Beruflich Dokumente

Kultur Dokumente

Job Safety Analysis: (Risk Assessment)

Hochgeladen von

Ped KapedOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Job Safety Analysis: (Risk Assessment)

Hochgeladen von

Ped KapedCopyright:

Verfügbare Formate

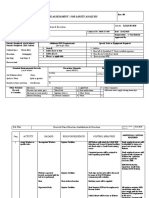

JOB SAFETY ANALYSIS

(RISK ASSESSMENT)

Area to be Access and/or Equipment Tag No. (KKS No.) : CCH-CNVR-800B (E3 Conveyor)

Work to be Done : Insert belt E3 conveyor with hot splicing

LOW √ HIGH : Underwater Work Confined Space Excavation √ Hot Work

Risk Category Job :

Refer to Paiton Instruction : PI-05-03-01 Complex Lifting Work Working at High On Line Low & High Voltage

Work Order No. : 1602191002 Priority No. 1 PAS Application No.

Work Period Date & Time Start Date & Time Finish

Applicant

Signature

:

(Work Parties)

Indah Budiar p Bagus J

RIC FA Supervisor HSE Section

Date : 19 February 2016 Time : 13.00

Ref. PI-05-03-01-F01 Page 1

Ref. PI-05-03-01-F01 Page 2

Work sequence Hazards Risk Control Measures

A. Work Preparation/ Persiapan Kerja

1. Inspect the existing belt, idler, scrapper and overall of E3 Dust during visual check Respiratory Use dust mask (PPE-N95)

conveyor on conveyor Eyes irritation Use safety glasses (PPE)

2. Prepare new belt BW 60” (C-C100m) with specification Ergonomic-manual back pain Briefing for ergonomic concern and stretching before

NN800/4Px5mmx2.0mm. transport and positioning under lifting/handling tools and work, work procedure and JSA

bend pulley area (100 meter) scaffolding (belt, lifting Team handling when move scaffold material & positive

Prepare platen for hot splicing at machine shop. Transport tools and splicing tools) communication during manual lifting

to E3 conveyor area Proper body position during handling loading pipe,

Prepare lifting tools, hot splicing kit & all hand tools as clamp, timber, wrench, etc

required to do belt replacement work Ensure good communication during handling

Marking the dust tray and cutting the dust tray Pitched point during Hand injury Use hand gloves and take care during material

handling scaffold and mobilization (work party awareness)

material (belt, lifting Positive communication between each personnel during

tools and splicing tools) handling

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Sharp object cut from Hand pinched injury Use hand gloves and take care during material

(belt, lifting tools and mobilization (work party awareness)

splicing tools) Wear proper cloth (long sleeve)

Dust/coal dust from coal Respiratory Use dust mask (PPE-N95)

pile Eyes irritation Use safety glasses (PPE)

B. Work Process/ Proses Kerja

3. Install lifting tools (Chain block 5 ton) at counterweight Ergonomic-manual back pain Briefing for ergonomic concern and stretching before

and lifting the counterweight (4 meter) lifting/handling tools and work, work procedure and JSA

scaffolding (pipe, wrench, Team lifting counterweight

clamp, etc) Ensure good communication during handling

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Sharp object cut from Hand pinched injury Use hand gloves and take care during material

lifting tools mobilization (work party awareness)

Wear proper cloth (long sleeve)

Dust/coal dust from coal respiratory Use dust mask (PPE-N95)

pile

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Ref. PI-05-03-01-F01 Page 3

Work sequence Hazards Risk Control Measures

Briefing for ergonomic concern and stretching before

work, work procedure and JSA

Serious injury due to Use body harness and check it by authorize person prior

Height elevation area

falls from height out work

Not phobia working at high

Install barricade under the dismantle area

Change weather rain Briefing for ergonomic concern and stretching before

work, work procedure and JSA

stop the work during the rain (light rain)

4. Dismantle scrapper, rubber skirt, and any skirt board Rotating equipment Serious injury Briefing for ergonomic concern and stretching before

(carrying roller and belt work, work procedure and JSA

conveyor) Isolation for breaker motor

Use hand gloves and take care during dismantle material

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Briefing for ergonomic concern and stretching before

work, work procedure and JSA

Serious injury due to Use body harness and check it by authorize person prior

Height elevation area

falls from height out work

Not phobia working at high

Install barricade under the dismantle area

5. Reposition ripped off belt, Cutting existing belt at tail Rotating equipment Serious injury Briefing for ergonomic concern and stretching before

pulley, joint the existing belt at carrying with the new belt (carrying roller and belt work, work procedure and JSA

with mechanical joint belt (Supers crew or flexco) conveyor) Isolation for breaker motor

Loosen clamp belt, attract existing belt, insert the new belt Use hand gloves and take care during dismantle material

up the roll out

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Pitched point (belt, lifting Hand injury Use hand gloves and take care during material

tools and splicing tools) mobilization (work party awareness)

Positive communication between each personnel during

handling

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Ref. PI-05-03-01-F01 Page 4

Work sequence Hazards Risk Control Measures

Sharp object cut from Hand pinched injury Use hand gloves and take care during material

(belt, lifting tools and mobilization (work party awareness)

splicing tools) Wear proper cloth (long sleeve)

Potential gravitation falling Install barricade

Handling using handling falling Install barricade

tools Handling tools must be good and have tagging

Operator must be certified

Lifting to SWL

6. Dismantle some carrying roller (4set) to make space for Rotating equipment Serious injury Briefing for ergonomic concern and stretching before

belt splicing table. Clamp belt (2 set) at position as needed (carrying roller and belt work, work procedure and JSA

conveyor) Isolation for breaker motor

Use hand gloves and take care during dismantle material

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

7. Install clamp belt, positioning roll new belt and pull with Rotating equipment Serious injury Briefing for ergonomic concern and stretching before

tripod so wear both ends of the new belt met. (carrying roller and belt work, work procedure and JSA

Centring belt 2 meters length at both side and overlap and conveyor) Isolation for breaker motor

step splice the lower part of the new belt. Use hand gloves and take care during dismantle material

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Potential gravitation falling Install barricade

Handling using handling falling Install barricade

tools Handling tools must be good and have tagging

Lifting to SWL

Mechanical hazard from Hand injury used the PPE (cotton gloves)

8. Joint of splice (install platen and vulcanizing the splice). rotating equipment isolation breaker for conveyor motor

Cleaning with solvent and STL RF

electricity have PPE (leather gloves, faceshield, dusk mask)

Fire

flammable tagging for electricity tools and good condition

reduction and remove the coal spillage with manual

dust for grinding the belt respiratory

cleaning or service water

Noise Hear loss PPE (ear plugh)

Ref. PI-05-03-01-F01 Page 5

Work sequence Hazards Risk Control Measures

flammable on A, B and C tagging on electricity tools

fire

type fire watcher, APAR, and fire blanket

spark for grinding belt skin irritation PPE ( faceshield and leather gloves)

Refers to MSDS

chemical hazard skin irritation

PPE (rubber gloves)

respiratory PPE (dust mask-N95)

Ergonomic hazard Back pain Briefing for ergonomic concern and stretching

Lifting on SWL

9. Finishing new belt joint, protecting belt joint surface Mechanical hazard from Hand injury PPE (cotton gloves)

sharpening surface isolation breaker for conveyor motor

dust for grinding the belt reduction and remove the coal spillage with manual

respiratory

and super screw cleaning or service water

flammable on A and C tagging on electricity tools

Fire

type fire watcher, APAR

spark for grinding belt skin irritation PPE ( faceshield and leather gloves)

10. Remove splicing table, belt clamp, lifting tools & other Mechanical hazard from Hand injury used the PPE (cotton gloves)

material sharpening surface isolation breaker for conveyor motor

Handling using handling Falling Install barricade

tools Handling tools must be good and have tagging

Operator must be certified

Lifting to SWL

11. Reinstall carrying idler set, reinstall & adjust scrapper as Rotating equipment Serious injury Briefing for ergonomic concern and stretching before

required, reinstall & adjust rubber skirt (carrying roller and belt work, work procedure and JSA

conveyor) Isolation for breaker motor

Use hand gloves and take care during dismantle material

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Briefing for ergonomic concern and stretching before

work, work procedure and JSA

Serious injury due to Use body harness and check it by authorize person prior

Height elevation area

falls from height out work

Not phobia working at high

Install barricade under the dismantle area

12. Release counterweight (4 meter) Ergonomic-manual back pain Briefing for ergonomic concern and stretching before

lifting/handling tools and work, work procedure and JSA

scaffolding (pipe, wrench, Team lifting counterweight

clamp, etc) Ensure good communication during handling

Ref. PI-05-03-01-F01 Page 6

Work sequence Hazards Risk Control Measures

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Sharp object cut from Hand pinched injury Use hand gloves and take care during material

lifting tools mobilization (work party awareness)

Wear proper cloth (long sleeve)

Dust/coal dust from coal respiratory Use dust mask (PPE-N95)

pile

Ergonomic-static Muscle pain Briefing for ergonomic concern and stretching before

postures work, work procedure and JSA

Proper body position during dismantle

Ensure good communication during dismantle

Briefing for ergonomic concern and stretching before

work, work procedure and JSA

Serious injury due to Use body harness and check it by authorize person prior

Height elevation area

falls from height out work

Not phobia working at high

Install barricade under the dismantle area

Change weather rain Briefing for ergonomic concern and stretching before

work, work procedure and JSA

stop the work during the rain (light rain)

C. Work Completion/ Demob/ Penyelesaian

13. Running test and House keeping and mobilization Ergonomic-manual back pain Briefing for ergonomic concern and stretching before

tools/material to Machine shop and Supra Container lifting/handling tools and work, work procedure and JSA

scaffolding (belt, lifting Team handling when move scaffold material & positive

tools and splicing tools) communication during manual lifting

Proper body position during handling loading pipe,

clamp, timber, wrench, etc

Ensure good communication during handling

Pitched point during Hand injury Use hand gloves and take care during material

handling scaffold and mobilization (work party awareness)

material (belt, lifting Positive communication between each personnel during

tools and splicing tools) handling

Sun exposure Dehydration caused Work party rotation

outdoor heat cram/rash Provide adequate drinking water and electrolyte

Wear proper cloth

Sharp object cut from Hand pinched injury Use hand gloves and take care during material

(belt, lifting tools and mobilization (work party awareness)

splicing tools) Wear proper cloth (long sleeve)

Dust/coal dust from coal Respiratory Use dust mask (PPE-N95)

pile Eyes irritation Use safety glasses (PPE)

Ref. PI-05-03-01-F01 Page 7

Additional Control Measures (please specify : state the other measures such as special work procedures, special emergency procedures etc) :

1. Isolation point at:

CCH-CNVR-800B (M) VARIABLE RACKED OUT AND LOCKED

2. Keep Communicate with CHCB OIS Operator

3. For prepare haven’t isolation

4. Install barricade for replacement belt process

The following test are required to assess the atmospheric conditions in the nominated space :

TEST REQUIRED

TEST FOR Permissible Exposure Limit (PEL)

YES NO

Ammonia Less than 25 ppm √

Carbon Dioxide Less than 5000 ppm √

Carbon Monoxide Less than 25 ppm √

Chlorine Less than 0.5 ppm √

Hydrogen Sulfide Less than 10 ppm √

Oxygen Greater than 19.5% & Less than 23.5% √

Ozone Less than 0.1 ppm √

Sulphur Dioxide Less than 2 ppm √

Hydrogen LEL = 4% & UEL = 75.6% √

LEL Less than/ ≤ 4% √

Note :

1. Reference (OSHA PEL – 2013)

2. For clarification on the test required to be carried out refer PI-05-03-02 (Testing of Confined Space)

Ref. PI-05-03-01-F01 Page 8

Das könnte Ihnen auch gefallen

- JSA-Hydraulic Press Testing For PilesDokument6 SeitenJSA-Hydraulic Press Testing For PilesUMUTNoch keine Bewertungen

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDokument3 SeitenHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834100% (1)

- JSA For Chimney Works 17.09.2021Dokument2 SeitenJSA For Chimney Works 17.09.2021Brenden PalanithangamNoch keine Bewertungen

- JSA - Structural Steel Fabrication and Installation WorksDokument3 SeitenJSA - Structural Steel Fabrication and Installation Workssakthi venkatNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- JSA Formet New Structural Steel FabricationDokument7 SeitenJSA Formet New Structural Steel Fabricationsakthi venkatNoch keine Bewertungen

- Risk Assess JSA Derrick Flare Structure Installation Erection 018Dokument11 SeitenRisk Assess JSA Derrick Flare Structure Installation Erection 018Abdeldjalil Ferhati100% (3)

- Hot Work and Modification PDFDokument19 SeitenHot Work and Modification PDFmyo lwinNoch keine Bewertungen

- Work Method Statement: Confined SpaceDokument3 SeitenWork Method Statement: Confined SpaceKarthik babu0% (1)

- Ast Jsa - Piping FabricationDokument3 SeitenAst Jsa - Piping Fabricationmd_rehan_2Noch keine Bewertungen

- Job Safety Analysis - Clinker StorageDokument4 SeitenJob Safety Analysis - Clinker StorageMohammed MinhajNoch keine Bewertungen

- MTA2018-JHA-012 Air Compressor OperationDokument10 SeitenMTA2018-JHA-012 Air Compressor OperationKelvin TanNoch keine Bewertungen

- 008 JSA - Manual BoringDokument3 Seiten008 JSA - Manual BoringMohammed MinhajNoch keine Bewertungen

- JSA For The Conveyor BeltDokument1 SeiteJSA For The Conveyor BeltSaklain MustakNoch keine Bewertungen

- Pharma MarketingDokument55 SeitenPharma MarketingArpan KoradiyaNoch keine Bewertungen

- SB - 55 - Manbasket ENDokument1 SeiteSB - 55 - Manbasket ENlê ngọc tùng0% (1)

- 2640.011SWP - Excavations and TrenchesDokument7 Seiten2640.011SWP - Excavations and TrenchesHasanuddin HAMIDNoch keine Bewertungen

- SOP of Pump Changing JobDokument11 SeitenSOP of Pump Changing JobDwitikrushna Rout100% (1)

- Jsa Fan Coil Unites MaintenanceDokument5 SeitenJsa Fan Coil Unites MaintenanceASLAM MULANINoch keine Bewertungen

- JSA Install Automatic Parking GateDokument6 SeitenJSA Install Automatic Parking GateMarhendraNoch keine Bewertungen

- JSA - Main Turbine Lub Oil Pumps - OHDokument2 SeitenJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Dokument4 SeitenHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinNoch keine Bewertungen

- Risk Assessment - Pipe Fit Up - Hot WorkDokument7 SeitenRisk Assessment - Pipe Fit Up - Hot WorkHanu JemberNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDokument3 SeitenJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNoch keine Bewertungen

- Risk Assessment Rib Erection & FabricationDokument2 SeitenRisk Assessment Rib Erection & FabricationAkash SharmaNoch keine Bewertungen

- JSA GC-5 Mobile ScaffoldingDokument6 SeitenJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Jsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsDokument6 SeitenJsa For Intallation of Sub Pipe Rack Incuding Grinding Cutting and Welding Near Condensate DrumsMohammed MinhajNoch keine Bewertungen

- Clan Survey Pa 297Dokument16 SeitenClan Survey Pa 297Sahara Yusoph SanggacalaNoch keine Bewertungen

- QR 390 Manual Partes Quincy 390Dokument31 SeitenQR 390 Manual Partes Quincy 390ramiro alvarezNoch keine Bewertungen

- 4..pipe Spool Air Blowing & Cleaning JSA 04Dokument2 Seiten4..pipe Spool Air Blowing & Cleaning JSA 04Francis Vinoj100% (1)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDokument3 SeitenR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNoch keine Bewertungen

- Jsa Loading and Unloading of Pile PipesDokument4 SeitenJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDokument2 SeitenProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- NORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceDokument33 SeitenNORMA - ANSI-AMCA Standard 250-05 Laboratory Methods of Testing Jet Tunnel Fans For PerformanceJose Antonio100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDokument11 SeitenThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- Conveyor Safety ChecklistDokument1 SeiteConveyor Safety Checklistdana setiawanNoch keine Bewertungen

- JSA For Piping-Hydro TestDokument10 SeitenJSA For Piping-Hydro TestMuthu AlaguRajNoch keine Bewertungen

- SOP - Maintenance of Bag FilterDokument22 SeitenSOP - Maintenance of Bag FilterAkash SharmaNoch keine Bewertungen

- DSCDokument7 SeitenDSCthanhnguyenhhvnNoch keine Bewertungen

- Period Based Accounting Versus Cost of Sales AccountingDokument13 SeitenPeriod Based Accounting Versus Cost of Sales AccountingAnil Kumar100% (1)

- Safety: JOB AnalysisDokument4 SeitenSafety: JOB AnalysisAjay kumar100% (1)

- Jha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Dokument1 SeiteJha For Painting Works Repainting of Control Room and Guard House at Switchyard (External)Jonas GonzalesNoch keine Bewertungen

- JSA - Crane Setuppdf PDFDokument12 SeitenJSA - Crane Setuppdf PDFChoko ChokriNoch keine Bewertungen

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Dokument6 SeitenJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNoch keine Bewertungen

- Jsa PDFDokument5 SeitenJsa PDFVAMSINoch keine Bewertungen

- Jsa Insulation WorkDokument20 SeitenJsa Insulation WorkazerNoch keine Bewertungen

- Grating Control ProcedureDokument25 SeitenGrating Control ProcedureMuneeb Rehman100% (1)

- PT-03 JSA Dismantling of Slip Form (22-05-09)Dokument10 SeitenPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibNoch keine Bewertungen

- Jsa For PCCDokument6 SeitenJsa For PCCCICON EngineersNoch keine Bewertungen

- Jsa Ducting Rev 00Dokument1 SeiteJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Noch keine Bewertungen

- Jsa n2 Purging PDF FreeDokument1 SeiteJsa n2 Purging PDF FreeSKH CultureNoch keine Bewertungen

- Nitoproof 230Dokument2 SeitenNitoproof 230Balasubramanian Ananth50% (2)

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDokument3 SeitenR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNoch keine Bewertungen

- Hira Ball Mill Line ReplacemenDokument2 SeitenHira Ball Mill Line Replacemenananthu.uNoch keine Bewertungen

- Grating RemovalDokument1 SeiteGrating RemovalKishor KoshyNoch keine Bewertungen

- Builder Hoist Erection JSA HSE ProfessionalsDokument2 SeitenBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONoch keine Bewertungen

- Erection Methodology PresentationDokument34 SeitenErection Methodology PresentationCyril BayugaNoch keine Bewertungen

- 07 Method Sytatement For Drilling MachineDokument5 Seiten07 Method Sytatement For Drilling MachineNishar Balkavade100% (1)

- SWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanDokument2 SeitenSWP-10 Loading & Unloading Using Lorry & Mobile Crane DaimanHassan AbdullahNoch keine Bewertungen

- Method Statement For Assembly of 200 Ton Crawler CraneDokument7 SeitenMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaNoch keine Bewertungen

- Asian Paints - Prem Gloss EnamelDokument1 SeiteAsian Paints - Prem Gloss EnamelwilliumstNoch keine Bewertungen

- Jsa Slip FormDokument5 SeitenJsa Slip Formputrasejahtra50% (2)

- 02JHA On Welding and Gas CuttingDokument8 Seiten02JHA On Welding and Gas CuttingPiyush SinghNoch keine Bewertungen

- Jsa-001 Manual Handling & Heavy LiftingDokument2 SeitenJsa-001 Manual Handling & Heavy LiftingDamien MonizeNoch keine Bewertungen

- Building De-Dusting JSADokument3 SeitenBuilding De-Dusting JSAJayesh J PillaiNoch keine Bewertungen

- Fabrication WorksDokument4 SeitenFabrication Worksmark jayson yabesNoch keine Bewertungen

- Ethods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Dokument5 SeitenEthods For Mitigation of Voltage Fluctuation Effects: Publication No Cu0208 Issue Date: November 2014Camilo CortesNoch keine Bewertungen

- ActiveScale P100 Installation GuideDokument97 SeitenActiveScale P100 Installation GuideZhou QianNoch keine Bewertungen

- Unreal Tournament CheatDokument3 SeitenUnreal Tournament CheatDante SpardaNoch keine Bewertungen

- Xpulse200t Manual de PartesDokument92 SeitenXpulse200t Manual de PartesAthiq Nehman100% (2)

- Computer Network-II Lab ProgramsDokument5 SeitenComputer Network-II Lab ProgramsAnshul ChauhanNoch keine Bewertungen

- DepEd Learner Information System (LIS) PDFDokument36 SeitenDepEd Learner Information System (LIS) PDFshasagailNoch keine Bewertungen

- Mass Flow SensorDokument0 SeitenMass Flow Sensorwong_arifNoch keine Bewertungen

- Revised Syllabus Filipino 2 PAGSASALINDokument8 SeitenRevised Syllabus Filipino 2 PAGSASALINErza Scarler100% (4)

- O21350 CMMKKDokument2 SeitenO21350 CMMKKwade.hynesoutlook.comNoch keine Bewertungen

- Internship Report (EWSD)Dokument23 SeitenInternship Report (EWSD)Spartacus GladNoch keine Bewertungen

- NASA Facts Apollo 17 Preflight SummaryDokument4 SeitenNASA Facts Apollo 17 Preflight SummaryBob Andrepont100% (1)

- Valve Face To Face Dimension ComparisonDokument12 SeitenValve Face To Face Dimension ComparisonRagul NNoch keine Bewertungen

- ASME B16.47 Series A FlangeDokument5 SeitenASME B16.47 Series A FlangePhạm Trung HiếuNoch keine Bewertungen

- Loupe S Dental Brochure Sur 6351Dokument16 SeitenLoupe S Dental Brochure Sur 6351bernadinadwiNoch keine Bewertungen

- HSC Chemistry SkillsDokument9 SeitenHSC Chemistry SkillsMartin KarlowNoch keine Bewertungen

- Operaional Manual: YZBF-120LDDokument16 SeitenOperaional Manual: YZBF-120LDMohamed AnwarNoch keine Bewertungen

- Faqs: Instant Credit Card Approval and IssuanceDokument1 SeiteFaqs: Instant Credit Card Approval and Issuancedaong_84Noch keine Bewertungen

- Yaesu VR 120Dokument44 SeitenYaesu VR 120Chema MelidaNoch keine Bewertungen

- Shell Gadus S3 T100 PDFDokument1 SeiteShell Gadus S3 T100 PDFAgung BaskaraNoch keine Bewertungen

- Swot Analysis of PTCLDokument5 SeitenSwot Analysis of PTCLM Aqeel Akhtar JajjaNoch keine Bewertungen

- 103096-CG9-20AD IIDokument30 Seiten103096-CG9-20AD IICristian Eduardo Chavez GallardoNoch keine Bewertungen

- TQM Model ExamDokument5 SeitenTQM Model ExamsaswarajNoch keine Bewertungen

- MSDS - LPGDokument9 SeitenMSDS - LPGPrathamesh ShevaleNoch keine Bewertungen

- Payment Advice Outward Telegraphic Transfer: DateDokument2 SeitenPayment Advice Outward Telegraphic Transfer: DateRomanov DalsheNoch keine Bewertungen