Beruflich Dokumente

Kultur Dokumente

IGL - Convertor Basket Replacement Philosophy

Hochgeladen von

Soumitra GuptaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

IGL - Convertor Basket Replacement Philosophy

Hochgeladen von

Soumitra GuptaCopyright:

Verfügbare Formate

Ammonia Convertor Basket Replacement,

Repair of Convertor Shell

&

Associated Work during Forthcoming ATR.

Introduction

Indo Gulf Fertilizers Limited (IGF) is engaged in production of Ammonia & Urea at its

plant located on Lucknow – Sultanpur highway & 90 Km away from Lucknow. During the

forthcoming Turnaround the old two bed Ammonia convertor catalyst basket S-200

(HTAS design) shall be replaced with Single bed S-50 (HTAS Design) in existing

convertor shell. Also there is crack in shell 5th CS weld joint up to depth of 50 mm from

inside & 1000 mm long.

Procedure for Replacement Activity

Pre Shutdown Activity

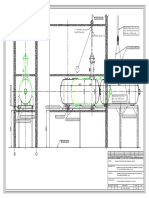

Ground preparation for main & tailing crane as marked up in drawing no

Mobilization activity for Tools & Machinery, manpower & execution staff.

All scaffolding for Convertor & piping work.

Fabrication of inspection cage & support for center pipe.

Laying of mat plate for crane movement.

Assembly of main & tailing crane & load test.

Shifting and placement in vertical position of existing basket container to

the foundation.

Welder Qualification.

Final checking of crane movement area.

Issuing & shifting of cone for handling basket from IGL store.

Review of activity scheme & JSA.

Shutdown Activity

Job Code Activity Remarks

SDA1 Removal of instrument items

SDA2 Removal of structure if required

SDA3 Removal of insulation, where shell to be repaired

SDA4 De-bolting & Removal of convertor top cover by the

help of EOT crane

SDA5 1st bed temporary cover placement

SDA6 Cutting & replacement of Control valves & allied piping

work as described in Enquiry document

SDA7 Removal of 1st bed & placement the same in between

two convertors with help of EOT crane

SDA8 Installation of temporary cover on 2nd bed

SDA9 Removal and placement of 2nd bed inside the container

SDA10 Supporting of convertor shell on hydraulic jack before

repair work

SDA11 Cutting & removal of convertor bottom lip seal and

piping

SDA12 Inspection of convertor shell and rectification of CS weld

joint including DHT, grinding, preheating, welding, SR,

NDT etc. Also checking of glands & if required same

shall be replaced with new one.

SDA13 Removal of hydraulic jacks after shell CS weld joint

repair

SDA14 Lifting of & placement of new basket container along

with basket to container foundation

SDA14A Installation of new basket in convertor shell

SDA15 Placement of top cover after catalyst loading

SDA16 Fixing of insulation old / new which removed for shell

repair work

SDA17 Fixing of insulation old / new which removed for shell

repair work

SDA18 Tightening of bolts as desired

SDA19 Placement of 1st bed inside the container and associated

assembly work and removal from foundation

SDA20 Placement of old and new basket container to

designated place

SDA21 Fixing of instruments

Details of Equipments to be handled

Sl. Wt

Description Remarks

No. (Mt)

1. Old Container Ø 3.0m x 28.0m 17.0 Shifting & Vertical placement

2. Convertor Top Cover Ø 4.0m 25.0 Removal & re-erection

3. 1st Basket Ø3.0m x 8m 25.0 Removal & placement in container

4. 2nd bed basket Ø 3.0m x 28m 65.0 Removal & placement in container

5. New Basket & container Ø3.0mx 28m 65.0 Shifting & Placement on foundation

6. New Basket Ø 3.0m x 28m 46.0 Installation in convertor shell

Shifting & placement of old container Space which is allotted

7. 108.0

with basket Ø 3.0m x 28m (approximately 100 m away)

Lowering, shifting of new empty Space which is allotted

8. 20.0

basket container. (approximately 100 m away)

9. Torque Tightening of Top cover studs

10. Torque Tightening of bottom studs

Execution Staff

Sl. No. Designation Nos. Remarks

1. Construction Manager 1

2. Lead Engineer 1

3. Execution Supervisor 4

4. Safety Supervisor 2

5. QA / Qc Engineer 1

4. Foreman 2

Allotted for Day for Day &

5. NDT & SR Technician 5

Night Shift.

6. HR & Administration 2

7. Electrician 2

8. Crane Operator Crew 5

9. Hydra Operator 2

10. Store 1

Execution Manpower

Sl. No. Designation Nos. Remarks

1. Mill Wright / General Fitter 2

2. Piping Fitter 4

4. High Pressure Welder 5

5. Tack Welder 2

Allotted for Day for Day &

6. Grinder 6

Night Shift.

7. Gas Cutter 2

8. Rigger 24

9. Helper 12

10. Scaffolder 6

Tools / Machinery / Consumables

Sl. No. Description Unit Qty Remarks

1. Crawler Crane 400 Mt No 01

2. Crawler Crane 150 Mt No 01

3. Hydra No 01

4. Welding Rectifier 400 Amps No 10

5. Grinding Machine No 08

6. Gas Cutting Set Set 04

7. Electrode Backing Oven No 01

8. Electrode Oven No 05

9. SR Equipments Set As required

10. RT Source (Cobalt 60) Set 01

11. Wire Rope Sling Ø75mm Pair 01

12. Wire Rope Sling Ø65 No 03

13. Wire Rope Sling Ø25 Pair 02

14. ‘D’ Shackle 120 Mt Pair 01

15. ‘D’ Shackle 80 Mt Pair 01

16. ‘D’ Shackle 50 Mt Pair 01

17. Nylon Rope Mtr Lot As required

18. Scaffolding Pipes No Lot As required

19. Scaffolding Clamps No Lot As required

20. Steel Chali No Lot As required

21. Aluminum Ladder No 03

22. Fitter Tool Box (Complete Set) No 06

23. Measuring Tools No As Required

24. Hydraulic Jack 50 Mt No 02

25. PPE’s No As Required

26. Spanner Set Set As required

27. Purging Paper Roll As required

28. UT Machine (Digital) Set 01

29. Hardness Tester (Digital) Set 01

30. Construction Electrical Facility Set 02

31. Wooden Sleeper No 30

32. Crane Mat Plate No 04

33. Welding Electrode Pkt Lot As required

34. O2 / DA / Argon Gas Cylinder No Lot As required

35. Cutting & Grinding Wheel No Lot As required

36. Welding Accessories Set Lot As required

37. TIG Set Set 06

38. Fire Retardant Cloth No Lot As required

Tentative Schedule

CRANE PLACEMENT SCHEME

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Labour Productivity Chart in UaeDokument9 SeitenLabour Productivity Chart in UaeAbraham Alex91% (32)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Fired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanyDokument21 SeitenFired Heaters: Esteem Projects Pvt. Ltd. The Fired Heater CompanySoumitra GuptaNoch keine Bewertungen

- Gas 21 Digital EditionDokument44 SeitenGas 21 Digital EditionForcus onNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 50% Construction Documents: Jacobs Medical Center East Campus Bed TowerDokument35 Seiten50% Construction Documents: Jacobs Medical Center East Campus Bed TowerSoumitra GuptaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- DFT Non Slam Vs Swing - 2018Dokument5 SeitenDFT Non Slam Vs Swing - 2018shwetaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Steam Explosion in Ammonia Plant: W.K. (Bill) Taylor, P. EngDokument10 SeitenSteam Explosion in Ammonia Plant: W.K. (Bill) Taylor, P. Engvaratharajan g rNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Turnaround Manhour Norms BlancoDokument106 SeitenTurnaround Manhour Norms BlancoElias Rizk86% (7)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- TENDER SOR MR 00b854Dokument137 SeitenTENDER SOR MR 00b854Soumitra GuptaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Directional Solidification of Steel CastingsDokument59 SeitenDirectional Solidification of Steel CastingsSUNDRAMNAGANoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- NEET Phase 2 Solutions PDFDokument65 SeitenNEET Phase 2 Solutions PDFsubhakpatel patelNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Pipeline Works: EstimateDokument42 SeitenPipeline Works: EstimateSoumitra GuptaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 11V-01 11C-05 - SHEET 1 ModelDokument1 Seite11V-01 11C-05 - SHEET 1 ModelSoumitra GuptaNoch keine Bewertungen

- RenewalReceipt 502-7066983 PolicyRenewalDokument2 SeitenRenewalReceipt 502-7066983 PolicyRenewalSoumitra GuptaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Chicken Ghee Roast RecipeDokument2 SeitenChicken Ghee Roast RecipeSoumitra GuptaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- TCL RGB 7-2-2016Dokument1 SeiteTCL RGB 7-2-2016Soumitra GuptaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hot BoltingDokument6 SeitenHot BoltingNickath Banu100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Seamless Pipe NipplesDokument2 SeitenSeamless Pipe NipplesDylan RamasamyNoch keine Bewertungen

- Iwp Hydrotesting Checklist: Appendix - 14Dokument4 SeitenIwp Hydrotesting Checklist: Appendix - 14Soumitra GuptaNoch keine Bewertungen

- Reliability Problems Synthesis Compressor-Drive TurbineDokument10 SeitenReliability Problems Synthesis Compressor-Drive TurbineSoumitra GuptaNoch keine Bewertungen

- Price List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedDokument24 SeitenPrice List For Painting Works: 2450 0000 PS 2300 03 A Mangalore Pta Plant JBF Petrochemicals LimitedSoumitra GuptaNoch keine Bewertungen

- Gas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GDokument28 SeitenGas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GSoumitra GuptaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Methodology ERECTION SCHEME For CFCLDokument4 SeitenMethodology ERECTION SCHEME For CFCLSoumitra GuptaNoch keine Bewertungen

- 11V-01 11C-05 - SHEET 1 ModelDokument1 Seite11V-01 11C-05 - SHEET 1 ModelSoumitra GuptaNoch keine Bewertungen

- Directional Solidification of Steel CastingsDokument59 SeitenDirectional Solidification of Steel CastingsSUNDRAMNAGANoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- GA-Ref For ErectionDokument1 SeiteGA-Ref For ErectionSoumitra GuptaNoch keine Bewertungen

- Earthing Diagram NFL CWDokument1 SeiteEarthing Diagram NFL CWSoumitra GuptaNoch keine Bewertungen

- CFCL - ATR'19 Revised - 25.05.2018Dokument31 SeitenCFCL - ATR'19 Revised - 25.05.2018Soumitra GuptaNoch keine Bewertungen

- Main Crane Application Flow Chart: Assembly of Main Crane at Urea Unit 6 DaysDokument1 SeiteMain Crane Application Flow Chart: Assembly of Main Crane at Urea Unit 6 DaysSoumitra GuptaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Preliminary Schedule CFCLDokument2 SeitenPreliminary Schedule CFCLSoumitra GuptaNoch keine Bewertungen

- Flux Cored and MIG Pipe WeldingDokument59 SeitenFlux Cored and MIG Pipe Weldingcentaury2013Noch keine Bewertungen

- Ador CWC Booklet WebDokument97 SeitenAdor CWC Booklet Webreeet87Noch keine Bewertungen

- Aspect 300: Emear EmearDokument20 SeitenAspect 300: Emear EmearAnand DoraisingamNoch keine Bewertungen

- SMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFDokument24 SeitenSMS - 603 - UTZ - 001 - Sulzer SPEKTRA Rev.00.pdf (TTD) PDFRosyidi danangNoch keine Bewertungen

- WPS-Shell To Shell Joint (CS-CS) .Dokument1 SeiteWPS-Shell To Shell Joint (CS-CS) .suria qaqcNoch keine Bewertungen

- Home Cmplab HTML Bbs Data Pds0086 3Dokument4 SeitenHome Cmplab HTML Bbs Data Pds0086 3ArpitRanderiaNoch keine Bewertungen

- Ln25 11283Dokument40 SeitenLn25 11283Huascar Rafael Robles Caceres100% (1)

- Vocational Training ReportDokument49 SeitenVocational Training ReportAkrit Kumar ChaturvediNoch keine Bewertungen

- Application For Permit To Work Permit No:: (Work Shall Not Commence Until Stage 1 To Stage 3 For Contract Jobs Is DultDokument3 SeitenApplication For Permit To Work Permit No:: (Work Shall Not Commence Until Stage 1 To Stage 3 For Contract Jobs Is DultReaz UddinNoch keine Bewertungen

- Wps Ausa Gtaw Smaw 002 2018 Ok RDokument2 SeitenWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Az-Homogenizer Pressure GaugeDokument3 SeitenAz-Homogenizer Pressure Gaugepankaj doshiNoch keine Bewertungen

- Consumables Catalogue EngDokument644 SeitenConsumables Catalogue EngLea EleuteriNoch keine Bewertungen

- Hunan Valin LianyuanDokument92 SeitenHunan Valin LianyuanrawatalokNoch keine Bewertungen

- Aws Er70sDokument4 SeitenAws Er70smanofNoch keine Bewertungen

- Welding SlidesDokument334 SeitenWelding SlidesAsad Bin Ala Qatari100% (13)

- Welding NPTEL Lecturers - Part1Dokument30 SeitenWelding NPTEL Lecturers - Part1Sai ChaithanyaNoch keine Bewertungen

- Welding Lecture and OrientationDokument57 SeitenWelding Lecture and OrientationHenry SyNoch keine Bewertungen

- Unit 1 Physics of Welding Arc WeldingDokument106 SeitenUnit 1 Physics of Welding Arc WeldingyashNoch keine Bewertungen

- Firepower TIG 200 AC/DC: Operating ManualDokument80 SeitenFirepower TIG 200 AC/DC: Operating ManualAlejandro CKNoch keine Bewertungen

- Industrial BoilersDokument33 SeitenIndustrial Boilersspalaniandavar07Noch keine Bewertungen

- Mesin Las LinconDokument3 SeitenMesin Las LinconIrwansyahNoch keine Bewertungen

- 20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERDokument403 Seiten20 Sandvik Welding Handbook - 30 September, 2015 - CHAPTERahmadNoch keine Bewertungen

- Article Iii Welding Performance Qualifications: QW-300 GeneralDokument9 SeitenArticle Iii Welding Performance Qualifications: QW-300 GeneralArifin Fauzi LubisNoch keine Bewertungen

- Uputstvo Castotig 2201Dokument79 SeitenUputstvo Castotig 2201Milan DuvnjakNoch keine Bewertungen

- Types WeldingDokument66 SeitenTypes WeldingRathnakraja50% (2)

- Austenitic High Temperature 153MA 253MA Stainless BrochureDokument16 SeitenAustenitic High Temperature 153MA 253MA Stainless BrochurezosternatNoch keine Bewertungen

- FCX-FUJI Pressure TransmittersDokument8 SeitenFCX-FUJI Pressure TransmittersAlphatech1Noch keine Bewertungen

- UWI-203 TP FlyerDokument2 SeitenUWI-203 TP FlyerChris TeohNoch keine Bewertungen

- DCI CatalogDokument20 SeitenDCI CatalogAbu AlAnda Gate for metal industries and Equipment.Noch keine Bewertungen

- ISO 9692-3-2002 Joint PreparationDokument16 SeitenISO 9692-3-2002 Joint PreparationtndeshmukhNoch keine Bewertungen