Beruflich Dokumente

Kultur Dokumente

DCS Overview

Hochgeladen von

Maulana Hidayatullah0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten23 SeitenDCS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDCS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten23 SeitenDCS Overview

Hochgeladen von

Maulana HidayatullahDCS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 23

Distributed Control Systems, DCS

• Individual Controllers communicating to a

central computers acting as workstations.

• Communication accomplished by digital

data highways, multidrop system, several

devices connected to the same network,

daisy chain.

Distributed Control Systems (DCS)

• The Database is the key, a well-defined coordinated

articulate database, seamless between devices.

• Failure of a single component will not cause system

failure, shutdown; sometimes called graceful degradation

• A hardware or software failure will not go undetected.

Usually done with status bits, or logic.

• I/O – Input Output, electrical signals connected to the

system

• Some systems use redundant I/O to increase reliability

DCS Hardware

• Analog inputs provides 12 bits 1 in 4096

• Analog Output 10 bits 1 in 1024

• The I/O are wired in card files and racked in electrical

cabinets, most often located in a shelter remote from the

operator control room.

• Industrial grade can handle harsh environments,

electrical noise transients, radio interference, etc.

• IEEE C37.90.1-1989 was called 472; defines an

electrical test that standardizes these conditions.

• Electrical Grounding - usually "isolated" from the plant

ground system, however it is connected at one point.

DCS Reliability

• Reliability – very high, usually defined example 2

hardware failures or less per year.

• MTBF mean time before failure 100 years

• MTTR mean time to repair 1 hour or less.

• Online diagnostics; provides a report of the

network traffic, communication errors, retries.

• Redundancy – will allow some or all components

in the system to be redundant. Provides status

and alarming for failures.

The DCS contains some to all of

the following:

• A Control Network; linking the components on the

network. Can have separate network for field devices

and centralized processor as well as a network for the

workstations, PCs

• Workstations, usually a PC used for real time

optimization programs executed there. Route data,

configure system

• Real Time Clock; all devices within the system have

coordinated and synchronized with a Global Position

Sensor.

• Operator Stations, usually a PC for operator interface,

can print, log alarms, and generate reports.

DCS Operator Stations

• Consoles or HMI, Human Machine

Interface– Computer consoles or

workstations are used for operator entry.

Special work surfaces are architecturally

designed to accommodate telephone,

paging in addition to the keyboard and

mouse, usually a track ball design.

• Consoles frequently incorporate dual

monitors, printers for plots and reports.

The DCS contains some to all of the

following, cont:

• Engineering Workstation PC used to develop

control strategy design or configure the system.

• Remote Control Units (RCU) Used to

communicate with remote units, multiplexers,

data concentrators, wireless.

• Application Stations PC run databases,

spreadsheet interface, simulations. Uses OPC

as a data link to the DCS database.

• Mass Storage Device, Archiving data; Data

compression algorithms allow archiving large

data sets.

DCS Historian

• Historian, short term, 90 day, and long term

historian. Long term historian is on a separate

computer, OPC connection used to

communicate the values. A DVD archiving

device.

• Because of the volume of data stored, many

systems incorporate a data compression

algorithm. Reduces the number of data points in

the historical database by not repeatedly storing

the point if it doesn't change by some small

value. All points are usually reported at some

interval even if they don't change.

DCS Alarm Management

• Alarms – DCS have sophisticated alarming conventions

• Alarm Hi HiHi, Lo, LoLo, etc, as well as rate of change.

• Alarms should have dead band to prevent chatter, on

and off at the same point due to noise.

• Configured in a priority manor with different sounds

colored schemes

• Can be suppressed, example during a startup, shutdown

sequence.

• Acknowledge in the console display where the variable is

configured, forces the operator to pay attention to the

variable's operation

• Alarm history file can be analyzed by an off line software

program to sort by various attributes.

DCS Report Generation

• Trend display

• Report generation, such as Shift, Daily,

reports etc.

• Generates an event file that shows all the

operations made to the system in a log

form.

• Engineering console is usually separate

from the operator's workstation.

DCS, Business System Integration

• DCS can be integrated with a

Process Management Manufacturing

Execution Systems

• Integrates business or enterprise resource

planning systems, (or computer program)

with real-time production data, plant can

schedule production, manage raw

materials, and optimize equipment use,

etc.

DCS, MES

• Manufacturing Execution Systems (MES), for

production automation systems.

• Provide open information exchange across

manufacturing production and business planning

systems

• Provide integrated real-time manufacturing

applications

• Also called Computer Integrated Manufacturing

or CIM

• Model the business enterprise in "Levels"

Level 1 Process measurement and control loop

Level 2 Plant Systems

Level 3 Business Systems

Sometimes add a 4th for corporate communications

The system is based upon Microsoft Technologies

COM (Component Object Model)

OPC (OLE for Process Control) for real-time information

XML (eXtensible Markup Language) for transactional information.

Communication standards that permit the free flow of information

across functional areas without an additional software applications

or multiple custom programmed interfaces.

The DCS contains some to all of the

following, cont:

• Inter nodal Communications DCS system

architecture allows data transfer to

manufacturing databases

• Summary – a DCS is more than just a

collection of controllers and a way to

operate them, it is a system designed to

interface with the overall manufacturing

environment.

Das könnte Ihnen auch gefallen

- Distributed Control System: Submitted By: Roll No:35 To 59Dokument35 SeitenDistributed Control System: Submitted By: Roll No:35 To 59sningleNoch keine Bewertungen

- Define? - Purpose of Using DCS?Dokument30 SeitenDefine? - Purpose of Using DCS?deep_the_creepNoch keine Bewertungen

- Practical Data Acquisition for Instrumentation and Control SystemsVon EverandPractical Data Acquisition for Instrumentation and Control SystemsNoch keine Bewertungen

- DCS System Layout and Its Different PartsDokument6 SeitenDCS System Layout and Its Different PartsVraja Kisori100% (1)

- Chapter 4Dokument35 SeitenChapter 4NenuNoch keine Bewertungen

- SCADA Fundamentals MS PDFDokument115 SeitenSCADA Fundamentals MS PDFSabith MohammedNoch keine Bewertungen

- Fundamentals of DCS: Digital Automation SystemsDokument93 SeitenFundamentals of DCS: Digital Automation SystemsSRINKAL199967% (6)

- 3-Overview of Embedded Systems-05!01!2024Dokument107 Seiten3-Overview of Embedded Systems-05!01!2024kx.graphyNoch keine Bewertungen

- 1-Unit-I Introduction To Embedded SystemsDokument29 Seiten1-Unit-I Introduction To Embedded SystemsNallappan Rajj ANoch keine Bewertungen

- Unit 5 SCADADokument52 SeitenUnit 5 SCADAShami KunalNoch keine Bewertungen

- 3.distributed Control SystemsDokument63 Seiten3.distributed Control SystemsPrasanth ChitturiNoch keine Bewertungen

- DCS ArchitectureDokument21 SeitenDCS Architecturedharanika100% (1)

- Aud5 Chapter-26Dokument27 SeitenAud5 Chapter-26Jay LloydNoch keine Bewertungen

- Scada: (Supervisory Control and Data Acquisition)Dokument13 SeitenScada: (Supervisory Control and Data Acquisition)AdamuNoch keine Bewertungen

- 3 Design Challenges, 05-01-2024Dokument74 Seiten3 Design Challenges, 05-01-2024kx.graphyNoch keine Bewertungen

- Control System: Types of Industrial Control SystemsDokument19 SeitenControl System: Types of Industrial Control SystemsAdnan Nawaz100% (2)

- Distributed Control System: The Next Era of Factory AutomationDokument19 SeitenDistributed Control System: The Next Era of Factory AutomationArjun Shantaram ZopeNoch keine Bewertungen

- Es Unit1 PPT FinalDokument99 SeitenEs Unit1 PPT FinalYadavilli VinayNoch keine Bewertungen

- XLS1000 System DescriptionDokument30 SeitenXLS1000 System DescriptionjosueNoch keine Bewertungen

- Industrial Automation Unit V: Prepared By: Pradnya SadigaleDokument31 SeitenIndustrial Automation Unit V: Prepared By: Pradnya Sadigalepradnya sadigaleNoch keine Bewertungen

- "Embedded System": Seminar OnDokument32 Seiten"Embedded System": Seminar Onwarking866Noch keine Bewertungen

- On DcsDokument36 SeitenOn DcsAnkit Meena100% (1)

- S C A D A: Acronym ForDokument22 SeitenS C A D A: Acronym ForNikunj Agarwal100% (1)

- Tutorial On PLCDokument33 SeitenTutorial On PLCmanojnancyNoch keine Bewertungen

- Dcs Vs ScadaDokument44 SeitenDcs Vs ScadaSAYED QAISAR SHAH100% (1)

- Difference Between PAC Hardware and PLC, DCSDokument2 SeitenDifference Between PAC Hardware and PLC, DCSsuudonNoch keine Bewertungen

- SOHO & ScadaDokument22 SeitenSOHO & ScadaSkully TNoch keine Bewertungen

- Dcs Training-BasicDokument96 SeitenDcs Training-BasicPuneet Bachal100% (2)

- WEEK 9 PPTDokument66 SeitenWEEK 9 PPTVenrick CamposNoch keine Bewertungen

- RTS-unit 3Dokument58 SeitenRTS-unit 3nawnish kumarNoch keine Bewertungen

- 6 - DCS IapcDokument14 Seiten6 - DCS IapcNikita ChaudhariNoch keine Bewertungen

- Embedded SystemDokument25 SeitenEmbedded Systemvidhya seemanNoch keine Bewertungen

- Distributed Control SystemDokument8 SeitenDistributed Control SystemParth ShethNoch keine Bewertungen

- A Doctor Is Configuring A Cardiac Pacemaker Inside His PatientDokument4 SeitenA Doctor Is Configuring A Cardiac Pacemaker Inside His PatientasifNoch keine Bewertungen

- Lecture 3 Distributed Control Systems PDFDokument17 SeitenLecture 3 Distributed Control Systems PDFSaif AlabdullahNoch keine Bewertungen

- Chapter 1 Introduction To Embedded Systems: ObjectivesDokument39 SeitenChapter 1 Introduction To Embedded Systems: Objectivessreen67Noch keine Bewertungen

- Embedd IntroDokument24 SeitenEmbedd IntroKumari MugilanNoch keine Bewertungen

- Unit - 3 Embedded Firmware DesignDokument29 SeitenUnit - 3 Embedded Firmware DesignMurali Dhara Sesha Giri Rao GoddantiNoch keine Bewertungen

- Lesson 1Dokument6 SeitenLesson 1OCTAL, Krisia Helena May C.Noch keine Bewertungen

- Scad ADokument8 SeitenScad AYasir KhanNoch keine Bewertungen

- Vehicle Tracking Using GSM, Gps & Arm7Dokument66 SeitenVehicle Tracking Using GSM, Gps & Arm7hemanth menta2001Noch keine Bewertungen

- Embedded System Design: Narina Thakur Bharti Vidyapeeth's College of Engineering Dept of Computer ScienceDokument45 SeitenEmbedded System Design: Narina Thakur Bharti Vidyapeeth's College of Engineering Dept of Computer Sciencekartika_krazeNoch keine Bewertungen

- Control Systems: Piu Ghosh Instrumentation and Control DepartmentDokument42 SeitenControl Systems: Piu Ghosh Instrumentation and Control Departmentpiu_ghosh9966100% (1)

- Distributed Control SystemDokument6 SeitenDistributed Control Systemsimonliu_68Noch keine Bewertungen

- Module 4 (Autosaved)Dokument97 SeitenModule 4 (Autosaved)Random ManNoch keine Bewertungen

- Embedded Systems Overview: - RTOS/EOS Design Concept - RTOS/EOS Case StudyDokument20 SeitenEmbedded Systems Overview: - RTOS/EOS Design Concept - RTOS/EOS Case StudyosmanatamNoch keine Bewertungen

- SCADA SYSTEMS - PPTX - by Engr Morelife Zibayiwa (MSU Zimbabwe)Dokument21 SeitenSCADA SYSTEMS - PPTX - by Engr Morelife Zibayiwa (MSU Zimbabwe)Morelife zibbsNoch keine Bewertungen

- Summary DCS - Diyah KusumawatiDokument2 SeitenSummary DCS - Diyah KusumawatiDyah kusumawatiNoch keine Bewertungen

- Addis Abeba Science and Technology University: College of Mechanical and Electrical EngineeringDokument50 SeitenAddis Abeba Science and Technology University: College of Mechanical and Electrical EngineeringMengesha KirosNoch keine Bewertungen

- Bms Tender SpecificationDokument19 SeitenBms Tender SpecificationharishupretiNoch keine Bewertungen

- Embedded System FinalDokument247 SeitenEmbedded System Finalprarup acharyaNoch keine Bewertungen

- Embedded System - Sec1320Dokument106 SeitenEmbedded System - Sec1320Sharmila chowdary tellaNoch keine Bewertungen

- Distributed Control System: Renu G Ap Eie FisatDokument36 SeitenDistributed Control System: Renu G Ap Eie Fisatshilpa.1595Noch keine Bewertungen

- Smart Dcs ManualDokument39 SeitenSmart Dcs ManualAmet koko TaroNoch keine Bewertungen

- Embedded System Power Point PresentationDokument25 SeitenEmbedded System Power Point PresentationAbhishek Mahajan100% (2)

- Embedded SystemsDokument24 SeitenEmbedded Systemspavi1402Noch keine Bewertungen

- Management Information System: Ghulam Yasin Hajvery University LahoreDokument42 SeitenManagement Information System: Ghulam Yasin Hajvery University LahoreBilawal ShabbirNoch keine Bewertungen

- Es - Unit 1Dokument55 SeitenEs - Unit 1Manish SinghalNoch keine Bewertungen

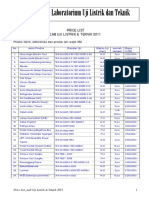

- Price List Produk Lab Listrik 2011Dokument4 SeitenPrice List Produk Lab Listrik 2011Maulana HidayatullahNoch keine Bewertungen

- Will CHROs Take Over The CEODokument1 SeiteWill CHROs Take Over The CEOMaulana HidayatullahNoch keine Bewertungen

- Product KeyDokument1 SeiteProduct Keymanoj_yadav191985Noch keine Bewertungen

- ETAP Training Manual PDFDokument36 SeitenETAP Training Manual PDFjopaypagas80% (35)

- Ir3245 PDFDokument58 SeitenIr3245 PDFMaulana HidayatullahNoch keine Bewertungen

- Dasar OpampDokument54 SeitenDasar OpampMaulana HidayatullahNoch keine Bewertungen

- Elektronika Dasar: Jurusan Teknik Elektro Fakultas Teknik UGM 2012Dokument47 SeitenElektronika Dasar: Jurusan Teknik Elektro Fakultas Teknik UGM 2012Maulana HidayatullahNoch keine Bewertungen

- Chapter 1 IntroductionDokument49 SeitenChapter 1 IntroductionGemex4fshNoch keine Bewertungen

- Corner ReflectorDokument1 SeiteCorner ReflectorYashNoch keine Bewertungen

- Optimizing AOD Refractory PerformanceDokument10 SeitenOptimizing AOD Refractory PerformanceJulio PurezaNoch keine Bewertungen

- Tech Specs - TC 5540 PDFDokument2 SeitenTech Specs - TC 5540 PDFziaarkiplanNoch keine Bewertungen

- Excel NotesDokument9 SeitenExcel NotesAhnNoch keine Bewertungen

- 3 1 5b Ohms Law WorksheetDokument5 Seiten3 1 5b Ohms Law Worksheetapi-291536660100% (1)

- Sap SCM TrainingDokument5 SeitenSap SCM TrainingGLOBAL TEQNoch keine Bewertungen

- Thermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10Dokument11 SeitenThermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10orso brunoNoch keine Bewertungen

- Nihonto Part IDokument38 SeitenNihonto Part IGergő VidaNoch keine Bewertungen

- HydrocarbonsDokument5 SeitenHydrocarbonsClaire Danes Tabamo DagalaNoch keine Bewertungen

- SPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityDokument19 SeitenSPE-183743-MS Maintaining Injectivity of Disposal Wells: From Water Quality To Formation PermeabilityAminNoch keine Bewertungen

- Guide-to-Proficiency-Testing-Australia 2019Dokument29 SeitenGuide-to-Proficiency-Testing-Australia 2019ffatikatuss100% (1)

- Siemens Micromaster 440 Manual PDFDokument312 SeitenSiemens Micromaster 440 Manual PDFGustavo Barrera100% (1)

- Nursing Research Lecture 4aDokument26 SeitenNursing Research Lecture 4asyamsul anwarNoch keine Bewertungen

- P 130881757895329843Dokument44 SeitenP 130881757895329843Vijay MohanNoch keine Bewertungen

- A Tutorial On Spectral Sound Processing Using Max/MSP and JitterDokument16 SeitenA Tutorial On Spectral Sound Processing Using Max/MSP and Jittertramazio0% (1)

- 02 Survey Calculations - PpsDokument96 Seiten02 Survey Calculations - PpsLeo Ivan Aviles RicaldiNoch keine Bewertungen

- ProjectDokument6 SeitenProjecthazimsyakir69Noch keine Bewertungen

- A Comparative Study On The Academic Performance ofDokument18 SeitenA Comparative Study On The Academic Performance ofDiether Allen L. YnionNoch keine Bewertungen

- 3PAR DISK MatrixDokument6 Seiten3PAR DISK MatrixShaun PhelpsNoch keine Bewertungen

- Fire Dynamic Damper Installation InstructionsDokument18 SeitenFire Dynamic Damper Installation InstructionsJohnMerrNoch keine Bewertungen

- Grade 12 Differentiation CHPT 7 & 8Dokument60 SeitenGrade 12 Differentiation CHPT 7 & 8Sri Devi NagarjunaNoch keine Bewertungen

- PHYSICSDokument24 SeitenPHYSICS21SO204 AnvithaNoch keine Bewertungen

- Creating Attachments To Work Items or To User Decisions in WorkflowsDokument20 SeitenCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- 3x Exemplar 2017 en PDFDokument4 Seiten3x Exemplar 2017 en PDFgudzalovNoch keine Bewertungen

- Body Deassembly 9 Interior TrimDokument7 SeitenBody Deassembly 9 Interior TrimCarlos TecnicNoch keine Bewertungen

- The Big TEGO. Products Services Data Sheets-75-150-16!76!31-61Dokument31 SeitenThe Big TEGO. Products Services Data Sheets-75-150-16!76!31-61DWI RAHMASARI FATMAWATINoch keine Bewertungen

- Notes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFDokument9 SeitenNotes For Class 11 Maths Chapter 8 Binomial Theorem Download PDFRahul ChauhanNoch keine Bewertungen

- MOVIDRIVE-B Lab7Dokument6 SeitenMOVIDRIVE-B Lab7GrungeokêNoch keine Bewertungen

- Blender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)Von EverandBlender 3D for Jobseekers: Learn professional 3D creation skills using Blender 3D (English Edition)Noch keine Bewertungen

- How to Do Nothing: Resisting the Attention EconomyVon EverandHow to Do Nothing: Resisting the Attention EconomyBewertung: 4 von 5 Sternen4/5 (421)

- The Internet Con: How to Seize the Means of ComputationVon EverandThe Internet Con: How to Seize the Means of ComputationBewertung: 5 von 5 Sternen5/5 (6)

- TikTok Algorithms 2024 $15,000/Month Guide To Escape Your Job And Build an Successful Social Media Marketing Business From Home Using Your Personal Account, Branding, SEO, InfluencerVon EverandTikTok Algorithms 2024 $15,000/Month Guide To Escape Your Job And Build an Successful Social Media Marketing Business From Home Using Your Personal Account, Branding, SEO, InfluencerBewertung: 4 von 5 Sternen4/5 (4)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosVon EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosBewertung: 5 von 5 Sternen5/5 (1)

- NFT per Creators: La guida pratica per creare, investire e vendere token non fungibili ed arte digitale nella blockchain: Guide sul metaverso e l'arte digitale con le criptovaluteVon EverandNFT per Creators: La guida pratica per creare, investire e vendere token non fungibili ed arte digitale nella blockchain: Guide sul metaverso e l'arte digitale con le criptovaluteBewertung: 5 von 5 Sternen5/5 (15)

- Ten Arguments for Deleting Your Social Media Accounts Right NowVon EverandTen Arguments for Deleting Your Social Media Accounts Right NowBewertung: 4 von 5 Sternen4/5 (388)

- How to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyVon EverandHow to Create Cpn Numbers the Right way: A Step by Step Guide to Creating cpn Numbers LegallyBewertung: 4 von 5 Sternen4/5 (27)

- Computer Science: A Concise IntroductionVon EverandComputer Science: A Concise IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (14)

- Web Copy That Sells: The Revolutionary Formula for Creating Killer Copy That Grabs Their Attention and Compels Them to BuyVon EverandWeb Copy That Sells: The Revolutionary Formula for Creating Killer Copy That Grabs Their Attention and Compels Them to BuyBewertung: 4 von 5 Sternen4/5 (13)

- Ultimate Guide to YouTube for BusinessVon EverandUltimate Guide to YouTube for BusinessBewertung: 5 von 5 Sternen5/5 (1)

- Branding: What You Need to Know About Building a Personal Brand and Growing Your Small Business Using Social Media Marketing and Offline Guerrilla TacticsVon EverandBranding: What You Need to Know About Building a Personal Brand and Growing Your Small Business Using Social Media Marketing and Offline Guerrilla TacticsBewertung: 5 von 5 Sternen5/5 (32)

- Kill All Normies: Online Culture Wars From 4Chan And Tumblr To Trump And The Alt-RightVon EverandKill All Normies: Online Culture Wars From 4Chan And Tumblr To Trump And The Alt-RightBewertung: 3.5 von 5 Sternen3.5/5 (240)

- The Social Media Bible: Tactics, Tools, and Strategies for Business SuccessVon EverandThe Social Media Bible: Tactics, Tools, and Strategies for Business SuccessBewertung: 3.5 von 5 Sternen3.5/5 (19)

- Your Network Is Your Net Worth: Unlock the Hidden Power of Connections for Wealth, Success, and Happiness in the Digital AgeVon EverandYour Network Is Your Net Worth: Unlock the Hidden Power of Connections for Wealth, Success, and Happiness in the Digital AgeBewertung: 3.5 von 5 Sternen3.5/5 (43)

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- Viralnomics: The Ultimate Guide on How to Go Viral! Learn All About Viral Marketing and the Elements of a Successful Viral CampaignVon EverandViralnomics: The Ultimate Guide on How to Go Viral! Learn All About Viral Marketing and the Elements of a Successful Viral CampaignBewertung: 5 von 5 Sternen5/5 (9)

- Get Into UX: A foolproof guide to getting your first user experience jobVon EverandGet Into UX: A foolproof guide to getting your first user experience jobBewertung: 4.5 von 5 Sternen4.5/5 (5)

- YouTube: How to Build and Optimize Your First YouTube Channel, Marketing, SEO, Tips and Strategies for YouTube Channel SuccessVon EverandYouTube: How to Build and Optimize Your First YouTube Channel, Marketing, SEO, Tips and Strategies for YouTube Channel SuccessBewertung: 4 von 5 Sternen4/5 (10)

- Hacks for TikTok: 150 Tips and Tricks for Editing and Posting Videos, Getting Likes, Keeping Your Fans Happy, and Making MoneyVon EverandHacks for TikTok: 150 Tips and Tricks for Editing and Posting Videos, Getting Likes, Keeping Your Fans Happy, and Making MoneyBewertung: 5 von 5 Sternen5/5 (3)

- Narrative Design for Indies: Getting StartedVon EverandNarrative Design for Indies: Getting StartedBewertung: 4.5 von 5 Sternen4.5/5 (5)