Beruflich Dokumente

Kultur Dokumente

Flare Gas Recovery Data Sheet PDF

Hochgeladen von

Mohamed Adel0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

119 Ansichten1 SeiteOriginaltitel

150288887-Flare-gas-recovery-data-sheet-pdf.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

119 Ansichten1 SeiteFlare Gas Recovery Data Sheet PDF

Hochgeladen von

Mohamed AdelCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

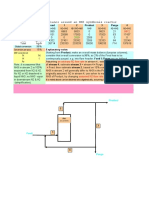

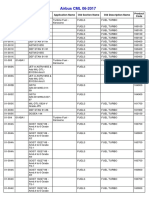

Flare Gas Recovery Unit Process Design

FLARE GAS RECOVERY DATE REV

PROCESS SPECIFICATION 18-Jul-2005 0

LOCATION: PROJECT REFERENCE:

FLARE SYSTEM DATA REV FEED GAS COMPOSITION

REV

1 FLARE EQUIPMENT NUMBER Compound Mole Fraction

2 FLARE TIP DIAMETER Select Units 60 Methane CH4

3 FLARE DESIGN (MAXIMUM) FLOW RATE Select Units 61 Ethane C2H6

4 FLARE SMOKELSS FLOW RATE Select Units 62 Propane C3H8

5 FLARE PRESSURE DROP FROM BASE TO TIP Select Units 63 n-Butane C4H10

6 ESTIMATED SUPPRESSION STEAM USAGE Select Units 64 Isobutane C4H10

7 FLARE HEADER LINE SIZE Select Units 65 n-Pentane C5H12

8 KNOCKOUT VESSEL INSTALLED? YES or NO 66 Isopentane C5H12

9 LIQUID SEAL VESSEL INSTALLED? YES or NO 67 Neopentane C5H12

10 LIQUID SEAL DEPTH Select Units 68 n-Hexane C6H14

11 LIQUID SEAL FLUID WATER or Other WATER 69 2-Methylpentane C6H14

SITE CONDITIONS 70 3-Methylpentane C6H14

12 ELEVATION ABOVE SEA LEVEL Select Units 71 Neohexane C6H14

13 ATMOSPHERIC PRESSURE Select Units 72 2,3-Dimethylbutane C6H14

14 AMBIENT AIR TEMPERATURE Maximum: Select Units 73 n-Heptane C7H16

15 Minimum: Select Units 74 2-Methylhexane C7H16

16 EARTHQUAKE ZONE Select Code Zone per location 75 3-Methylhexane C7H16

17 SITE DESIGN WINDSPEED [ASCE 7, latest edition] Select Units 76 3-Ethylpentane C7H16

18 AREA CLASSIFICATION Select Code 77 2,2-dimethylpentane C7H16

FEED GAS PROPERTIES 78 2,4-dimethylpentane C7H16

19 HEATING VALUE, [LHV] Btu/scf Value based on gas composition 79 3,3-dimethylpentane C7H16

20 MOLECULAR WEIGHT Value based on gas composition 80 Triptane C7H16

21 SPECIFIC GRAVITY [AIR = 1.0] Value based on gas composition 81 n-Octane C8H18

OPERATING UTILITIES 82 Diisobutyl C8H18

22 ELECTRICAL POWER SUPPLY 60 Hz or 50Hz 83 Osooctane C8H18

23 FOR MOTORS <250 HP 480 VAC or 2300 VAC or Other 84 n-Nonane C9H20

24 FOR MOTORS >250 HP 2300 VAC or 4160 VAC or Other 85 n-Decane C10H22

25 FOR CONTROL ELEMENTS 120 VAC or 24 VDC 86 Cyclopentane C5H10

26 INSTRUMENT AIR SUPPLY PRESSURE Select Units 87 Methylcyclopentane C6H12

27 SERVICE WATER SUPPLY PRESSURE Select Units 88 Cyclohexane C6H12

28 COOLING WATER SUPPLY Maximum Temperature: Select Units 89 Methylcyclohexane C7H14

29 Minimum Pressure: Select Units 90 Ethylene C2H4

30 COOLING WATER RETURN Maximum Temperature: Select Units 91 Propene C3H6

31 Minimum Pressure: Select Units 92 1-Butene C4H8

ECONOMIC FACTORS 93 Cis-2-Butene C4H8

32 VALUE OF ELECTRICAL POWER Select Units 94 Trans-2-Butene C4H8

33 VALUE OF STEAM Select Units 95 Isobutene C4H8

34 VALUE OF RECOVERED GAS AS FUEL Select Units 96 1-Pentene C5H10

35 VALUE OF RECOVERED GAS AS PROCESS FEED Select Units 97 1,2-Butadiene C4H6

DESIGN BASIS 98 1,3-Butadiene C4H6

36 DESIGN (MAXIMUM) GAS RECOVERY RATE Select Units 99 Isoprene C5H8

37 FEED GAS TEMPERATURE Select Units 100 Acetylene C2H2

38 FEED GAS PRESSURE Select Units 101 Benzene C6H6

39 RECOVERED GAS DELIVERY TEMPERATURE LIMIT Select Units 102 Toluene C7H8

40 RECOVERED GAS MINIMUM DISCHARGE PRESSURE Select Units 103 Ethylbenzene C8H10

41 RECOVERED GAS INTENDED USE FUEL or PROCESS FEED 104 o-Xylene C8H10

42 CONTROL SYSTEM PLATFORM DCS or PLC 105 m-Xylene C8H10

NOTES AND COMMENTS 106 p-Xylene C8H10

43 text: 107 Styrene C8H10

44 108 Isopropylbenzene C9H12

45 109 Methyl Alcohol CH4O

46 110 Ethyl Alcohol C2H6O

47 111 Carbon Monoxide CO

48 112 Carbon Dioxide CO2

49 113 Hydrogen Sulfide H2S

50 114 Sulfur Dioxide SO2

51 115 Ammonia NH3

52 116 Air N2O2

53 117 Hydrogen H2

54 118 Oxygen O2

55 119 Nitrogen N2

56 120 Chlorine Cl2

57 121 Water H2O

58 122 Helium He

59 123 Hydrogen Chloride HCl

Form Version 6.06 ©2006 John Zink Company, LLC Constituent Total:

JOHN ZINK COMPANY, LLC

11920 E Apache Street, Tulsa, Oklahoma 74116 USA PHONE: 918-234-2903 FAX: 918-234-1968 WEBSITE: www.johnzink.com

Das könnte Ihnen auch gefallen

- Hydrocarbon Recovery: JUNIO 2017Dokument32 SeitenHydrocarbon Recovery: JUNIO 2017Soniale Sánchez GómezNoch keine Bewertungen

- Concepts For Efficient Hydrogen LiquefactionDokument16 SeitenConcepts For Efficient Hydrogen LiquefactionDilla WahabNoch keine Bewertungen

- Compressors BrochureDokument8 SeitenCompressors BrochureRanto GunawanNoch keine Bewertungen

- Defence: The Las Tlineo FDokument5 SeitenDefence: The Las Tlineo FMuhamad Nur HusenNoch keine Bewertungen

- Transat Particles in PipesDokument17 SeitenTransat Particles in Pipesمحمد توفيق عراقيNoch keine Bewertungen

- X.S. Bai Turbulent Premixed FlamesDokument52 SeitenX.S. Bai Turbulent Premixed FlamesIka WidyasariNoch keine Bewertungen

- Proposal Layout LPG Mundu Model ADokument1 SeiteProposal Layout LPG Mundu Model ASugeng WahyudiNoch keine Bewertungen

- John Zink - ATTACH H VCU Catalogs Leaflets (Brochure)Dokument8 SeitenJohn Zink - ATTACH H VCU Catalogs Leaflets (Brochure)Pedro Ferrugem KaiserNoch keine Bewertungen

- The Process Piping: Introduction To Ori Ce FlangeDokument6 SeitenThe Process Piping: Introduction To Ori Ce FlangeMohamed AdelNoch keine Bewertungen

- H2 PSA SlidesDokument16 SeitenH2 PSA SlidesCristian TorrezNoch keine Bewertungen

- 1.0 J1415 QF200-2 PSA DatasheetDokument2 Seiten1.0 J1415 QF200-2 PSA DatasheetCarlos MagNoch keine Bewertungen

- Pressurized Glycol Dehy SystemsDokument11 SeitenPressurized Glycol Dehy SystemsJagan BoseNoch keine Bewertungen

- Redundant Solenoid ValveDokument2 SeitenRedundant Solenoid ValveAmanda PorterNoch keine Bewertungen

- CMPAPPP Separator Vessel and Filter Design GuideDokument18 SeitenCMPAPPP Separator Vessel and Filter Design GuideJWilson73Noch keine Bewertungen

- Eagleburgmann Compressor Seals: Dry Gas Seal UpgradesDokument30 SeitenEagleburgmann Compressor Seals: Dry Gas Seal UpgradesTasawwur TahirNoch keine Bewertungen

- Bunner ControlDokument19 SeitenBunner ControlHai NguyenNoch keine Bewertungen

- MAHLE IF PremiumSelectElements ENDokument6 SeitenMAHLE IF PremiumSelectElements ENJamin SmtpngNoch keine Bewertungen

- Filtration in HydrotreatingDokument2 SeitenFiltration in Hydrotreatingck196548400% (1)

- Flare Gas Recovery Using Gas EjectorDokument8 SeitenFlare Gas Recovery Using Gas Ejectoremmanuel limaNoch keine Bewertungen

- E07 QDokument20 SeitenE07 QSoledad Fernández SantosNoch keine Bewertungen

- Compressors How To Achieve High Reliability & Availability (Electronics)Dokument55 SeitenCompressors How To Achieve High Reliability & Availability (Electronics)Anonymous IGtWHoi0Noch keine Bewertungen

- Dow-UCarsol Physical Solvent PDFDokument3 SeitenDow-UCarsol Physical Solvent PDFJenn BellNoch keine Bewertungen

- Simulation Study of Lube Based Extraction UnitDokument5 SeitenSimulation Study of Lube Based Extraction Unitrvsingh100% (2)

- Que Mad Ores Gordon PiattDokument8 SeitenQue Mad Ores Gordon PiattJUANI34214Noch keine Bewertungen

- PDS For Hot Regenerator - R0.Dokument13 SeitenPDS For Hot Regenerator - R0.idilfitriNoch keine Bewertungen

- Air Separation Unit Atmospheric AirDokument2 SeitenAir Separation Unit Atmospheric Airv.satyanarayana EthaNoch keine Bewertungen

- Ammonia Synthesis Material Balence CalulDokument1 SeiteAmmonia Synthesis Material Balence CalulDhruv RanaNoch keine Bewertungen

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDokument5 SeitenOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNoch keine Bewertungen

- LNG UNIT-1 2018-19 PDFDokument13 SeitenLNG UNIT-1 2018-19 PDFAnil KumarNoch keine Bewertungen

- TITAN 130: Gas Turbine Mechanical Drive PackageDokument2 SeitenTITAN 130: Gas Turbine Mechanical Drive Package'Izzad AfifNoch keine Bewertungen

- Page 1 of 5 Compressor Blocked Discharge - Chemical EngineersDokument5 SeitenPage 1 of 5 Compressor Blocked Discharge - Chemical EngineersKarthikeyan SivaNoch keine Bewertungen

- Process DescriptionDokument6 SeitenProcess Descriptionافكر اشتري كورياNoch keine Bewertungen

- Reliance - Flare Gas Recovery IMPDokument6 SeitenReliance - Flare Gas Recovery IMPsvnaik14Noch keine Bewertungen

- MetoxidoDokument8 SeitenMetoxidocessavelinoNoch keine Bewertungen

- Centrifugal PumpsDokument14 SeitenCentrifugal PumpsAshishAgarwalNoch keine Bewertungen

- XFH 9Dokument33 SeitenXFH 9haosfNoch keine Bewertungen

- Liquid Monopropellant CombustionDokument4 SeitenLiquid Monopropellant Combustionherdi sutanto adigunaNoch keine Bewertungen

- Captive Power Plant - Encon Measures: A Sunrise Project For A Sunshine FutureDokument20 SeitenCaptive Power Plant - Encon Measures: A Sunrise Project For A Sunshine Futuremujeebtalib100% (1)

- Curvas de FuncionamientoDokument12 SeitenCurvas de FuncionamientoENMANUELNoch keine Bewertungen

- LMF-GP LX15-8 - 10 - 13Dokument2 SeitenLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- NGL SeparationDokument6 SeitenNGL SeparationhoustonmathNoch keine Bewertungen

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Dokument2 SeitenA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNoch keine Bewertungen

- Thermo-Economic Performance Comparison of Two Configurations ofDokument17 SeitenThermo-Economic Performance Comparison of Two Configurations ofSallyNoch keine Bewertungen

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDokument8 SeitenUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rNoch keine Bewertungen

- Water Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureDokument11 SeitenWater Vapor Content of Gaseous Fuels by Measurement of Dew-Point TemperatureDIAZCORDOBANoch keine Bewertungen

- CryoStar PresentationDokument26 SeitenCryoStar PresentationLelosPinelos123Noch keine Bewertungen

- Flare Gas Recovery PDFDokument13 SeitenFlare Gas Recovery PDFSadad MohamadNoch keine Bewertungen

- Performance Optimization of Low-Temperature Power Generation by Supercritical ORCs Using Low GWP Working FluidsDokument14 SeitenPerformance Optimization of Low-Temperature Power Generation by Supercritical ORCs Using Low GWP Working Fluidsmonsterh5Noch keine Bewertungen

- FlowmeterDokument22 SeitenFlowmeterAnandNoch keine Bewertungen

- Asme GT2005-68799 PDFDokument9 SeitenAsme GT2005-68799 PDFJeeEianYannNoch keine Bewertungen

- Modeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitDokument8 SeitenModeling and Simulation of Methanation Catalytic Reactor in Ammonia UnitMartin NizNoch keine Bewertungen

- SMR Hydrogen Generators-Technologies and Producers 2009Dokument28 SeitenSMR Hydrogen Generators-Technologies and Producers 2009Zoran JuricNoch keine Bewertungen

- Dehydration Plant Twenty Years PaperDokument5 SeitenDehydration Plant Twenty Years Papersejerson07Noch keine Bewertungen

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDokument1 SeiteVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduNoch keine Bewertungen

- Cyclonic Wellhead DesanderDokument2 SeitenCyclonic Wellhead DesanderKapwell LimitedNoch keine Bewertungen

- Borsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationDokument15 SeitenBorsodchem MCHZ, Czech Republic 6,000 NM /H HTCR Topsøe Hydrogen Plant A Case Story: 18 Months From Engineering To OperationlaquetengoNoch keine Bewertungen

- Burckhardt BOG Compressor DesignDokument12 SeitenBurckhardt BOG Compressor DesignThomas MazzoleniNoch keine Bewertungen

- Lurgi's MPG Gasification Plus Rectisol Gas Purification - Advanced Process Combination For Reliable Syngas ProductionDokument22 SeitenLurgi's MPG Gasification Plus Rectisol Gas Purification - Advanced Process Combination For Reliable Syngas Productionpippo2378793Noch keine Bewertungen

- Instr Loop Check PDFDokument3 SeitenInstr Loop Check PDFMohamed AdelNoch keine Bewertungen

- ANSI B16.5 Pressure & TemperatureDokument1 SeiteANSI B16.5 Pressure & TemperatureMuhamad ZahdiNoch keine Bewertungen

- Valve Pit 5th DecDokument3 SeitenValve Pit 5th DecMohamed AdelNoch keine Bewertungen

- World Class ManufacturingPlant Start Up and Commissioning ProcedureDokument17 SeitenWorld Class ManufacturingPlant Start Up and Commissioning ProcedureMohamed AdelNoch keine Bewertungen

- Refractory Dry Out Procedures PDFDokument18 SeitenRefractory Dry Out Procedures PDFTamer Abd Elrasoul0% (2)

- Lavith CV 1-5Dokument4 SeitenLavith CV 1-5Mohamed AdelNoch keine Bewertungen

- API Refractory Lining and Burner Brick RequirementDokument29 SeitenAPI Refractory Lining and Burner Brick RequirementsprathNoch keine Bewertungen

- CBR Test Procedure Determination of California Bearing Ratio For Road Design PDFDokument5 SeitenCBR Test Procedure Determination of California Bearing Ratio For Road Design PDFMohamed AdelNoch keine Bewertungen

- Equipment Used During VentingDokument9 SeitenEquipment Used During VentingRahulChoudharyNoch keine Bewertungen

- Mansil-125 P-GDokument1 SeiteMansil-125 P-Gkanu PatelNoch keine Bewertungen

- Zeolite 4A White Powder For Detergent Det Build 150Dokument2 SeitenZeolite 4A White Powder For Detergent Det Build 150kanu Patel100% (1)

- Catalyst ProcedureDokument99 SeitenCatalyst Procedurejtirenti50% (2)

- Motor Testing and General Checks FormatDokument4 SeitenMotor Testing and General Checks FormatRaj Kiran77% (22)

- Method Statement For Instrument Calibration PDFDokument14 SeitenMethod Statement For Instrument Calibration PDFMohamed AdelNoch keine Bewertungen

- Supported Metal Catalysts PreparationDokument9 SeitenSupported Metal Catalysts Preparationandyblabla100% (1)

- Cooling Tower Project ReportDokument51 SeitenCooling Tower Project ReportOsama Hasan97% (31)

- Molecular Sieve Type 5ADokument2 SeitenMolecular Sieve Type 5Akanu PatelNoch keine Bewertungen

- Supported Metal Catalysts PreparationDokument9 SeitenSupported Metal Catalysts Preparationandyblabla100% (1)

- Erection and Commissioning ProcedureDokument94 SeitenErection and Commissioning Procedurekdsrathod5100% (6)

- Vacuum Drying TheoryDokument5 SeitenVacuum Drying TheoryShishir Koyare100% (1)

- Oil Flushing PDFDokument51 SeitenOil Flushing PDFMohamed AdelNoch keine Bewertungen

- Hydrocarbon Vapor Recovery Systems PDFDokument26 SeitenHydrocarbon Vapor Recovery Systems PDFMohamed AdelNoch keine Bewertungen

- RBS 6000 Commissioning Procedure - PA1Dokument17 SeitenRBS 6000 Commissioning Procedure - PA1He Ro90% (10)

- Hydrocracking Technology: Prepared By: GuideDokument12 SeitenHydrocracking Technology: Prepared By: GuideMohamed AdelNoch keine Bewertungen

- Pressure Rating PDFDokument4 SeitenPressure Rating PDFMohamed AdelNoch keine Bewertungen

- GGS Operating Manual Vol 1Dokument271 SeitenGGS Operating Manual Vol 1SDP02100% (1)

- Check List For Instrumentation Design PDFDokument22 SeitenCheck List For Instrumentation Design PDFMohamed AdelNoch keine Bewertungen

- Boiler Chemical Cleaning Procedure PDFDokument11 SeitenBoiler Chemical Cleaning Procedure PDFheppy prastyo nugroho100% (1)

- 2-MS. Cleaning and Flushing of PipeworkDokument7 Seiten2-MS. Cleaning and Flushing of PipeworkBaha'a F. AbdulhadiNoch keine Bewertungen

- Lubritec: Synthetic Lubricant Cross Reference Chart SeriesDokument4 SeitenLubritec: Synthetic Lubricant Cross Reference Chart SeriesahmerkhateebNoch keine Bewertungen

- 02 - SCORE Furnaces - Case StudiesDokument22 Seiten02 - SCORE Furnaces - Case StudiesAbhimanyu SharmaNoch keine Bewertungen

- Reservior Drive Mechanism.: Okoh Oluchi IdamDokument22 SeitenReservior Drive Mechanism.: Okoh Oluchi IdamOko Id100% (1)

- Result of Analysis: NO. Test Method Results Spesification Test Item UnitDokument1 SeiteResult of Analysis: NO. Test Method Results Spesification Test Item UnitIkhsan RamdhaniNoch keine Bewertungen

- El Sayed: Amer HassanDokument1 SeiteEl Sayed: Amer Hassaneng20072007Noch keine Bewertungen

- Healthiest Cooking Oil Comparison Chart With Smoke Points and Omega 3 Fatty Acid RatiosDokument6 SeitenHealthiest Cooking Oil Comparison Chart With Smoke Points and Omega 3 Fatty Acid RatiosiegorjNoch keine Bewertungen

- 2014 Award Recipients: 2014 Outstanding Student ChaptersDokument5 Seiten2014 Award Recipients: 2014 Outstanding Student ChaptersErma PrastyaNoch keine Bewertungen

- CH 3 Sustainable Energy CengageDokument45 SeitenCH 3 Sustainable Energy CengageDr Mohammad AlzoubyNoch keine Bewertungen

- Lecture 2 - Intro To Fosil Fuels BDokument81 SeitenLecture 2 - Intro To Fosil Fuels BGomolemo BaarxxNoch keine Bewertungen

- Material Safety Data Sheet: Revision Date: May 3, 2012Dokument8 SeitenMaterial Safety Data Sheet: Revision Date: May 3, 2012Ulizt ArlojiNoch keine Bewertungen

- List VendorDokument8 SeitenList VendorsariardNoch keine Bewertungen

- Avantgarde Ultra 15w40 568321Dokument1 SeiteAvantgarde Ultra 15w40 568321Rabeh BougouffaNoch keine Bewertungen

- 2016 AFPM Cat Cracker Seminar - Preserving Octane For A Tier 3 Gasoline MarketDokument32 Seiten2016 AFPM Cat Cracker Seminar - Preserving Octane For A Tier 3 Gasoline Marketsaleh4060Noch keine Bewertungen

- Imporatance of Biology in Petroleum EngineeringDokument1 SeiteImporatance of Biology in Petroleum EngineeringSana NgaNoch keine Bewertungen

- Learning Activity Sheet: Bachelor of Science in Marine TransportationDokument3 SeitenLearning Activity Sheet: Bachelor of Science in Marine TransportationMark Adrian RancesNoch keine Bewertungen

- Comparative Analysis of Sae Grade Engine Oil Vs Non Edible OilDokument15 SeitenComparative Analysis of Sae Grade Engine Oil Vs Non Edible OilananthakumarNoch keine Bewertungen

- Formation Evaluation and Well Log CorrelationDokument27 SeitenFormation Evaluation and Well Log CorrelationNguyen Truong SonNoch keine Bewertungen

- Petroleum Industry - CPT150SDokument33 SeitenPetroleum Industry - CPT150Smonkey manNoch keine Bewertungen

- Gas FluctuationDokument11 SeitenGas FluctuationAjeay PamintuanNoch keine Bewertungen

- FDP 1Dokument73 SeitenFDP 1AdolfWaydaDollesinNoch keine Bewertungen

- Catalyticreformingprocess 17Dokument29 SeitenCatalyticreformingprocess 17Sahil Gupta100% (1)

- Lubricants 05 00044Dokument17 SeitenLubricants 05 00044Jesus OcampoNoch keine Bewertungen

- Reserves Estimation and ClassificationDokument32 SeitenReserves Estimation and ClassificationSherif HamedNoch keine Bewertungen

- Thermax Limited O&M Manual - Lubrication Schedule: (Boiler & Heater Group)Dokument4 SeitenThermax Limited O&M Manual - Lubrication Schedule: (Boiler & Heater Group)Nguyễn Thanh LâmNoch keine Bewertungen

- What Is Shale GasDokument3 SeitenWhat Is Shale GasDavid SiburianNoch keine Bewertungen

- Bongkot Field 20 Year AnniversaryDokument8 SeitenBongkot Field 20 Year AnniversaryAnonymous ntK705RtNoch keine Bewertungen

- Duhok Polytechnic University Technical College of Engineering Petrochemical DepartmentDokument4 SeitenDuhok Polytechnic University Technical College of Engineering Petrochemical DepartmentIbrahimNoch keine Bewertungen

- Recommended Lubricants For Behringer SawsDokument1 SeiteRecommended Lubricants For Behringer SawsMed Elhedi NasfiNoch keine Bewertungen

- Code Oil PDFDokument112 SeitenCode Oil PDFNguyen TrungNoch keine Bewertungen

- 116 Lubricant Base StocksDokument4 Seiten116 Lubricant Base StocksHariajahNoch keine Bewertungen