Beruflich Dokumente

Kultur Dokumente

Concrete Construction Article PDF - Folded Slab Roofs

Hochgeladen von

richuroseOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Concrete Construction Article PDF - Folded Slab Roofs

Hochgeladen von

richuroseCopyright:

Verfügbare Formate

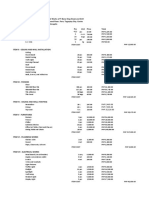

Placing concrete in one of two roof

forms consisting of a series of wood

trusses sheathed with 3⁄4-inch marine

plywood. Each 4-inch thick section

covered 400 square feet and weighed

11 tons.

FOLDED SLAB ROOFS

Are they already a practical reality for low-budget construction?

BY NELSON A. FAERBER, A.I.A. associated with present concrete roof on each form, using the lift-slab

construction methods. In analyzing principle of stacking one slab on top

the various methods, including lift- of the other. Separation was accom-

slab, precasting, and thin-shell de- plished by means of polyvinyl film.

I n this day of advanced engineer-

ing techniques and dynamic ar-

chitectural design, it is not unusual

sign, it was decided that the individ-

ual economies of these methods

might successfully be combined in-

The reinforcing steel was placed on

one form, while a roof section was

cast on the other form the same day,

to encounter many fine examples of to one new and more economical thus allowing a casting schedule of

thin-shell concrete construction. type of construction. This resulted one section per day. The average la-

However, to the average architec- in the development of the principle bor time of pouring and finish trow-

tural firm, these monuments can of site precasting sections of a fold- eling one section was little more

only be admired from a distance; ed slab design on a ground form and than that required for placing a slab

unfortunately these feats are usual- lifting them into place. on grade of similar area. The 400-

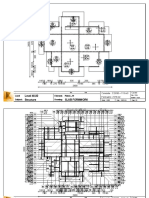

ly achieved only with large con- The building was designed in the square foot sections were designed

struction budgets. Rare indeed is shape of an octagon, incorporating 4 inches thick, using 3750 psi con-

the average commercial or residen- 8 separate gables, each engineered crete. Each section weighed 11 tons.

tial budget which allows the archi- as a folded slab. In order to reduce The first three sections which

tect to consider a thin-shell con- both labor and materials for form- were cast employed concrete in-

crete structure. ing, two forms were constructed on serts. Due to the difficulty of holding

During the designing of a resi- the ground, utilizing a series of these inserts in place during casting,

dence for Mr. and Mrs. John Cowles, wood trusses sheathed over with 3⁄4- 1

⁄2-inch steel plates, threaded to re-

of Naples, Florida, it was decided to inch marine plywood. This allowed ceive 3⁄4-inch bolts from the lifting

investigate all means of economy the casting of four sections of the apparatus, were substituted for the

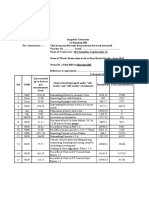

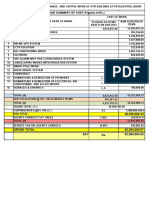

remaining sections. The edge of SITE PRECAST FOLDED SLAB ROOF

each section was cast in a key to ac-

commodate a 11⁄2-inch grouted joint Summation of Construction Costs

at each valley. Each slab was cast 3

feet short of the total radius dimen- I FORMWORK

sion of the roof, to allow for a 6-foot Material $1,067.00

octagonal skylight. After the sec-

tions were erected a reinforced con- Labor 1,041.00

crete tension curb was poured Total Cost $2,108.00 $.65 per square foot

around the skylight, receiving three

No. 5 bars turned up from each of

the 8 slabs. II SUPPORTING STRUCTURE

The slabs rested directly on 6- Steel Columns, Tie

inch lally columns with 12- by 12- Rods & Lifting Beams,

inch bearing plates at the top. A

spacer block 1 1⁄2 inch wide was etc.

placed on top of each of the bearing Total Cost $768.00 $.24 per square foot

plates to prevent the adjoining sec-

tion edges from compressing by

contact. Around the 8 exterior III CASTING SLABS

columns a peripheral 1-inch tie-rod Material:

with a turnbuckle at each bay was Steel $1,759.00

employed. The turnbuckles allowed

plumbing of columns, and were Conc. 805.00

welded after all slabs were in place. Labor 720.00

Prior to erection of the slabs tempo- Total Cost $3,284.00 $1.03 per square foot

rary X-bracing and 6- by 6-inch

wood columns were used beneath

the ridge of each section to lessen IV ERECTION

the initial thrust to the columns be- Total Cost $1,056.00 $.33 per square foot

fore the adjoining slabs were set in

place.

In this first project an erection Total Construction Cost = $7,216.00 @ 3200 square foot =

time of 28 hours was required. Un- $2.25 per square foot

fortunately it was found necessary

to make slight alterations and adap-

tations to the lifting apparatus for Roof slabs were cast one on top of the other as in the lift-slab method of

each concrete section, and many construction. Sheets of polyethylene film were used to facilitate separation. Note

hours of erection time could have the keyed edges which were formed to accommodate 11⁄2-inch grouted joints

been eliminated by the use of a between adjacent sections.

more accurate template for locating

the lifting plates. This item, plus

other small difficulties correctable

in future projects, should easily cut

the erection time in half.

In spite of these problems, 3200

square feet of concrete roof was in-

stalled for a cost of $2.25 per square

foot of roof area, including the sup-

porting columns. The roof surface is

being finished with three coats of

masonry water-repellent coating,

for approximately one-half the cost

of conventional built-up roofing. In

this particular design, acoustical

plaster and stucco will be employed

on the underside of the slabs to

Placing the last of 8 sections which formed the folded-slab roof of the octagonal building. Each section was cast 3 feet

short of the total radius of the roof to provide a 6-foot octagonal skylight in the center.

achieve a finished ceiling. With ad-

ditional care in steel trowel finish-

ing of the sections during the cast-

ing process, this extra expense for

finished ceiling will be eliminated

entirely, thus further reducing the

cost of the finished roof in place.

It is the opinion of the architect

that this project proves that a vast

field of medium-budget construc-

tion can now benefit from the archi-

tectural and engineering advan-

tages of precast thin-shell concrete

design.

PUBLICATION #C580508

Copyright © 1958, The Aberdeen Group

All rights reserved

Das könnte Ihnen auch gefallen

- I Confess BoldlyDokument2 SeitenI Confess BoldlyrichuroseNoch keine Bewertungen

- AMSC ProductivityDokument119 SeitenAMSC Productivityrichurose100% (3)

- HVAC Productivity ManualDokument22 SeitenHVAC Productivity Manualrichurose75% (4)

- Claiming Work in The Profession PdusDokument7 SeitenClaiming Work in The Profession PdusrichuroseNoch keine Bewertungen

- How To Instil Good Financial Habits inDokument8 SeitenHow To Instil Good Financial Habits inrichuroseNoch keine Bewertungen

- Baptism Class BookDokument20 SeitenBaptism Class BookrichuroseNoch keine Bewertungen

- Alleppy by Laurie Baker PDFDokument92 SeitenAlleppy by Laurie Baker PDFrichuroseNoch keine Bewertungen

- How To Save Tax For Fy 2018 19 PDFDokument45 SeitenHow To Save Tax For Fy 2018 19 PDFsenthilkumarkskNoch keine Bewertungen

- 1 - Vastu Principles (Ankit Mishra-08010381364) PDFDokument100 Seiten1 - Vastu Principles (Ankit Mishra-08010381364) PDFSampath Kumar100% (2)

- Duration TypesDokument3 SeitenDuration TypesTrilok Singh TakuliNoch keine Bewertungen

- Symbols in ExcelDokument1 SeiteSymbols in ExcelrichuroseNoch keine Bewertungen

- MUD by Laurie BakerDokument90 SeitenMUD by Laurie BakerrichuroseNoch keine Bewertungen

- Custom FunctionsDokument15 SeitenCustom FunctionsrichuroseNoch keine Bewertungen

- 1566Dokument2 Seiten1566richuroseNoch keine Bewertungen

- Output Rate DceDokument5 SeitenOutput Rate DcerichuroseNoch keine Bewertungen

- Modern Risk ManagementDokument15 SeitenModern Risk ManagementDr Sarbesh Mishra100% (2)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Interior Fitting Out Works Bill of MaterialsDokument15 SeitenInterior Fitting Out Works Bill of MaterialsAnn MoralesNoch keine Bewertungen

- R0 ManDokument70 SeitenR0 ManAnne Margareth Dela CruzNoch keine Bewertungen

- Switch Board ScheduleDokument4 SeitenSwitch Board ScheduleSoham GarrixNoch keine Bewertungen

- Alternate and Low Cost Construction Materials & Techniques Developed Through R & D Efforts at Council For Works and Housing ResearchDokument45 SeitenAlternate and Low Cost Construction Materials & Techniques Developed Through R & D Efforts at Council For Works and Housing ResearchbuilconsNoch keine Bewertungen

- LPDDokument2 SeitenLPDDesigner ForeverNoch keine Bewertungen

- Township BOQ With CorrigendumDokument40 SeitenTownship BOQ With CorrigendumPoornima D GowdaNoch keine Bewertungen

- NOTESDokument6 SeitenNOTESJella DulatreNoch keine Bewertungen

- Daniel Tian Li: Concrete Column Design Based On ACI 318-05Dokument3 SeitenDaniel Tian Li: Concrete Column Design Based On ACI 318-05Lee Kar FungNoch keine Bewertungen

- Summary 1st BillDokument10 SeitenSummary 1st BillZahid Bashir cheemaNoch keine Bewertungen

- Masonry 2103.3 - TABLE 2103.7 (1) : A C D BDokument2 SeitenMasonry 2103.3 - TABLE 2103.7 (1) : A C D BRafeeq Ur RahmanNoch keine Bewertungen

- Presentation ON Beam, Slab, ColumnDokument42 SeitenPresentation ON Beam, Slab, ColumnTinzar LattNoch keine Bewertungen

- Shera PlanksDokument61 SeitenShera Planksakankshas06Noch keine Bewertungen

- Grillage FoundationDokument17 SeitenGrillage FoundationKareenaNoch keine Bewertungen

- Architectural Drawings of A BungalowDokument1 SeiteArchitectural Drawings of A BungalowJOHN PAULO I LICUPNoch keine Bewertungen

- Building Construction Terms ExplainedDokument39 SeitenBuilding Construction Terms ExplainedClarissa PasiaNoch keine Bewertungen

- PosiStrut Floor and Roof Installation InstructionsDokument28 SeitenPosiStrut Floor and Roof Installation InstructionsBrad La PortaNoch keine Bewertungen

- Estimate Barpali....Dokument42 SeitenEstimate Barpali....Sagarika SahooNoch keine Bewertungen

- Raft DesignDokument28 SeitenRaft DesignMkh Engcivil75% (4)

- Unit 2 Part I The Slave DynastyDokument51 SeitenUnit 2 Part I The Slave DynastyMutant NinjaNoch keine Bewertungen

- BAL ChartDokument1 SeiteBAL ChartFilozófus ÖnjelöltNoch keine Bewertungen

- Estimates for CHB Wall, Wall Footing and Cyclone Wire FenceDokument7 SeitenEstimates for CHB Wall, Wall Footing and Cyclone Wire Fencehenjie mirasolNoch keine Bewertungen

- Autodesk Robot Structural Analysis Professional 2014Dokument5 SeitenAutodesk Robot Structural Analysis Professional 2014tovarNoch keine Bewertungen

- Romanesque Architecture: A Unifying Style Across EuropeDokument37 SeitenRomanesque Architecture: A Unifying Style Across Europetanu kukrejaNoch keine Bewertungen

- Advanced Construction Methods in R.C.C: Prestessed ConcreteDokument12 SeitenAdvanced Construction Methods in R.C.C: Prestessed Concretepoosa annupriyaNoch keine Bewertungen

- Anchor Roma Classic Price List Nov 2021Dokument9 SeitenAnchor Roma Classic Price List Nov 2021srbh1977Noch keine Bewertungen

- Prestressed Hollow-Core Walls: A Name Truly Cast in ConcreteDokument6 SeitenPrestressed Hollow-Core Walls: A Name Truly Cast in Concreteomar42170Noch keine Bewertungen

- Observed Behaviour of Earthen Structures During The Pisco (Peru) Earthquake of August 15, 2007Dokument8 SeitenObserved Behaviour of Earthen Structures During The Pisco (Peru) Earthquake of August 15, 2007my09Noch keine Bewertungen

- Brick Composition and PropertiesDokument81 SeitenBrick Composition and PropertiesGlistering DharNoch keine Bewertungen

- Sapthagiriyam Apartments SpecsDokument20 SeitenSapthagiriyam Apartments SpecsYazhisai SelviNoch keine Bewertungen

- Stacked Minimalist 3 Storey HouseDokument12 SeitenStacked Minimalist 3 Storey HouseTrazon Triestian Pedrera CardeñoNoch keine Bewertungen