewertungen

- Steel Washers for Channel Sections (DIN 434Dokument1 SeiteSteel Washers for Channel Sections (DIN 434Dhananjay ShindeNoch keine Bewertungen

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDokument2 SeitenMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PnothingNoch keine Bewertungen

- Metric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PDokument2 SeitenMetric, Heavy Hex Nuts, ASTM A194M 2H, Plain: Page 1 of 2 REV-01 Date: March 18, 2016 M.HHN.2H.PjoseocsilvaNoch keine Bewertungen

- Metric Hex PDFDokument2 SeitenMetric Hex PDFCarlos Eduardo Cardenas SochaNoch keine Bewertungen

- Calculation of The Pile From XinChuangDokument5 SeitenCalculation of The Pile From XinChuangDier K-riboNoch keine Bewertungen

- Mme Assignment Solution.Dokument11 SeitenMme Assignment Solution.Peace AdetunmibiNoch keine Bewertungen

- Area of SteelDokument26 SeitenArea of Steelaqib.syed1011Noch keine Bewertungen

- Estimation SampleDokument65 SeitenEstimation SamplePraveen ChaudharyNoch keine Bewertungen

- Technical Data Sheet For Mgs and MGSRDokument3 SeitenTechnical Data Sheet For Mgs and MGSRFILID MADNoch keine Bewertungen

- Singly Reinforced Doubly Reinforced: U, Lim 2 U 2Dokument5 SeitenSingly Reinforced Doubly Reinforced: U, Lim 2 U 2Kumar Prasanna HNNoch keine Bewertungen

- GBT 1228-2006 High Strength Bolts With Large Hexagon Head For Steel StructuresDokument7 SeitenGBT 1228-2006 High Strength Bolts With Large Hexagon Head For Steel Structures494328514Noch keine Bewertungen

- Gage Repeatability and Reproducibility Data Sheet AnalysisDokument30 SeitenGage Repeatability and Reproducibility Data Sheet AnalysisCarlosPazNoch keine Bewertungen

- Kadamane Mini Hydel Scheme Stiffener Plate CalculationDokument5 SeitenKadamane Mini Hydel Scheme Stiffener Plate CalculationKumaranNoch keine Bewertungen

- Grade 8.8 Bolt & Nut (Iso)Dokument1 SeiteGrade 8.8 Bolt & Nut (Iso)ADJNoch keine Bewertungen

- Metric DIN 609 SpecDokument4 SeitenMetric DIN 609 SpecCAT MINING SHOVELNoch keine Bewertungen

- Macalloy Brochure Tension Structures December - 2017 - V1Dokument16 SeitenMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNoch keine Bewertungen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- MFG Tooling - 13 Inspection FixtureDokument15 SeitenMFG Tooling - 13 Inspection FixtureJuan Posada GNoch keine Bewertungen

- Is 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsDokument37 SeitenIs 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsAmit SinghNoch keine Bewertungen

- Zamil Steel ManualDokument469 SeitenZamil Steel ManualDhanu Padhu80% (5)

- DatumsDokument60 SeitenDatumsgaganesan1972100% (1)

- GENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFDokument43 SeitenGENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFhasib_07Noch keine Bewertungen

- Structural WasherDokument1 SeiteStructural WasherHARDEEP SINGHNoch keine Bewertungen

- Design and Analysis of Progressive Tool: CH - Mastanamma, K.Prasada Rao, Dr. M.Venkateswara RaoDokument11 SeitenDesign and Analysis of Progressive Tool: CH - Mastanamma, K.Prasada Rao, Dr. M.Venkateswara Raoraghunath670743Noch keine Bewertungen

- ProSteel V8i AutoCAD 3D Modeling Fundamentals (Metric) TRN015490-1-0004Dokument288 SeitenProSteel V8i AutoCAD 3D Modeling Fundamentals (Metric) TRN015490-1-0004HARDEEP SINGHNoch keine Bewertungen

- 228 22 PDFDokument6 Seiten228 22 PDFHARDEEP SINGHNoch keine Bewertungen

- Din 934Dokument0 SeitenDin 934mjinspectorNoch keine Bewertungen

- Is 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsDokument37 SeitenIs 4326 1993 - Code of Practice For Earthquake Resistant Design and Construction of BuildingsAmit SinghNoch keine Bewertungen

- GENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFDokument43 SeitenGENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFhasib_07Noch keine Bewertungen

- Structural WasherDokument1 SeiteStructural WasherHARDEEP SINGHNoch keine Bewertungen

- Xpress ManualDokument12 SeitenXpress ManualHARDEEP SINGHNoch keine Bewertungen

- Mbma 96Dokument144 SeitenMbma 96HARDEEP SINGHNoch keine Bewertungen

- Din 934Dokument0 SeitenDin 934mjinspectorNoch keine Bewertungen

- As User Guide 2015 en Metric 140408Dokument170 SeitenAs User Guide 2015 en Metric 140408Saad Al HelyNoch keine Bewertungen

- TATA Structura BrochureDokument20 SeitenTATA Structura Brochurecjm100% (2)

- Structural WasherDokument1 SeiteStructural WasherHARDEEP SINGHNoch keine Bewertungen

- IS-875-Part1 - Dead Loads For DesignDokument39 SeitenIS-875-Part1 - Dead Loads For Designlokesh2325100% (7)

- GENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFDokument43 SeitenGENERAL ENGINEERING Handbook-of-Formulae - And-Constants PDFhasib_07Noch keine Bewertungen

- Alma Phase 2 Community Facilities: 16-084 FFE SpecificationDokument21 SeitenAlma Phase 2 Community Facilities: 16-084 FFE Specificationjoe whiteNoch keine Bewertungen

- Vulkem NEM - Data SheetDokument2 SeitenVulkem NEM - Data SheetRobertNoch keine Bewertungen

- Quality Control Program:: Construction of Adgawan River Flood Control, (Incl. ROW) Limits: Test To Be PerformedDokument24 SeitenQuality Control Program:: Construction of Adgawan River Flood Control, (Incl. ROW) Limits: Test To Be PerformedFBVid Uploads0% (1)

- MaxxShot & MaxxShot Plus Extend Die LifeDokument4 SeitenMaxxShot & MaxxShot Plus Extend Die LifeDhinesh DftNoch keine Bewertungen

- Loxeal InfotechDokument16 SeitenLoxeal InfotechAlexNoch keine Bewertungen

- Mat UrbanismDokument11 SeitenMat UrbanismBadr ZeinaNoch keine Bewertungen

- PRovincial Architecture GujratDokument31 SeitenPRovincial Architecture GujratPiyush Mahakalkar67% (3)

- Concrete Flag Pavements Design GuideDokument31 SeitenConcrete Flag Pavements Design GuideNguyễn Hoàng Bảo100% (2)

- Install Refnet branches for Daikin heat pumpsDokument4 SeitenInstall Refnet branches for Daikin heat pumpsIloaie FlorinNoch keine Bewertungen

- Imphal EasaaDokument1 SeiteImphal EasaaKosygin LeishangthemNoch keine Bewertungen

- 4 Design of Slab Bridges PDFDokument6 Seiten4 Design of Slab Bridges PDFsohanpmeharwadeNoch keine Bewertungen

- 11-1 Light-C V 5 - Earthquake Protection DevicesDokument28 Seiten11-1 Light-C V 5 - Earthquake Protection DevicesPACO PAQUETINESNoch keine Bewertungen

- B-1050 EL Resilient 2012-08Dokument24 SeitenB-1050 EL Resilient 2012-08Karthick VenkateshNoch keine Bewertungen

- Yamuna Sports ComplexDokument37 SeitenYamuna Sports ComplexHimanshu GoodwaniNoch keine Bewertungen

- Thumb Rules in Civil ConstructionDokument9 SeitenThumb Rules in Civil ConstructionAnish Chandran100% (1)

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDokument349 SeitenBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- PIP PCECV001 Guidelines For Application of Control ValvesDokument39 SeitenPIP PCECV001 Guidelines For Application of Control ValvesAndresNoch keine Bewertungen

- D7032 1213477 1 PDFDokument11 SeitenD7032 1213477 1 PDFBodhi RudraNoch keine Bewertungen

- L-CKD Heavy Duty Industrial Gear OilDokument3 SeitenL-CKD Heavy Duty Industrial Gear OilDavidNoch keine Bewertungen

- 32 Samss 022Dokument11 Seiten32 Samss 022naruto256Noch keine Bewertungen

- Spare Parts Catalog: 4 WG 160 Material Number: 4656.054.039 Current Date: 10.06.2020Dokument70 SeitenSpare Parts Catalog: 4 WG 160 Material Number: 4656.054.039 Current Date: 10.06.2020Romuald Pogorzelczyk100% (2)

- Sikafloor - 161 PDFDokument5 SeitenSikafloor - 161 PDFShaik FazilNoch keine Bewertungen

- A Presentation On Doors & WindowsDokument45 SeitenA Presentation On Doors & WindowsFarheen BanoNoch keine Bewertungen

- The Arctic Shutter - Thermal Window Shutter For Cold ClimatesDokument1 SeiteThe Arctic Shutter - Thermal Window Shutter For Cold ClimatesKhanh DamNoch keine Bewertungen

- Daily RFI Schedule 20210302Dokument1 SeiteDaily RFI Schedule 20210302samwel kariukiNoch keine Bewertungen

- Qdoc - Tips - Flange Asme VIIIDokument41 SeitenQdoc - Tips - Flange Asme VIIIHormedo RodriguezNoch keine Bewertungen

- Structural Drawings: Sl/Adb/St-CsDokument35 SeitenStructural Drawings: Sl/Adb/St-Csharold romuald Lele FotsoNoch keine Bewertungen

- N-G-HE - 200 - EN Pressure Safety ReliefDokument77 SeitenN-G-HE - 200 - EN Pressure Safety ReliefMEGAN ASBROCK100% (1)

- Presentation On LEED Green Building Rating SystemsDokument64 SeitenPresentation On LEED Green Building Rating SystemsMadhusmitaDash100% (1)

- Sudhar PipesDokument5 SeitenSudhar Pipesyashas sNoch keine Bewertungen