Beruflich Dokumente

Kultur Dokumente

Macalloy 650 Fully Threaded Bar SRG

Hochgeladen von

selvan44Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Macalloy 650 Fully Threaded Bar SRG

Hochgeladen von

selvan44Copyright:

Verfügbare Formate

July 2011

Macalloy 650 Stainless

Fully Threaded Bar Systems

2

Macalloy 650 Stainless specification

Macalloy has been the leader Stainless has been introduced from one source both stainless

in the design, manufacture and to complement the existing and carbon systems for their

supply of threaded bar systems carbon steel Macalloy 500 range, threaded bar requirements.

since 1948. The Macalloy 650 enabling customers to purchase

Macalloy 650 stainless bar can be used as an alternative to end threaded stainless re-bar. The thread form

complies with a Type 2 deformation in accordance with BS4449 and BS6744.

If necessary it can be end threaded only, rather than be supplied fully threaded.

Table 1: Mechanical properties of Macalloy 650 Stainless

Bar diameters Minimum ultimate tensile strength Minimum 0.2% proof stress

mm N/mm2 N/mm2

16 to 50 800 650

The System Quality Assurance

The Macalloy 650 Stainless is Macalloy is a quality assured

a high strength continuously company holding CARES

threaded bar system. It is accreditation to BS EN ISO 9001.

available from stock in diameters The Macalloy 650 Stainless

16 to 50mm. Fittings come as System is manufactured under a

standard across the range, testing system in accordance with

standard lengths are 6 metre. this quality regime.

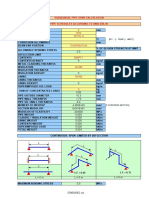

Table 2: Range and Characteristic Loads of Macalloy 650 Stainless

Bar reference Major diameter Stress area Mass per metre Thread pitch load Minimum falling load Minimum 0.2% proof

mm mm mm Kg/m mm mm kN

16 17.6 167 1.50 5 133 108

20 21.8 261 2.37 5 209 170

24 25.3 380 3.17 6 304 247

27 28.9 495 4.10 6 395 312

32 36.2 778 6.40 6 622 506

36 40.2 978 8.20 6 782 636

40 45.3 1199 10.10 8 959 780

50 54.8 1963 15.72 8 1570 1275

Steel Quality Threads complies with the requirements for

Macalloy 650 Stainless has a The coarse thread is rolled a class 2 deformed bar. (BS 8110:

minimum guaranteed yield stress directly onto the bar, of a form 1997)

after threading of 650N/mm2. It specially designed to give speed

is available as standard in grade and ease of assembly. The thread The threads are rolled on the

304, grade 316 stainless steel. gives the minimum anchorage bars in the factory with stringent

strengths as given in table 2. controls on tolerance and form.

The bond value of the coarse Load is transferred from bar to

thread when cast into concrete, fittings over the full circumference

or grouted into a preformed hole, of the bars allowing the use of

compact fittings.

EXPERIENCE INNOVATION QUALITY

3

Macalloy 650 Stainless accessories

Table 3: Macalloy 650 Stainless Accessories

Couplers Nominal Diameter 16 20 24 27 32 36 40

Ref No. 650SC16 650SC20 650SC24 650SC27 650SC32 650SC36 650SC40

Length (L) mm 52.0 70.0 76.0 84.0 90.0 100 110

Outside (D) mm 28.6 35.0 38.1 44.5 57.2 63.5 69.8

Diameter

Full Nuts Nominal Diameter 16 20 24 27 32 36 40

Ref No. 650SN16 650SN20 650SN24 650SN27 650SN32 650SN36 650SN40

Length (L) mm 22.0 30.0 33.0 37.0 41.0 46.0 51.0

Width A/F 25.4 32.0 38.1 44.5 56.4 60.3 69.4

Lock Nuts Nominal Diameter 16 20 24 27 32 36 40

Ref No. 650SLN16 650SLN20 650SLN24 650SLN27 650SLN32 650SLN36 650SLN40

Length (L) mm 11.0 15.0 16.5 18.5 20.0 23.0 25.0

Width A/F 25.4 32.0 38.1 44.5 56.4 60.3 69.4

Flat Plates Nominal Diameter 16 20 24 27 32 36 40

Ref No. 650SP16 650SP20 650SP24 650SP27 650SP32 650SP36 650SP40

100 x 100 x 8 125 x 125 x10 150 x 150 x 10 150 x 150 x 10 215 x 215 x 15 245 x 245 x 20 260 x 260 x 30

For sizes between 33mm and 48mm please contact our sales department.

Also available within the Macalloy 650 Stainless Steel range are dished plate washers, pattress plates, lantern spacers and

hemispherical load nuts. Full details available upon request.

Site Stressing Other Stainless Systems from

Hydraulic jacking equipment is Macalloy

available to apply load to the bars. A further stainless bar offered

Jacks are provided with gauges by Macalloy is the high strength

calibrated against a certified Macalloy S1030 system

load cell to register the force with a 0.1% proof stress of

exerted on the bars. In addition, 835N/mm2 and an ultimate

load cells are available to give stress of 1030N/mm2. Details

an independent check on the of this system can be found in

accuracy of the pump gauge if our Macalloy Post Tensioning

necessary. brochure.

Hand and air operated pumps are

available to drive the full range

of jacks. Our site service team is

also available to provide on-site

stressing and training.

EXPERIENCE INNOVATION QUALITY

4

Applications of Macalloy 650 Stainless

Pipe supports– U-bolts Shuttering or building ties

Holding down bolts Rockbolts, soil nails, ground anchors

and micropile reinforcement

Timeball Tower, Durban, South Africa

Architects - CNN Architects (Pty) Ltd

Contractor - Rebcon Engineering (Pty) Ltd

Engineer - Arup Consulting Engineers (Pty) Ltd in association with Linda Ness Associates

The lower section that contains a central core tube is post tensioned by use of 36 diameter

grade 316 stainless steel Macalloy tendons, post tensioned by means of hydraulic

jacking prior to erection.

This publication provides the technical details currently used by Macalloy in the manufacture of its components.

The company reserves the right to amend technical details as and where necessary in line with its policy of continuous development.

Macalloy, Caxton Way, Dinnington, Sheffield S25 3QE, U.K. Tel: +44 (0)1909 519200. Fax: +44 (0)1909 519201

Website: www.macalloy.com Email: sales@macalloy.com

is a Registered Trade Mark of McCalls Special Products Ltd.

EXPERIENCE INNOVATION QUALITY

Das könnte Ihnen auch gefallen

- Cylindrical Gears InspectionDokument128 SeitenCylindrical Gears InspectionMickloSoberan100% (2)

- SteelDesignSeries SDS3Dokument9 SeitenSteelDesignSeries SDS3dongheep811Noch keine Bewertungen

- Asme B1.20.5-1991 (2014)Dokument72 SeitenAsme B1.20.5-1991 (2014)Anwar Mohamed50% (2)

- Torque Details-Hex Bolt DIN 933Dokument2 SeitenTorque Details-Hex Bolt DIN 933coolkaisy100% (2)

- Manufacturing Technology for Aerospace Structural MaterialsVon EverandManufacturing Technology for Aerospace Structural MaterialsBewertung: 5 von 5 Sternen5/5 (2)

- Design of Small Canal StructuresDokument458 SeitenDesign of Small Canal StructuresCarlos Castro100% (6)

- Work, An Illustrated Magazine...Dokument16 SeitenWork, An Illustrated Magazine...Ricardo Luis Martin Sant'AnnaNoch keine Bewertungen

- Internal ACME Thread General Purpose Size ChartDokument12 SeitenInternal ACME Thread General Purpose Size ChartlutzzNoch keine Bewertungen

- Ci33 1112 Pernos de AnclajeDokument10 SeitenCi33 1112 Pernos de AnclajeShadin Asari ArabaniNoch keine Bewertungen

- (Product) Macalloy Bar SystemDokument21 Seiten(Product) Macalloy Bar SystemRAJENDRA PRASADNoch keine Bewertungen

- Reinforce Concrete PipeDokument2 SeitenReinforce Concrete PipeBrylle Anthony Vida100% (1)

- Din 933Dokument2 SeitenDin 933Sugumar0% (1)

- 460681-JCB 1CX Backhoe LoaderDokument232 Seiten460681-JCB 1CX Backhoe Loaderneruxneru2100% (1)

- Linde All Parts NumbersDokument1.944 SeitenLinde All Parts NumbersEMRE ARSLAN100% (1)

- Manual de Volquete Camc PDFDokument535 SeitenManual de Volquete Camc PDFRicardo Aguirre100% (2)

- Mediumvoltage 1Dokument41 SeitenMediumvoltage 1Yolanda Leah UrbanoNoch keine Bewertungen

- Uniform Standard For Wood Pallets 2014 (REV) PDFDokument72 SeitenUniform Standard For Wood Pallets 2014 (REV) PDFkamskrlNoch keine Bewertungen

- Materials Screws & Nuts Arrangement / Design / AssemblyDokument78 SeitenMaterials Screws & Nuts Arrangement / Design / AssemblyDaniel TomescuNoch keine Bewertungen

- Hra Panel SpecDokument4 SeitenHra Panel SpecMuhammad Arslan Khurshid BhattiNoch keine Bewertungen

- Asme Tubesheet (Heater 10m2)Dokument23 SeitenAsme Tubesheet (Heater 10m2)Omil Rastogi100% (1)

- Howo Sinotruk 371 2021 3.0 Transmission-传动系 CAFK20100294Dokument72 SeitenHowo Sinotruk 371 2021 3.0 Transmission-传动系 CAFK20100294Karsten JaneckeNoch keine Bewertungen

- CIBSE Pipe Sizing V2.2Dokument9 SeitenCIBSE Pipe Sizing V2.2Mohamed AdelNoch keine Bewertungen

- prEN 13774 (2011) PDFDokument30 SeitenprEN 13774 (2011) PDFneiva2019100% (1)

- CIBSE Pipe Sizing V2.2Dokument9 SeitenCIBSE Pipe Sizing V2.2mohamed adelNoch keine Bewertungen

- Cyclic Group ProblemsDokument2 SeitenCyclic Group Problemsselvan44Noch keine Bewertungen

- Macalloy S650 May 2020 V5Dokument2 SeitenMacalloy S650 May 2020 V5bradenNoch keine Bewertungen

- Prestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFDokument54 SeitenPrestressed Concrete Analysis and Design Fundamentals 2nd Ed CAP 2 PDFCarlos Alberto Pacheco SierraNoch keine Bewertungen

- E-Ductile Iron1Dokument11 SeitenE-Ductile Iron1alep azizNoch keine Bewertungen

- CIBSE Pipe Sizing V2.2Dokument9 SeitenCIBSE Pipe Sizing V2.2Sarmad ShahNoch keine Bewertungen

- CIBSE Pipe Sizing V2Dokument13 SeitenCIBSE Pipe Sizing V2Sameer UddinNoch keine Bewertungen

- Experience Innovation Quality: Applications of Macalloy 650 StainlessDokument2 SeitenExperience Innovation Quality: Applications of Macalloy 650 StainlessMaitrabarun KarjeeNoch keine Bewertungen

- The Wear-Resistant SteelDokument16 SeitenThe Wear-Resistant SteelredNoch keine Bewertungen

- Mac AlloyDokument16 SeitenMac AlloyAnonymous u7YkrCwCNoch keine Bewertungen

- Macalloy Brochure Tension Structures December - 2017 - V1Dokument16 SeitenMacalloy Brochure Tension Structures December - 2017 - V1Isabel Christina Gonzalez MoralesNoch keine Bewertungen

- Hexagon Head Bolts/Screws: Metric Series-DimensionsDokument7 SeitenHexagon Head Bolts/Screws: Metric Series-DimensionsVishal MistryNoch keine Bewertungen

- Flexible Metal HosesDokument16 SeitenFlexible Metal Hosesyoonchankim0911Noch keine Bewertungen

- Anchor BoltDokument18 SeitenAnchor BoltDa WongNoch keine Bewertungen

- CTC Technical Manual.86918081Dokument45 SeitenCTC Technical Manual.86918081Mohd AjmainNoch keine Bewertungen

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesDokument10 SeitenAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranNoch keine Bewertungen

- CIBSE Pipe Sizing V2.2Dokument9 SeitenCIBSE Pipe Sizing V2.2thanhquan nguyenNoch keine Bewertungen

- LV PVC - LeaderDokument26 SeitenLV PVC - LeaderDavid LimNoch keine Bewertungen

- Katalog AnkeraDokument20 SeitenKatalog AnkeraBosko MiljevicNoch keine Bewertungen

- Documents - Pub Pipe Span With Point LoadsDokument75 SeitenDocuments - Pub Pipe Span With Point LoadsThanhNoch keine Bewertungen

- Column ExampleDokument4 SeitenColumn ExampleMaha Moddather HassanNoch keine Bewertungen

- NonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021Dokument5 SeitenNonPre Hex 8.8 Nonpreloaded88hex S275 BS5950 UK 15 - 06 - 2021yasser elnessaryNoch keine Bewertungen

- MiscellaneousDokument49 SeitenMiscellaneousjrsvalenzuelaNoch keine Bewertungen

- CNT-400 Product SpecificationsDokument3 SeitenCNT-400 Product SpecificationsddragoNoch keine Bewertungen

- TDS - M SeriesDokument8 SeitenTDS - M SeriesDevang A Panchal100% (1)

- Xlpe/Swa/Pvc: 4-CORE BS 5467 600/1000 VDokument2 SeitenXlpe/Swa/Pvc: 4-CORE BS 5467 600/1000 VMus AqiemNoch keine Bewertungen

- Shear and Tension Capacity of Stainless Steel Bolts Shear and Tension Capacity of Stainless Steel BoltsDokument4 SeitenShear and Tension Capacity of Stainless Steel Bolts Shear and Tension Capacity of Stainless Steel Boltsmehrdad khoeiNoch keine Bewertungen

- MV Cable Current Carrying Capacity NA2XSEYBY SucacoDokument1 SeiteMV Cable Current Carrying Capacity NA2XSEYBY SucacoharisNoch keine Bewertungen

- Macalloy PDFDokument12 SeitenMacalloy PDFmperelmuterNoch keine Bewertungen

- AWA Unipolares Clase 2Dokument1 SeiteAWA Unipolares Clase 2Juan AdrianzenNoch keine Bewertungen

- Steel Wires For Prestressed Concrete - Catalogue PDFDokument8 SeitenSteel Wires For Prestressed Concrete - Catalogue PDFDian Jaka PraharaNoch keine Bewertungen

- High Tensile Bolts TechnicalDokument6 SeitenHigh Tensile Bolts Technicalventhan_kalaiNoch keine Bewertungen

- Datasheet Sanicro 26mo For Wirelines enDokument3 SeitenDatasheet Sanicro 26mo For Wirelines enafonsomlima_1Noch keine Bewertungen

- CNT-400 Product SpecificationDokument3 SeitenCNT-400 Product SpecificationFilgueiras JrNoch keine Bewertungen

- Data Sheet Acoustic Floor Mat 21 ENDokument2 SeitenData Sheet Acoustic Floor Mat 21 ENjonruaNoch keine Bewertungen

- Ductile Iron Pipes PDFDokument3 SeitenDuctile Iron Pipes PDFKhamees Marwan MuhiesenNoch keine Bewertungen

- CATALOGO Cadena SEGHIMET PDFDokument4 SeitenCATALOGO Cadena SEGHIMET PDFSebastian Amago PratoNoch keine Bewertungen

- Drincable 600 Flat CableDokument2 SeitenDrincable 600 Flat Cableheri fauziNoch keine Bewertungen

- Pipe Wrap Tape BrochureDokument8 SeitenPipe Wrap Tape BrochureRamadon BernalNoch keine Bewertungen

- BS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsDokument3 SeitenBS6622/BS7835 Three Core Armoured 6.6kV XLPE Stranded Copper ConductorsBhagoo HatheyNoch keine Bewertungen

- Covalence S1301-M Epoxy Primer: DescriptionDokument4 SeitenCovalence S1301-M Epoxy Primer: DescriptionJuan Carlos Contreras CherresNoch keine Bewertungen

- Bolt Data: Non-Preloaded Ordinary Bolts Grade 4.6 Bolts in S275 DmeterDokument1 SeiteBolt Data: Non-Preloaded Ordinary Bolts Grade 4.6 Bolts in S275 DmeterAlphyl BalasabasNoch keine Bewertungen

- SHIMS Permabloc BrochureDokument4 SeitenSHIMS Permabloc BrochurehrstgaNoch keine Bewertungen

- Catálogo - Acoplamento L - MetricDokument8 SeitenCatálogo - Acoplamento L - MetricMarcos Marcandali de JesusNoch keine Bewertungen

- Prysmian EU 11kV 1core ArmourDokument5 SeitenPrysmian EU 11kV 1core ArmourBhagoo HatheyNoch keine Bewertungen

- Bondstrand PDFDokument8 SeitenBondstrand PDFkrisNoch keine Bewertungen

- 2016 A4 Post Tensioning 1030 Brochure FINALDokument12 Seiten2016 A4 Post Tensioning 1030 Brochure FINALJames MizziNoch keine Bewertungen

- Roller SupportsDokument14 SeitenRoller SupportsArun KumarNoch keine Bewertungen

- 15 KV Cable Data SheetDokument8 Seiten15 KV Cable Data SheetanilNoch keine Bewertungen

- JIS G3474 High Tensile Strength Steel Tubes For Tower Structural PurposesDokument8 SeitenJIS G3474 High Tensile Strength Steel Tubes For Tower Structural PurposesGerardo Emmanuel Romana BrianoNoch keine Bewertungen

- RITZ Screw Specification PDFDokument12 SeitenRITZ Screw Specification PDFThawatchai DanwangkhawNoch keine Bewertungen

- EPR Insulated AC Medium-Voltage Submarine CableDokument3 SeitenEPR Insulated AC Medium-Voltage Submarine CableGcNoch keine Bewertungen

- No Cost Overruns. No Delays.: Now You Can Relax!Dokument15 SeitenNo Cost Overruns. No Delays.: Now You Can Relax!selvan44Noch keine Bewertungen

- Introduction of ROBDokument5 SeitenIntroduction of ROBpriyanka uphamNoch keine Bewertungen

- Available CodesDokument14 SeitenAvailable CodesPankaj MunjalNoch keine Bewertungen

- Form No. 10baDokument1 SeiteForm No. 10baSanthosh PrabhuNoch keine Bewertungen

- Critical Lift PlanDokument2 SeitenCritical Lift PlanjeffotNoch keine Bewertungen

- Scour CalcsDokument9 SeitenScour CalcsAziz ul HakeemNoch keine Bewertungen

- 3.2.6-Beam DesignDokument34 Seiten3.2.6-Beam Designraunak .comNoch keine Bewertungen

- Form No. 10baDokument1 SeiteForm No. 10baSanthosh PrabhuNoch keine Bewertungen

- U Type Sheet Piles (Ths Sp-4) : 【Size & Dimension】Dokument1 SeiteU Type Sheet Piles (Ths Sp-4) : 【Size & Dimension】selvan44Noch keine Bewertungen

- Chapter11 DrainageDokument39 SeitenChapter11 DrainageBurlacu Marian AlinNoch keine Bewertungen

- Do 278 S2003Dokument13 SeitenDo 278 S2003selvan44Noch keine Bewertungen

- TNPSC Css-I Original PaperDokument8 SeitenTNPSC Css-I Original PaperKendra MuellerNoch keine Bewertungen

- Cutie Tractive Toyota RRDokument88 SeitenCutie Tractive Toyota RRDavidescu IoanNoch keine Bewertungen

- Fastener Design Manual, Part OneDokument10 SeitenFastener Design Manual, Part OneHibozoNoch keine Bewertungen

- Loctite 243Dokument4 SeitenLoctite 243ablemathew173974Noch keine Bewertungen

- 1.0 General: Drafting ManualDokument8 Seiten1.0 General: Drafting ManualMubashar Khalil Hashmi100% (1)

- N Diagnostic PDFDokument13 SeitenN Diagnostic PDFZahir KhiraNoch keine Bewertungen

- BS 4a 111-1993 (1999)Dokument10 SeitenBS 4a 111-1993 (1999)son gokuNoch keine Bewertungen

- Dovetail Form ToolsDokument52 SeitenDovetail Form ToolsAnonymous pMVR77x1Noch keine Bewertungen

- TDS 011 Metric Products PDFDokument2 SeitenTDS 011 Metric Products PDFmuathNoch keine Bewertungen

- HYDAC High Pressure Ball ValvesDokument8 SeitenHYDAC High Pressure Ball ValvesOscar Andrés Aponte MurciaNoch keine Bewertungen

- Grounding Prod CatalogueDokument10 SeitenGrounding Prod CatalogueMark KrumpholzNoch keine Bewertungen

- Koc MP 030 Part 1Dokument14 SeitenKoc MP 030 Part 1Ravi MahetoNoch keine Bewertungen

- Haltec 2018 PDFDokument59 SeitenHaltec 2018 PDFUsuarioTurbioNoch keine Bewertungen

- Standard Specification For Carbon Steel Bolts and Studs, 60.000 PSI Tensile StrengthDokument5 SeitenStandard Specification For Carbon Steel Bolts and Studs, 60.000 PSI Tensile StrengthEnrique BassNoch keine Bewertungen

- GB Catalog Threading 2014 LRDokument113 SeitenGB Catalog Threading 2014 LRPrle TihiNoch keine Bewertungen

- W01 358 8048Dokument29 SeitenW01 358 8048MROstop.comNoch keine Bewertungen

- TR Hank - Self-Clinching Studs and PinsDokument32 SeitenTR Hank - Self-Clinching Studs and PinsPat RNoch keine Bewertungen

- DS-1 Volume 4 Addendum PDFDokument15 SeitenDS-1 Volume 4 Addendum PDFMuhammad Bilal KhattakNoch keine Bewertungen

- Ancon CXL Coupler Brochure International Version 2015Dokument10 SeitenAncon CXL Coupler Brochure International Version 2015AhmedMahmoudNoch keine Bewertungen