Beruflich Dokumente

Kultur Dokumente

Cement Grout Type F

Hochgeladen von

abualamalCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cement Grout Type F

Hochgeladen von

abualamalCopyright:

Verfügbare Formate

Fosroc®

Conbextra HF constructive solutions

Highly fluid, dual shrinkage compensated Technical Support

precision, cementitious grout for gaps Parchem offers a comprehensive range of high performance,

10mm to 125mm thickness high quality construction products. In addition, the company

offers a technical support package to specifiers and contractors

Uses as well as technical advice from staff experienced in the

construction industry.

Conbextra HF is used for free flow precision grouting in a wide

range of applications. Typical pplications include:

Specification Clauses

Critical machine base plates, sole plates and columns

Supplier specification

Joints between pre-cast concrete panels

All precision grouting (specify details and areas of application)

Pumped grouting applications must be carried out using Conbextra HF manufactured by

Grouting applications where pouring access is restricted Parchem and used in accordance with the manufacturer’s

current Technical Data Sheet.

Advantages

Performance specification

Excellent initial flow and flow retention To the nominated area(s) (specify details and areas of

Rapid strength gain facilitates efficient installation and application), grouting must be carried out using a pre-packaged,

operation of plant non-metallic and chloride free, dry powder blend of cements,

graded fillers and chemical additives.

High ultimate strength and low permeability ensure

durability of the hardened grout It is to be mixed with clean water to the required consistency.

The plastic grout must not bleed or segregate. The storage,

Hydrogen-free gaseous expansion handling and placement of the grout must be in strict accordance

Chloride free with the manufacturer’s instructions.

Suitable for pumping or pouring A positive volumetric expansion up to 3% shall occur while the

grout is plastic by means of a gaseous, hydrogen free system.

Additionally the grout is to be formulated to compensate for

Standards Compliance

longer term expansion in the hardened state.

AS 1478.2-2005 Appendix E Early Volume Change

It shall exhibit Flow Characteristics when tested to AS

AS 1478.2-2005 Table 4.1.2.2 Consistency 1478.2.2005 of 10 - 30 seconds using the flow cone procedure.

The compressive strength of the grout must exceed 40MPa at

Description 7 days and 60MPa at 28 days.

Conbextra HF, dual shrinkage compensated cementitious

precision grout, is supplied as a ready to use dry powder. The

addition of a controlled amount of clean water produces a free-

flowing precision grout for gap thicknesses up to 125 mm. In

addition the low water requirement ensures high early strength

and long term durability.

Conbextra HF is a blend of Portland cements, graded fillers

and chemical additives which impart controlled expansion in

both the plastic and hardened states.

The filler grading minimises segregation and bleeding over a

wide range of application consistencies.

Maximum aggregate size for pumping is 2.5 mm.

Jun 2018 Page 1

Fosroc®

Conbextra HF

Properties

Test Method Standard Result

Compressive Strength AS 1478.2:2005 Consistency Water Addition 1 Day 7 Days 28 Days

Stiff 2.6-3.4 50 68 77

Plastic 3.4-3.6 38 53 64

Flowable 3.6-3.8 31 48 62

Fluid 3.8-4.0 27 46 60

Bond Strength by Pull Off EN 1542:1999 2.6MPa

Chloride ion Content EN 1015-17:2000 0.004%

Fire Rating EN 13687-1:2002 Class A1 Non-Combustible

Flexural Strength (Modulus AS 1012.11 - 2000 1 Day 3.2 MPa

of Rupture) 7 Days 9.5 MPa

28 Days 10.0 MPa

Indirect Tensile Strength AS 1012.10.2000 1 Day 2.5 MPa

7 Days 4.5 MPa

28 Days 4.7 MPa

Setting Time AS 1012.18:1996 5.5 hours - initial set

7.5 hours - final set

Fresh Wet Density 2200 kg/m³ - depending on consistency used

Alkali reactive particles Rapid Mortar Bar Non-reactive

Test (RTA T363)

Flow Characteristics AS 1478.2:2005 19-25 seconds (Flow Cone)

Minimum Thickness 10mm

Maximum Thickness 125mm

Clarification of property values: The typical properties given above are derived from laboratory testing. Compressive strengths

stated above were measured using cube samples. Test results obtained will vary if carried out to an alternative standard or sample

dimensions are used.

Note: Compressive strengths stated were measured at bottom end water, eg., the 28 day strength of 62 MPa for flowable consistency

was obtained at a water addition of 3.6 litres water per 20kg bag of Conbextra HF.

Test Results to ASTM Specification C1107: 2001

Test Method Standard Result

Flow Consistency ASTM C1437:2007 145%

Setting Time ASTM C191:2008 Initial: 5.75 hours

Final: 6.75 hours

Plastic Volume Change ASTM C1090:2010 +0.57%

Hardened Volume Change ASTM:C827:2010 1 day 0.12%

3 days 0.12%

14 days 0.12%

28 days 0.12%

56 days 0.10%

Compressive Strength ASTM C109:2011b 1 day 34.4 MPa

3 days 53.5 MPa

7 days 63.7 MPa

28 days 70.1 MPa

Note: All tests were carried out at 25oC ± 2oC until the age of the test. All above test results are independent third party results.

Copies of these test results are available on request. The tests were carried out at a water addition rate of 3.6 litres per 20kg.

constructive solutions Page 2

Fosroc®

Conbextra HF

Flow properties of mixed grout

The flow distances given below in (mm) are intended as a guide. Actual flow distances will vary depending on site conditions:

Gap Depth Flowable 100mm head Flowable 250mm head Fluid 100mm head Fluid 250mm head

(mm) (mm) (mm) (mm) (mm)

10 360 1200 900 2500

20 950 2600 1900 3000

30 1500 3000 3000 3000+

40 2200 3000+ 3000+ 3000+

50 3000 3000+ - -

Preparation Mixing

A forced-action mixer is essential. Mix for 3 to 5 minutes at a

Foundation surface slow speed (400/500 rpm) in a suitably sized drum using

The substrate surface must be free from oil, grease or any appropriate equipment such the Ransom MDR59 140 x 600

loosely adherent material. Concrete laitance should be removed M14 Helical mixing paddle (product code: N4020892-UNIT)

using low impact scabbling or with needle guns to the degree fitted to a heavy-duty 1600W mixer, such as Ransom RAN160

where aggregate is starting to show. (product code: NP7AN160-UNIT ) or equivalent.

Bolt holes or fixing pockets must be blown clean of any dirt or Larger quantities will require a high shear vane mixer. Do not

debris. Bolt holes should also be roughen up using mechanical use a colloidal impeller mixer.

means.

It is essential that machine mixing capacity and labour availability

is adequate to enable grouting operation to be carried out

Pre-soaking

continuously. This may require the use of a holding tank with

Several hours prior to grouting, the area of cleaned foundation provision for gentle agitation to maintain fluidity.

should be flooded with fresh water. Immediately before grouting

takes place, any free water should be removed. Particular care The selected water content should be accurately measured

should be taken to blow out all bolt holes and pockets. into the mixer. Slowly add the total contents of the Conbextra

HF bag, mix continuously for 5 minutes, ensuring a smooth,

Base plate / grout interface even consistency is obtained.

It is essential that this is clean and free from oil, grease, scale,

Deeper grout pours

paint or coating of any kind. Air pressure relief holes should be

provided to allow venting of any isolated high spots. Where grout gap depth is in excess of 125 mm up to 500 mm,

Conbextra Deep Pour should be used.

Levelling shims

Placing

If these are to be removed after the grout has hardened, they

should be treated with a thin layer of grease. Place the grout within 15 minutes of mixing to gain the full

benefit of the expansion process.

Formwork Conbextra HF can be placed in thicknesses from 10 mm up to

The formwork should be constructed to be leakproof as 125 mm in a single pour when used as an underplate grout.

Conbextra HF is a free flowing grout. This can be achieved by Where the grouting gap beneath the base plate exceeds the

using foam rubber strip or Construction Silicone* beneath the maximum thickness allowed, then the grout can filled / bulked

constructed formwork and between joints. out with Conbextra Grout Aggregate* to minimise exotherm

heat build up. Alternatively Conbextra Deep Pour is available

In some cases it is practical to use a sacrificial semi-dry sand for pours up to 500 mm thick.

and cement formwork. The formwork should include outlets for

the pre-soaking water. Filling/bulking out of the grout should not exceed a ratio of 1:1.

Please refer to the Conbextra Grout Aggregate TDS for more

The unrestrained surface area of the grout must be kept to a guidance on bulking out of cement based grouts.

minimum. Generally the gap width between the perimeter

formwork and the plate edge should not exceed 150 mm on Any bolt pockets must be grouted prior to grouting between the

the pouring side and 50 mm on the opposite side. There should substrate and the base plate. Continuous grout flow is essential.

be no gap at the flank sides.

constructive solutions Page 3

Fosroc®

Conbextra HF

For larger pours the grout may be hand placed or pumped into Limitations

a removable hopper (trough).

Low temperature working

Sufficient grout must be available prior to starting and the time

taken to pour a batch must be regulated to the time taken to When the air or contact surface temperatures are 5°C or below

prepare the next one. Continual grout pour must be ensured. on a falling thermometer, warm water (30-40°C) is recommended

to accelerate strength development.

The mixed grout should be poured only from one side of the

void to eliminate the entrapment of air or surplus pre-soaking For ambient temperatures below 10oC the grout consistency

water. This is best achieved by pouring the grout across the should be flowable and the formwork should be maintained in

shortest distance of travel. place for at least 36 hours.

The grout head must be maintained at all times so that a Normal precautions for winter working with cementitious

continuous grout front is achieved. materials should then be adopted.

Please refer to the Conbextra Cementitous Grouts Application High temperature working

Guide for further information. This is available from the website At ambient temperatures above 35°C the mixed grout should

or your local Parchem branch. be stored in the shade. Cool water (below 20°C) should be

used for mixing the grout.

Pumping

Where large volumes have to be placed Conbextra HF may be Estimating

pumped. A heavy duty diaphragm pump is recommended for

this purpose. Screw feed and piston pumps may also be suitable. Supply

Maximum aggregate is 2.5 mm. Ensure pump is capable of

pumping this size aggregate. Conbextra HF 20 kg bags.

Material code: FC501050-20KG

Curing

On completion of the grouting operation, exposed areas should Yield

be thoroughly cured. This should be done by the use of Concure

A99 curing membrane or wet hessian. Consistency Yield / 20 kg bag

(AS 1478.2-2005 Table (Litres of mixed

Cleaning 4.1.2.2) material)

Conbextra HF should be removed from tools and equipment

Stiff 10.4 litres

with clean water immediately after use. Cured material can be

removed mechanically. Plastic 10.7 litres

Flowable 10.8 litres

Fluid 10.9 litres

Storage

Conbextra HF has a shelf life of 24 months from date of

manufacture if kept in a dry store in the original, unopened

bags. Refer to the Use by Date indicated on the packaging. If

stored in high temperature and high humidity locations the

shelf life may be reduced.

Important notice

A Safety Data Sheet (SDS) and Technical Data Sheet (TDS) are available from the Parchem website or upon request from the nearest Parchem sales office. Read the SDS and TDS carefully

prior to use as application or performance data may change from time to time. In emergency, contact any Poisons Information Centre (phone 13 11 26 within Australia) or a doctor for advice.

Product disclaimer

This Technical Data Sheet (TDS) summarises our best knowledge of the product, including how to use and apply the product based on the information available at the time. You should read

this TDS carefully and consider the information in the context of how the product will be used, including in conjunction with any other product and the type of surfaces to, and the manner in

which, the product will be applied. Our responsibility for products sold is subject to our standard terms and conditions of sale. Parchem does not accept any liability either directly or indirectly for

any losses suffered in connection with the use or application of the product whether or not in accordance with any advice, specification, recommendation or information given by it.

*Manufactured and sold under license from Fosroc Parchem Construction Supplies Pty Ltd

International Limited. Fosroc, Conbextra and the Fosroc 7 Lucca Road, Wyong NSW 2259

logo are trade marks of Fosroc International Limited, used Phone: 1300 737 787

under license. www.parchem.com.au

ABN 80 069 961 968

constructive solutions Page 4

Distributed in New Zealand by: Concrete Plus Ltd

23 Watts Rd, Sockburn 8042 Ph: 0800 657 156

Das könnte Ihnen auch gefallen

- Simplified Approach For Soil-Spring Stiffness Prediction of Pile GroupDokument12 SeitenSimplified Approach For Soil-Spring Stiffness Prediction of Pile Groupabualamal100% (1)

- Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesDokument10 SeitenThin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesabualamalNoch keine Bewertungen

- قهوة باليورانيومDokument193 Seitenقهوة باليورانيومHazem MohamedNoch keine Bewertungen

- Test Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamDokument25 SeitenTest Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamabualamalNoch keine Bewertungen

- Load Carrying Capacity of PilesDokument75 SeitenLoad Carrying Capacity of PilesabualamalNoch keine Bewertungen

- Astm C900 06Dokument10 SeitenAstm C900 06abualamalNoch keine Bewertungen

- Megger-DET 5 - 4RDokument2 SeitenMegger-DET 5 - 4RarsenaldoNoch keine Bewertungen

- BS en 13888-2009Dokument18 SeitenBS en 13888-2009abualamal100% (2)

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsDokument10 SeitenThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalNoch keine Bewertungen

- Shear Area Correction-Direct ShearDokument1 SeiteShear Area Correction-Direct ShearabualamalNoch keine Bewertungen

- E1 16Dokument30 SeitenE1 16mitualves100% (1)

- Astm e 100Dokument32 SeitenAstm e 100abualamalNoch keine Bewertungen

- Aggregates FMDokument5 SeitenAggregates FMabualamalNoch keine Bewertungen

- Nbsbulletinv12n4p469 A2b PDFDokument10 SeitenNbsbulletinv12n4p469 A2b PDFAnonymous FmtXlUVyMGNoch keine Bewertungen

- BS en 03745-301-2012Dokument10 SeitenBS en 03745-301-2012abualamalNoch keine Bewertungen

- BS en 00003-5-1996Dokument18 SeitenBS en 00003-5-1996abualamalNoch keine Bewertungen

- BS en 419251-1-2013Dokument54 SeitenBS en 419251-1-2013abualamalNoch keine Bewertungen

- BS en Iso 17892-12Dokument36 SeitenBS en Iso 17892-12abualamal80% (5)

- BS en 14602-2012Dokument16 SeitenBS en 14602-2012abualamal100% (1)

- BS en 00477-1999Dokument8 SeitenBS en 00477-1999abualamalNoch keine Bewertungen

- Asphalt Test Specific GravityDokument2 SeitenAsphalt Test Specific GravityabualamalNoch keine Bewertungen

- Cement Grout AAADokument4 SeitenCement Grout AAAabualamalNoch keine Bewertungen

- Wrana 2015 4 PDFDokument11 SeitenWrana 2015 4 PDFarslanpasaNoch keine Bewertungen

- EDR ADR CtalougeDokument33 SeitenEDR ADR CtalougeabualamalNoch keine Bewertungen

- Engineering Properties of MaterialsDokument6 SeitenEngineering Properties of Materialspapilolo2008Noch keine Bewertungen

- Chapter 4 Mix Design MethodDokument10 SeitenChapter 4 Mix Design Methodprobook450_ehsanNoch keine Bewertungen

- Raft Foundation Settlement on Sand Using SPTDokument6 SeitenRaft Foundation Settlement on Sand Using SPTabualamalNoch keine Bewertungen

- MarshalDokument3 SeitenMarshalabualamalNoch keine Bewertungen

- Estimation of The Coefficient of Permeability in Deep Sedimentary GroundDokument5 SeitenEstimation of The Coefficient of Permeability in Deep Sedimentary GroundabualamalNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ug01 Add Form-TqbDokument1 SeiteUg01 Add Form-TqbMuhd AmirulNoch keine Bewertungen

- Caja de Piso Ref 25249-FBADokument4 SeitenCaja de Piso Ref 25249-FBACristianDuarteSandovalNoch keine Bewertungen

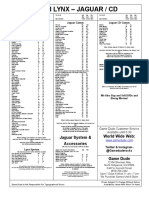

- Atari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebDokument1 SeiteAtari Lynx - Jaguar / CD: Jaguar System & Accessories World Wide WebGame DudeNoch keine Bewertungen

- SPM TRIAL 2019 - Melaka - P2 PDFDokument18 SeitenSPM TRIAL 2019 - Melaka - P2 PDFS SuhaidanNoch keine Bewertungen

- ROX PVPCalcAA Crit FalconDokument6 SeitenROX PVPCalcAA Crit FalconGanorienNoch keine Bewertungen

- Sirena WT4911 ManualDokument32 SeitenSirena WT4911 ManualMateescu CristianNoch keine Bewertungen

- En FR Current Dep BookDokument312 SeitenEn FR Current Dep BookVanioRamosNoch keine Bewertungen

- MP 60 and MP 80 Miniature Usb 20 Power Meters Fiberchek Pro Integration Data Sheets enDokument2 SeitenMP 60 and MP 80 Miniature Usb 20 Power Meters Fiberchek Pro Integration Data Sheets enRocky LeeNoch keine Bewertungen

- The Old Axolotl - Hardware Dream - Jacek DukajDokument188 SeitenThe Old Axolotl - Hardware Dream - Jacek Dukajferuyo100% (2)

- GSE Model 675: Precision Counting ScaleDokument48 SeitenGSE Model 675: Precision Counting ScaleJuan Antonio Becerra SánchezNoch keine Bewertungen

- CISSP NotesDokument95 SeitenCISSP Notespranjay1487Noch keine Bewertungen

- Chapter 4Dokument38 SeitenChapter 4WANNoch keine Bewertungen

- Sheet1: Site Admin URLDokument5 SeitenSheet1: Site Admin URLLordson JeromeNoch keine Bewertungen

- Evaluation of Grade 4 Science Learning Packet #4Dokument2 SeitenEvaluation of Grade 4 Science Learning Packet #4GLENDA OLIQUINONoch keine Bewertungen

- Temenos T24 Ac - Expected.Receipts: User GuideDokument46 SeitenTemenos T24 Ac - Expected.Receipts: User GuideVincentNoch keine Bewertungen

- Standardization of Building Codes, Standards and Specifications For Low-Cost (Affordable) Units-2021 - CompressedDokument314 SeitenStandardization of Building Codes, Standards and Specifications For Low-Cost (Affordable) Units-2021 - CompressedMohib Ullah KhanNoch keine Bewertungen

- Ethical HackerDokument1 SeiteEthical HackerJimmy KhanNoch keine Bewertungen

- Bicol University College of Engineering Civil Engineering DepartmentDokument2 SeitenBicol University College of Engineering Civil Engineering DepartmentMa Ella Mae LogronioNoch keine Bewertungen

- BCP EjorDokument25 SeitenBCP EjorSitraka Fitia Rosanna RaharizoNoch keine Bewertungen

- Rev 01 Part - 1 Structural Drawing 202012225Dokument6 SeitenRev 01 Part - 1 Structural Drawing 202012225Aung Thit LwîñNoch keine Bewertungen

- ICON Tutorial 2019 Time Series ForecastingDokument129 SeitenICON Tutorial 2019 Time Series Forecastingkiran gollaNoch keine Bewertungen

- NACA ACR L4L07 - Tests of A Curtiss Propeller On P47CDokument36 SeitenNACA ACR L4L07 - Tests of A Curtiss Propeller On P47CAnonymous xD8wUeMyNoch keine Bewertungen

- Safe Transportation System: A Project Submitted byDokument29 SeitenSafe Transportation System: A Project Submitted byshahinNoch keine Bewertungen

- Calculation of Crack Width As Per Is:456-2000Dokument4 SeitenCalculation of Crack Width As Per Is:456-2000Gautam DuttaNoch keine Bewertungen

- Railway Operational Communication Solution GTSOFTX3000V200R001C01 Product Description V1.0 (20130311)Dokument89 SeitenRailway Operational Communication Solution GTSOFTX3000V200R001C01 Product Description V1.0 (20130311)Leonardo MorallosNoch keine Bewertungen

- Mark Java ResumeDokument4 SeitenMark Java ResumesravanpaulNoch keine Bewertungen

- U1 PDFDokument20 SeitenU1 PDFFarah AlhamadNoch keine Bewertungen

- Digital Communication Using GNU Radio - Unit 3 - Week 0Dokument3 SeitenDigital Communication Using GNU Radio - Unit 3 - Week 0rensiNoch keine Bewertungen

- Determining the Optimal Price for Atlantic's New Server BundleDokument3 SeitenDetermining the Optimal Price for Atlantic's New Server BundleApoorva SharmaNoch keine Bewertungen

- PROWIRL F200 - Manuale Di InstallazioneDokument12 SeitenPROWIRL F200 - Manuale Di InstallazioneGiuseppeNoch keine Bewertungen