Beruflich Dokumente

Kultur Dokumente

2009 07 ClickCoat Technikum GB

Hochgeladen von

Costas AggelidisCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2009 07 ClickCoat Technikum GB

Hochgeladen von

Costas AggelidisCopyright:

Verfügbare Formate

www.coatema.

de

Coatema Fachartikel – Coatema Technical Reports

Coatema - the mechanical engineering company

for coating, laminating and printing plants

Coatema Coating Machinery GmbH is a manufacturer of

coating and laminating plants for R2R applications.

Coatema has been supplying solutions for the most

different markets like textiles, foil, paper and

renewable energies for 30 years now. These solutions

may consist of small lab coating plants, of pilot plants

as well as of turn-key production plants for the coating,

laminating and printing of roll-to roll substrates

Coatema uses more than 38 different application

systems for their plants, like e.g.

Knife System

Double Side System

Commabar System

Case Knife System

Engraved Roller System

2 Roller System

3 Roller System

Micro Roller System

5 Roller System

Reverse Roll System

Rotary Screen System

Dipping System

Slot Die System

Curtain Coating System

Hotmelt Slot DieSystem

Powder Scattering System.

For printing are used

Screen printing

Flexo printing

Gravure printing

Inkjet

The fields of application for these systems reach from

functional textiles, batteries, fuel cells,

prepreg/composites, foils and flexible electronics.

Examples of modular and printing

coating systems

Coatema Coating Machinery GmbH, Roseller Straße 4, 41539 Dormagen

Tel.: + 49 (0) 21 33 / 97 84 - 0, Fax: + 49 (0) 21 33 / 97 84 - 170, e-mail: coatema@coatema.de

www.coatema.de

Coatema Fachartikel – Coatema Technical Reports

The right plant in the scale-up process

Coatema offers different expertise from the lab to the

pilot up to the production plant

Easycoater (Lab plant)

The Easycoater can be used for discontinuous operation

in DIN A 4 size. On the Easycoater the prozesses

Screen System

Slot Die System Lab plant - Easycoater: for discontinous

Knife System operation in DIN A 4 size

Engraved Roller System

are possible.

Basecoater (Pilot plant)

On the Basecoater it is possible to run smaller

production operations..

Equipment overview

Working width from 200 mm to 500 mm

Line speed 0,1 - 10 m/min

Encapsulation of the coating head

State of the art heating and curing system

Sintering available

Laminating and embossing capacity

Modular exchangeable printing and coating

systems Pilot plant - Basecoater: for realization of smaller

production operations

Benefits

Less consumption of chemicals and materials

Encapsulation for dust-free operations

Reproducible R2R scale up processes

Production plant

Based on these experiences the next steps are high

speed and very efficient production scale solutions with

working widths up to 5.500 mm. Depending on the

application inert atmospheres can be considered.

Custom made solutions

Another of Coatema´s specialties are custom made Production plant – BL: with high speed

and working width up to 5.500 mm

solutions.

Coatema Coating Machinery GmbH, Roseller Straße 4, 41539 Dormagen

Tel.: + 49 (0) 21 33 / 97 84 - 0, Fax: + 49 (0) 21 33 / 97 84 - 170, e-mail: coatema@coatema.de

www.coatema.de

Coatema Fachartikel – Coatema Technical Reports

Click&Coat

Coatema has developed the innovative Click&Coat

concept for pilot plants to be able to react faster and in

a more cost-saving way to the most different

requirements. Click&Coat permits the flexibility of the

individual coating heads but also of the entire plant:

The individual plant components are movable and can

be brought into the right position by a simple "click"

and be connected to the recently developed control

system. This is a unique way to combine different

Click&Coat coating plant

processes in modular design.

Here, more than 30 different modules in the most

varied combination can be integrated into the plant.

Moreover, an extension of production processes like

e.g. the additional use of dryer components, can be

realised much easier with the Click&Coat concept

Coatema R&D Centre

The Click&Coat system is at the customer´s disposal in Click&Coat: the individual plant components can be

brought into the right position by a simple “click”

Coatema´s company-own lab, which is said to be the

largest lab worldwide and offers on 1.200 m²:

Besides the R&D Centre offers

11 pilot plants

1 production

in working widths from 250 up to 2.000 mm.

The experts in our lab will support you during coating

trials and from your idea to the finished product.

Coatema Symposium

On the occasion of the annual COATEMA Symposium,

coating theory, presented by experts in lectures, is put

into practice on the coating, printing and laminating

Click&Coat-plant in Coatema´s R&D Centre

plants in Coatema´s lab.

The 10th Coatema Symposium will take place on

September 30th - October 1st 2009 and will surely

answer a lot of questions and give new suggestions for

the future. Please see our website

www.coatema.de/eng/symposia/next.php for the latest

news on our Symposiums and for your registration.

Coatema R&D Centre on 1.200 m2

Working Widths from 250 up to 2.000 mm

Coatema Coating Machinery GmbH, Roseller Straße 4, 41539 Dormagen

Tel.: + 49 (0) 21 33 / 97 84 - 0, Fax: + 49 (0) 21 33 / 97 84 - 170, e-mail: coatema@coatema.de

www.coatema.de

Coatema Fachartikel – Coatema Technical Reports

Conclusion

Coatema´s delivery programme ranges from small lab

coating units and pilot plants for the realisation of even

small batches up to production plants.

Coatema is one of the few companies in the market

that offers as a competent partner laminating and

printing solutions according to specific plant layouts,

getting new ideas and their profitable realisation up to

the serial production.

Because of the singular, company-own coating lab and

the longtime expertise in the engineering of small- and

large-scale plants, the research and the upscale of

coating, laminating and printing processes are a vital

component of Coatema´s competence.

Coatema Coating Machinery GmbH, Roseller Straße 4, 41539 Dormagen

Tel.: + 49 (0) 21 33 / 97 84 - 0, Fax: + 49 (0) 21 33 / 97 84 - 170, e-mail: coatema@coatema.de

Das könnte Ihnen auch gefallen

- Xervon: Your Experts For Specialty Surface CoatingsDokument5 SeitenXervon: Your Experts For Specialty Surface CoatingsCostas AggelidisNoch keine Bewertungen

- Asset Integrity Management Petroleum Industry: For TheDokument4 SeitenAsset Integrity Management Petroleum Industry: For TheCostas AggelidisNoch keine Bewertungen

- Inspection of Subsea Pipelines and Offshore Tubular StructuresDokument6 SeitenInspection of Subsea Pipelines and Offshore Tubular StructuresCostas AggelidisNoch keine Bewertungen

- XERVON Up2date 01 2014 ENG FinalDokument32 SeitenXERVON Up2date 01 2014 ENG FinalCostas AggelidisNoch keine Bewertungen

- Za ZN LL3 IGn CL Cy 6 W JT 7 H WW RG Hgy K882 QL SLX0 C CEDokument20 SeitenZa ZN LL3 IGn CL Cy 6 W JT 7 H WW RG Hgy K882 QL SLX0 C CECostas AggelidisNoch keine Bewertungen

- 9 PIM Forum: 15 - 17 March 2016, Berlin, GermanyDokument6 Seiten9 PIM Forum: 15 - 17 March 2016, Berlin, GermanyCostas AggelidisNoch keine Bewertungen

- FLAME 2013 Brochure UpdatedDokument12 SeitenFLAME 2013 Brochure UpdatedCostas AggelidisNoch keine Bewertungen

- SoR Abst 19aDokument170 SeitenSoR Abst 19aCostas AggelidisNoch keine Bewertungen

- ICR DailySchedule 08122020Dokument4 SeitenICR DailySchedule 08122020Costas AggelidisNoch keine Bewertungen

- The Society of Rheology: 91 Annual Meeting Program and AbstractsDokument170 SeitenThe Society of Rheology: 91 Annual Meeting Program and AbstractsCostas AggelidisNoch keine Bewertungen

- 2019 Master Schedule Inspection SummitDokument3 Seiten2019 Master Schedule Inspection SummitCostas AggelidisNoch keine Bewertungen

- Conference Details Athens 010816Dokument14 SeitenConference Details Athens 010816Costas AggelidisNoch keine Bewertungen

- Raleigh Convention Center, Raleigh, North Carolina: The Society of Rheology 91 Annual MeetingDokument12 SeitenRaleigh Convention Center, Raleigh, North Carolina: The Society of Rheology 91 Annual MeetingCostas AggelidisNoch keine Bewertungen

- Fauré and French Musical Aesthetics: Carlo CaballeroDokument23 SeitenFauré and French Musical Aesthetics: Carlo CaballeroCostas AggelidisNoch keine Bewertungen

- Symposium Programme: 14th Fundamental Research Symposium St. Anne's College, Oxford 13-18 September 2009Dokument3 SeitenSymposium Programme: 14th Fundamental Research Symposium St. Anne's College, Oxford 13-18 September 2009Costas AggelidisNoch keine Bewertungen

- 2019 Inspection Summit Training Course Descriptions 8-2-18 - v2Dokument6 Seiten2019 Inspection Summit Training Course Descriptions 8-2-18 - v2Costas AggelidisNoch keine Bewertungen

- J.S. Bach's Fugue in C Minor, BWV 871 (From The Well-Tempered Clavier Book II)Dokument12 SeitenJ.S. Bach's Fugue in C Minor, BWV 871 (From The Well-Tempered Clavier Book II)Costas Aggelidis100% (1)

- A Quantitative Approach To Evolution of Music and PhilosophyDokument22 SeitenA Quantitative Approach To Evolution of Music and PhilosophyCostas AggelidisNoch keine Bewertungen

- Wells Integrity Management Training Course PDFDokument4 SeitenWells Integrity Management Training Course PDFCostas AggelidisNoch keine Bewertungen

- Distance Learning Corporate FinanceDokument9 SeitenDistance Learning Corporate FinanceCostas AggelidisNoch keine Bewertungen

- Workshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopDokument5 SeitenWorkshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopCostas AggelidisNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Carga Nitrogeno NPK PDFDokument5 SeitenCarga Nitrogeno NPK PDFhenry vega100% (1)

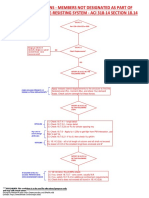

- Concrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14Dokument2 SeitenConcrete Columns - Members Not Designated As Part of The Seismic-Force-Resisting System - Aci 318-14 Section 18.14stephanie madridNoch keine Bewertungen

- DismantlementTechnologies PDFDokument76 SeitenDismantlementTechnologies PDFdwipaNoch keine Bewertungen

- Rust Remover For ConcreteDokument4 SeitenRust Remover For ConcretemudasarNoch keine Bewertungen

- Effect of Rice Husk Ash On Properties of ConcreteDokument4 SeitenEffect of Rice Husk Ash On Properties of ConcreteEduardo Fernando Alarcon PrincipeNoch keine Bewertungen

- Hardtop Clear: Technical Data SheetDokument5 SeitenHardtop Clear: Technical Data SheetHussain AlsadahNoch keine Bewertungen

- DO - 106 - s2017 - Standard Specification On ITEM 1051 - RailingsDokument7 SeitenDO - 106 - s2017 - Standard Specification On ITEM 1051 - Railingsalterego1225Noch keine Bewertungen

- Thermodynam TasksDokument1 SeiteThermodynam TasksEhtıram SeyıdovNoch keine Bewertungen

- Liquid Ferric Sulfate Product Data Sheet: DescriptionDokument1 SeiteLiquid Ferric Sulfate Product Data Sheet: DescriptionAnastasijaNoch keine Bewertungen

- WEEK 2-3 Describe The Changes in Solid Materials When They Are Bent, Pressed, Hammered, or Cut (S4MT-Ie-f-5)Dokument5 SeitenWEEK 2-3 Describe The Changes in Solid Materials When They Are Bent, Pressed, Hammered, or Cut (S4MT-Ie-f-5)MalynNoch keine Bewertungen

- Meprophos M 60 ProcessDokument4 SeitenMeprophos M 60 ProcessSatyendra PandeyNoch keine Bewertungen

- GulfSea DE Compressor Oil Series 100Dokument2 SeitenGulfSea DE Compressor Oil Series 100Md.Obydur RahmanNoch keine Bewertungen

- Sampel Cylinder 1 (MS-01-177) R0Dokument6 SeitenSampel Cylinder 1 (MS-01-177) R0herysyam1980Noch keine Bewertungen

- Metal Organic Frameworks Vs Buffers Case Study of Ui o 66 StabilityDokument19 SeitenMetal Organic Frameworks Vs Buffers Case Study of Ui o 66 StabilitymahahajNoch keine Bewertungen

- Roxas PWD BuildingDokument32 SeitenRoxas PWD BuildingDennis SariegoNoch keine Bewertungen

- CSMB - VERNACULAR TERMSDokument2 SeitenCSMB - VERNACULAR TERMSChari Madlang-awa BunagNoch keine Bewertungen

- Endangered ElementsDokument4 SeitenEndangered ElementsJerry GzzNoch keine Bewertungen

- Chem022 - To Dye ForDokument4 SeitenChem022 - To Dye ForPaige DarbonneNoch keine Bewertungen

- IC-TGD-100 User's ManualDokument29 SeitenIC-TGD-100 User's ManualJboy SchlossNoch keine Bewertungen

- Boeco Mantas de CalentamientoDokument2 SeitenBoeco Mantas de CalentamientoJhon VallejoNoch keine Bewertungen

- Polymer ChemistryDokument115 SeitenPolymer Chemistrywaheedlakho0% (2)

- Asbestos AwarenessDokument57 SeitenAsbestos AwarenessEric JamesNoch keine Bewertungen

- Liquid Phase SinteringDokument242 SeitenLiquid Phase SinteringAbir Roy100% (1)

- Aggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1Dokument24 SeitenAggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1T JNoch keine Bewertungen

- MECA 332 Mechatronics Component Design: Week 8 Ps - IvDokument19 SeitenMECA 332 Mechatronics Component Design: Week 8 Ps - IvArda GunayNoch keine Bewertungen

- Kubota Super Udt: Safety Data SheetDokument14 SeitenKubota Super Udt: Safety Data SheetMichaelNoch keine Bewertungen

- RA Sep-Dec 2020 EditedDokument104 SeitenRA Sep-Dec 2020 EditedMymoon MoghulNoch keine Bewertungen

- EkshaDokument16 SeitenEkshaSumitKumarNoch keine Bewertungen

- Technical Specification FOBDokument6 SeitenTechnical Specification FOBANDRESNoch keine Bewertungen

- 1 Memoriu Tehnic CS enDokument219 Seiten1 Memoriu Tehnic CS enIuly AnaNoch keine Bewertungen