Beruflich Dokumente

Kultur Dokumente

SteelSheet PDF

Hochgeladen von

Darshan PanchalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SteelSheet PDF

Hochgeladen von

Darshan PanchalCopyright:

Verfügbare Formate

Steel Properties

Sheet

There are many different kinds of stainless steel alloy available on the market, from the commonly-known grade 304 to the less well-

known grade 420. There are thousands of unique alloys available to manufacturers, each with a unique combination of characteristics.

Austenitic Stainless Steels.

The most common variety of stainless steel on the market. This includes alloys

such as 304, 316, and 317. Of the stainless steels, these have the highest corrosion

resistance because of their chromium content. Also, they are non-magnetic and may

only be hardened by cold work (but may become magnetic after cold working).

Ferritic Stainless Steels

These alloys are the second-most common form of stainless steel and include

alloys such as grade 430 and 434 SS. These alloys are magnetic and can be

hardened by cold work. Also, these alloys are less expensive because of their

reduced nickel content.

Martensitic Stainless Steels

Alloys in this category are among the least common formulations of stainless steel.

While their corrosion resistance is lower than the Austenitic or Ferritic alloys, they

have the highest hardness. This makes them ideal for applications requiring high

tensile strength and impact resistance.

To better understand stainless steel, here is a small chart comparing the most common

alloys from each of the different categories of stainless steel:

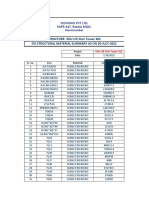

Alloy Tensile Maximum Use Melting Point Resistances/Uses Nickel Chromium Molybdenum Manganese

Strength Temp. Content Content Content Content

Austenitic

621 MPa (90 ksi) 870°C (1679°F) 1399°C -1454°C Good overall corrosion 8 - 10.5% 18 - 20% Not Specified 2%

304 (2550°F - resistance. Used in many Maximum

2650°F) different applications.

579 MPa (84 ksi) ~800°C 1371°C - 1399°C High resistance to 10 - 14% 16 - 18% 2 - 3% 2%

(1472°F) (2500°F - chlorides (such as salt). Maximum

316

2550°F) Used in cookware, naval,

and other applications.

517 MPa (75 ksi) ~800°C 1371°C - 1421°C As a modified version of 11 - 15% 18 - 20% 3.5% max 2%

(1472°F) (2500°F - 316 stainless steel, 317 Maximum

317

2590°F) is often used in many of

the same applications.

Ferritic

450 MPa (65 ksi) 815°C (1499°F) 1425°C - 1510°C Resists nitric acid. Useful 0.75% max 16 - 18% Not Specified 1%

(2597°F - for automotive trim Maximum

430

2750°F) and specific chemical

applications

540 MPa (78 ksi) 815°C (1499°F) 1426°C - 1510°C Superior pitting None 16 - 18% 0.75 - 1.3% 1%

(2600°F - resistance compared Maximum

434 2750°F) to 430. Used in

automotive and exterior

applications.

Martensitic

450 MPa (65 ksi) 650°C (1202°F 1482°C - 1532°C Resistant to hot gases, 0.75% max 11.5 - 13.5% Not Specified 1%

- scaling (2700°F - mild acids & alkalis, and Maximum

410 resistance 2790°F) water. Less resistant

declines past than austenitic or ferritic

this temp). alloys.

586 MPa (85 ksi) 650°C (1202°F 1454°C - 1510°C When hardened, 420 None 12 - 14% Not Specified 1%

Annealed - scaling (2649°F - resists mild acids, water, Maximum

resistance 2750°F) alkalis, and some food

1586 MPa (230

420 declines past compounds. Often used

ksi) Hardened

this temp). in cutlery.

and Stress

Relieved

Contact Us At: (410) 644-7456

Marlin Steel Wire

Was this guide helpful? Share it Products

2640 Merchant Drive

Baltimore, MD 21230-3307

Das könnte Ihnen auch gefallen

- Specification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Dokument2 SeitenSpecification Sheet: Alloy 410: (UNS S41000) / W.Nr. 1.4006Rahul KhoslaNoch keine Bewertungen

- Specification Sheet: Alloy 410 Stainless SteelDokument2 SeitenSpecification Sheet: Alloy 410 Stainless SteelThomasJolyNoch keine Bewertungen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Most Common Types of Stainless SteelDokument3 SeitenMost Common Types of Stainless SteelShoukath AliNoch keine Bewertungen

- Grade Data Sheet: Heat ResistanceDokument2 SeitenGrade Data Sheet: Heat Resistanceapurv bhartiNoch keine Bewertungen

- ASM Material Data SheetDokument2 SeitenASM Material Data Sheetducchinh080Noch keine Bewertungen

- Alloy 410s Spec SheetDokument2 SeitenAlloy 410s Spec SheetALONSO GOMEZNoch keine Bewertungen

- Alloy 410S Spec SheetDokument2 SeitenAlloy 410S Spec SheetPrakash SundharamNoch keine Bewertungen

- 420 Stainless Steel DS 201406 PDFDokument3 Seiten420 Stainless Steel DS 201406 PDFAlexander Saavedra MambuscayNoch keine Bewertungen

- Atlas Grade Datasheet 410 Rev May 2008Dokument2 SeitenAtlas Grade Datasheet 410 Rev May 2008Satendra ThakurNoch keine Bewertungen

- ASM Material Data Sheet 316Dokument2 SeitenASM Material Data Sheet 316.xNoch keine Bewertungen

- Alloy 400 Data SheetDokument2 SeitenAlloy 400 Data SheetelglockNoch keine Bewertungen

- Alloy 825 - 2.4858Dokument4 SeitenAlloy 825 - 2.4858M RNoch keine Bewertungen

- Alloy321 SpecSheetDokument2 SeitenAlloy321 SpecSheetVinod tiwariNoch keine Bewertungen

- Alloy Pipe DetailsDokument4 SeitenAlloy Pipe Detailsprashant.kumarNoch keine Bewertungen

- High-strength martensitic stainless steel alloyDokument2 SeitenHigh-strength martensitic stainless steel alloySuriyachai NiamsornNoch keine Bewertungen

- Lss-A286 Astm A453 PDFDokument2 SeitenLss-A286 Astm A453 PDFmazolasboNoch keine Bewertungen

- Hoja de Especificaciones Del Acero T-410Dokument2 SeitenHoja de Especificaciones Del Acero T-410cristobal_tl2277Noch keine Bewertungen

- LSS 4140-4142HTDokument2 SeitenLSS 4140-4142HTrezaNoch keine Bewertungen

- Ginplate Ni - 426: Technical Data SheetDokument7 SeitenGinplate Ni - 426: Technical Data SheetLuuThiThuyDuongNoch keine Bewertungen

- AISI 440 Martensit PDFDokument4 SeitenAISI 440 Martensit PDFJimmyVargasNoch keine Bewertungen

- Alloy 400: Chemical CompositionDokument2 SeitenAlloy 400: Chemical CompositionFirdaus IzaraeeNoch keine Bewertungen

- 17 4PH Spec SheetDokument2 Seiten17 4PH Spec Sheettrong tan dongNoch keine Bewertungen

- Metal-Sheathed Cable XACTPAKDokument9 SeitenMetal-Sheathed Cable XACTPAKEliasNoch keine Bewertungen

- 420 Martensitic Stainless Steel BarDokument4 Seiten420 Martensitic Stainless Steel BarAHMED FATHINoch keine Bewertungen

- Properties of Ss410Dokument5 SeitenProperties of Ss410gregkilatonNoch keine Bewertungen

- Properties s45cDokument3 SeitenProperties s45ctomas duranNoch keine Bewertungen

- Chemical CompositionDokument6 SeitenChemical CompositionAkbar DarmawansyahNoch keine Bewertungen

- LGHB 2Dokument2 SeitenLGHB 2sergio.sanchezcmiNoch keine Bewertungen

- 17-7 Material PDFDokument5 Seiten17-7 Material PDFJothi ManiNoch keine Bewertungen

- Stainless Steel Grade AISI 430/430FDokument2 SeitenStainless Steel Grade AISI 430/430Fabhijit.ghotane100% (1)

- 410 Data Sheet PDFDokument2 Seiten410 Data Sheet PDFraviteja036Noch keine Bewertungen

- Aalco Metals LTD Stainless Steel 14021 Bar 311Dokument2 SeitenAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNoch keine Bewertungen

- Plastech 85P: Product DataDokument2 SeitenPlastech 85P: Product DataFaisal YaniNoch keine Bewertungen

- 17 4 PH Stainless SteelDokument10 Seiten17 4 PH Stainless SteelWILLIAN RICARDO DOS SANTOSNoch keine Bewertungen

- Grade 316 Stainless Steel Properties and ApplicationsDokument2 SeitenGrade 316 Stainless Steel Properties and ApplicationsmarklaforestNoch keine Bewertungen

- ASM Material Data Sheet PDFDokument2 SeitenASM Material Data Sheet PDFtiele_barcelosNoch keine Bewertungen

- PLASTECH_90P (1)Dokument2 SeitenPLASTECH_90P (1)anderson añezNoch keine Bewertungen

- Data Sheet 316LDokument2 SeitenData Sheet 316LkhalidNoch keine Bewertungen

- Steel PropertiesDokument22 SeitenSteel PropertiesMOHD SALMANNoch keine Bewertungen

- Stainless Steel PlateDokument19 SeitenStainless Steel PlateHarsh AdvaniNoch keine Bewertungen

- Trim Number Chart API ValveDokument2 SeitenTrim Number Chart API ValveVelu .cNoch keine Bewertungen

- 316 Stainless Steel, Anneal...Dokument3 Seiten316 Stainless Steel, Anneal...Moisés Vázquez ToledoNoch keine Bewertungen

- 17 4Dokument3 Seiten17 4John ParkerNoch keine Bewertungen

- Alloy 410 Stainless Steel Specs and PropertiesDokument4 SeitenAlloy 410 Stainless Steel Specs and PropertiesDavid CabreraNoch keine Bewertungen

- High Tensile Steel 4140Dokument2 SeitenHigh Tensile Steel 4140Lazzarus Az GunawanNoch keine Bewertungen

- Alloy904L SpecSheetDokument2 SeitenAlloy904L SpecSheetROYAL LION GAMERNoch keine Bewertungen

- SS316LNDokument4 SeitenSS316LNsamruddhiNoch keine Bewertungen

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDokument3 SeitenStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNoch keine Bewertungen

- AMS 5699 Wire - Inconel Alloy X750 (Aug 2015)Dokument1 SeiteAMS 5699 Wire - Inconel Alloy X750 (Aug 2015)mini p shendeNoch keine Bewertungen

- Aisi e 52100 SteelDokument2 SeitenAisi e 52100 SteelFelipeTadeuNoch keine Bewertungen

- 316L-SS-annealed Bar and Cold DrawnDokument2 Seiten316L-SS-annealed Bar and Cold DrawnARUNKANNANNoch keine Bewertungen

- Cartech Trimrite® Stainless: IdentificationDokument7 SeitenCartech Trimrite® Stainless: IdentificationYassinSalahNoch keine Bewertungen

- Specification Sheet: Alloy 317L: (UNS S31703) W. Nr. 1.4438Dokument2 SeitenSpecification Sheet: Alloy 317L: (UNS S31703) W. Nr. 1.4438ega novialentNoch keine Bewertungen

- 420 Stainless Steel: Corrosion Resistance Magnetic Increased Strength and HardnessDokument3 Seiten420 Stainless Steel: Corrosion Resistance Magnetic Increased Strength and HardnessSai reddyNoch keine Bewertungen

- Tech-Rod 630: DescriptionDokument1 SeiteTech-Rod 630: DescriptionRajendra ChoudharyNoch keine Bewertungen

- Valve Materials Service.1 PDFDokument2 SeitenValve Materials Service.1 PDFshaonaaNoch keine Bewertungen

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Dokument2 SeitenSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182Noch keine Bewertungen

- Transportation - Bearing LoadDokument3 SeitenTransportation - Bearing LoadDarshan PanchalNoch keine Bewertungen

- Vanillin Crude B Column Mechanical DatasheetDokument3 SeitenVanillin Crude B Column Mechanical DatasheetDarshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDokument4 SeitenVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcDokument4 SeitenVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalNoch keine Bewertungen

- Design Notes and AssumptionsDokument19 SeitenDesign Notes and AssumptionsDarshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDokument130 SeitenVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNoch keine Bewertungen

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDokument3 SeitenPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalNoch keine Bewertungen

- IBIC Nozzle Local LoadDokument1 SeiteIBIC Nozzle Local LoadDarshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDokument270 SeitenVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcDokument270 SeitenVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalNoch keine Bewertungen

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDokument130 SeitenVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNoch keine Bewertungen

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Dokument1 SeiteLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNoch keine Bewertungen

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Dokument1 SeiteLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNoch keine Bewertungen

- LOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Dokument1 SeiteLOCATION LIST AND SHOP MATERIAL LIST FOR 1 ASSEMBLY MKD.SR38Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- Calculate Hertz Contact Stresses SafelyDokument5 SeitenCalculate Hertz Contact Stresses SafelyDarshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Darshan PanchalNoch keine Bewertungen

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Dokument1 SeiteB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalNoch keine Bewertungen

- VDU Lift Stair Tower 302 - Material Summary - ListDokument4 SeitenVDU Lift Stair Tower 302 - Material Summary - ListDarshan PanchalNoch keine Bewertungen

- Innovation in Civil Engineering 369Dokument20 SeitenInnovation in Civil Engineering 369talatzahoorNoch keine Bewertungen

- SeaRox SL 620: improved fire safety and acousticsDokument2 SeitenSeaRox SL 620: improved fire safety and acousticsAnh Le NgocNoch keine Bewertungen

- Deflections Due To Loading As Per ACIDokument8 SeitenDeflections Due To Loading As Per ACIRishabh LalaNoch keine Bewertungen

- Rolling ProcessDokument17 SeitenRolling ProcessRavichandran GNoch keine Bewertungen

- Zetkama Fig. 234 SpecsDokument8 SeitenZetkama Fig. 234 SpecsAntonio VelardeNoch keine Bewertungen

- Mechanical Properties of SteelDokument1 SeiteMechanical Properties of SteelrianrureNoch keine Bewertungen

- FogbugzDokument15 SeitenFogbugzLim Wee BengNoch keine Bewertungen

- Green Building and Sustainable Construction: CE142 Dr. J. Berlin P. JuanzonDokument56 SeitenGreen Building and Sustainable Construction: CE142 Dr. J. Berlin P. JuanzonJoseph Berlin Juanzon100% (1)

- Adfreezing and Frost Heaving of FoundationsDokument9 SeitenAdfreezing and Frost Heaving of FoundationsAhmed AbdelazizNoch keine Bewertungen

- Technical data sheet translation noteDokument2 SeitenTechnical data sheet translation noteCarlesNoch keine Bewertungen

- Arora BookDokument18 SeitenArora BookGowtham SmartyNoch keine Bewertungen

- Technical Delivery Conditions For Seamless Carbon Steel FittingsDokument2 SeitenTechnical Delivery Conditions For Seamless Carbon Steel FittingsTanpreet Singh100% (1)

- Btech Acadcivil4Dokument23 SeitenBtech Acadcivil4Tvc TejaNoch keine Bewertungen

- Level Set Method Implementation in SNUFOAM (High Speed Planing Hull)Dokument19 SeitenLevel Set Method Implementation in SNUFOAM (High Speed Planing Hull)Marcopolo Espinoza HaroNoch keine Bewertungen

- TDS Tubings and Fittings-GlandsDokument2 SeitenTDS Tubings and Fittings-GlandstetioNoch keine Bewertungen

- 01 ElevatorsDokument14 Seiten01 Elevatorsengineer63Noch keine Bewertungen

- Matrial ListDokument1 SeiteMatrial ListRukksana SayyedNoch keine Bewertungen

- Reality Lighting 2022 灯饰目录Dokument277 SeitenReality Lighting 2022 灯饰目录qq1691492197Noch keine Bewertungen

- Mechanical Supervisor ResumeDokument4 SeitenMechanical Supervisor ResumeAnwar Rahman100% (4)

- Domestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaDokument24 SeitenDomestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaHaibo LVNoch keine Bewertungen

- B 36 - B 36M - 13Dokument9 SeitenB 36 - B 36M - 13Ahmed BilalNoch keine Bewertungen

- Thermo Exam QuestionsDokument4 SeitenThermo Exam QuestionssiskieoNoch keine Bewertungen

- Heat and Thermodynamics: This Chapter CoversDokument10 SeitenHeat and Thermodynamics: This Chapter CoversLaxankNoch keine Bewertungen

- KIRLOSKAR HVAC BrochureDokument24 SeitenKIRLOSKAR HVAC Brochureedward baskaraNoch keine Bewertungen

- BanbgroupDokument59 SeitenBanbgroupVenkata RajuNoch keine Bewertungen

- TITUS Catalog - Grilles & RegistersDokument16 SeitenTITUS Catalog - Grilles & RegistersZainul Abedin SayedNoch keine Bewertungen

- Rheolate® 212 - ElementisDokument2 SeitenRheolate® 212 - ElementisHiba NaserNoch keine Bewertungen

- Barrier Performance of Common Plastic FilmDokument1 SeiteBarrier Performance of Common Plastic FilmAriane Victoria DantesNoch keine Bewertungen

- G-R 25Dokument27 SeitenG-R 25Duncan VanderwallNoch keine Bewertungen

- sp001 5thedition ChecklistsDokument14 Seitensp001 5thedition ChecklistsJavier Mauricio Higuera MoraNoch keine Bewertungen