Beruflich Dokumente

Kultur Dokumente

Anchor Bolts (Make-Hilti) PDF

Hochgeladen von

Shino UlahannanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anchor Bolts (Make-Hilti) PDF

Hochgeladen von

Shino UlahannanCopyright:

Verfügbare Formate

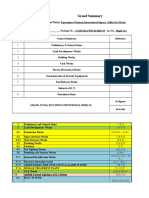

Product Data Sheet

HSA stud anchor

HSA stud anchor

Anchor version Benefits

small edge distance and spacing

three different embedment depth

HSA Carbon steel

for each anchor size

with DIN 125 washer

approved for diamond drilled

HSA-R Stainless holes

steel A4 simple and quick machine setting

HSA-R2 Stainless with torque bar for torque control

steel A2

with DIN 125 washer

HSA-BW Carbon

steel with DIN 9021

washer

A4

316

Concrete Small edge Fire Corrosion Diamond European CE PROFIS

distance resistance resistance drilled Technical conformity anchor design

& spacing holes Approval software

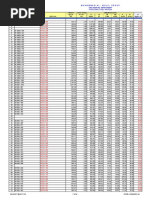

Basic loading data (for a single anchor)

All data in this section applies to

Correct setting (See setting instruction) Minimum base material thickness

Non cracked concrete C 20/25 fck,cube = 25 N/mm2

Steel failure

Recommended loads

Anchor size M6 M8 M10

Effective anchorage depth hef [mm] 30 40 60 30 40 70 40 50 80

Tensile Nrec a)

HAS, HAS-R [Nm] 3.7 4.5 5.4 4.9 7.7 9.6 7.7 10.7 15

Shear Vrec a)

HAS [Nm] 3.7 3.7 3.7 3.9 6.1 6.1 10.8 10.8 10.8

HAS-R [Nm] 4.0 4.1 4.1 3.9 7.0 7.0 12.9 12.9 12.9

Anchor size M12 M16 M20

Effective anchorage depth hef [mm] 50 65 100 65 80 120 75 100 115

Tensile Nrec a)

HAS, HAS-R [Nm] 10.7 15.9 20.9 15.9 21.7 30.0 19.7 30.4 37.3

Shear Vrec a)

HAS [Nm] 16.9 16.9 16.9 29.1 29.1 29.1 31.2 49.0 49.0

HAS-R [Nm] 16.7 16.7 16.7 32.3 32.3 32.3 31.2 52.5 52.5

shall be taken from national regulations.

page 1 February 2013

Product Data Sheet

HSA stud anchor

Description Authority / Laboratory No. / date of issue

European technical approval a) DIBt, Berlin ETA-11/0374 / 2012-07-19

Fire test report IBMB, Brunswick 3215/229/12 / 2012-08-09

a) All data given in this section according ETA-11/0374, issue 2012-07-19.

Setting details

Anchor size M6 M8 M10

Nominal anchorage depth hnom [mm] 37 47 67 39 49 79 50 60 90

Minimum base material

thickness hmin [mm] 100 100 120 100 100 120 100 120 160

Minimum spacing smin [mm] 35 35 35 35 35 35 50 50 50

Minimum edge distance c min [mm] 35 35 35 40 35 35 50 40 40

Nominal diameter of

drill bit do [mm] 6 8 10

Cutting diameter of

drill bit dcut [mm] 6.4 8.45 10.45

Depth of drill hole h1 [mm] 42 52 72 44 54 84 55 65 95

Diameter of clearance hole

df [mm] 7 9 12

Torque moment Tinat [Nm] 5 15 25

Width across SW [mm] 10 13 17

Anchor size M12 M16 M20

Nominal anchorage depth hnom [mm] 64 79 114 77 92 132 90 115 130

Minimum base material

thickness hmin [mm] 100 140 180 140 160 180 160 220 220

Minimum spacing smin [mm] 70 70 70 90 90 90 195 175 175

Minimum edge distance c min [mm] 70 65 55 80 75 70 130 120 120

Nominal diameter of

drill bit do [mm] 12 16 20

Cutting diameter of

drill bit dcut [mm] 12.5 16.5 20.55

Depth of drill hole h1 [mm] 72 87 122 85 100 140 98 123 138

Diameter of clearance hole

df [mm] 14 18 22

Torque moment Tinat [Nm] 50 80 200

Width across SW [mm] 19 24 30

page 2 February 2013

Product Data Sheet

HSA stud anchor

Setting instructions

Drill and clean borehole

Standard drilling method Alternative drilling method

M6 – M20: Hammer drilling (HD) M12 – M20: Diamond drilling (DD)

Install anchor with hammer or machine setting tool

Standard setting method Alternative setting method

M6 – M20: Hammer setting M8 – M16: Machnine setting

For detailed information on installation see instruction for use given with the package of the product.

page 3 February 2013

Product Data Sheet

HSA stud anchor

Machine tightening of the anchor for standard installation torque

Type HSA, HSA-BW, HSA-R2, HSA-R

Anchor size M6 M8 M10 M12 M16 M20

Setting position 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3

Nominal

anchorage depth hnom [mm] 37 47 67 39 49 79 50 60 90 64 79 114 77 92 132 90 115 130

Standard

installation torque Tinat [Nm] - 15 25 50 80 -

Setting tool S-TB HSA S-TB HSA S-TB HSA S-TB HSA

M8 M10 M12 M16

Impact screw driver Hilti SIW 14-A Hilti

Hilti SIW 22-A SIW 22T-A

- -

HSA, HSA-BW 1 1

Speed 3 - 1)

HSA-R2, HSA-R 3 3

Width across tsety [sec.] 4

Setting instruction for HSA, HSA-BW, HSA-R2 and HSA-R M8 – M16

Tightening the anchor - alternatively with imact screw driver and special socket

Selecting the impact screw driver, battery and special socket

Selecting the speed setting and state of charge of the battery

Tighten the anchor and check the installation

For detailed information on installation see instruction for use given with the package of the product.

page 4 February 2013

Das könnte Ihnen auch gefallen

- Bar Bending ScheduleDokument15 SeitenBar Bending ScheduleNAqash ArshadNoch keine Bewertungen

- C & Zed Purlins Design Manual and Catalogue BC783d01Dokument31 SeitenC & Zed Purlins Design Manual and Catalogue BC783d01GnabBangNoch keine Bewertungen

- BOlts ListDokument3 SeitenBOlts ListBikki Cyama100% (2)

- Peb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsDokument2 SeitenPeb Steel Structures Tolerance Table As Per Aisc: Builtup/ Hotroll BeamsSamsuNoch keine Bewertungen

- Fabrication Tolerances for Cold-Formed and Built-Up Structural MembersDokument4 SeitenFabrication Tolerances for Cold-Formed and Built-Up Structural MembersSyed Tauseef ShahNoch keine Bewertungen

- Working Stress Design Method and Its Assumptions With LimitationsDokument3 SeitenWorking Stress Design Method and Its Assumptions With LimitationsSmart KhanNoch keine Bewertungen

- Isolated Column Footing Design in ExcelDokument11 SeitenIsolated Column Footing Design in ExcelderdushaNoch keine Bewertungen

- Mitek 12kN Pile FixingDokument2 SeitenMitek 12kN Pile FixingTuroyNoch keine Bewertungen

- OneSteel Hot Rolled PropertiesDokument22 SeitenOneSteel Hot Rolled PropertiesRajeev SharanNoch keine Bewertungen

- E Z Wall 2006Dokument16 SeitenE Z Wall 2006nhulugallaNoch keine Bewertungen

- Design Example of Pipe Rack StructureDokument16 SeitenDesign Example of Pipe Rack StructureJimit PayNoch keine Bewertungen

- PF2Dokument4 SeitenPF2nhulugallaNoch keine Bewertungen

- CASTELLATED BEAM PropertiesDokument2 SeitenCASTELLATED BEAM PropertiesHemant SonawadekarNoch keine Bewertungen

- Software Verification: AISC-360-10 Example 001Dokument9 SeitenSoftware Verification: AISC-360-10 Example 001Davico HernandezNoch keine Bewertungen

- Revit To Advance Steel Collaboration Method AULON18281-AU2018 - JB - Powerpoint - Show - V2Dokument48 SeitenRevit To Advance Steel Collaboration Method AULON18281-AU2018 - JB - Powerpoint - Show - V2Fongho Eric SinclairNoch keine Bewertungen

- Calculating Length of Reinforcing BarsDokument3 SeitenCalculating Length of Reinforcing BarsswarluNoch keine Bewertungen

- Steel Connection Guide 211 EnuDokument64 SeitenSteel Connection Guide 211 EnuAnonymous TRthlKkWWNoch keine Bewertungen

- Steel Tables by R Agor, Birla Publications PDFDokument97 SeitenSteel Tables by R Agor, Birla Publications PDFankitNoch keine Bewertungen

- Constructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsDokument35 SeitenConstructions: Load Bearing Constructions Using Wood-Concrete-Composite Technique With Glued-In - Shear ConnectorsPATRICIO SARAVIANoch keine Bewertungen

- Retaining Wall Design Calculation Example: SolutionDokument12 SeitenRetaining Wall Design Calculation Example: SolutionhkgNoch keine Bewertungen

- ACI Deflection MOD MotiurDokument5 SeitenACI Deflection MOD Motiurbasum matNoch keine Bewertungen

- Base Plate Verification ExampleDokument10 SeitenBase Plate Verification ExampleffyuNoch keine Bewertungen

- Steel Section PropertiesDokument2 SeitenSteel Section Propertiesman.drakeNoch keine Bewertungen

- KDS 41 17 00 건축물 내진설계기준Dokument131 SeitenKDS 41 17 00 건축물 내진설계기준colt0Noch keine Bewertungen

- Sample Spiral Stair Assembly Drawing PDFDokument1 SeiteSample Spiral Stair Assembly Drawing PDFvna29710% (1)

- Design of Base Plate by EurocodeDokument13 SeitenDesign of Base Plate by EurocodeBharati MajlekarNoch keine Bewertungen

- SECTION 03490 Glass Fiber Reinforced Concrete (GFRC)Dokument17 SeitenSECTION 03490 Glass Fiber Reinforced Concrete (GFRC)SunilNoch keine Bewertungen

- Purlins: Rails Eaves Beams AccessoriesDokument48 SeitenPurlins: Rails Eaves Beams AccessoriesRam AravindNoch keine Bewertungen

- Purlins Technical PDFDokument8 SeitenPurlins Technical PDFРостислав ВасилевNoch keine Bewertungen

- HILTI Anchor Selection GuideDokument4 SeitenHILTI Anchor Selection Guidesebastian9033Noch keine Bewertungen

- HSFG Bolt PDFDokument6 SeitenHSFG Bolt PDFSatish PawarNoch keine Bewertungen

- Standard Hole and Slot Sizes for Bolted Steel ConnectionsDokument3 SeitenStandard Hole and Slot Sizes for Bolted Steel ConnectionsStephen KokoNoch keine Bewertungen

- Calculate decking capacity and recommended span for AP 70/215 steel profileDokument9 SeitenCalculate decking capacity and recommended span for AP 70/215 steel profileWaqar FaziNoch keine Bewertungen

- CivilBay Structural Engineering Spreadsheet Tutorial on Anchorage DesignDokument153 SeitenCivilBay Structural Engineering Spreadsheet Tutorial on Anchorage Designhatot100% (1)

- Structural Calculations For Metal Structure and Fence Legalization PlansDokument34 SeitenStructural Calculations For Metal Structure and Fence Legalization PlansAlejandro MorelNoch keine Bewertungen

- Staged Construction Analysis in STAADDokument7 SeitenStaged Construction Analysis in STAADNagar NitinNoch keine Bewertungen

- Stability Analysis - Direct Analysis Method - Staad Pro AISC 360Dokument4 SeitenStability Analysis - Direct Analysis Method - Staad Pro AISC 360chidsalazarNoch keine Bewertungen

- 1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandDokument79 Seiten1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandRianto FelissimoNoch keine Bewertungen

- Clubhouse Structural NotesDokument17 SeitenClubhouse Structural NotesCarlo Doragos100% (1)

- Reinforced concrete design of two-way slabsDokument8 SeitenReinforced concrete design of two-way slabsBehairy AhmedNoch keine Bewertungen

- Source: Aisc Shapes Database V14.0 American Hot Rolled Bars & Sections Per Aisc StandardDokument4 SeitenSource: Aisc Shapes Database V14.0 American Hot Rolled Bars & Sections Per Aisc StandardAldin AlicNoch keine Bewertungen

- SWD-CSA-A23.3-04 Shear Wall Design ManualDokument82 SeitenSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimNoch keine Bewertungen

- Schedule of anchor bolts and typical detailsDokument1 SeiteSchedule of anchor bolts and typical detailsShuvam SarkarNoch keine Bewertungen

- The Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsDokument12 SeitenThe Development of A New Design Procedure For Conventional Single-Plate Shear ConnectionsMiguelNoch keine Bewertungen

- Chapter 5 Buried Structures Bridge Plan Development GuideDokument43 SeitenChapter 5 Buried Structures Bridge Plan Development GuideBhoomika KhannaNoch keine Bewertungen

- SFD Csa S16 09Dokument116 SeitenSFD Csa S16 09Ly PisethNoch keine Bewertungen

- Shear Lug Verification Example 2Dokument1 SeiteShear Lug Verification Example 2Nasrul AdliNoch keine Bewertungen

- Circular Section Crack Width Under Pure TensionDokument1 SeiteCircular Section Crack Width Under Pure TensionAbinash ModakNoch keine Bewertungen

- GRATING ANALYSIS TOOLDokument32 SeitenGRATING ANALYSIS TOOLJuan PulidoNoch keine Bewertungen

- Glass ThicknessDokument2 SeitenGlass ThicknessShanil BussooaNoch keine Bewertungen

- Steel Sections Std.Dokument64 SeitenSteel Sections Std.Sayavi Nicole Sayavi Nick100% (3)

- BS 5950 Design Guide PDFDokument12 SeitenBS 5950 Design Guide PDFNuzhat Az0% (1)

- EFCO LITE Column and Hand E FormDokument7 SeitenEFCO LITE Column and Hand E FormsonymeganNoch keine Bewertungen

- AD 261 - Elastic Modulus of AnglesDokument1 SeiteAD 261 - Elastic Modulus of Anglessymon ellimacNoch keine Bewertungen

- Hilti Re500 Embedded LengthDokument1 SeiteHilti Re500 Embedded LengthPYAINoch keine Bewertungen

- Section Modulus Equations and Calculators Common Shapes: Got It!Dokument4 SeitenSection Modulus Equations and Calculators Common Shapes: Got It!Fatih AdamNoch keine Bewertungen

- HiltiDokument5 SeitenHilticipsiccNoch keine Bewertungen

- FTM 2012-11 HsaDokument35 SeitenFTM 2012-11 HsaSteven DierckNoch keine Bewertungen

- 175 013100Dokument2 Seiten175 013100Shino UlahannanNoch keine Bewertungen

- CFD Examination QuestionsDokument48 SeitenCFD Examination QuestionsGurleen KaurNoch keine Bewertungen

- Analytical Solution of PDEsDokument88 SeitenAnalytical Solution of PDEsRaul GonzalezNoch keine Bewertungen

- Response Spectra As A Useful Design and Analysis Tool For Practicing Structural EngineersDokument13 SeitenResponse Spectra As A Useful Design and Analysis Tool For Practicing Structural Engineersjay_medrano_1Noch keine Bewertungen

- Vibration modes and coordinatesDokument4 SeitenVibration modes and coordinatesShino UlahannanNoch keine Bewertungen

- ANSYS Buckling and Post-buckling AnalysisDokument6 SeitenANSYS Buckling and Post-buckling AnalysisShino UlahannanNoch keine Bewertungen

- 04 SAMSS 005 Check ValvesDokument9 Seiten04 SAMSS 005 Check ValvesShino UlahannanNoch keine Bewertungen

- ANSYS For Harmonic Transient and PSDDokument23 SeitenANSYS For Harmonic Transient and PSDMohammad Ahmad GharaibehNoch keine Bewertungen

- 04 SAMSS 051 Ball ValvesDokument11 Seiten04 SAMSS 051 Ball ValvesShino UlahannanNoch keine Bewertungen

- SAE - Rules PDFDokument50 SeitenSAE - Rules PDFShino UlahannanNoch keine Bewertungen

- Chemical compositions of common austenitic stainless steel gradesDokument4 SeitenChemical compositions of common austenitic stainless steel gradesShino UlahannanNoch keine Bewertungen

- Safehull Finite Element Analysis of Hull Structures: Guidance Notes OnDokument50 SeitenSafehull Finite Element Analysis of Hull Structures: Guidance Notes OntdfsksNoch keine Bewertungen

- Foundations of Materials Science and Engineering 5/e: Problems and Solutions To Smith/HashemiDokument71 SeitenFoundations of Materials Science and Engineering 5/e: Problems and Solutions To Smith/HashemiLoady DasNoch keine Bewertungen

- EPRI - Chapter 13Dokument42 SeitenEPRI - Chapter 13Shino Ulahannan100% (2)

- Density of Materials & Comparison of Ss 304 Vs Ss316LDokument4 SeitenDensity of Materials & Comparison of Ss 304 Vs Ss316LShino UlahannanNoch keine Bewertungen

- ARAMCO SPECTACLE BLIND SIZESDokument1 SeiteARAMCO SPECTACLE BLIND SIZESnedumaran.sNoch keine Bewertungen

- 28379tysaeedooler PDFDokument8 Seiten28379tysaeedooler PDFsaekNoch keine Bewertungen

- Advancing Thermoacoustics Through CFD SimulationDokument11 SeitenAdvancing Thermoacoustics Through CFD SimulationShino UlahannanNoch keine Bewertungen

- Astm A572 - 04Dokument1 SeiteAstm A572 - 04Hai TranNoch keine Bewertungen

- Fatigue Analysis of Composite Material - White PaperDokument2 SeitenFatigue Analysis of Composite Material - White PaperShino UlahannanNoch keine Bewertungen

- Astm A572 - 04Dokument1 SeiteAstm A572 - 04Hai TranNoch keine Bewertungen

- Civil - Modified Abst Estt..J-Shop 3rd BayDokument6 SeitenCivil - Modified Abst Estt..J-Shop 3rd BaysanjoybapiNoch keine Bewertungen

- 029D2B0002 (9000B2C) 9710astraluxDokument15 Seiten029D2B0002 (9000B2C) 9710astraluxAstraluxNoch keine Bewertungen

- Iso 898-7:1992Dokument7 SeitenIso 898-7:1992Anastasia Potapova50% (2)

- GSCC005 Rev3Dokument24 SeitenGSCC005 Rev3Palade CristiNoch keine Bewertungen

- Geze HardwareDokument40 SeitenGeze HardwareAhmed Adel ShatlaNoch keine Bewertungen

- Bolted JointsDokument13 SeitenBolted JointsGirish ChandranNoch keine Bewertungen

- Expansion of Osmani International AirportDokument563 SeitenExpansion of Osmani International AirportJayampathi AsangaNoch keine Bewertungen

- ENGEL E-Mac enDokument13 SeitenENGEL E-Mac enTim SawtellNoch keine Bewertungen

- L.D. College Structural Design TutorialsDokument7 SeitenL.D. College Structural Design Tutorialscuckoomodi1527Noch keine Bewertungen

- Continuous Assessment Test I: January 2019 Reg. No.Dokument2 SeitenContinuous Assessment Test I: January 2019 Reg. No.Venkatram PrabhuNoch keine Bewertungen

- Report KamcoDokument17 SeitenReport Kamcoshamins123Noch keine Bewertungen

- RateDokument372 SeitenRatethetpaing soeNoch keine Bewertungen

- Mason Seismic Restraint Guidelines PDFDokument234 SeitenMason Seismic Restraint Guidelines PDFsunmechanical100% (1)

- Parts List: Industrial Sewing MachinesDokument37 SeitenParts List: Industrial Sewing MachinesTharindu50% (2)

- Career Episode 3 Design and Analysis of An Electrical Grinding MachineDokument6 SeitenCareer Episode 3 Design and Analysis of An Electrical Grinding MachineNishar Alam Khan 19MCD0042Noch keine Bewertungen

- Ingersoll CAT-009 HoleM TechDokument30 SeitenIngersoll CAT-009 HoleM TechLLNoch keine Bewertungen

- Investigation of High-Strength Bolt-Tightening Verification TechniquesDokument51 SeitenInvestigation of High-Strength Bolt-Tightening Verification TechniquesTrung Trần BảoNoch keine Bewertungen

- BC03 Fire DamperDokument20 SeitenBC03 Fire DamperabhishekNoch keine Bewertungen

- Reeeeeeeeeeeeeport 2Dokument27 SeitenReeeeeeeeeeeeeport 2Mahantesh ValiNoch keine Bewertungen

- Owner's Manual Mode D'emploi Manual de Uso: CT50 SeriesDokument16 SeitenOwner's Manual Mode D'emploi Manual de Uso: CT50 SeriesRamSan LinTo DiabNoch keine Bewertungen

- Transport and Main Roads Specifications MRTS06 Reinforced Soil StructuresDokument24 SeitenTransport and Main Roads Specifications MRTS06 Reinforced Soil StructuresPak Hei LINoch keine Bewertungen

- Laboratory Glassware CatalogueDokument52 SeitenLaboratory Glassware CatalogueashkansoheylNoch keine Bewertungen

- Lokotrack LT1213S Parts ListDokument634 SeitenLokotrack LT1213S Parts ListFabian Cortes Serrano100% (13)

- Service Manual: Spring Brake ActuatorDokument24 SeitenService Manual: Spring Brake ActuatorPatricio G. ArrienNoch keine Bewertungen

- DIY Tutorial Pallet Coffee Table 1001palletsDokument11 SeitenDIY Tutorial Pallet Coffee Table 1001palletsPeggy RussellNoch keine Bewertungen

- Sunjoy A102008100 Assembly Instruction enDokument35 SeitenSunjoy A102008100 Assembly Instruction enTerrence JonesNoch keine Bewertungen

- 3 Cylinder Diesel Engine Turbocharger Parts ListDokument3 Seiten3 Cylinder Diesel Engine Turbocharger Parts ListMANUALESNoch keine Bewertungen

- Ford Figo Body Repair Manual B517 PDFDokument718 SeitenFord Figo Body Repair Manual B517 PDFjgarfield420Noch keine Bewertungen

- Oculus: Free Plan: Oculus Supercap FFDokument68 SeitenOculus: Free Plan: Oculus Supercap FFDarren-Edward O'NeillNoch keine Bewertungen

- 17-3 Metal Doors & WindowsDokument10 Seiten17-3 Metal Doors & WindowsZuberYousufNoch keine Bewertungen