Beruflich Dokumente

Kultur Dokumente

ButterflyValves PDF

Hochgeladen von

mkiani2Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ButterflyValves PDF

Hochgeladen von

mkiani2Copyright:

Verfügbare Formate

BUTTERFLY VALVES

APPLICATION: FLSmidth is proud to offer a new line

of high quality butterfly valves to meet

the requirements of today's market.

Combining years of field application

experience in the minerals and cement

markets, with research and

development, FLSmidth has designed Butterfly Valve

many unique features into the valve,

resulting in longer service life, greater

reliability, ease of parts replacement

and interchangeability of components.

SPECIFICATION: DISC AND STEM CONNECTION

Features a high-strength through stem

design. The close tolerance connection that

drives the valve disc is a special feature of

the FLSmidth valve. It eliminates stem

retention components being exposed to the

line media, such as disc screws and taper

pins, which commonly result in leak paths,

corrosion, and vibration failures. Disc screws

or taper pins, due to wear and corrosion,

often require difficult machining for

disassembly. Disassembly of the FLSmidth

stem is just a matter of pulling the stem out

of the disc. Without fasteners obstructing the

line flow, the Cv values are higher than many

other valves, turbulence is reduced, and

pressure recovery is increased. The stem

ends and top mounting flange are

standardized for interchangeability with

FLSmidth actuators.

DISC

Casting is spherically machined, hand

polished to provide a bubble-tight shut off,

minimum torque, and longer seat life. The

disc O.D. clearance is designed to work with

all standard piping. Double Connection

STEM RETAINING ASSEMBLY

The stem is retained in the body by means

of a unique Stainless Steel retaining ring, a

thrust washer and two C-rings,

manufactured from brass as standard,

stainless steel upon request. The retaining

ring may be easily removed with a standard

hand tool. The stem retaining assembly also

prevents accidental removal of stem during

field service.

FLSmidth Inc. Butterfly Valves

www.fls-pt.com

BUTTERFLY VALVES

STEM BUSHING

Non-corrosive, heavy duty acetal bushing absorbs actuator

side thrusts

STEM SEAL

Double “U” cup seal design is self adjusting and gives positive

sealing in both directions. Prevents external substances from

entering stem bore.

NECK

Extended neck length allows for 2” of piping insulation and is

easily accessible for mounting actuators.

PRIMARY AND SECONDARY SEALS

The Primary Seal is achieved by an interference fit of the

unique molded seat flat with the disc hub. The Secondary Seal

is created because the stem diameter is greater than the

diameter of the seat stem hole. These seals prevent line

media from coming in contact with the stem or body.

TYPE SB & USB MAXIMUM TEMPERATURE 250°F (121°C)

Type SB & USB wafer-style Butterfly Valve for gas service

only, reduced diameter disc, ANSI class 125/150, 80% vacuum

to 50 PSI differential pressure, cast iron body, phosphate-

coated D.I. disc, 416 stainless steel shaft, EPDM seat

TYPE HB & UHB MAXIMUM TEMPERATURE 400°F (205°C)

Type HB & UHB wafer-style Butterfly Valve for gas service

only, reduced diameter disc, ANSI class 125/150, 80% vacuum

to 50 PSI differential pressure, cast iron body, phosphate-

coated D.I. disc, 416 stainless steel shaft, VITON seat

FLSMIDTH UNIQUE SEAT DESIGN

One of the valve's key elements is the unique tongue-and-groove seat design. This

resilient seat features lower torque than many valves on the market today and

provides complete isolation of flowing media from the body. The tongue-and-groove

seat to body retention method is superior to traditional designs, making field

replacement simple and fast. The seat is specifically designed to seal with slip-on or

weld-neck flanges. The seat features a molded O-ring which eliminates the use of

flange gaskets. An important maintenance feature is that all resilient seats for

FLSmidth butterfly valves are completely interchangeable.

ACTUATOR MOUNTING FLANGE AND STEM CONNECTION

Universally designed to ISO 5211 for direct mounting of FLSmidth power actuators

and manual operators. Tongue and Groove Design

FLANGE LOCATING HOLES

Provides quick and proper alignment during installation.

BODY

One-piece wafer style. Polyester coating for excellent corrosion resistance. FLSmidth valve bodies meet ANSI 150

pressure ratings for hydrostatic shell test requirements.

TEMPERATURE RANGE OF SEATS

Type Max Min

EPDM + 250°F (+121°C) -40°F (-40°C)

Viton + 400°F (+204°C) 0°F (-18°C)

FLSmidth Inc. Butterfly Valves

www.fls-pt.com

BUTTERFLY VALVES

DESIGN FEATURES

The FLSmidth Butterfly valve is a wafer version with flange locating holes. All FLSmidth valves are tested to 110% of full

pressure rating before shipment.

A major design advantage of FLSmidth valve product lines is international compatibility. The same valve is compatible

with most world flange standards - ANSI Class 125/150, BS 10 Tables D and E, BS 4504 NP 10/16, DIN ND 10/16 AS

2129 and JIS 10. In addition, the valves are designed to comply with ISO 5752 face-to-face and ISO 5211 actuator

mounting flanges. Therefore, one valve design can be used in many different world markets.

Due to a modular concept of design, all FLSmidth handles, manual gear operators, and pneumatic and electric actuators

mount directly to FLSmidth valves. No brackets or adapters are required. The standard FLSmidth design includes the

pneumatic actuator.

FLSmidth interchangeability and compatibility offers you the best in uniformity of product line and low-cost performance

in the industry today.

POLYESTER CORROSION PROTECTIVE COATED

FLSmidth’s standard product offers valve bodies with a polyester coating, providing excellent corrosion and wear

resistance to the valve’s surface. The FLSmidth polyester coating is a hard, gloss finish.

Chemical Resistance - resists a broad range of chemicals including: dilute aqueous acids and alkalies, petroleum

solvents, alcohols, greases, and oils. Offers outstanding resistance to humidity and water

Weatherability - outdoor tested, resistant to ultra-violet radiation

Abrasion Resistance - excellent resistance to abrasion

Impact Resistance - withstands impact without chipping or cracking

RECOMMENDED SPECIFICATIONS FOR FLSMIDTH VALVES SHALL BE:

• Polyester coated, cast iron, wafer bodies

• Through-stem direct drive design requiring no disc screws or pins to connect stem to disc with no possible leak paths in

disc/stem connection

• Stem mechanically retained in body neck and no part of stem or body exposed to line media

• Tongue-and-groove seat design with primary hub seal and a molded O-ring suitable for weld-neck and slip-on flanges.

Seat totally encapsulates the body with no flange gaskets required.

• Spherically machined, hand-polished disc edge and hub for minimum torque and maximum sealing capability

• Equipped with non-corrosive bushing and self-adjusting stem seal

• Bi-directional and tested to 110% of full rating’

• Bi-directional pressure ratings:

Item No. Qty Description

• 2”-12” valves: 175 psi

1 1 Body

• 14”-20” valves: 150 psi

2 1 Seat

• No field adjustment necessary to maintain optimal performance

• The valve shall be FLSmidth or equal 3 1 Disc

4 1 Stem

MATERIALS SELECTION 5 1 Stem Seal

• 2” - 20” (50mm - 500mm) 6 1 Stem Bushing

7 2 Stem Retainer

BODY

8 1 Thrust Washer

• Cast Iron ASTM A126 Class B

9 1 Retaining Ring

SEAT

• EPDM - Food Grade

• Viton

STEM

• 416 Stainless Steel ASTM A582 Type 416

DISC

• Coated Ductile Iron ASTM A536 Gr. 65-45-12

ACTUATORS

• Hand lever

• Air cylinder

FLSmidth Inc. Butterfly Valves

www.fls-pt.com

BUTTERFLY VALVES

Valve Size

Ass'y Weight

Inches mm A B C D E F F G H J L Lbs *

2” 50 3.69” 1.62” 2.00” 2.84” 5.50” 13.84” 14.67” 3.46” 6.00” 1.32” 1/8” 10

2.5” 65 4.19” 1.75” 2.50” 3.34” 6.00” 14.34” 15.17” 3.46” 6.00” 1.91” 1/8” 11

3" 80 4.88" 1.75" 3.00" 4.03" 6.25" 15.40" 16.23" 4.27" 7.89" 2.55" 1/8" 15

4" 100 6.06" 2.00" 4.00" 5.16" 7.00" 16.15" 16.98" 4.27" 7.89" 3.57" 1/8" 20

5" 125 7.06" 2.12" 5.00" 6.16" 7.50" 16.65" 17.48" 4.27" 7.89" 4.63" 1/8" 22

6" 150 8.12" 2.12" 5.75" 7.02" 8.00" 17.49" 18.32" 4.61" 8.91" 5.45" 1/8" 27

8" 200 10.50" 2.50" 7.75" 9.47" 9.50" 19.90" 20.73" 5.52" 12.10" 7.45" 1/4" 53

10" 250 12.75" 2.50" 9.75" 11.47" 10.75" 21.15" 21.98" 6.52" 12.10" 9.53" 1/4" 68

12" 300 14.88" 3.00" 11.75" 13.47" 12.25" 24.93" 25.76" 7.80" 15.45" 11.47" 1/4" 105

14" 350 17.05" 3.00" 13.25" 15.28" 13.62" 26.30" 27.13" 7.80" 15.45" 13.04" 1/4" 133

16" 400 19.21" 4.00" 15.25" 17.41" 14.75" 29.67" 30.50" 10.04" 18.92" 14.85" 1/4" 205

18" 450 21.12" 4.25" 17.25" 19.47" 16.00" 30.92" 31.75" 10.04" 18.92" 16.85" 1/4" 270

20" 500 23.25" 5.00" 19.25" 21.59" 17.25" 32.17" 33.00" 10.04" 18.92" 18.73" 1/4" 330

* Without solenoid and position indicator

NOTE:

1. VALVE IS SHOWN WITH HAVING BEEN LAST

SUPPLIED TO PORT “B” OF THE ACTUATOR,

VALVE IS CLOSED

2. SUPPLYING AIR TO PORT “A” OF THE

ACTUATOR WILL CAUSE THE VALVE TO OPEN

NOTE:

3. OPERATOR OPTION TYPE “AI”, ACTUATOR IS

MOUNTED PARALLEL TO PIPELINE.

4. OPERATOR OPTION TYPE “AP”, ACTUATOR IS

MOUNTED PERPENDICULAR TO PIPELINE.

5. ALL SOLENOID VALVES SUPPLIED WITH MANUAL

OVER-RIDE AND OPEN-CLOSE ADJUSTABLE SPEED

CONTROL EXHAUST MUFFLERS.

6. FLANGE LOCATING HOLES MEET ANSI CLASS

125/150 DRILLINGS.

7. ADD 3 LBS. FOR SOLENOID.

8. ADD 3 LBS. FOR POSITION INDICATOR.

“B”

Our brochure makes no offers, representations or warranties (express or implied), and information and data contained in this brochure are for general

reference only and may change at any time. Please contact us for specific information or data that may relate to your interests.

DENMARK USA INDIA

FLSmidth A/S FLSmidth Inc. FLSmidth Ltd.

12-2006 BFLY LS

Vigerslev Allé 77 2040 Avenue C Capital Towers

DK-2500 Valby Bethlehem, PA 18017-2188 180, Kodambakkam High Road

www.fls-pt.com Copenhagen Tel:+1 610-264-6011 Nungambakkam

Tel:+45 36 18 10 00 Tel:+1 800-523-9482 Chennai 600 034

Up-to-date addresses of worldwide Fax:+45 36 30 18 20 Fax:+1 610-264-6170 Tel:+91 – 44-52 191234

subsidiaries and sales offices are Email: info@flsmidth.com E-mail: info-us@flsmidth.com Fax:+91 – 44-2827 9393

available from our website E-mail: indiainfo@flsmidth.com

Das könnte Ihnen auch gefallen

- Sevice Manual BOBCAT S630 PDFDokument890 SeitenSevice Manual BOBCAT S630 PDFArtemio Garcia Barrientos100% (11)

- Greddy E-Manage Installation ManualDokument6 SeitenGreddy E-Manage Installation ManualTHMotorsports.net100% (2)

- Apron Feeder Power Calculations PDFDokument4 SeitenApron Feeder Power Calculations PDFtuba25% (4)

- Conveyor CalculationsDokument10 SeitenConveyor CalculationsCristhian PortocarreroNoch keine Bewertungen

- Apron Feeder Power CalculationsDokument1 SeiteApron Feeder Power Calculationsmkiani2Noch keine Bewertungen

- Hospital Building Civil ProjectDokument128 SeitenHospital Building Civil ProjectArun Ragu100% (6)

- Double Offset High Performance Butterfly Valves: DescriptionDokument16 SeitenDouble Offset High Performance Butterfly Valves: Descriptionmanmohansingh1999Noch keine Bewertungen

- Series 2200 Butterfly Valve Product BrochureDokument18 SeitenSeries 2200 Butterfly Valve Product BrochureSandesh KambleNoch keine Bewertungen

- Apollo-HP 215L-215WDokument16 SeitenApollo-HP 215L-215WDaniel SanNoch keine Bewertungen

- Section S - Double Offset High Performance Butterfly Valves: DescriptionDokument17 SeitenSection S - Double Offset High Performance Butterfly Valves: Descriptionjhonny sanchezNoch keine Bewertungen

- L&T Ball Valves: 3-Piece DesignDokument8 SeitenL&T Ball Valves: 3-Piece DesignmahaveenNoch keine Bewertungen

- Resilient Seated: CommercialDokument25 SeitenResilient Seated: Commercialagung wijayaNoch keine Bewertungen

- BRAY_7500_7700Dokument4 SeitenBRAY_7500_7700omorales.cyvsaNoch keine Bewertungen

- BRAY F15 Ball ValveDokument12 SeitenBRAY F15 Ball ValveRicardoNoch keine Bewertungen

- Flanged Series: Flow-TekDokument8 SeitenFlanged Series: Flow-Teklcs2006mvNoch keine Bewertungen

- L&T Process Ball Valves PDFDokument16 SeitenL&T Process Ball Valves PDFUnna MalaiNoch keine Bewertungen

- Vosa Butterfly Valve: World Class Performance in Drinking, Raw and Wastewater Reticulation SystemsDokument8 SeitenVosa Butterfly Valve: World Class Performance in Drinking, Raw and Wastewater Reticulation SystemsCorneNoch keine Bewertungen

- Brands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Dokument8 SeitenBrands You Trust.: CENTER LINE® - Resilient Seated Butterfly Valves Now All Ductile Iron Body Standard On Series 200Yamil Diaz SantosNoch keine Bewertungen

- Bray Flanged ValvesDokument8 SeitenBray Flanged ValvesdrewtwitchNoch keine Bewertungen

- Product Overview: Valves Actuators Automation TechnologyDokument36 SeitenProduct Overview: Valves Actuators Automation TechnologyBrion Bara IndonesiaNoch keine Bewertungen

- Fire HydrantsDokument22 SeitenFire HydrantsRaduNoch keine Bewertungen

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDokument8 SeitenW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999Noch keine Bewertungen

- The High Performance CompanyDokument5 SeitenThe High Performance CompanyMichelle Camacho HerediaNoch keine Bewertungen

- Concentric-Valves-API-609-A (Inglés)Dokument12 SeitenConcentric-Valves-API-609-A (Inglés)whiskazoo100% (1)

- BV : 1 : 1 : 13 - Concise for Ball Valve DocumentDokument16 SeitenBV : 1 : 1 : 13 - Concise for Ball Valve DocumentRamaswamy Neelakantan NNoch keine Bewertungen

- Trunnion Mounted Ball Valves: Flow-TekDokument8 SeitenTrunnion Mounted Ball Valves: Flow-TekJuan RodriguezNoch keine Bewertungen

- Delta T Series High Performance Butterfly Valves BrochureDokument8 SeitenDelta T Series High Performance Butterfly Valves BrochureOnkar DograNoch keine Bewertungen

- KennedyDokument18 SeitenKennedyHimat KhimaniNoch keine Bewertungen

- Guardian K81D Hydrant Meets AWWA and UL/FM StandardsDokument18 SeitenGuardian K81D Hydrant Meets AWWA and UL/FM Standardsvicvic34Noch keine Bewertungen

- AVK Gate Valve Maintenance-Free Design ConceptDokument8 SeitenAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNoch keine Bewertungen

- Trunnion Mounted Ball Valves: Flow-TekDokument8 SeitenTrunnion Mounted Ball Valves: Flow-TekFrancescoNoch keine Bewertungen

- Valve Design: Body-Bonnet ConnectionsDokument2 SeitenValve Design: Body-Bonnet Connectionsvj kumarNoch keine Bewertungen

- Abnt NBR 15514Dokument20 SeitenAbnt NBR 15514Andre alexander dos santosNoch keine Bewertungen

- Flowserve - BrochureDokument12 SeitenFlowserve - BrochureNurul LailyahNoch keine Bewertungen

- LR C515 RS Gate Vale R0Dokument6 SeitenLR C515 RS Gate Vale R0Gilberto YoshidaNoch keine Bewertungen

- Data Sheets Optiseal Wafer Lugged Keystone en en 5445860Dokument12 SeitenData Sheets Optiseal Wafer Lugged Keystone en en 5445860Miyka'el PaunNoch keine Bewertungen

- SERIES 7000/8000: 3 Piece Full Port " - 12"Dokument8 SeitenSERIES 7000/8000: 3 Piece Full Port " - 12"ErickNoch keine Bewertungen

- A Series 7500 Eccentric Disc Butterfly Valve - 2022Dokument20 SeitenA Series 7500 Eccentric Disc Butterfly Valve - 2022Ali Altoukhy100% (1)

- W4.9 Ozkan Seal On Disc Butterfly Valve PDFDokument8 SeitenW4.9 Ozkan Seal On Disc Butterfly Valve PDFmanmohansingh1999Noch keine Bewertungen

- Abz Valve 400Dokument9 SeitenAbz Valve 400John Harry RamirezNoch keine Bewertungen

- Perar Compact Ball ValvesDokument16 SeitenPerar Compact Ball ValvesshamekhalmaamariNoch keine Bewertungen

- Dembla Resilient Seated Butterfly Valve BrochureDokument8 SeitenDembla Resilient Seated Butterfly Valve Brochurereach_arindomNoch keine Bewertungen

- ProValve Double Offset High PerformanceDokument12 SeitenProValve Double Offset High PerformanceHarry HonchoNoch keine Bewertungen

- DEMCO Butterfly ValvesDokument36 SeitenDEMCO Butterfly ValvesLuis Pol SistiNoch keine Bewertungen

- Ball Valve (Maxflow)Dokument16 SeitenBall Valve (Maxflow)vishnuNoch keine Bewertungen

- KN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentDokument14 SeitenKN Ife Ga Te & Bu Tte Rfly Va Lve S E: Valves & EquipmentravishankarNoch keine Bewertungen

- SERIES 200 AND 300 KNIFE GATE VALVESDokument12 SeitenSERIES 200 AND 300 KNIFE GATE VALVESVignesh NadimuthuNoch keine Bewertungen

- Butterfly Valves: EngineeringDokument12 SeitenButterfly Valves: EngineeringKarla RamirezNoch keine Bewertungen

- 40.20.31.pdf New Labrynth Input SealDokument2 Seiten40.20.31.pdf New Labrynth Input SealMichel FloresNoch keine Bewertungen

- Duo-Chek II - The High Performance Check ValveDokument27 SeitenDuo-Chek II - The High Performance Check ValveZak CahuichNoch keine Bewertungen

- MA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsDokument8 SeitenMA Stewart L-D-4-S-E-LH Butterfly Valves Drawings and SpecificationsFawn DixonNoch keine Bewertungen

- FlowTek Ball Valve DesignDokument0 SeitenFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNoch keine Bewertungen

- Check Valve - Position IndicatorDokument2 SeitenCheck Valve - Position Indicatorunibalaji_05Noch keine Bewertungen

- Cpe Pacific Forged Ps Tds en A4 2019-04-15 WebDokument12 SeitenCpe Pacific Forged Ps Tds en A4 2019-04-15 WebKumarNoch keine Bewertungen

- Norm Ex ValvesDokument6 SeitenNorm Ex Valvesapi-3712612Noch keine Bewertungen

- PK Valve Page-13-17Dokument5 SeitenPK Valve Page-13-17ICASA IngenieríaNoch keine Bewertungen

- BTVDokument12 SeitenBTVJuan HernandezNoch keine Bewertungen

- Valdisk150TBDokument8 SeitenValdisk150TBpanametshNoch keine Bewertungen

- Abz Valves PDFDokument8 SeitenAbz Valves PDFrenzo condeNoch keine Bewertungen

- High Performance SeriesDokument8 SeitenHigh Performance SeriesRonCarNoch keine Bewertungen

- M-Class Custom Metal Seated Ball ValvesDokument20 SeitenM-Class Custom Metal Seated Ball ValvesJoseNoch keine Bewertungen

- Series 65-72 Ball Valve 2019 - v4 - FinalDokument8 SeitenSeries 65-72 Ball Valve 2019 - v4 - FinalPrathamesh Pradeep MashilkarNoch keine Bewertungen

- B-1050 Resilient-Valves 2020 08 17 4Dokument4 SeitenB-1050 Resilient-Valves 2020 08 17 4satphoenixNoch keine Bewertungen

- 11 - Butterfly ValvesDokument22 Seiten11 - Butterfly ValvesLuisNoch keine Bewertungen

- Jamesbury 4000Dokument12 SeitenJamesbury 4000Dinesh ChouguleNoch keine Bewertungen

- Liebherr Press Information Crane Planner Version 1point7Dokument4 SeitenLiebherr Press Information Crane Planner Version 1point7mkiani2Noch keine Bewertungen

- 19 Introduction To Design of Helical SpringsDokument12 Seiten19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Liebherr Press Information Crane Planner Version 1point7Dokument4 SeitenLiebherr Press Information Crane Planner Version 1point7mkiani2Noch keine Bewertungen

- Design and Analysis of An ElectrostaticDokument6 SeitenDesign and Analysis of An Electrostaticmkiani2Noch keine Bewertungen

- Performance LogDokument1 SeitePerformance LogsstuparusNoch keine Bewertungen

- Application and FeaturesDokument9 SeitenApplication and Featuresmkiani2Noch keine Bewertungen

- Idoc - Pub - Forex Trading With Clouds Ichimokupdf PDFDokument5 SeitenIdoc - Pub - Forex Trading With Clouds Ichimokupdf PDFodzew1826Noch keine Bewertungen

- Gripper Chain BrochureDokument6 SeitenGripper Chain Brochuremkiani2Noch keine Bewertungen

- Dura-Splice Clamp Belt Fastener For Elevator Belts: STR Ong! Saf E! Reliab Le! Pro Ven!Dokument1 SeiteDura-Splice Clamp Belt Fastener For Elevator Belts: STR Ong! Saf E! Reliab Le! Pro Ven!mkiani2Noch keine Bewertungen

- Design of A Composting Bin To Convert Aui's Biomass To An Organic Feltilizer PDFDokument55 SeitenDesign of A Composting Bin To Convert Aui's Biomass To An Organic Feltilizer PDFmkiani2Noch keine Bewertungen

- Installation Maintenance Roller Conveyor ChainDokument32 SeitenInstallation Maintenance Roller Conveyor Chainsat0112100% (1)

- Bucket ElevatorsDokument8 SeitenBucket ElevatorsmkpqNoch keine Bewertungen

- Sample - Belt Bucket Elevator DesignDokument7 SeitenSample - Belt Bucket Elevator Designmfhasnain100% (1)

- Aumund Doniambo en 117397963 PDFDokument3 SeitenAumund Doniambo en 117397963 PDFmkiani2Noch keine Bewertungen

- Solids Notes 10 Hopper DesignDokument26 SeitenSolids Notes 10 Hopper Designellantidinesh100% (1)

- Aumund Doniambo en 117397963 PDFDokument3 SeitenAumund Doniambo en 117397963 PDFmkiani2Noch keine Bewertungen

- Bucket Elevator ChainDokument4 SeitenBucket Elevator Chainluisreng100% (1)

- Iso GD&TDokument39 SeitenIso GD&TSanjay Kumar SinghNoch keine Bewertungen

- Datasheet FLENDER Gear Units B3SH03A22,4 MLFB-Ordering DataDokument3 SeitenDatasheet FLENDER Gear Units B3SH03A22,4 MLFB-Ordering Datamkiani2Noch keine Bewertungen

- Textured Buckets: Press ReleaseDokument1 SeiteTextured Buckets: Press Releasemkiani2Noch keine Bewertungen

- Bucket Elevator Capacity FormulasDokument3 SeitenBucket Elevator Capacity Formulasmkiani2Noch keine Bewertungen

- Bucket Elevator Capacity Formulas REVISEDDokument1 SeiteBucket Elevator Capacity Formulas REVISEDbrpnaidu2157Noch keine Bewertungen

- Belt Chain Bucket ElevatorsDokument2 SeitenBelt Chain Bucket Elevatorsmkiani2Noch keine Bewertungen

- Aumund India Rebuilds The Worlds Hightest Bucket Elevator 6973726 76194919Dokument2 SeitenAumund India Rebuilds The Worlds Hightest Bucket Elevator 6973726 76194919mkiani2Noch keine Bewertungen

- WP00142 A GBTraining KursprogrammonlineDokument1 SeiteWP00142 A GBTraining Kursprogrammonlinemkiani2Noch keine Bewertungen

- Vibrator 3typesDokument1 SeiteVibrator 3typesmkiani2Noch keine Bewertungen

- Communication in AfricaDokument5 SeitenCommunication in AfricaJaque TornneNoch keine Bewertungen

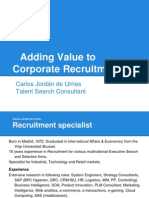

- Adding Value To Corporate Recruitment: Carlos Jordán de Urries Talent Search ConsultantDokument8 SeitenAdding Value To Corporate Recruitment: Carlos Jordán de Urries Talent Search ConsultantCarlos Jordan de UrriesNoch keine Bewertungen

- SDLC Phases Feasibility Analysis RequirementsDokument4 SeitenSDLC Phases Feasibility Analysis RequirementsBrandon Mitchell0% (1)

- EY Global Commercial Banking Survey 2014Dokument28 SeitenEY Global Commercial Banking Survey 2014Share WimbyNoch keine Bewertungen

- Manual ReaperDokument466 SeitenManual ReaperJuan Camilo Arroyave ArangoNoch keine Bewertungen

- Dekut Teaching Practice ManualDokument20 SeitenDekut Teaching Practice Manualstephen njorogeNoch keine Bewertungen

- Computer LanguagesDokument3 SeitenComputer LanguagesGurvinder Singh100% (1)

- Gold Series Dust Collector: Installation, Operation and MaintenanceDokument85 SeitenGold Series Dust Collector: Installation, Operation and MaintenanceDAVID ALFONSO CARABALLO PATIÑONoch keine Bewertungen

- Calculation Procedure, Low-Finned Tubes: Exxon EngineeringDokument56 SeitenCalculation Procedure, Low-Finned Tubes: Exxon Engineeringvin ssNoch keine Bewertungen

- How to Size a Fire Pump and Understand Performance CurvesDokument12 SeitenHow to Size a Fire Pump and Understand Performance CurvesAmar kobitaNoch keine Bewertungen

- Mara Vatz, "Knowing When To Stop: The Investigation of Flight 191"Dokument30 SeitenMara Vatz, "Knowing When To Stop: The Investigation of Flight 191"MIT Comparative Media Studies/WritingNoch keine Bewertungen

- BS Basics Boundary Scan PDFDokument2 SeitenBS Basics Boundary Scan PDFShankar ArunmozhiNoch keine Bewertungen

- How To Enable Nationality Field in IrecruitmentDokument2 SeitenHow To Enable Nationality Field in IrecruitmentnhawiNoch keine Bewertungen

- 220 KV GSS, HeerapuraDokument56 Seiten220 KV GSS, Heerapurapikeshjain33% (3)

- Managing Operations AssignmentDokument17 SeitenManaging Operations AssignmentNaidu01100% (1)

- Manual em Portugues DGX230Dokument120 SeitenManual em Portugues DGX230Agosthis0% (1)

- FL40AC-FL60AC EX Electrical Schematic 177666Dokument1 SeiteFL40AC-FL60AC EX Electrical Schematic 177666Omayr QureshiNoch keine Bewertungen

- History Gelatin DryingDokument3 SeitenHistory Gelatin DryingLe Thi Kim KhanhNoch keine Bewertungen

- Slabs Are Plate Elements Forming Floors andDokument5 SeitenSlabs Are Plate Elements Forming Floors andyasas89Noch keine Bewertungen

- Air Car SeminarDokument24 SeitenAir Car SeminarSatyajit MenonNoch keine Bewertungen

- 3 Spaces Nov 09Dokument62 Seiten3 Spaces Nov 09Somy ElseNoch keine Bewertungen

- Fiedler's Contingency Model of Leadership Effectiveness: Background and Recent DevelopmentsDokument24 SeitenFiedler's Contingency Model of Leadership Effectiveness: Background and Recent DevelopmentsEdielyn Gonzalvo GutierrezNoch keine Bewertungen

- WFT Composite PlugsDokument11 SeitenWFT Composite Plugsahmad haqkim muhamad malackNoch keine Bewertungen

- Co-Ordinated By: DR Parul Presented By: DR GurneetDokument45 SeitenCo-Ordinated By: DR Parul Presented By: DR Gurneetreenujohney100% (2)

- Price List (011) New2020 PDFDokument3 SeitenPrice List (011) New2020 PDFAyush BansalNoch keine Bewertungen

- Design of Miniature Maglev Using Hybrid MagnetsDokument4 SeitenDesign of Miniature Maglev Using Hybrid MagnetsErmin FazlicNoch keine Bewertungen

- Marketing Research of Pre-Start-UpDokument2 SeitenMarketing Research of Pre-Start-UpafsalpkgroupNoch keine Bewertungen