Beruflich Dokumente

Kultur Dokumente

ABC Analysis Problem

Hochgeladen von

Taz UddinCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABC Analysis Problem

Hochgeladen von

Taz UddinCopyright:

Verfügbare Formate

SUPPLY CHAIN INVENTORY MANAGEMENT CHAPTER 9 337

is interpreting the results in making decisions, the software re- 5. Southern Markets, Inc., is considering the use of ABC

places entirely the manual calculations. analysis to focus on the most critical SKUs in its inven-

1. A part is produced in lots of 1,000 units. It is assembled tory. Currently, there are approximately 20,000 different

from 2 components worth $50 total. The value added in SKUs with a total dollar usage of $10,000,000 per year.

production (for labor and variable overhead) is $60 per a. What would you expect to be the number of SKUs and

unit, bringing total costs per completed unit to $110. The the total annual dollar usage for A items, B items and C

average lead time for the part is 6 weeks and annual de- items at Southern Markets, Inc.?

mand is 3,800 units, based on 50 business weeks per year. b. The following table provides a random sample of

a. How many units of the part are held, on average, in cycle the unit values and annual demands of eight SKUs.

inventory? What is the dollar value of this inventory? Categorize these SKUs as A, B, and C items.

b. How many units of the part are held, on average, in

pipeline inventory? What is the dollar value of this in- SKU Code Unit Value Demand (Units)

ventory? (Hint: Assume that the typical part in pipeline A104 $2.10 2,500

inventory is 50 percent completed. Thus, half the labor

and variable overhead cost has been added, bringing D205 $2.50 30

the unit cost to $80, or $50 + $60/2.)

X104 $0.85 350

2. Prince Electronics, a manufacturer of consumer elec-

tronic goods, has five distribution centers in different U404 $0.25 250

regions of the country. For one of its products, a high- L205 $4.75 20

speed modem priced at $350 per unit, the average weekly

demand at each distribution center is 75 units. Average S104 $0.02 4,000

shipment size to each distribution center is 400 units, and

X205 $0.35 1,020

average lead time for delivery is 2 weeks. Each distribu-

tion center carries 2 weeks’ supply as safety stock but L104 $4.25 50

holds no anticipation inventory.

a. On average, how many dollars of pipeline inventory 6. Yellow Press, Inc., buys paper in 1,500-pound rolls for

will be in transit to each distribution center? printing. Annual demand is 2,500 rolls. The cost per roll

is $800, and the annual holding cost is 15 percent of the

b. How much total inventory (cycle, safety, and pipeline)

cost. Each order costs $50 to process.

does Prince hold for all five distribution centers?

a. How many rolls should Yellow Press, Inc., order at a time?

3. Terminator, Inc., manufactures a motorcycle part in lots of

250 units. The raw materials cost for the part is $150, and b. What is the time between orders?

the value added in manufacturing 1 unit from its compo- 7. Babble, Inc., buys 400 blank cassette tapes per month for

nents is $300, for a total cost per completed unit of $450. use in producing foreign language courseware. The ordering

The lead time to make the part is 3 weeks, and the annual cost is $12.50. Holding cost is $0.12 per cassette per year.

demand is 4,000 units. Assume 50 working weeks per year.

a. How many tapes should Babble, Inc., order at a time?

a. How many units of the part are held, on average, as

b. What is the time between orders?

cycle inventory? What is its value?

8. At Dot Com, a large retailer of popular books, demand

b. How many units of the part are held, on average, as

is constant at 32,000 books per year. The cost of placing

pipeline inventory? What is its value?

an order to replenish stock is $10, and the annual cost of

4. Oakwood Hospital is considering using ABC analysis to holding is $4 per book. Stock is received 5 working days

classify laboratory SKUs into three categories: those that after an order has been placed. No backordering is al-

will be delivered daily from their supplier (Class A items), lowed. Assume 300 working days a year.

those that will be controlled using a continuous review

a. What is Dot Com’s optimal order quantity?

system (B items), and those that will be held in a two bin

system (C items). The following table shows the annual b. What is the optimal number of orders per year?

dollar usage for a sample of eight SKUs. Rank the SKUs, c. What is the optimal interval (in working days) between

and assign them to their appropriate category. orders?

SKU Dollar Value Annual Usage d. What is demand during the lead time?

e. What is the reorder point?

1 $0.01 1,200

f. What is the inventory position immediately after an

2 $0.03 120,000

order has been placed?

3 $0.45 100

9. Leaky Pipe, a local retailer of plumbing supplies, faces de-

4 $1.00 44,000 mand for one of its SKUs at a constant rate of 30,000 units

5 $4.50 900 per year. It costs Leaky Pipe $10 to process an order to

6 $0.90 350 replenish stock and $1 per unit per year to carry the item

in stock. Stock is received 4 working days after an order is

7 $0.30 70,000

placed. No backordering is allowed. Assume 300 working

8 $1.50 200 days a year.

Das könnte Ihnen auch gefallen

- LPP - orDokument12 SeitenLPP - orbharat_v79Noch keine Bewertungen

- Inventory Management Techniques for Optimal Cost ControlDokument39 SeitenInventory Management Techniques for Optimal Cost ControlTriani WulidatiNoch keine Bewertungen

- MRP Material Requirements PlanningDokument2 SeitenMRP Material Requirements PlanningsaisenthNoch keine Bewertungen

- Value Analysis and Material ManagementDokument9 SeitenValue Analysis and Material Managementsimply_cooolNoch keine Bewertungen

- Chapter IV Material ManagementDokument22 SeitenChapter IV Material ManagementFiraaNoch keine Bewertungen

- Production ManagementDokument25 SeitenProduction ManagementAurelio Espinoza AbalosNoch keine Bewertungen

- Operation Research & Decision Models EditedDokument26 SeitenOperation Research & Decision Models EditedChandru ThulasidassNoch keine Bewertungen

- 7.0 Inventory ManagementDokument24 Seiten7.0 Inventory Managementrohanfyaz00Noch keine Bewertungen

- Work Study and Work MeasurementDokument68 SeitenWork Study and Work Measurementolyad teshomeNoch keine Bewertungen

- Chapter 5 MRP ErpDokument22 SeitenChapter 5 MRP ErpKelly ObrienNoch keine Bewertungen

- Assignment 5 - Capacity PlanningDokument1 SeiteAssignment 5 - Capacity Planningamr onsyNoch keine Bewertungen

- Process Selection LecDokument35 SeitenProcess Selection LecMekaiel Amil MekaielNoch keine Bewertungen

- Reliability and Its Application in TQMDokument15 SeitenReliability and Its Application in TQMVijay Anand50% (2)

- 17: Theory of ProductionDokument43 Seiten17: Theory of Productionnageswara_mutyala100% (1)

- Mobile Phone HolderDokument13 SeitenMobile Phone Holdersagar roperiaNoch keine Bewertungen

- EOQ Sample Calculation.Dokument4 SeitenEOQ Sample Calculation.Magoiga SNNoch keine Bewertungen

- Inventory: Economic Order QuantityDokument11 SeitenInventory: Economic Order QuantitySolomon GetachewNoch keine Bewertungen

- 4 CVP AnalysisDokument36 Seiten4 CVP AnalysisBibaswan BanerjeeNoch keine Bewertungen

- TQM Anna University QBDokument37 SeitenTQM Anna University QBKarthiga SengottuvelNoch keine Bewertungen

- SWOT Analysis of the Software Development IndustryDokument28 SeitenSWOT Analysis of the Software Development IndustrySindhuja VijayakumarNoch keine Bewertungen

- Material Requirement PlanningDokument5 SeitenMaterial Requirement Planningshwa_jn889Noch keine Bewertungen

- Work StudyDokument70 SeitenWork StudyNinad100% (3)

- What Is A Purchasing SystemDokument7 SeitenWhat Is A Purchasing SystemJerah JabicanNoch keine Bewertungen

- Assignment MRPDokument5 SeitenAssignment MRPKhánh Linh NguyễnNoch keine Bewertungen

- Pom Inventory ProblemsDokument8 SeitenPom Inventory ProblemsSharath Kannan0% (2)

- Online Mid-Term POM May-Aug 2020 G-6Dokument5 SeitenOnline Mid-Term POM May-Aug 2020 G-6Hossain TanjilaNoch keine Bewertungen

- Queuing TheoryDokument17 SeitenQueuing TheoryPrakhar SIngh100% (1)

- Quantech Network ModelsDokument32 SeitenQuantech Network ModelsCha chaNoch keine Bewertungen

- Midterm Case FinalDokument6 SeitenMidterm Case FinalChristina Parillo100% (1)

- Chapter 17 - Waiting LinesDokument4 SeitenChapter 17 - Waiting Lineshello_khayNoch keine Bewertungen

- Economic Order QuantityDokument2 SeitenEconomic Order QuantitytomedavNoch keine Bewertungen

- A Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreDokument25 SeitenA Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreKrishna Murthy ANoch keine Bewertungen

- 03 Quality Control Lecture 3 1 PDFDokument26 Seiten03 Quality Control Lecture 3 1 PDFJoJa JoJaNoch keine Bewertungen

- Inventory ModelDokument8 SeitenInventory ModelCharlyn FloresNoch keine Bewertungen

- Chapter 2Dokument37 SeitenChapter 2zelalem tesseraNoch keine Bewertungen

- EOQ With Quantity DiscountsDokument23 SeitenEOQ With Quantity DiscountsCarey HillNoch keine Bewertungen

- Operations Management - Process Design SampleDokument2 SeitenOperations Management - Process Design SampleArun ThevarNoch keine Bewertungen

- Linear Programming ApplicationDokument8 SeitenLinear Programming ApplicationMartin AndreanNoch keine Bewertungen

- Operations & Supply Chain ManagementDokument35 SeitenOperations & Supply Chain ManagementAnimesh kumarNoch keine Bewertungen

- MPR Lot Sizing Rules (L4L)Dokument30 SeitenMPR Lot Sizing Rules (L4L)ajeng.saraswatiNoch keine Bewertungen

- Goal Programming: Case Study 9.1Dokument13 SeitenGoal Programming: Case Study 9.1Ikbal NugrahaNoch keine Bewertungen

- JOB DESIGN AND WORK MEASUREMENT GUIDEDokument20 SeitenJOB DESIGN AND WORK MEASUREMENT GUIDEAlexis V. Larosa100% (2)

- DJF Unit 1pptDokument71 SeitenDJF Unit 1pptmansoorNoch keine Bewertungen

- Chapter 13 - Material Requirements PlanningDokument3 SeitenChapter 13 - Material Requirements Planninghello_khayNoch keine Bewertungen

- Managing Inventory in Supply Chain: Industrial Engineering Department University of SurabayaDokument53 SeitenManaging Inventory in Supply Chain: Industrial Engineering Department University of SurabayaRosyid asNoch keine Bewertungen

- Find Solutions For Your Homework: (1 Bookmark) Enter QuestionDokument2 SeitenFind Solutions For Your Homework: (1 Bookmark) Enter Questionady joffriy100% (1)

- Demand ForecastingDokument36 SeitenDemand Forecastingkcdelacruz.knowledgeNoch keine Bewertungen

- Work Measurement 3Dokument16 SeitenWork Measurement 3Miguel HernandezNoch keine Bewertungen

- Chase Method of Aggregate PlanningDokument23 SeitenChase Method of Aggregate Planningkaushalsingh20Noch keine Bewertungen

- ProductivityDokument25 SeitenProductivitysau1994Noch keine Bewertungen

- Pom Class Note 6 Location PlanningDokument22 SeitenPom Class Note 6 Location PlanningSADY MOHAMMEDNoch keine Bewertungen

- Facility Location & LayoutDokument27 SeitenFacility Location & LayoutDnyaneshwar1986Noch keine Bewertungen

- Lecture 2 - Process Planning PDFDokument30 SeitenLecture 2 - Process Planning PDFFoxsoer100% (5)

- BPB31103 Production & Operations Management ch8Dokument89 SeitenBPB31103 Production & Operations Management ch8Anis TajuldinNoch keine Bewertungen

- Ch08 - InventoryDokument112 SeitenCh08 - InventoryAdam Yans JrNoch keine Bewertungen

- 0perationsmanagement 1Dokument29 Seiten0perationsmanagement 1naufalmamet100% (1)

- Operations ManagementDokument1 SeiteOperations ManagementSouravNoch keine Bewertungen

- Mechathon Problem Statement-2 PDFDokument3 SeitenMechathon Problem Statement-2 PDFFarhan Ahamed HameedNoch keine Bewertungen

- Demand Forecasting in A Supply Chain: Chopra and Meindl, Chapter 4Dokument43 SeitenDemand Forecasting in A Supply Chain: Chopra and Meindl, Chapter 4Girish Dey0% (1)

- Operations Management Pactice QuestionsDokument8 SeitenOperations Management Pactice QuestionsHumphrey OsaigbeNoch keine Bewertungen

- Sample Reflection Paper SNKDokument1 SeiteSample Reflection Paper SNKTaz UddinNoch keine Bewertungen

- Substation Grounding Tutorial: Joe Gravelle, P.E. Eduardo Ramirez-Bettoni, P.EDokument104 SeitenSubstation Grounding Tutorial: Joe Gravelle, P.E. Eduardo Ramirez-Bettoni, P.EAhmed AwadenNoch keine Bewertungen

- Nox Removal System by SCR ProcessDokument4 SeitenNox Removal System by SCR ProcessTaz UddinNoch keine Bewertungen

- A001064 07e PDFDokument114 SeitenA001064 07e PDFTaz UddinNoch keine Bewertungen

- 900-0545 I3iWatch100Dokument87 Seiten900-0545 I3iWatch100thegr8t1Noch keine Bewertungen

- GU - Cabine MT BT (EN) - 1VCP000591 1511Dokument88 SeitenGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariNoch keine Bewertungen

- Bangladesh National Building CodeDokument1.870 SeitenBangladesh National Building CodeTaz UddinNoch keine Bewertungen

- Motor Start TheoryDokument30 SeitenMotor Start TheoryMIBALINoch keine Bewertungen

- Basler Transformer Protection Application Guide PDFDokument33 SeitenBasler Transformer Protection Application Guide PDFAbrakain69Noch keine Bewertungen

- Elevated Neutral-To-Earth Voltage in Distribution Systems IncludiDokument35 SeitenElevated Neutral-To-Earth Voltage in Distribution Systems IncludiTaz UddinNoch keine Bewertungen

- Elevated Neutral-to-Earth Voltage in Distribution Systems Includi PDFDokument187 SeitenElevated Neutral-to-Earth Voltage in Distribution Systems Includi PDFTaz UddinNoch keine Bewertungen

- KeyDokument1 SeiteKeyTaz UddinNoch keine Bewertungen

- Alternate Delivery Service Enrollment Form - V.1.0 PDFDokument4 SeitenAlternate Delivery Service Enrollment Form - V.1.0 PDFTaz UddinNoch keine Bewertungen

- Electronic Engines Support 05 2017Dokument320 SeitenElectronic Engines Support 05 2017Anonymous Qca07FTr100% (1)

- Robin HoodDokument36 SeitenRobin HoodTaz UddinNoch keine Bewertungen

- 056-091 Equipotential Earth BondingDokument2 Seiten056-091 Equipotential Earth BondingJaime GanozaNoch keine Bewertungen

- Managing - Change & Transition - Harvard Business Review PressDokument113 SeitenManaging - Change & Transition - Harvard Business Review PressTaz UddinNoch keine Bewertungen

- 056-057 SW1andSW2Dokument2 Seiten056-057 SW1andSW2Jesus IzaguirreNoch keine Bewertungen

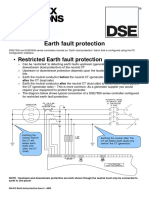

- 056-019 Earth Fault Protection PDFDokument2 Seiten056-019 Earth Fault Protection PDFmigas_migue2856Noch keine Bewertungen

- Robin Hood: Case 23Dokument2 SeitenRobin Hood: Case 23Taz UddinNoch keine Bewertungen

- Electronic Engines Support 05 2017Dokument320 SeitenElectronic Engines Support 05 2017Anonymous Qca07FTr100% (1)

- Nyse Dis 2017Dokument110 SeitenNyse Dis 2017Ngọc Trâm ĐặngNoch keine Bewertungen

- Alternate Delivery Service Enrollment Form - V.1.0 PDFDokument4 SeitenAlternate Delivery Service Enrollment Form - V.1.0 PDFTaz UddinNoch keine Bewertungen

- Robin Hood: Case 23Dokument2 SeitenRobin Hood: Case 23Taz UddinNoch keine Bewertungen

- Chapter 4 SolutionsDokument13 SeitenChapter 4 SolutionsAhmed FahmyNoch keine Bewertungen

- Nox Removal System by SCR ProcessDokument4 SeitenNox Removal System by SCR ProcessTaz UddinNoch keine Bewertungen

- 2000 Report CompanyDokument113 Seiten2000 Report CompanyЂорђе МалешевићNoch keine Bewertungen

- Nyse Dis 2017Dokument110 SeitenNyse Dis 2017Ngọc Trâm ĐặngNoch keine Bewertungen

- Chapter Twelve: Managing Multinational Cash FlowDokument23 SeitenChapter Twelve: Managing Multinational Cash FlowTaz UddinNoch keine Bewertungen

- Process Costing Methods and CalculationsDokument21 SeitenProcess Costing Methods and CalculationsKaen Meagan Gasmen92% (12)

- Quiz Finals CostDokument3 SeitenQuiz Finals CostALLYSON BURAGANoch keine Bewertungen

- Marcom BudgetingDokument17 SeitenMarcom Budgetingsiddharth devnaniNoch keine Bewertungen

- Question 1 (Accounting)Dokument2 SeitenQuestion 1 (Accounting)David DavidNoch keine Bewertungen

- 10E - Build A Spreadsheet 02-43Dokument2 Seiten10E - Build A Spreadsheet 02-43MISRET 2018 IEI JSCNoch keine Bewertungen

- Key Performance Indicators Sample ChapterDokument48 SeitenKey Performance Indicators Sample ChapterMihaela Dobre100% (1)

- Module Number 7 - Production Management - TQMDokument9 SeitenModule Number 7 - Production Management - TQMEden Dela Cruz100% (1)

- Bulaklak Films Case StudyDokument13 SeitenBulaklak Films Case StudyNiña Joy Ceño Campeciño100% (1)

- A Project Report On Working Capital Management Nidhi SrivastavaDokument82 SeitenA Project Report On Working Capital Management Nidhi SrivastavaNand DubeyNoch keine Bewertungen

- BDD Product CostingDokument5 SeitenBDD Product CostingPramod ShettyNoch keine Bewertungen

- CH 8 Abs-Var Costing & Inv MNGTDokument21 SeitenCH 8 Abs-Var Costing & Inv MNGTArnalistan EkaNoch keine Bewertungen

- Contoh Business PlanDokument32 SeitenContoh Business PlanAmirulhelmiNoch keine Bewertungen

- Mr Chicken Cost Accounting ProjectDokument19 SeitenMr Chicken Cost Accounting ProjectMuhammad HamzaNoch keine Bewertungen

- Module 8 - Breakeven AnalysisDokument3 SeitenModule 8 - Breakeven AnalysisMART MATICNoch keine Bewertungen

- CUCUMI SCOOPSDokument38 SeitenCUCUMI SCOOPSPhclivranNoch keine Bewertungen

- Numericals Cost Volume Profit AnalysisDokument21 SeitenNumericals Cost Volume Profit AnalysisDhiren AgrawalNoch keine Bewertungen

- Absorption and Variable CostingDokument2 SeitenAbsorption and Variable CostingJenni Lorico67% (3)

- IHM Chennai Food and Beverage Management NotesDokument113 SeitenIHM Chennai Food and Beverage Management NotesSpatiha Pathmanaban94% (17)

- Unit Rate AnalysisDokument169 SeitenUnit Rate AnalysisYasichalew sefineh0% (1)

- CH14 ABC systems 練習題Dokument3 SeitenCH14 ABC systems 練習題sslbsNoch keine Bewertungen

- Standard Costing and Variance Analysis 2Dokument33 SeitenStandard Costing and Variance Analysis 2jp bNoch keine Bewertungen

- Management Decision & Control - Paper 11Dokument8 SeitenManagement Decision & Control - Paper 11Jacob Baraka OngengNoch keine Bewertungen

- Case Problem-Vajra ToolsDokument2 SeitenCase Problem-Vajra ToolsSayali Ugale100% (1)

- Manufacturing Account Worksheet 9Dokument3 SeitenManufacturing Account Worksheet 9Timo wernereNoch keine Bewertungen

- Accounting 202 Chapter 9 NotesDokument15 SeitenAccounting 202 Chapter 9 NotesnitinNoch keine Bewertungen

- Understand Cost Concepts, Behavior and FlowDokument36 SeitenUnderstand Cost Concepts, Behavior and FlowYunita LalaNoch keine Bewertungen

- Activity-Based Costing: Coffee Bean IncDokument6 SeitenActivity-Based Costing: Coffee Bean IncNahid Hussain AdriNoch keine Bewertungen

- Cost Accounting Vol-IDokument48 SeitenCost Accounting Vol-ImanoNoch keine Bewertungen

- Process Costing Using Weighted Average MethodDokument3 SeitenProcess Costing Using Weighted Average MethodAnne Danica TanNoch keine Bewertungen

- Lecture PDFDokument5 SeitenLecture PDFNigussie Gelalcha ChukoNoch keine Bewertungen

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterVon EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterBewertung: 4 von 5 Sternen4/5 (467)

- The Machine That Changed the World: The Story of Lean Production-- Toyota's Secret Weapon in the Global Car Wars That Is Now Revolutionizing World IndustryVon EverandThe Machine That Changed the World: The Story of Lean Production-- Toyota's Secret Weapon in the Global Car Wars That Is Now Revolutionizing World IndustryBewertung: 4.5 von 5 Sternen4.5/5 (40)

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritVon EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Plan and Organize Your Life: Achieve Your Goals by Creating Intentional Habits and Routines for SuccessVon EverandPlan and Organize Your Life: Achieve Your Goals by Creating Intentional Habits and Routines for SuccessBewertung: 5 von 5 Sternen5/5 (19)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Von EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Bewertung: 4 von 5 Sternen4/5 (17)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosVon EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosBewertung: 3.5 von 5 Sternen3.5/5 (8)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyVon EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyBewertung: 4 von 5 Sternen4/5 (40)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingVon EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingBewertung: 4.5 von 5 Sternen4.5/5 (843)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeVon EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNoch keine Bewertungen

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyVon EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyBewertung: 4 von 5 Sternen4/5 (276)

- The Goal: A Process of Ongoing Improvement - 30th Aniversary EditionVon EverandThe Goal: A Process of Ongoing Improvement - 30th Aniversary EditionBewertung: 4 von 5 Sternen4/5 (684)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingVon EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingBewertung: 4 von 5 Sternen4/5 (2993)

- Nobody Wants Your Sh*t: The Art of Decluttering Before You DieVon EverandNobody Wants Your Sh*t: The Art of Decluttering Before You DieBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeVon EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeBewertung: 4.5 von 5 Sternen4.5/5 (164)

- Tortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringVon EverandTortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringBewertung: 4.5 von 5 Sternen4.5/5 (51)

- Dwelling: Simple Ways to Nourish Your Home, Body, and SoulVon EverandDwelling: Simple Ways to Nourish Your Home, Body, and SoulBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Extraordinary Projects for Ordinary People: Do-It-Yourself Ideas from the People Who Actually Do ThemVon EverandExtraordinary Projects for Ordinary People: Do-It-Yourself Ideas from the People Who Actually Do ThemBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Simplified Organization: Learn to Love What Must Be DoneVon EverandSimplified Organization: Learn to Love What Must Be DoneNoch keine Bewertungen

- Let It Go: Downsizing Your Way to a Richer, Happier LifeVon EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeBewertung: 4.5 von 5 Sternen4.5/5 (67)

- Identity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringVon EverandIdentity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringBewertung: 5 von 5 Sternen5/5 (44)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsVon EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsBewertung: 5 von 5 Sternen5/5 (338)

- Homegrown & Handmade: A Practical Guide to More Self-Reliant LivingVon EverandHomegrown & Handmade: A Practical Guide to More Self-Reliant LivingBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Process!: How Discipline and Consistency Will Set You and Your Business FreeVon EverandProcess!: How Discipline and Consistency Will Set You and Your Business FreeBewertung: 4.5 von 5 Sternen4.5/5 (5)