Beruflich Dokumente

Kultur Dokumente

Coal Quality Report

Hochgeladen von

PT. Jayakhisma Globe IndonesiaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Coal Quality Report

Hochgeladen von

PT. Jayakhisma Globe IndonesiaCopyright:

Verfügbare Formate

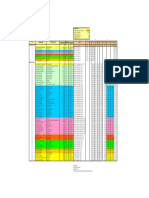

PRE-QUALIFICATION OF COAL BLEND / COAL BRAND

SCHEDULE A – COAL QUALITY DATA

COAL BLEND / COAL BRAND NAME:

__________________________________________

LOAD PORT: _____________________________ MINE NAME/S:

___________________

REJECTION LIMIT PARAMETER UNITS BASIS PROPERTY VALUE

Calorific Value Kcal/kg AR Min

Total Moisture % AR Max

Ash % AR Max

Total Sulfur % AR Max

Volatile Matter % AR Min

Volatile Matter % ADB Min

Fuel Ratio - - Min

-

HGI - Min

o

AFT Initial Deformation C Red Atm Min

Sizing (>50 mm) % AR Max

Sizing (<3 mm) % AR Max

Sizing (<2 mm) % AR Max

PROPERTY (As Received Basis) UNITS BASIS TYPICAL MIN MAX

Calorific Value Kcal/kg AR

Total Moisture % AR

Surface Moisture % AR

Ash % AR

Volatile Matter % AR

Total Sulfur % AR

Phosphorous % DB

Chlorine ppm AR

Sodium in Ash % AR

Fuel Ratio - -

PROXIMATE ANALYSIS (Air Dried Basis) UNITS BASIS TYPICAL MIN MAX

Calorific Value Kcal/kg ADB

Moisture % ADB

Ash % ADB

Volatile Matter % ADB

Fixed Carbon % ADB

Total Sulfur % ADB

ULTIMATE ANALYSIS (Dry Ash Free) UNITS BASIS TYPICAL MIN MAX

Carbon % DAF

Hydrogen % DAF

Nitrogen % DAF

Sulfur % DAF

Oxygen % DAF

Name: Signature:

Position: Company Stamp: Page | 3

PRE-QUALIFICATION OF COAL BLEND / COAL BRAND

SCHEDULE A – COAL QUALITY DATA

COAL BLEND / COAL BRAND NAME: __________________________________________

LOAD PORT: _____________________________ MINE NAME/S: ___________________

ULTIMATE ANALYSIS (Air Dried Basis) UNITS BASIS TYPICAL MIN MAX

Carbon % ADB

Hydrogen % ADB

Nitrogen % ADB

Sulfur % ADB

Oxygen % ADB

Ash % ADB

Inherent Moisture % ADB

ULTIMATE ANALYSIS (As Received) UNITS BASIS TYPICAL MIN MAX

Carbon % AR

Hydrogen % AR

Nitrogen % AR

Sulfur % AR

Oxygen % AR

Ash % AR

Total Moisture % AR

ULTIMATE ANALYSIS (Dry Basis) UNITS BASIS TYPICAL MIN MAX

Carbon % DB

Hydrogen % DB

Nitrogen % DB

Sulfur % DB

Oxygen % DB

Ash % DB

ASH FUSION TEMPERATURE (Reducing UNITS TYPICAL MIN MAX

Atmosphere)

o

Initial Deformation C

o

Softening C

o

Hemispherical Deformation C

o

Flow C

Name: Signature:

Position: Company Stamp: Page | 4

PRE-QUALIFICATION OF COAL BLEND / COAL BRAND

SCHEDULE A – COAL QUALITY DATA

COAL BLEND / COAL BRAND NAME: __________________________________________

LOAD PORT: _____________________________ MINE NAME/S: ___________________

ASH FUSION TEMPERATURE (Oxidizing UNITS TYPICAL MIN MAX

Atmosphere)

o

Initial Deformation C

o

Softening C

o

Hemispherical Deformation C

o

Flow C

PHYSICAL PROPERTIES UNITS TYPICAL MIN MAX

Hardgrove Grindability Index -

SIZE DISTRIBUTION UNITS TYPICAL MIN MAX

> 50 mm %

< 3 mm %

< 2 mm %

ASH ANALYSIS PROPERTY (Dry Basis) UNITS BASIS TYPICAL MIN MAX

SiO2 % DB

Al2O3 % DB

Fe2O3 % DB

CaO % DB

MgO % DB

Na2O % DB

K2O % DB

TiO2 % DB

Mn2O3 % DB

Mn3O4 % DB

SO3 % DB

P2O5 % DB

Name: Signature:

Position: Company Stamp: Page | 5

PRE-QUALIFICATION OF COAL BLEND / COAL BRAND

SCHEDULE A – COAL QUALITY DATA

COAL BLEND / COAL BRAND NAME: __________________________________________

LOAD PORT: _____________________________ MINE NAME/S: ___________________

Trace Elements in Coal (Dry Basis) UNITS BASIS TYPICAL MIN MAX

Arsenic ppm DB

Boron ppm DB

Barium ppm DB

Beryllium ppm DB

Cadmium ppm DB

Cobalt ppm DB

Chromium ppm DB

Chlorine ppm DB

Copper ppm DB

Fluorine ppm DB

Mercury ppm DB

Lithium ppm DB

Manganese ppm DB

Molybdenum ppm DB

Nickel ppm DB

Lead ppm DB

Phosphorus % DB

Silver ppm DB

Selenium ppm DB

Tin ppm DB

Strontium ppm DB

Uranium ppm DB

Vanadium ppm DB

Zinc ppm DB

Note 1: 1.0 Kcal = 4.1868 kJ ADB = Air Dried Basis

1.0 Btu = Kcal/kg x 1.8 lb. DAF = Dry Ash Free

AR = As Received DMMF = Dry Mineral Matter Free

Basis

DB = Dry Basis PPM = Parts per million

Note 2: All properties based on ISO test methods.

Name: Signature:

Position: Company Stamp: Page | 6

PRE-QUALIFICATION OF COAL BLEND / COAL

BRAND

SCHEDULE B – APPLICANT’S DETAILS

1. Applicant Name:

2. Address:

3. Mine Name:

4. Mine Owner:

5. Mine Address:

6. Applicant’s Business Structure to the Mine Owner (Please tick)

Self Producer Joint Marketing Trader Agent Others

Venture Arm (please specify)

7. Applicant’s Paid Up Capital:

_________________________________________________

Name: Signature:

Position: Company Stamp: Page | 7

8. Applicant Shareholding Details Evidencing Control Over the Mine

(%) Controlling Stake to

Name of Applicant and Produce, Blend, Sell, Trade,

No. (%) Stake in the Mine

other Shareholders Export etc. of the mine’s coal

(please specify)

*Please furnish copy of undertaking letter by Mine Owner or Mine Producer defining the

relationship with the Applicant, agreements, contracts, details of company structure, ownership

details, audited annual reports, company brochures and other information deemed relevant. This

information to be attached as Schedule E (a)

9. (i) Contact Person of Applicant

Name:

Designation:

Phone Number:

Fax Number:

Email Address:

(ii) Contact Person of Applicant

Name:

Designation:

Phone Number:

Fax Number:

Email Address:

(iii) Contact Person of Applicant

Name:

Designation:

Phone Number:

Fax Number:

Email Address:

(iv) Contact Person of Applicant

Name:

Designation:

Phone Number:

Fax Number:

Email Address:

Name: Signature:

Position: Company Stamp: Page | 8

10. Mining Permit Details based on the Relevant Government Authority (Mining

Lease; Coal Contract of Work; Izin Usaha Pertambangan Operasi Produksi and its

relevant Sertifikat Clear and Clean; Perjanjian Karya Penguasahaan Pertambangan

Batubara and etc.)

No. Name of Permit Serial No. Validity Duration

(Start / End)

10.1. Blending Permit Details based on Relevant Government Authority (Izin

Usaha Pertambangan Operasi Produksi Khusus untuk Pengolahan dan

Pemurnian, Persetujuan Izin Blending, Persetujuan Pencampuran Batubara

PT… Dengan PT … and etc.)

No. Name of Permit Serial No. Validity Approval to Blend

Duration coal from which

(Start / End) mine

concession(s)

10.2. Trading Permit Details based on Relevant Government Authority (Izin

Usaha Pertambangan Operasi Produksi Khusus untuk Pengangkutan dan

Penjualan and etc.)

No. Name of Permit Serial No. Validity Approval to Trade

Duration coal from which

(Start / End) mine

concession(s)

Name: Signature:

Position: Company Stamp: Page | 9

10.3. Export Permit Details based on the Relevant Government Authority (Eksportir

Terdaftar and etc.)

No. Name of Permit Serial No. Validity Approval to Export

Duration coal from which

(Start / End) mine

concession(s)

*Please furnish a letter on your company letterhead affirming that you hold the rights

granted by the relevant Authorities to produce, blend, trade, sell and export coal from

mine(s) as stated in this document. This information to be attached as Schedule E (b)

11. Customer Details

Please specify the top 5 customers for 2017, 2016 and 2015 (with reference to the

tonnage sold)

11.1 Year 2017

No. Customer’s Name Country Quantity Contract Duration

(mt) (Start / End)

11.2 Year 2016

No. Customer’s Name Country Quantity Contract Duration

(mt) (Start / End)

Name: Signature:

Position: Company Stamp: Page | 10

11.3 Year 2015

No. Customer’s Name Country Quantity Contract Duration

(mt) (Start / End)

12. Contract Details with TNBF (past / present)

No. Contract No. Country Quantity Contract Duration

(mt) (Start / End)

13. Bill of Ladings for Handymax, Panamax and Capesize shipments, Certificate of

Sampling and Analysis, Certificate of Origin and its Relevant Laporan Surveyor

Ekspor (For Indonesian Shipment).

Laporan

Mother COSA COO

Surveyor

No. Vessel BL Date Customer (Please (Please

Ekspor

Name tick) tick)

(Please tick)

*Please attach copies of 3 latest Bill of Ladings, its 3 respective Certificate of Sampling and

Analysis, its 3 respective Certificate Of Origin and its 3 respective Laporan Surveyor for the

Coal Blend / Coal Brand offered in Schedule A. This information to be attached as

Schedule E (c).

Name: Signature:

Position: Company Stamp: Page | 11

PRE-QUALIFICATION OF COAL BLEND / COAL BRAND

FOR TNB FUEL SERVICES SDN. BHD.

TNBF NO. PQ 01/16

SCHEDULE C– MINE PROFILE FOR COAL BLEND / COAL BRAND SUBMITTED IN

SCHEDULE A

1. Coal Reserves Data for Coal Blend / Coal Brand Proposed

Measured Tonnage

Indicated Tonnage

Inferred Tonnage

Estimated Remaining Mine Life

*Please furnish the Coal Mine concession/geological survey on the coal resources, reserve,

quality etc. based on International Standards report i.e. Joint Ore Reserves Committee

Code (JORC Code), South African Code for the Reporting of Mineral Resources and

Mineral Reserves (SAMREC), Standard National Indonesia (SNI) or equivalent. This

information to be attached as Schedule E (d)

2. Mine Details

Mine Concession Mine Concession 2

1 (For blended coal only)

Mine Name

Commencement Date of Mine

Remaining Mine Life

Blending Proportion (%) – if any

Production Rate (mt/day)

Total Manpower

Mine Stockpile Capacity

3. Coal Quality Data (For Blended Coal)

Item Property Basis Unit Limit Value

Coal for Mine Coal for Mine

Concession 1 Concession 2

1 Gross Calorific Value As Received Kcal/kg Min

2 Total Moisture As Received % Max

3 Ash Contents As Received % Max

4 Total Sulfur As Received % Max

5 Volatile Matter As Received % Min

6 HGI As Received - Min

0

7 AFT (IDT) Reducing C Min

Atmosphere

*Please add additional attachments if coal blended from more than 2 Mine Concessions.

Name: Signature:

Position: Company Stamp: Page | 13

4. Washing Method

Unwashed (%) Washed (%)

*Please furnish details on the washing facilities and other information deemed

relevant. This information to be attached as Schedule E (e)

5. Production Details

5.1 Past Production

5.1.1 Year 2015 - 2017

Export Sales

Year Total Production (mt) Domestic Sales (mt)

(mt)

2015

2016

2017

5.2 Production Forecast

5.2.1 Year 2018 - 2021

Export Sales

Year Total Production (mt) Domestic Sales (mt)

(mt)

2018

2019

2020

2021

*Please furnish details on the mine expansion programs and other information deemed

relevant. This information to be attached as Schedule E (i)

6. Mining Method (please tick)

Open Cut Underground

Drag Line Long Wall

Truck and Shovel Room and Pillar

Others (Please specify) Others (Please specify)

…………………………………. ………………………………….

Name: Signature:

Position: Company Stamp: Page | 14

7. Mine Logistic Details

Mode of Transportation (please tick)

Distance Capacity of Inland Truck Conveyor Train Barge Others

(Mine to Load Transportation (please

Port / km) (mt / year) specify)

*Please furnish details on the transportation facilities from mine to port and other

information deemed relevant. This information to be attached as Schedule E (g)

8. Laboratory

8.1 Coal Sampling Practice at Mine Site (please tick)

Own Lab Independent Inspection Companies (If √, please specify name )

8.2 Coal Quality Parameters Monitored (please tick)

Heating Total Ash Sulphur Volatile Others (please

Value Moisture Content Content matter specify)

*Please furnish details of the sampling done at each of the key logistic points from

the mine to the load port, sampling equipment (manual / automatic) used by the

above quality inspection companies and other information deemed relevant. This

information to be attached as Schedule E (h)

Name: Signature:

Position: Company Stamp: Page | 15

PRE-QUALIFICATION OF COAL BLEND / COAL

BRAND

SCHEDULE D – LOADING PORTS DETAILS FOR COAL BLEND / COAL BRAND

SUBMITTED IN SCHEDULE A

NAME OF VESSEL LOADING PORT : ………………………………………………………

Facility

Drafts at low water (m)

Entrance Channel

Approach Channel

Berth

SWAD (Salt Water Arrival Draft)

Tidal Range

MWHS (Mean High Water Spring)

MWHN (Mean High Water Neap)

Vessel Restrictions

Length Overall

Beam

Airdraft

Max. Vessel Size (Fully laden in DWT)

Loading Facilities suitable for (vessel Geared Gearless Both

type)

Loading Equipment/Type

Stockpile Capacity Available to Shipper

Annual Capacity of Load Port

Name of Independent Surveyor operating

at port (for weight and quality verification)

Loading Rate

Vessel Size (dwt) or Cargo Loaded Loading Rate (tonne) per 24 hrs

50,001 - 79,999

80,000 – 100,000

above 100,000

Despatch / Demurrage Rate

Despatch per 24 hours in Demurrage per 24

Vessel Size (dwt) USD (pro-rata for part) hours in USD (pro-

rata for part)

50,001 - 79,999

80,000 – 100,000 As per Charter Party As per Charter Party

above 100,000

*Please furnish details on the future port expansion and infrastructure improvements programs

(if any) and other information deemed relevant. This information to be attached as Schedule E

(i)

Name: Signature:

Position: Company Stamp: Page | 16

BARGE LOADING POINT DETAILS FOR COAL BLEND / COAL BRAND SUBMITTED IN

SCHEDULE A (IF APPLICABLE)

Jetty 1

1. Barge Loading Point

Owner:

2. Location:

3. Ownership*: Public or Private

4. Conveyor Belt Facilities*: Yes or No

5. Barge Loading Rate (mt/hr):

6. Barge Stockpile Capacity (mt):

7. Blending Facility*: Yes or No

8. Sampling*: Automatic or Manual

9. Barge size (DWT and draft)

10. Turnaround time:

Full Load

Without Load

11. Approaching channel Constraint(s):

Name: Signature:

Position: Company Stamp: Page | 17

Das könnte Ihnen auch gefallen

- APAC ProspectusDokument84 SeitenAPAC Prospectusshare818Noch keine Bewertungen

- InPA Coal FormationDokument1 SeiteInPA Coal FormationsantosoNoch keine Bewertungen

- Coal Mining ExecutiveDokument2 SeitenCoal Mining ExecutiveBudi Siadjeng100% (2)

- Report on Consulting Services for Coal Sourcing, Transportation and Handling of Power Plants in BangladeshDokument497 SeitenReport on Consulting Services for Coal Sourcing, Transportation and Handling of Power Plants in Bangladeshদেওয়ানসাহেবNoch keine Bewertungen

- Steam Coal Price: Indonesian Version Product ListDokument4 SeitenSteam Coal Price: Indonesian Version Product ListIrfan Nasution MhdNoch keine Bewertungen

- Coal Investment Thailand enDokument12 SeitenCoal Investment Thailand enKhan Ahmed MuradNoch keine Bewertungen

- Mine SpecificationDokument8 SeitenMine SpecificationRizal TengkuNoch keine Bewertungen

- 34 GarDokument1 Seite34 Garapi-174139371Noch keine Bewertungen

- Pt. Jayeon SejahteraDokument52 SeitenPt. Jayeon SejahteraTrends Property100% (1)

- Dissertation - International Trade of CoalDokument15 SeitenDissertation - International Trade of CoalRano Joy100% (1)

- NTPC Coal Supply Bid DocumentDokument0 SeitenNTPC Coal Supply Bid DocumentmdphilipNoch keine Bewertungen

- 2 Compro BGC Jan 2021Dokument20 Seiten2 Compro BGC Jan 2021Andreas HalimNoch keine Bewertungen

- Ar Bayan 09Dokument198 SeitenAr Bayan 09lpj gsvcNoch keine Bewertungen

- 2 - Minepract - Presentasi Pertambangan Mineral Batubara (UU 4-2009)Dokument51 Seiten2 - Minepract - Presentasi Pertambangan Mineral Batubara (UU 4-2009)Erie Haryanto100% (1)

- Harga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) February 2020Dokument8 SeitenHarga Batubara Acuan (Hba) & Harga Patokan Batubara (HPB) February 2020Endro Suhadi100% (1)

- Cash FlowDokument1 SeiteCash FlowDEDYNoch keine Bewertungen

- PT TUBINDO PRODUCTION PLAN BUDGETDokument14 SeitenPT TUBINDO PRODUCTION PLAN BUDGETAchmad DjunaidiNoch keine Bewertungen

- Draft LC at SightDokument7 SeitenDraft LC at SightSAHABAT GANJAR SULBARNoch keine Bewertungen

- Contract Sales Purchase Agreement - TJU, RRU - ChinaDokument7 SeitenContract Sales Purchase Agreement - TJU, RRU - Chinagarut beraksiNoch keine Bewertungen

- Draft-Spa-Fob MVDokument13 SeitenDraft-Spa-Fob MVIbnu ShobariNoch keine Bewertungen

- ZUL - Steam Coal - Loi - 29th Aug 2017Dokument4 SeitenZUL - Steam Coal - Loi - 29th Aug 2017Chandan JstNoch keine Bewertungen

- Investment Opportunity of Mineral and Coal in IndonesiaDokument26 SeitenInvestment Opportunity of Mineral and Coal in IndonesiaKrisdanyolan SimarmataNoch keine Bewertungen

- Calculation of Coal PriceDokument4 SeitenCalculation of Coal PricearinNoch keine Bewertungen

- Progress Transhipment Vessel MV Manalagi TisyaDokument1 SeiteProgress Transhipment Vessel MV Manalagi TisyaMuhammad Rabbil AlbadriNoch keine Bewertungen

- Contoh Loi BatubaraDokument2 SeitenContoh Loi BatubaraRidwan KJRNoch keine Bewertungen

- Tata Full Corporate Offer (FCO) 7000++Dokument2 SeitenTata Full Corporate Offer (FCO) 7000++Sharma Sanjeev KumarNoch keine Bewertungen

- PT. MERCUSUAR INDONESIA INVESTASI - PrihandiyonoMurdantobowoProfileDokument5 SeitenPT. MERCUSUAR INDONESIA INVESTASI - PrihandiyonoMurdantobowoProfileChristian 'cis' YohanesNoch keine Bewertungen

- PT Sumber Coal Supply LetterDokument2 SeitenPT Sumber Coal Supply LetterGora PribadiNoch keine Bewertungen

- 45 Gar KaltimDokument1 Seite45 Gar Kaltimapi-174139371Noch keine Bewertungen

- Indonesia 2nd Edition The Transfer Pricing Law ReviewDokument22 SeitenIndonesia 2nd Edition The Transfer Pricing Law ReviewArianty Damaiance SilabanNoch keine Bewertungen

- INDONESIA'S ROLE AS A TOP COAL EXPORTERDokument79 SeitenINDONESIA'S ROLE AS A TOP COAL EXPORTERFarah Rizka Rahmatia100% (2)

- PT Tohoma Mandiri Plans Local Grinding Media Manufacturer <40Dokument16 SeitenPT Tohoma Mandiri Plans Local Grinding Media Manufacturer <40EcyNoch keine Bewertungen

- Alur Trading Batubara-Lc Non PB Versi EnglishDokument3 SeitenAlur Trading Batubara-Lc Non PB Versi Englishagus salimNoch keine Bewertungen

- Indonesian Coal Supply OfferDokument2 SeitenIndonesian Coal Supply OfferLIOE JINNoch keine Bewertungen

- Cadangan ABKDokument10 SeitenCadangan ABKTatanyaAndiRaditNoch keine Bewertungen

- PT - APM QUOTATION IUP OPK RevisiDokument2 SeitenPT - APM QUOTATION IUP OPK RevisikanayaNoch keine Bewertungen

- FCO GAR 5500 FOB MV and CFR Qingdao - 020658Dokument2 SeitenFCO GAR 5500 FOB MV and CFR Qingdao - 020658ances fanleo sinagaNoch keine Bewertungen

- Jayakhisma ComProDokument94 SeitenJayakhisma ComProAchmad DjunaidiNoch keine Bewertungen

- Brosur - 9 April 2019Dokument8 SeitenBrosur - 9 April 2019fernandoNoch keine Bewertungen

- HBA Juli 2010Dokument1 SeiteHBA Juli 2010Ichsan NNNoch keine Bewertungen

- EXCUTIVE SUMMARY KP PT. NUSA BARA - (New Updated 2019)Dokument1 SeiteEXCUTIVE SUMMARY KP PT. NUSA BARA - (New Updated 2019)agus rukmagaNoch keine Bewertungen

- Coal Trading - Part 1 Information For Sourcing Coal.Dokument4 SeitenCoal Trading - Part 1 Information For Sourcing Coal.DayalNoch keine Bewertungen

- 42 GarDokument1 Seite42 Garapi-174139371Noch keine Bewertungen

- Shenhua Coal Conversion DevelopmentDokument51 SeitenShenhua Coal Conversion Developmentstavros7Noch keine Bewertungen

- UntitledDokument11 SeitenUntitledrian putraNoch keine Bewertungen

- Coa TB Rimau 1607 BG Rimau 3005 - 4000Dokument1 SeiteCoa TB Rimau 1607 BG Rimau 3005 - 4000achwan febriantoNoch keine Bewertungen

- Mangkuraja Company ProfileDokument11 SeitenMangkuraja Company Profilemuhammad rizalNoch keine Bewertungen

- Coa Gar 6300-6100Dokument4 SeitenCoa Gar 6300-6100Powell Bara BaktiNoch keine Bewertungen

- Coal Company CSR ReportDokument14 SeitenCoal Company CSR ReportIchsan NNNoch keine Bewertungen

- Bahan Presentasi PT Indonesia Puqing PDFDokument18 SeitenBahan Presentasi PT Indonesia Puqing PDFDex TerNoch keine Bewertungen

- Customer List PT. Jembatan Timbang Cikarang PDFDokument3 SeitenCustomer List PT. Jembatan Timbang Cikarang PDFFitra WahyudiNoch keine Bewertungen

- Coal Trading Summary ProjectDokument7 SeitenCoal Trading Summary ProjectFinda RaniNoch keine Bewertungen

- 2014 Annual Report Optimized for GrowthDokument183 Seiten2014 Annual Report Optimized for GrowthSandykoNoch keine Bewertungen

- Specification Steam Coal IndonesiaDokument2 SeitenSpecification Steam Coal IndonesiaUdino Towero0% (1)

- LHV TranslateDokument1 SeiteLHV TranslateRevita AzilaNoch keine Bewertungen

- CTI PresentationDokument19 SeitenCTI PresentationSantosh BeheraNoch keine Bewertungen

- Coal Supply in IndonesiaDokument25 SeitenCoal Supply in IndonesiaSunapaNoch keine Bewertungen

- Waste Profile Sheet SummaryDokument2 SeitenWaste Profile Sheet SummarygenebabaNoch keine Bewertungen

- Envirocoal Coal Specs 2015 PDFDokument2 SeitenEnvirocoal Coal Specs 2015 PDFtoniNoch keine Bewertungen

- Checklist Cooling TowerDokument1 SeiteChecklist Cooling TowerAfraz ShaikhNoch keine Bewertungen

- Sujigtei Mine Project Shows Potential for Multi-Million Ounce Gold DepositDokument40 SeitenSujigtei Mine Project Shows Potential for Multi-Million Ounce Gold DeposittonybainNoch keine Bewertungen

- Rhyolite PFS - Section 1 - Executive Summary - FinalDokument39 SeitenRhyolite PFS - Section 1 - Executive Summary - FinalAli MahmoudNoch keine Bewertungen

- Dilution and Losses in Underground MiningDokument4 SeitenDilution and Losses in Underground MiningConstanza Díaz Fuentes100% (2)

- Vanadium Concept Study Progress Update 10 April 2018 124586Dokument5 SeitenVanadium Concept Study Progress Update 10 April 2018 124586djabiaNoch keine Bewertungen

- The 2018-19 Botswana Mineral Accounts Technical ReportDokument40 SeitenThe 2018-19 Botswana Mineral Accounts Technical ReportBrian KebatenneNoch keine Bewertungen

- Introduction To Ore Mineralogy - ThalhammerDokument43 SeitenIntroduction To Ore Mineralogy - ThalhammerSyilvia ManurungNoch keine Bewertungen

- Kanmantoo Copper Mine Ore Reserve EstimateDokument19 SeitenKanmantoo Copper Mine Ore Reserve EstimatekokoamikNoch keine Bewertungen

- Minrom Training BrochureDokument3 SeitenMinrom Training BrochureSaronga JuliusNoch keine Bewertungen

- South32 to acquire 45% stake in Sierra Gorda copper mineDokument40 SeitenSouth32 to acquire 45% stake in Sierra Gorda copper mineBill LiNoch keine Bewertungen

- UNFC Classification - Feb 2022Dokument50 SeitenUNFC Classification - Feb 2022Shibashis BanerjeeNoch keine Bewertungen

- MCCARTHY - Mining Dilution and Losses in Mining PDFDokument4 SeitenMCCARTHY - Mining Dilution and Losses in Mining PDFAshanti Utahel100% (1)

- Russian Resource Code Vs International CodeDokument38 SeitenRussian Resource Code Vs International CodeJi MaNoch keine Bewertungen

- Technical Report Ok TediDokument155 SeitenTechnical Report Ok TediCeejay Thomas100% (3)

- Dealing With High Grades in Resource EstimationDokument10 SeitenDealing With High Grades in Resource EstimationRoberto Rolo100% (1)

- MMC - Interim Report - 2013 - Eng PDFDokument90 SeitenMMC - Interim Report - 2013 - Eng PDFGanBolor TogtokhbayarNoch keine Bewertungen

- 01 CV-Adi Fahdrurozi 2017 (10Dokument6 Seiten01 CV-Adi Fahdrurozi 2017 (10killaruna04Noch keine Bewertungen

- Tr-Form 01: Exploration Results and Mineral Resources: Rogel A. Santos, PHDDokument20 SeitenTr-Form 01: Exploration Results and Mineral Resources: Rogel A. Santos, PHDEmmanuel CaguimbalNoch keine Bewertungen

- Mil Resources Acquires Option To Purchase 100% of Amazon Bay Iron Sands ProjectDokument4 SeitenMil Resources Acquires Option To Purchase 100% of Amazon Bay Iron Sands ProjectLiNoch keine Bewertungen

- Micromine Consulting Services BrochureDokument11 SeitenMicromine Consulting Services BrochureHussein MohsinNoch keine Bewertungen

- White Paper - Mine Planners Lie With NumbersDokument20 SeitenWhite Paper - Mine Planners Lie With NumbersGbi Mining Intelligence100% (2)

- 2016 MSC Cut-Off Grade Optimisation For A Bimetallic DepositDokument126 Seiten2016 MSC Cut-Off Grade Optimisation For A Bimetallic DepositYusuf Efe OzdemirNoch keine Bewertungen

- 420jjpb2wmtfx0 PDFDokument19 Seiten420jjpb2wmtfx0 PDFDaudSutrisnoNoch keine Bewertungen

- Decreasing Metal Ore Grades - CopperDokument14 SeitenDecreasing Metal Ore Grades - CopperSoren K. GroupNoch keine Bewertungen

- Vedanta Prospectus - December 2003Dokument416 SeitenVedanta Prospectus - December 2003Tejas SakhardandeNoch keine Bewertungen

- Understanding Mineral DepositsDokument26 SeitenUnderstanding Mineral DepositsSean PastranaNoch keine Bewertungen

- Heron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectDokument45 SeitenHeron Resources Delivers Robust Feasibility Study For Wooodlawn ProjectYojan Ccoa CcopaNoch keine Bewertungen

- Taonga Simari MRMDokument7 SeitenTaonga Simari MRMTaonga SimariNoch keine Bewertungen

- Categorization of Mineral Resources Based On Different Geostatistical Simulation Algorithms: A Case Study From An Iron Ore DepositDokument25 SeitenCategorization of Mineral Resources Based On Different Geostatistical Simulation Algorithms: A Case Study From An Iron Ore DepositSyahrul AzizNoch keine Bewertungen

- Asian Battery Minerals - Investor Presentation Oct 2022Dokument30 SeitenAsian Battery Minerals - Investor Presentation Oct 2022Erkhembayar MyagmarjavNoch keine Bewertungen

- Ammop Style Guide For AuthorsDokument15 SeitenAmmop Style Guide For AuthorsBobsqwartNoch keine Bewertungen