Beruflich Dokumente

Kultur Dokumente

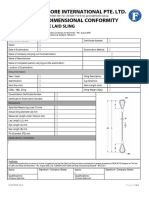

JN P/D Qty Cust Reject # of Roll Screened Screening Result: Sentienx

Hochgeladen von

Jason Roberts0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 SeiteOriginaltitel

gel.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten1 SeiteJN P/D Qty Cust Reject # of Roll Screened Screening Result: Sentienx

Hochgeladen von

Jason RobertsCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

I have looked into the product record and conducted a study.

The study was conducted looking at all the fundamentals without taking any consideration of

known contrarian or defending or accusing any party.

It is a purely a root cause analysis asking why when the going’s does not seem logical or reasonable.

It would be a platform to ask our self what we can do better. Its about PIC, Responsibly and Accountability.

The RED FLAG shows how our respond can be better.

Moving forward

1) Can we produce this product to the Customers’ Specification with what we have in terms of equipment, skills and supervision?

2) We need to tighten Process and Quality Control of this product.

3) Can we be more Proactive, more disciplined in our control ?

a) Production Record

JN P/D Qty Cust Reject # of roll Screening result RED FLAG

screened

64017 10/1/2018 100 Sentienx 10 --- 10 Screening on 18/01/2018 50 % of Screening found

rolls 115 rolls % 1) 1 roll - 4 black gel (3 joints) problems.

2) 5 rolls - No report of issue 1) Why problem was not

3) 4 rolls - a lot of black gel >= 0.6mm detected during production ?

2) At 50 % Reject why No 100

% Screening of the lot?

3) Who makes the decision?

4) Why QA not informed of the

situation?

1) 5) How Even the 4 rolls

rejected during screening

were sent

64018 18/1/18 48 0 (48 rolls) was put On-Hold due to black gel 1) Why wait until 4 months to

rools issue and line was stopped for die cleaning conduct investigation ?

After Customer Reject:

On May-18, screening was conducted on the 48

rolls put On-Hold and disposition was made to

scrapped these 48 rolls due to excessive black

gel issue.

64062 16/3/2018 200 Terang Nusa 4 1) 3 rolls no

rolls 371 rolls issue 2)

1 roll - 1 black gel & 1 white gel. ( 1 joint)

100

10/4/2018 3 Black gel

64135 rolls 1

64136 9/5/2018 200 1 2 joints - 2 black gel

rolls Currently 30 rolls on-hold due to customer

complaint

30 rolls with Oil Mark

100 Found Black & White Oil mark during production.

64147 11/4/2018 rolls 61 Roll 1 to 60 was put on-hold for screening.

64190 16/5/2018 200 0

rolls

Summary of the rejected lots from Terang Nusa

a) 371 rolls rejected out of 600 rolls produced (62%)

b) 1 lot produce in March-18 and 2 lots produced in May-18.

c) March Production – Screen 4 rolls. 3 rolls no report of issue.

d) May Production – Total 400 rolls produced. Screened 1 roll – Reported 2 black gel

Summary of the rejected lots from Sentienx

a) 115 rolls rejected out of 300 rolls produced (38%)

b) 1 lot produce in January-18 and 2 lots produced in April-18.

c) January Production – Screened 10 rolls

d) April Production – Total 200 rolls produced. Total screened 62 rolls.

For JN 64147 – 61 rolls was put on-hold due to Oil Mark. No reported of Gel issue during the screening for Oil mark.

Das könnte Ihnen auch gefallen

- LMA Guide to London Market ProcessingDokument65 SeitenLMA Guide to London Market ProcessingNanthawat Babybeb100% (1)

- Radical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim ScottDokument5 SeitenRadical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim Scottzafytuwa17% (12)

- WACP Anat Path Accreditation Checklist (Correcetd)Dokument18 SeitenWACP Anat Path Accreditation Checklist (Correcetd)Godwin Iko AyubaNoch keine Bewertungen

- Calibration StickerDokument1 SeiteCalibration StickerJason Roberts100% (1)

- Amcor Safety Wallet Card PDFDokument2 SeitenAmcor Safety Wallet Card PDFJason RobertsNoch keine Bewertungen

- Amcor Safety Wallet Card PDFDokument2 SeitenAmcor Safety Wallet Card PDFJason RobertsNoch keine Bewertungen

- UBT-13 Paper (20-03-24)Dokument48 SeitenUBT-13 Paper (20-03-24)anshchau2007Noch keine Bewertungen

- G Sample Methods NamiDokument4 SeitenG Sample Methods NamiJetlogzzszszsNoch keine Bewertungen

- Amedica - Research PresentationDokument16 SeitenAmedica - Research Presentationapi-343458772Noch keine Bewertungen

- Buplint For NiggaDokument1 SeiteBuplint For Niggafbray320Noch keine Bewertungen

- APPI-VAL-004 Validation of Control Measure Effectiveness of Standard Size of Glue ApplicatorDokument3 SeitenAPPI-VAL-004 Validation of Control Measure Effectiveness of Standard Size of Glue Applicatormonik manuelNoch keine Bewertungen

- Request Form Wheat Testing ServicesDokument2 SeitenRequest Form Wheat Testing ServicesWildhan LesmanaNoch keine Bewertungen

- Cortisol ELISA Kit: Item No. 500360Dokument21 SeitenCortisol ELISA Kit: Item No. 500360Ahmed AliNoch keine Bewertungen

- 2018 July - L01 P1 Lab ScheduleDokument3 Seiten2018 July - L01 P1 Lab ScheduleNurshahanimNoch keine Bewertungen

- 20140909b 013108001Dokument1 Seite20140909b 013108001vinjamurisivaNoch keine Bewertungen

- SGS-iis - Consumer Products Iis18A06Dokument2 SeitenSGS-iis - Consumer Products Iis18A06Doulat RamNoch keine Bewertungen

- Sampling PlanDokument8 SeitenSampling Planvipulsharma655Noch keine Bewertungen

- Testing & Quality Control Lab Report (8) : Title: To Check Colorfastness To Dry-CleaningDokument6 SeitenTesting & Quality Control Lab Report (8) : Title: To Check Colorfastness To Dry-CleaningAsad Jamil RanaNoch keine Bewertungen

- DPPs BOOKLET-1 REPRODUCTION CHAPTERDokument21 SeitenDPPs BOOKLET-1 REPRODUCTION CHAPTERNilesh JhaNoch keine Bewertungen

- Completion Requirements: Three-Quarters The Length of The Slide)Dokument2 SeitenCompletion Requirements: Three-Quarters The Length of The Slide)PRECIOUS DIANNE BARDON-MEMPINNoch keine Bewertungen

- Bab Iv: Rencana Usulan Kegiatan Dan Usulan Kebutuhan Puskesmas Tembuku Ii TAHUN 2018Dokument7 SeitenBab Iv: Rencana Usulan Kegiatan Dan Usulan Kebutuhan Puskesmas Tembuku Ii TAHUN 2018Anonymous gpNr8cLWNoch keine Bewertungen

- Tbars AssayDokument13 SeitenTbars AssaySHIVAGOVINDANNoch keine Bewertungen

- BPS 2110 F2015 Lecture Supplement A - CLEANDokument13 SeitenBPS 2110 F2015 Lecture Supplement A - CLEANSumayah Al-SamiNoch keine Bewertungen

- Oil Analysis Fundamentals Lubricant Condition Monitoring PDFDokument36 SeitenOil Analysis Fundamentals Lubricant Condition Monitoring PDFRMascil100% (2)

- Oil Analysis Fundamentals PDFDokument36 SeitenOil Analysis Fundamentals PDFHendra DNoch keine Bewertungen

- Grand test 3 key highlights scoresDokument27 SeitenGrand test 3 key highlights scoresPrabha DarlingNoch keine Bewertungen

- USDA standards for sorghum gradesDokument4 SeitenUSDA standards for sorghum gradesNICOLE STEFANIE ORELLANA PINTONoch keine Bewertungen

- 0901d19680075963 PDF Preview MediumDokument2 Seiten0901d19680075963 PDF Preview MediumclenilsoNoch keine Bewertungen

- 4FertilizerSampling (Straight and Compound) Rv3Dokument6 Seiten4FertilizerSampling (Straight and Compound) Rv3Shami KamisNoch keine Bewertungen

- Catalogue Immuno CellDokument24 SeitenCatalogue Immuno Cellly lyNoch keine Bewertungen

- D 4005 - 92 R01 - RdqwmduDokument2 SeitenD 4005 - 92 R01 - RdqwmduPrakash MakadiaNoch keine Bewertungen

- Tissue ProcessingDokument32 SeitenTissue ProcessingAnas KhanNoch keine Bewertungen

- Bab 4 Seminar Chitosan FixDokument29 SeitenBab 4 Seminar Chitosan FixFridolin Siringo-ringoNoch keine Bewertungen

- Question 6 FSTDokument24 SeitenQuestion 6 FSTamanweshdasNoch keine Bewertungen

- Module 4 Deviations RCA Tools CAPAs No Assessments2Dokument41 SeitenModule 4 Deviations RCA Tools CAPAs No Assessments2Rui SantosNoch keine Bewertungen

- Worksheet 3: (2 Points) (2 Points)Dokument2 SeitenWorksheet 3: (2 Points) (2 Points)KingxMagic lopezNoch keine Bewertungen

- Online ExaminationDokument6 SeitenOnline ExaminationThimmaiah NKNoch keine Bewertungen

- 17tre-137 Pi ReportDokument4 Seiten17tre-137 Pi ReportjuanaaalejandrasalcedosamperNoch keine Bewertungen

- Astellas Ireland Comnpany LTD Ampoule Inspection MachineDokument33 SeitenAstellas Ireland Comnpany LTD Ampoule Inspection MachineRajib SarkarNoch keine Bewertungen

- Botany 5Dokument5 SeitenBotany 5Vibushitha KabardineshwarNoch keine Bewertungen

- Class 11 - Chemistry - PT 1 - BP - 2023Dokument1 SeiteClass 11 - Chemistry - PT 1 - BP - 2023samforperosnal99Noch keine Bewertungen

- BTS-22 Paper (25-Nov-2023)Dokument25 SeitenBTS-22 Paper (25-Nov-2023)anushkasingh300806Noch keine Bewertungen

- Pelayanan Gigi & MulutDokument8 SeitenPelayanan Gigi & MulutVerie BorneoNoch keine Bewertungen

- Example Round Problem of Well LoggingDokument3 SeitenExample Round Problem of Well LogginganwaarsantosooNoch keine Bewertungen

- Rolling Bearing Failure V2Dokument34 SeitenRolling Bearing Failure V2dshalev869460% (5)

- 7 Problem Solving Tools ExplainedDokument116 Seiten7 Problem Solving Tools ExplainedAyalew TayeNoch keine Bewertungen

- Latanoprost ELISA Kit BookletDokument19 SeitenLatanoprost ELISA Kit BookletKate AnagnostouNoch keine Bewertungen

- Is 101 6 5 1997 PDFDokument23 SeitenIs 101 6 5 1997 PDFdombipinNoch keine Bewertungen

- RM Yield Improvement by Dropout ReductionDokument50 SeitenRM Yield Improvement by Dropout Reductionrohit negiNoch keine Bewertungen

- Evaluation Report Scope Analysis ComplianceDokument2 SeitenEvaluation Report Scope Analysis Compliance王坚强Noch keine Bewertungen

- Scoggins Report - March 25 2011 - Spec Market ScorecardDokument5 SeitenScoggins Report - March 25 2011 - Spec Market ScorecardJason ScogginsNoch keine Bewertungen

- Ayob Khan IpcrDokument2 SeitenAyob Khan IpcrAmjad MacaumbangNoch keine Bewertungen

- Organoleptic Analysis Results Frozen ShrimpDokument1 SeiteOrganoleptic Analysis Results Frozen ShrimpDevaraj SubramanyamNoch keine Bewertungen

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Dokument4 SeitenE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Zainal ArifinNoch keine Bewertungen

- Stuck Pipe Prevention 1637664167Dokument14 SeitenStuck Pipe Prevention 1637664167jerikhoNoch keine Bewertungen

- Gujarat Technological UniversityDokument1 SeiteGujarat Technological UniversityRohit patelNoch keine Bewertungen

- 408 Agriculture SQPDokument6 Seiten408 Agriculture SQPranapratapmondal155Noch keine Bewertungen

- Precision Worldwide: Group Members: Adityanarayanan Iyer Neeraj Arora Ritu Mathur Rajan Kumar Subhranshu SekharDokument5 SeitenPrecision Worldwide: Group Members: Adityanarayanan Iyer Neeraj Arora Ritu Mathur Rajan Kumar Subhranshu SekharvsyoiNoch keine Bewertungen

- Accessories For IVF CenterDokument2 SeitenAccessories For IVF CenterNay Myo HtetNoch keine Bewertungen

- Park (En)Dokument5 SeitenPark (En)Rusman Adi SaputraNoch keine Bewertungen

- Keep 425Dokument12 SeitenKeep 425Johan SukweenadhiNoch keine Bewertungen

- Xii Blue PrintDokument15 SeitenXii Blue PrintSibasis RanaNoch keine Bewertungen

- Qa Probability WBDokument5 SeitenQa Probability WBChirag ChadhaNoch keine Bewertungen

- 1619928348861forensic Science UNIT - VII 1 PDFDokument159 Seiten1619928348861forensic Science UNIT - VII 1 PDFVyshnav RNoch keine Bewertungen

- Mak Kee Qua Ity Policy v3Dokument1 SeiteMak Kee Qua Ity Policy v3Jason RobertsNoch keine Bewertungen

- DoorsDokument2 SeitenDoorsJason RobertsNoch keine Bewertungen

- Mks E001 - 2021-1Dokument1 SeiteMks E001 - 2021-1Jason RobertsNoch keine Bewertungen

- Mks E001 - 2021-1Dokument1 SeiteMks E001 - 2021-1Jason RobertsNoch keine Bewertungen

- Gel DetectionDokument2 SeitenGel DetectionJason RobertsNoch keine Bewertungen

- A7ii ManualDokument290 SeitenA7ii ManualRiker Cabo ChuNoch keine Bewertungen

- Annex DDokument2 SeitenAnnex DJason RobertsNoch keine Bewertungen

- FOI-ISD-REP0001 Rev 00 - Certificate of Dimensional Conformity Flemish LockDokument1 SeiteFOI-ISD-REP0001 Rev 00 - Certificate of Dimensional Conformity Flemish LockJason RobertsNoch keine Bewertungen

- Gel DetectionDokument2 SeitenGel DetectionJason RobertsNoch keine Bewertungen

- Amcor Qpolicy NewDokument1 SeiteAmcor Qpolicy NewJason RobertsNoch keine Bewertungen

- Effects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+cDokument6 SeitenEffects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+ctania0639Noch keine Bewertungen

- Test ComparedDokument1 SeiteTest ComparedJason RobertsNoch keine Bewertungen

- Amcor Qpolicy NewDokument1 SeiteAmcor Qpolicy NewJason RobertsNoch keine Bewertungen

- TrendDokument3 SeitenTrendJason RobertsNoch keine Bewertungen

- Amcor Qpolicy NewDokument1 SeiteAmcor Qpolicy NewJason RobertsNoch keine Bewertungen

- Effects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+cDokument6 SeitenEffects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+ctania0639Noch keine Bewertungen

- Accident Investigation Questionnaire: AFP (M) Form OHSA 016-1Dokument6 SeitenAccident Investigation Questionnaire: AFP (M) Form OHSA 016-1Jason RobertsNoch keine Bewertungen

- Material HseDokument6 SeitenMaterial HseOsmar JrNoch keine Bewertungen

- ISO/TR 7596-1982 (E) Technical report on resin socketing procedures for wire ropesDokument6 SeitenISO/TR 7596-1982 (E) Technical report on resin socketing procedures for wire ropesJason RobertsNoch keine Bewertungen

- Grommets PDFDokument1 SeiteGrommets PDFJason RobertsNoch keine Bewertungen

- Risk Assessment Worksheet: SiteDokument1 SeiteRisk Assessment Worksheet: SiteJason RobertsNoch keine Bewertungen

- Effects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+cDokument6 SeitenEffects of Changing Parameters a, b, c in Quadratic Functions ax^2+bx+ctania0639Noch keine Bewertungen

- Swager Safety GuideDokument18 SeitenSwager Safety GuideJason RobertsNoch keine Bewertungen

- Report North Point IncidentDokument29 SeitenReport North Point Incidentsimoncarter313Noch keine Bewertungen

- D 6287 - 98 - Rdyyodc - PDFDokument3 SeitenD 6287 - 98 - Rdyyodc - PDFJason Roberts100% (1)

- Peel Testing PDFDokument1 SeitePeel Testing PDFJason RobertsNoch keine Bewertungen

- D 6988 - 03 Medicion de CalibreDokument7 SeitenD 6988 - 03 Medicion de CalibreMiguelAngelPerezEsparzaNoch keine Bewertungen

- CV Raman's Discovery of the Raman EffectDokument10 SeitenCV Raman's Discovery of the Raman EffectjaarthiNoch keine Bewertungen

- 4idealism Realism and Pragmatigsm in EducationDokument41 Seiten4idealism Realism and Pragmatigsm in EducationGaiLe Ann100% (1)

- Garden Silk Mills Ltd.Dokument115 SeitenGarden Silk Mills Ltd.jkpatel221Noch keine Bewertungen

- Applying Ocs Patches: Type Area Topic AuthorDokument16 SeitenApplying Ocs Patches: Type Area Topic AuthorPILLINAGARAJUNoch keine Bewertungen

- 7 JitDokument36 Seiten7 JitFatima AsadNoch keine Bewertungen

- Shaft design exercisesDokument8 SeitenShaft design exercisesIvanRosellAgustíNoch keine Bewertungen

- EdiTasc EDokument89 SeitenEdiTasc EOglasnik MostarNoch keine Bewertungen

- C1 Reading 1Dokument2 SeitenC1 Reading 1Alejandros BrosNoch keine Bewertungen

- Pengenalan Icd-10 Struktur & IsiDokument16 SeitenPengenalan Icd-10 Struktur & IsirsudpwslampungNoch keine Bewertungen

- User Manual: Swift S3Dokument97 SeitenUser Manual: Swift S3smnguyenNoch keine Bewertungen

- Fluorescent sensors for detection of heavy metalsDokument36 SeitenFluorescent sensors for detection of heavy metalskawtherahmedNoch keine Bewertungen

- From The Light, On God's Wings 2016-14-01, Asana Mahatari, JJKDokument26 SeitenFrom The Light, On God's Wings 2016-14-01, Asana Mahatari, JJKPaulina G. LoftusNoch keine Bewertungen

- Carnot CycleDokument3 SeitenCarnot CyclealexontingNoch keine Bewertungen

- Structural Testing Facilities at University of AlbertaDokument10 SeitenStructural Testing Facilities at University of AlbertaCarlos AcnNoch keine Bewertungen

- Evidence My Favorite PlayerDokument2 SeitenEvidence My Favorite PlayerReynel Soir0% (1)

- MC145031 Encoder Manchester PDFDokument10 SeitenMC145031 Encoder Manchester PDFson_gotenNoch keine Bewertungen

- Math Curriculum Overview Grades 1 8Dokument1 SeiteMath Curriculum Overview Grades 1 8GuiselleNoch keine Bewertungen

- Conclusion For A Research Paper About BullyingDokument7 SeitenConclusion For A Research Paper About Bullyingafnkjuvgzjzrgl100% (3)

- Indian Oil Corporation- Leading Indian State-Owned Oil and Gas CompanyDokument10 SeitenIndian Oil Corporation- Leading Indian State-Owned Oil and Gas CompanyPrakhar ShuklaNoch keine Bewertungen

- Tiger Facts: Physical Characteristics of the Largest CatDokument14 SeitenTiger Facts: Physical Characteristics of the Largest CatNagina ChawlaNoch keine Bewertungen

- Manual For The MCPL Programming LanguageDokument74 SeitenManual For The MCPL Programming Languagechri1753Noch keine Bewertungen

- Jakobson Linguistics and PoeticsDokument8 SeitenJakobson Linguistics and PoeticsPhil KostovNoch keine Bewertungen

- Studies On Diffusion Approach of MN Ions Onto Granular Activated CarbonDokument7 SeitenStudies On Diffusion Approach of MN Ions Onto Granular Activated CarbonInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Saline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshDokument6 SeitenSaline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNoch keine Bewertungen

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDokument25 SeitenL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyNoch keine Bewertungen

- D5435 PDFDokument6 SeitenD5435 PDFZamir Danilo Morera ForeroNoch keine Bewertungen

- New Microsoft Word DocumentDokument5 SeitenNew Microsoft Word DocumentxandercageNoch keine Bewertungen

- Neptune Sign House AspectDokument80 SeitenNeptune Sign House Aspectmesagirl94% (53)