Beruflich Dokumente

Kultur Dokumente

Determination of Moisture Content by Oven Drying Method

Hochgeladen von

HaLa SalahOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Determination of Moisture Content by Oven Drying Method

Hochgeladen von

HaLa SalahCopyright:

Verfügbare Formate

1.

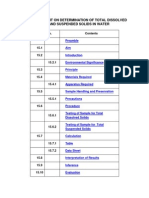

DETERMINATION OF MOISTURE CONTENT BY OVEN DRYING

METHOD

INTRODUCTION

The moisture content which results from oven drying method depends on the type of food stuff used. The

determination of moisture in a food is done for many purposes such as assessment of quality, quality

control, quality assurance, detection and estimation of adulteration, conformity with food standards and

other statutory requirement, calculation of total food solids content, assessment of stability, shelf life and

storage life.

Water in a food item can be present in 2 ways:

•

Free water (which is physically linked to the food matrix and easily

lost by evaporation or drying as a separate constituent)

•

Bound water ( include water molecules chemically bonded to ionic and

polar groups or water of crystallization or hydrates which is difficult to remove)

These types may occur in varying quantities in food and are held by physical chemical forces of diverse

nature. Even though the accuracy and precision of moisture result is low; the reproducibility results can be

obtained under a set of standardized condition.

The water activity of any product depends on,

•

The chemical composition of food

•

The state of aggregation of its constituent

•

The water content

•

Temperature of thThe shelf life of the product depends on water activity. Moisture can be determined by

using following methods,

•

Thermal Drying method

Drying either hot air oven at 105 0C in 2-3 hours or in vacuum ovens which is widely used for sugar based

foods. The measurement of the weight loss which results due to the evaporation of H 2O at or near boiling

point is taken here. The loss in weight depend on the particle size, weight of the sample used, type of the

dish and temperature variation in the ovens etc.

•

Chemical assay

This is based on the non-stoicheometric reaction of water.

•

Physical method

Involves physical and physiochemical reaction in food.

Oven drying method is widely used. The weight loss due to the removal of water by heating under specific

conditions is considered here. The loss of weight due to drying is considered as a measure of the

moisture content of the sample.

Page2

MATERIALS AND METHOD

MATERIALS

Moisture dish made of stainless steel

Oven maintained at 1050C

Weighing balance

Cinnamon sample

METHOD

About 5 g of the sample was weighed in to a moisture dish which was previously dried in an oven and

weighed. Then the uncovered dish was dried along side for 21/2 hrs. The dish was covered and was

transferred to desiccators and weighed quickly as possible as the dish was cooled. The heating and

weighing procedures was repeated until successive weight did not differ by more than one milligram .Loss

in weights were recorded.

RESULTS AND CALCULATIONS

RESULTS

CALCULATIONS

Moisture % m/m

=

Weight loss

x 100

Weight of the sample

=

m2-m3

x 100

m2-m1

m1

=

Weight of empty dish

m2

=

Weight of empty dish + sample before drying

m3

=

Weight of empty dish + sample after drying

DISCUSSION

Oven drying method is widely used in determination of moisture. Water is removed due to heating at 105

°C. Loss of weight due to vaporization of water is taken as weight of moisture. But spices like cinnamon

contain volatile oil in addition to moisture and these volatile oils also get loss during oven drying. Due to

this the weight loss due to the loss of volatile oils also gets counted for moisture determination. This is the

main disadvantage of oven drying method. This method is not suitable to determine the moisture content

of thermally unstable compounds and this method removes only free water. Since oven drying method is

simple, low cost and easy, it is widely used for routine analysis.

The accuracy of results of moisture determination is affected by, drying temperature, relative humidity,

particle size of sample, handling method of sample, amount of sample, type of evaporation dish, variation

in temperature inside the oven. To minimize these errors various precautions should be taken. i.e. sample

should be dried in stainless steel containers, which is not decompose during heating. Three consecutive

samples were carried out to eliminate the errors of the handlers, usually 5 g of ground sample was taken

to facilitate the drying, and this encourages the evaporation because particle size is small

2. DETERMINATION OF MOISTURE CONTENT BY DEAN STARK

DISTILLATION METHOD

INTRODUCTION

Distillation methods are particularly useful for foods with low moisture content and for products containing

volatile oils such as herbs and spices. Since the oils remain dissolved in the organic solvent the

disadvantages are that they have often been reported to give low values and their requirements for

flammable solvent pose small but significant hazards

The Dean and Stark method is widely used in determination of moisture. A known weight of food is placed

in a flask with an organic solvent such as xylene or toluene. The organic solvent must be insoluble with

water; have a higher boiling point than water; be less dense than water; and be safe to use. The flask

containing the sample and the organic solvent is attached to a condenser by a side arm and the mixture is

heated. The water in the sample evaporates and moves up into the condenser where it is cooled and

converted back into liquid water, which then trickles into the graduated tube. When no more water gets

collect in the graduated tube, distillation is stopped and the volume of water is read from the tube.

Distillation with a boiling liquid provides an effective means of heat transfer, the water is removed rapidly.

If the boiling liquid is lighter than the water, the collecting trap usually contains a tube with tap at the

bottom and calibrated upward. This form requires reading only one meniscus in measuring the amount of

collected water. The calibrated portion of the tube may be cooled by a water bath to standard

temperature.

Many difficulties may arise in the determination of moisture by distillation method. These include relatively

low precision of the receiving measuring device, difficulties in reading the meniscus, adherence of

moisture droplets to the glass, over boiling, suitability of water in the distillation liquid, incomplete

evaporation of water and underestimation of moisture contents, and distillation of water-soluble

components. Adherence of water to the walls of the condenser tube of sides of the receiving tubes can

generally be prevented by using thoroughly cleaned glassware. Use of small amount of wetting agent will

also

improve meniscus reading. Incomplete recovery of water due to the formation of an

emulsion can be avoided by adding small amount of amyl or isobutyl alcohol.

MATERIALS AND METHOD

MATERIALS

Dean Stark Distillation unit

Measuring cylinder

Beaker (250 ml)

Drying oven

Weighing balance

Toluene

METHOD

All the glass wares were cleaned and dried in an oven. 50 ml Toluene solution and some pumice stones

were added to a boiling flask. The calibrated arm was fixed on the flask and was boiled until the

graduated tube gets constant volume of water.2.00 ml of water was added to the flask and was boiled

until constant volume obtained. Then accurately weighed (about 2 g) was added and boiled until the

graduated tube indicates a constant volume for the extracted water layer. This is equal to the same value

of water in gram.

RESULTS AND CALCULATIONS

RESULTS

CALCULATIONS

% moisture m/m = Volume of water collected in the graduated tube X 100

Weight of the sample

Volume of water added to the flask

=

2.0 ml

Recovered volume of water after distillation

=

1.95 ml

Correction factor

=

2.0 / 1.95 = 1.026

Weight of sample

=

2.0172 g

Volume of water contained in the sample

=

0.2 ml

Volume of water (x correction factor)

=

0.2 x 1.026 = 0.2052

Moisture content %

=

0.2052/2.0172 x 100

Moisture content of cinnamon

=

10.17 %

DISCUSSION

In this practical we have used toluene as the solvent. There are few reasons to do so,

Advantages in using toluene,

1.) It is immiscible with water .Then we can get a measurement.

2.) Low density than water.

3.) It has a high boiling point. So we can heat the sample till we get the whole water

amount out.

4.) Toluene will dissolves all the volatiles in the sample. So we can get the pure

measurement.

Advantages in this technique,

1.) Less contamination can happened

2.) Fewer utensils needed.

3.) No need to pay much attention.

Disadvantages in this technique

1.) Water drops will remains on the walls of the distillate tube. So can get a wrong

measurement.

Dean & Stark method is suitable for determination of moisture in foods containing volatile matters. But this

method is not suitable for routing testing and is employed only when conventional oven drying method is

not suitable. It is also not suitable determine small amount of water. It needs little attention, no

contamination.

The solvent should be irreversible, higher boiling point and lower specific gravity than water. Since

toluene has high boiling point (110-111 °C), lower density (0.86 g/ml) and immiscible with water, it was

used as the solvent. Other than the toluene, heptane, xylene a mixture of N-amyl alcohol and xylene can

be used as solvent. For high precision, a distillation factor correction was done by standardizing the

apparatus with known amount of water and measuring the recovered amount water.

Method of moisture determination is varied according to the sample to be tested. i.e. viscose foods such

as oils, fats done by adding clean dry sand , which facilitate evaporation by increasing surface area and to

avoid formation of films and crusts. Due to the experimental errors we got higher value for moisture

content.

REFERENCES:

•

Pearson, David, 1976, The chemical analysis of foods, First-4th ed. By H.E.Cox

Mendham J, 2003, Vogel’s Quantitative Chemical Analysis, Sixth edition.,

Pearson Education(Singapore)Pte.

•

Potter Norman N, Hotchickjss Joseph H, Food Science, Fifth edition, Cbs

Publishers and distributors

Das könnte Ihnen auch gefallen

- Lab Report Food Analaysis-MoistureDokument11 SeitenLab Report Food Analaysis-MoistureSHAFIKANOR366193% (15)

- Lab 3 PROXIMATE ANALYSIS 2017Dokument8 SeitenLab 3 PROXIMATE ANALYSIS 2017Sam ElleNoch keine Bewertungen

- Determination of Moisture Content or Total SolidsDokument12 SeitenDetermination of Moisture Content or Total SolidsfikerykNoch keine Bewertungen

- SM 2540 Solids (1997) PDFDokument7 SeitenSM 2540 Solids (1997) PDFJames RobinsonNoch keine Bewertungen

- Synthesis of Benzoic Acid Lab ReportDokument7 SeitenSynthesis of Benzoic Acid Lab Reportstephanie damajNoch keine Bewertungen

- AbcDokument7 SeitenAbcLingga NurhayatiNoch keine Bewertungen

- What Is Loss On Drying-Total SolidsDokument7 SeitenWhat Is Loss On Drying-Total SolidsMuhammad Masoom Akhtar0% (1)

- Inspire Cast FinalDokument195 SeitenInspire Cast Finalamele25100% (1)

- Astm C365-00Dokument3 SeitenAstm C365-00Nasos MasourasNoch keine Bewertungen

- Food Analysis-7Dokument52 SeitenFood Analysis-7MD. Humayun KobirNoch keine Bewertungen

- Determination of Moisture ContentDokument8 SeitenDetermination of Moisture ContentLaksilu Viduraga Peiris100% (13)

- Determination of Moisture ContentDokument7 SeitenDetermination of Moisture ContentLaksilu Viduraga Peiris71% (7)

- Solids: TitleDokument15 SeitenSolids: TitleMuhammad UsmanNoch keine Bewertungen

- Moisture and Total SolidsDokument68 SeitenMoisture and Total Solidsgardenia delfin100% (1)

- Exp. No. 1 Moisture (NFE 428)Dokument11 SeitenExp. No. 1 Moisture (NFE 428)Nasima akterNoch keine Bewertungen

- 14.0 Experiment On Determination of Total Solids in Water: Sl. NoDokument12 Seiten14.0 Experiment On Determination of Total Solids in Water: Sl. NoLely CasTroNoch keine Bewertungen

- Determinacion de Humedad - CocoaDokument9 SeitenDeterminacion de Humedad - CocoakarinahinojosadcNoch keine Bewertungen

- Moisture and Ash ContentDokument14 SeitenMoisture and Ash ContentMaksudurRahman0% (1)

- Methods of Determining Moisture ContentDokument4 SeitenMethods of Determining Moisture ContentwycliffkamajowaNoch keine Bewertungen

- Laporan Penentuan Kadar AirDokument9 SeitenLaporan Penentuan Kadar AirSubhan Aristiadi RachmanNoch keine Bewertungen

- Miscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueDokument28 SeitenMiscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueShoaib Muhammad100% (1)

- CONCLUSION-food AnalysisDokument2 SeitenCONCLUSION-food AnalysisFadhlin Sakinah100% (1)

- Determination of TurbidityDokument12 SeitenDetermination of TurbidityAkash SahuNoch keine Bewertungen

- Analysis of Water Content, Total Solids & Water ActivityDokument31 SeitenAnalysis of Water Content, Total Solids & Water ActivitySafaa TahaNoch keine Bewertungen

- Lec 4 MoistureDokument27 SeitenLec 4 Moisturemamoonfareed20Noch keine Bewertungen

- Standard Methods For The Examination of Water and WastewaterDokument6 SeitenStandard Methods For The Examination of Water and WastewaterJihadinita El HajjiNoch keine Bewertungen

- Analytical Tools in Nutrition..Dokument5 SeitenAnalytical Tools in Nutrition..Huzaifa CHNoch keine Bewertungen

- Foods: Rapid Estimation of Parameters For Gelatinization of Waxy Corn StarchDokument10 SeitenFoods: Rapid Estimation of Parameters For Gelatinization of Waxy Corn StarchMuhammad IlyasNoch keine Bewertungen

- BrineDokument15 SeitenBrinekasun12374590% (1)

- Experiment 4 Determination of Total SolidsDokument6 SeitenExperiment 4 Determination of Total Solidselha e. maruquinNoch keine Bewertungen

- 15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterDokument15 Seiten15.0 Experiment On Determination of Total Dissolved and Suspended Solids in Waterhero100% (2)

- Aquametry: East West UniversityDokument17 SeitenAquametry: East West UniversityApurba Sarker Apu100% (4)

- General Methods For Proximate and Mineral AnalysisDokument2 SeitenGeneral Methods For Proximate and Mineral Analysisf jjNoch keine Bewertungen

- Experiment 1 Evt637Dokument5 SeitenExperiment 1 Evt637Azmi AslamNoch keine Bewertungen

- 04 Moisture AnalysisDokument6 Seiten04 Moisture AnalysisMelati Aprilani100% (2)

- Analysis of Water Content, Total Solids & Water ActivityDokument31 SeitenAnalysis of Water Content, Total Solids & Water ActivityRita Farida100% (1)

- Gravimetric AnalysisDokument5 SeitenGravimetric AnalysisjeffjerardcandaNoch keine Bewertungen

- Example Lab ReportDokument12 SeitenExample Lab ReportHung Dang QuangNoch keine Bewertungen

- Laboratory Activity No. 1Dokument4 SeitenLaboratory Activity No. 1Christopher Andrei Salonga LimNoch keine Bewertungen

- Lab Report DETERMINATION OF PERCENT COMPOSITION IN HYDRATE COMPUNDSDokument6 SeitenLab Report DETERMINATION OF PERCENT COMPOSITION IN HYDRATE COMPUNDSRikachu100% (1)

- 1586333153Dokument6 Seiten1586333153Sar OyaNoch keine Bewertungen

- CMT 564 ReportDokument9 SeitenCMT 564 ReportMuhammad Fakhrizzaki100% (1)

- EDM - Notes 3Dokument8 SeitenEDM - Notes 3sahilofficial1509Noch keine Bewertungen

- Experiment: 01: Object PrincipleDokument12 SeitenExperiment: 01: Object PrincipleAreeba WaseemNoch keine Bewertungen

- Experiment 4Dokument13 SeitenExperiment 4Renu SekaranNoch keine Bewertungen

- Lab 1 - Water ActivityDokument7 SeitenLab 1 - Water ActivityLian WidawatiNoch keine Bewertungen

- Water Sampling and Analysis: Chemical Physical PropertiesDokument38 SeitenWater Sampling and Analysis: Chemical Physical Propertiescarlos neiraNoch keine Bewertungen

- Lab 2 - Suspended Solids (Full)Dokument8 SeitenLab 2 - Suspended Solids (Full)NorhazerahYussopNoch keine Bewertungen

- EXP 2 NikDokument6 SeitenEXP 2 NikNurul AtikahNoch keine Bewertungen

- Aguas - Sólidos Totales DisueltosDokument5 SeitenAguas - Sólidos Totales DisueltosRina Licet Socompi AguilarNoch keine Bewertungen

- Laboratory Report On Mositure ContentDokument6 SeitenLaboratory Report On Mositure ContentEst LijNoch keine Bewertungen

- (Lab Report Operation Unit) Experiment 4: INTRODUCTION TO A BATCH PROCESS: SIMPLE BATCH DISTILLATIONDokument10 Seiten(Lab Report Operation Unit) Experiment 4: INTRODUCTION TO A BATCH PROCESS: SIMPLE BATCH DISTILLATIONFazsroul86% (7)

- 15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterDokument15 Seiten15.0 Experiment On Determination of Total Dissolved and Suspended Solids in WaterJomana JomanaNoch keine Bewertungen

- Drying (Partial), Freeze Drying, Freeze Concentration, and Pasteurisation Class LectureDokument61 SeitenDrying (Partial), Freeze Drying, Freeze Concentration, and Pasteurisation Class Lecturenabil100% (1)

- CHM 207 Experiment 2Dokument7 SeitenCHM 207 Experiment 2MUHAMMAD AFIQ SAMSURINoch keine Bewertungen

- Jun 2020 DMK5042 - Lab Manual Total SolidsDokument3 SeitenJun 2020 DMK5042 - Lab Manual Total SolidsnityaNoch keine Bewertungen

- Analisis Lab 2Dokument21 SeitenAnalisis Lab 2xinyiNoch keine Bewertungen

- Determination of Salinity of Given Water Sample Using Salinity MeterDokument6 SeitenDetermination of Salinity of Given Water Sample Using Salinity MeterDani MughalNoch keine Bewertungen

- Standard methods for the examination of water and sewageVon EverandStandard methods for the examination of water and sewageNoch keine Bewertungen

- JeBouffe Home Canning Step by Step Guide (second edition) Revised and ExpandedVon EverandJeBouffe Home Canning Step by Step Guide (second edition) Revised and ExpandedNoch keine Bewertungen

- Paleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveVon EverandPaleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveNoch keine Bewertungen

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterVon EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNoch keine Bewertungen

- LentilDokument8 SeitenLentilHaLa SalahNoch keine Bewertungen

- Arsenic: Environmental Health Guidance NoteDokument3 SeitenArsenic: Environmental Health Guidance NoteHaLa SalahNoch keine Bewertungen

- Mark's 2002 Research Seminar 4Dokument44 SeitenMark's 2002 Research Seminar 4HaLa SalahNoch keine Bewertungen

- Mark's 2002 Research Seminar 4Dokument44 SeitenMark's 2002 Research Seminar 4HaLa SalahNoch keine Bewertungen

- Borophene As An Anode Material For CA MG Na or Li Ion Storage A Firstprinciple StudyJournal of Power SourcesDokument6 SeitenBorophene As An Anode Material For CA MG Na or Li Ion Storage A Firstprinciple StudyJournal of Power Sourcesbala11ap4598Noch keine Bewertungen

- HQ Series InsertDokument19 SeitenHQ Series InsertAnderson ReisNoch keine Bewertungen

- Mathmatics and Physics 1 (Versie 7 Okt 2019) PDFDokument250 SeitenMathmatics and Physics 1 (Versie 7 Okt 2019) PDFŁukasz MorozNoch keine Bewertungen

- O.M. - 14.0 - BT1000 - BT1500 - BT2000 Plus - BT3000 - Plus - BT3500 PDFDokument280 SeitenO.M. - 14.0 - BT1000 - BT1500 - BT2000 Plus - BT3000 - Plus - BT3500 PDFmessaoud_fethi80% (10)

- Science and Health 6Dokument2 SeitenScience and Health 6MA. PATRIA MANDAPNoch keine Bewertungen

- Design of Structural Steel Pipe Racks PDFDokument12 SeitenDesign of Structural Steel Pipe Racks PDFmobin1978100% (3)

- Iit Ashram: Class: 9 - Cbse-Gseb Science Board Pattern Test-2Dokument3 SeitenIit Ashram: Class: 9 - Cbse-Gseb Science Board Pattern Test-2Rutvik SenjaliyaNoch keine Bewertungen

- Industrial Crops & Products: Bishwajit Changmai, Putla Sudarsanam, Lalthazuala RokhumDokument10 SeitenIndustrial Crops & Products: Bishwajit Changmai, Putla Sudarsanam, Lalthazuala RokhumIdemudia VictorNoch keine Bewertungen

- AssignmentDokument3 SeitenAssignmentdola indupriyaNoch keine Bewertungen

- Physics 2150 Lab 03 - The Hall EffectDokument6 SeitenPhysics 2150 Lab 03 - The Hall EffectJeet Saurav SrivastavaNoch keine Bewertungen

- Assignment No. 4 - 2020-21 PDFDokument2 SeitenAssignment No. 4 - 2020-21 PDFnikhil khanwaniNoch keine Bewertungen

- Power Cable Installation ManualDokument50 SeitenPower Cable Installation ManualAnn DodsonNoch keine Bewertungen

- Mathematics in The Modern WorldDokument4 SeitenMathematics in The Modern WorldYonneNoch keine Bewertungen

- Jgeot.21.00089 OffprintDokument11 SeitenJgeot.21.00089 OffprintBrian SheilNoch keine Bewertungen

- Refrigeration Troubleshooting GuideDokument8 SeitenRefrigeration Troubleshooting GuideJuan Jose Ramirez CorralesNoch keine Bewertungen

- SD-NOC-EC-602 Pre-Commissioning ExecutionDokument156 SeitenSD-NOC-EC-602 Pre-Commissioning ExecutionBadri AbdullahNoch keine Bewertungen

- HK MalikDokument840 SeitenHK MalikHarsan Singh100% (1)

- Modulation Schemes of The Three-Phase Impedance Source Inverters - Part II: Comparative AssessmentDokument13 SeitenModulation Schemes of The Three-Phase Impedance Source Inverters - Part II: Comparative Assessmentek9925Noch keine Bewertungen

- Product Specifications: AVA5-50FXDokument3 SeitenProduct Specifications: AVA5-50FXhassan329100% (1)

- 05 Stress DistributionDokument29 Seiten05 Stress DistributionJoshua OrcalesNoch keine Bewertungen

- Unit 6 Differentiation: StructureDokument30 SeitenUnit 6 Differentiation: StructuretapansNoch keine Bewertungen

- Fully Automatic Current and Voltage Transformer Test SetDokument8 SeitenFully Automatic Current and Voltage Transformer Test SetMuhammad ShahidNoch keine Bewertungen

- Cell and Molecular Biology Module (Lecture and Laboratory)Dokument200 SeitenCell and Molecular Biology Module (Lecture and Laboratory)RM Montemayor100% (2)

- SUper Perc-ElexDokument23 SeitenSUper Perc-ElexNo MarNoch keine Bewertungen

- Lab Assignment 1 EEE-466, Power Electronics Lab: Design and Simulation of Bridge RectifiersDokument9 SeitenLab Assignment 1 EEE-466, Power Electronics Lab: Design and Simulation of Bridge RectifiersKhairulNoch keine Bewertungen

- C15 and C18 Generator SetDokument4 SeitenC15 and C18 Generator Setspider blackNoch keine Bewertungen

- Week 12 Myp 4 HWDokument2 SeitenWeek 12 Myp 4 HWAnchal ChadhaNoch keine Bewertungen

- I. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Dokument4 SeitenI. Melc.: Perpetual Succour Academy, Inc. National Rd. Poblacion Dos, Malabuyoc, Cebu Science 10Cry BeroNoch keine Bewertungen