Beruflich Dokumente

Kultur Dokumente

Design of POT-PTFE (Fixed)

Hochgeladen von

NONGTHONCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of POT-PTFE (Fixed)

Hochgeladen von

NONGTHONCopyright:

Verfügbare Formate

08/21/2018

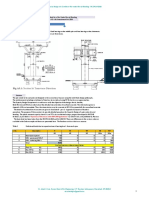

DESIGN OF 6400 KN CAPACITY FIXED POT BEARINGS FOR BRIDGE A/C GANDAK RIVER

DESIGN PARAMETERS : DT: 04/03/14

1) Grade of Concrete

a) Pedestal : 45 Mpa SIZE: 1400*1400 MM

b) Superstructure : 45 Mpa

2) Permissible Stress in Concrete

Normal Case Seismic Case

a) Bottom sb : 22.50 N/mm2 28.13 N/mm2

b) Top st : 22.50 N/mm2 28.13 N/mm2

3) Permissible Bearing Stress in Concrete

Normal Case Seismic Case

a) Bottom sbc : 14.85 N/mm2 18.56 N/mm2

b) Top stc : 14.85 N/mm2 18.56 N/mm2

4) Grade of Cast Steel : 340 -570W of IS:1030

Permissible stress in Cast Steel (Cl. 926.2.2) where fy = 340.0 N/mm2

sst : 204 N/mm 2

sp : 255 N/mm2

5) Vertical Load

a) Vmax : 6376.0 KN

b) Vmin : 2550.0 KN

c) Vmax-ses : 6376.0 KN

d) Vmin-ses : 2550.0 KN

6) Horizontal Force under Normal Condition

a) Longitudinal Hbf : 490.5 KN

b) Transverse Hbt : 319 KN

c) Resultant HRn : 585.11 KN

Since HRn < 10% of Vmax

HRn 637.60 KN (Cl. 926.1.4)

7) Since Horizontal Force in Longitudinal Seismic is more than Transverse Seismic and Wind Condition

\ Horizontal Force under Seismic Condition

a) Longitudinal Hsl : 1668 KN

b) Transverse Hst : 1717 KN

c) Resultant HRs : 1717.00 KN

HRs 1594.00 KN Hrs < 25% *Vmax (Cl. 926.1.4)

8) Rotation (Normal, Seismic)

a) Resultant Rotation, q : 0.01 radians

b) Resultant rotation due to permanent action and long term effects , qp : 0.0040 radians

c) Resultant rotation due to variable action , qv : 0.0060 radians

Assumed qp = 40 % of q & qv = 60.0063 % of q

Since D5 / Tn = 13.25 As per table 3 of IRC:83 (Part III)-2002 Cl. 926.1.5.1)

k1 = 2

k2 = 70

Confidential Tefcon Bearings P. Ltd. 1 of 8

08/21/2018

BEARING PARAMETERS 6400 KN QTY. : 03 Nos.

I) POT :

Effective diameter of bottom plate A1 = 730 mm

Diameter of Pot at Bottom A = 730 mm

Thickness of Pot at Base A2 = 50 mm

Depth of Pot A3 - A2 = 63.5 mm

Total Ht. of Pot A3 113.5

Outer Diameter of Pot A7 = 710 mm

Inner Diameter of Pot D5 = 530 mm

Horizontal Lever Arm A5 = 99 mm

Pot Thickness Pth = 90 mm

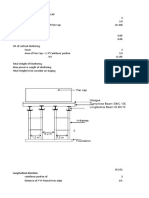

II) ELASTOMERIC PAD :

Diameter of Elastomeric Pad D5 = 530 mm

Thickness of Elastomeric Pad Tn = 40 mm

Effective Thickness of Elastomeric Pad Nt-eff = 36 mm

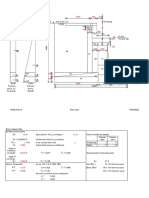

III) TOP PLATE :

Effective Diameter B1 = 730 mm

Diameter of Top Plate B = 730 mm

Diameter of Piston Dp = 528.75 mm

Diameter of Top plate at bottom face B3 = 525 mm

Thickness B2 = 51.25 mm

Overall thickness of Top Plate B6 = 83.25 mm

Distance of line of Horz. force from top B5 = 74.25 mm

Contact side width of Piston w = 18 mm

Piston recess Rc = 14 mm

IV) ANCHOR BOLT :

Diameter of Bolt Bf = 30 mm

Total Number of Bolts N = 8 nos.

Grade of Bolt = Grade 10.8

V) LUGS :

Length Ll = 100 mm

Width Ll = 100 mm

Thickness Lt = 33 mm

VI) ANCHOR SLEEVES :

Diameter of Sleeve D = 63 mm

Sleeve length for Bottom Lb = 450 mm

Sleeve length for Top Ls = 450 mm

Confidential Tefcon Bearings P. Ltd. 2 of 8

08/21/2018

DESIGN CHECK :

I) ELASTOMERIC PAD :

1) Diameter to Thickness Ratio (Cl. 926.2.3.6)

D5/Tn = 13.25 </= 15

2) Strain in Elastomer (Cl. 926.2.3.4)

tneo = 0.5 x D5 x q

Nt-eff

= 0.0736 </= 0.15

3) Average Compressive Stress under normal condition (Cl. 926.2.3.2)

sneo = Vmax x 1000

p/4 x D52

= 28.90 < 35 N/mm2

4) Average Compressive Stress under Seismic condition (Cl. 926.2.3.2)

sneo-ses = Vmax-ses x 1000

p/4 x D52

= 28.90 < 35 N/mm2

5) Minimum Average Stress (Cl. 926.2.3.3)

sneo-min = Vmin x 1000

p/4 x D52

= 11.56 > 5 N/mm2

6) Moment due to resistance to rotation due to tilting stiffness of elastomeric pad (Cl. 926.1.5.1)

Me-d = D5 x [(k1 x qp) +(k2 x qv)]

3

= 6.37E+07 N-mm

7) Moment due to friction at the piston-cylinder contact surface under normal condition (Cl. 926.1.5.2)

MR-d(n) = 0.2 x (D5 / 2) x HRn x 1000

= 3.38E+07 N-mm

8) Moment due to friction at the piston-cylinder contact surface under Seismic condition (Cl. 926.1.5.2)

MR-d(s) = 0.2 x (D5 / 2) x HRs x 1000

= 8.45E+07 N-mm

9) Total induce Moment under normal condition (Cl. 926.1.5.3)

MT-d(n) = Me-d + MR-d(n)

= 9.75E+07 N-mm

10) Total induce Moment under Seismic condition (Cl. 926.1.5.3)

MT-d(s) = Me-d + MR-d(s)

= 1.48E+08 N-mm

11) Compressive Stress in Neoprene at Edges under normal condition (Cl. 926.2.3.2)

sneo(edge) = sneo + MT-d(n)

p/32 x D53

= 35.57 < 40 N/mm2

12) Compressive Stress in Neoprene at Edges under Seismic condition (Cl. 926.2.3.2)

snoe-s(edge) = sneo-ses + MT-d(s)

p/32 x D53

= 39.04 < 40 N/mm2

13) Check for deflection at perimeter

Deflection at the perimeter = 0.5 X D5 X q

Tn

= 0.066 < 0.15

It is o.k.

Confidential Tefcon Bearings P. Ltd. 3 of 8

08/21/2018

II) POT :

1) Direct Bearing Stress in concrete due to vertical load under normal condition (Cl. 926.1.5)

sn = Vmax x 1000

p/4 x A12

= 15.23 < 22.5 N/mm2

2) Direct Bearing Stress in concrete due to vertical load under Seismic condition (Cl. 926.1.5)

sses = Vmax-ses x 1000

p/4 x A12

= 15.23 < 28.1 N/mm2

3) Flexural Stress due to active moment resulting from acting Horizontal Load under Normal Condition

sn-f = HRn x 1000 x A5

p/32 x A13

= 1.65 N/mm2

4) Flexural Stress due to active moment resulting from acting Horizontal Load under Seismic Condition

sses-f = HRs x 1000 x A5

p/32 x A13

= 4.13 N/mm2

5) Flexural Stress due to induced Moment resulting from resistance to Rotation under normal condition

sn-e = MT-d(n)

p/32 x A13

= 2.54 N/mm2

6) Flexural Stress due to induced Moment resulting from resistance to Rotation under Seismic condition

sses-e = MT-d(s)

p/32 x A13

= 3.88 N/mm2

7) Total Flexural stress under normal condition (Cl. 926.2.1.2)

sn-tf = sn-f + sn-e

= 4.19 < 14.85 N/mm2

8) Total Flexural stress under Seismic condition (Cl. 926.2.1.2)

sses-tf = sses-f + sses-e

= 8.01 < 18.56 N/mm2

9) Co-existing Direct & Flexural Stress under normal condition (Cl. 926.2.1.3)

sn + sn-tf = 0.95922 </= 1

sb sbc

10) Co-existing Direct & Flexural Stress under Seismic condition (Cl. 926.2.1.3)

sses + sses-tf = 0.97324 </= 1

1.25 x sb 1.25 x sbc

11) Hoop Stress in Pot under normal condition (Cl. 926.3.1.1.7.1)

Qn = (sneo x D5 x Tn) + (HRn x 1000)

2Pth x (A3-A2)

= 109.39 < 204 N/mm2

12) Hoop Stress in Pot under Seismic condition (Cl. 926.3.1.1.7.1)

Qs = (sneo-ses x D5 x Tn) + (HRs x 1000)

2Pth x (A3-A2)

= 193.06 < 204.0 N/mm2

13) Shear stress at cylinder wall and base interface considering 1mm radial slice under normal condition

Fluid Pressure tvm1 = sneo x Tn

Pth

= 12.84 N/mm2

Horizontal Pressure tvm2 = 1.5 x HRn x 1000

D5 x Pth

= 20.05 N/mm2

Total Shear Stress tvm = tvm1+ tvm2

= 32.89 < 153.0 N/mm2 (Cl. 926.3.1.1.7.2)

14) Bending stress at cylinder wall and base interface considering 1mm radial slice under normal condition

Fluid Pressure sbt1 = 6 x sneo x Tn 2

2 x Pth2

= 17.13 N/mm2

Horizontal Force sbt2 = 1.5 x 6 x HRn x 1000 x (Tn + w/2)

D5 x Pth2

= 65.50 N/mm2

Total Bending Stress sbt = sbt1 + sbt2

= 82.62 < 224.4 N/mm2 (Cl. 926.3.1.1.7.3)

Confidential Tefcon Bearings P. Ltd. 4 of 8

08/21/2018

15) Equivalent Combined Stress

seqc = (sbt + 3 x tvm )

2 2 1/2

= 100.36 < 306 N/mm2 (Cl. 926.3.1.1.7.4)

16) Shear stress at cylinder wall and base interface considering 1mm radial slice under Seismic condition

Fluid Pressure tvm1 = sneo-ses x Tn

Pth

= 12.84 N/mm2

Horizontal Pressure tvm2 = 1.5 x HRs x 1000

D5 x Pth

= 50.13 N/mm2

Total Shear Stress tvm = tvm1+ tvm2

= 62.97 < 153.0 N/mm2 (Cl. 926.3.1.1.7.2)

17) Bending stress at cylinder wall and base interface considering 1mm radial slice under Seismic condition

Fluid Pressure sbt1 = 6 x sneo-ses x Tn 2

2 x Pth2

= 17.13 N/mm2

Horizontal Force sbt2 = 1.5 x 6 x HRs x 1000 x (Tn + w/2)

D5 x Pth2

= 163.74 N/mm2

Total Bending Stress sbt = sbt1 + sbt2

= 180.87 < 224.4 N/mm2 (Cl. 926.3.1.1.7.3)

18) Equivalent Combined Stress

seqc = (sbt + 3 x t

2

vm

)

2 1/2

= 211.21 < 306.0 N/mm2 (Cl. 926.3.1.1.7.4)

III) TOP PLATE :

1) Average Compressive Stress in concrete under normal condition (Cl. 926.1.5)

sc(avt-n) = Vmax x 1000

p/4 x B12

= 15.23 < 22.50 N/mm2

2) Average Compressive Stress in concrete under Seismic condition (Cl. 926.1.5)

sc(avt-s) = Vmax-ses x 1000

p/4 x B12

= 15.23 < 28.13 N/mm2

3) Flexural Stress due to active moment resulting from acting Horizontal Load under Normal Condition

sc-f = HRn x 1000 x B5

p/32 x B13

= 1.24 N/mm2

4) Flexural Stress due to active moment resulting from acting Horizontal Load under Seismic Condition

sc(ses-f) = HRs x 1000 x B5

p/32 x B13

= 3.10 N/mm2

5) Flexural Stress due to induced Mome

.

sc(n-c) = MT-d(n)

p/32 x B13

= 2.55 N/mm2

6) Flexural Stress due to induced Moment resulting from resistance to Rotation under Seismic condition

sc(ses-c) = MT-d(s)

p/32 x B13

= 3.88 N/mm2

7) Total Flexural stress under normal condition (Cl. 926.2.1.2)

sct(n-f) = sc-f + sc(n-c)

= 3.79 < 14.85 N/mm2

8) Total Flexural stress under Seismic condition (Cl. 926.2.1.2)

sct(ses-f) = sc(ses-f) + sc(ses-c)

= 6.98 < 18.56 N/mm2

9) Co-existing Direct & Compressive Flexural Stress under normal condition (Cl. 926.2.1.3)

sc(avt-n) + sct(n-f) = 0.932 </= 1

st stc

10) Co-existing Direct & Compressive Flexural Stress under Seismic condition (Cl. 926.2.1.3)

sc(avt-s) + sct(ses-f) = 0.917597 </= 1

1.25 x st 1.25 xstc

Confidential Tefcon Bearings P. Ltd. 5 of 8

08/21/2018

11) Effective contact width of piston cylinder interface (Cl. 926.3.1.3.1)

Since HRs > HRn We

= 1.3*H/(6p*Dp)

= 15.33 mm < 18 mm (Provided)

12) Minimum Theoritical Depth of effective contact width of piston at design rotation

= A6 - Tn - We - q(D5 / 2)

= 5.52 mm > 5 mm (Cl. 926.3.1.3.3)

13) Minimum Theoretical clearance between the pot top & the Top plate bottom edge at design rotation

= hn -5.5- q(C3 / 2)

= 5.88 mm > 5 mm (Cl. 926.3.1.3.4)

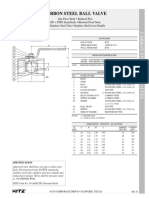

IV) ANCHOR BOLTS : (Cl. 926.3.6.2)

Size of bolts Bf = 30 mm

Effective area of bolt Ab = 572.265 mm2

Number of bolts n = 8

Co-efficient of friction between steel & concrete m = 0.2

Grade of Bolt = Grade 10.8

Permissible shear stress tvf = 237 N/mm2

i) Total resistive force against the shifting of bearing under normal condition

= Vmin x m + n x Ab x tvf

1000

= 1595.01 kN > HRn = 637.60 kN

ii) Total resistive force against the shifting of bearing under Seismic condition

= Vmin-ses x m + n x Ab x tvf

1000

= 1595.01 kN > HRs = 1594.00 kN

V) ANCHOR SLEEVES : (Cl. 926.3.6.5)

Diameter of Sleeve D = 63 mm

Sleeve length for Bottom Lb = 450 mm

Sleeve length for Top Ls = 450 mm

Peak stress scpk = 3 x Ab x tvf

DxL

Peak stress under Seismic condition

For Bottom Plate scpk = 14.35 < 18.73 N/mm2

For Top Plate scpk = 14.35 < 18.73 N/mm2

VI) LUGS

Thickness of Lug Lt = 33 mm

Length of Lug Ll = 100 mm

Area of Bolt Hole Ab = 804.25 mm2 1056

Area of Lugs Al = 3300.00 mm2

Effective area of lug Ae = 2495.75 mm2 ###

Horizontal force on each lug under normal condition

Hln = HRn

n

= 637.60

8

= 79.70 kN

Stress on lug due to horizontal force under normal condition

Sln = Hln x 1000

Ae

= 79700

2495.7504

= 31.93 < 153 N/mm2 35.51693

Horizontal force on each lug under Seismic condition

Hls = HRs

n

= 1594.00

8

= 199.25 kN

Stress on lug due to horizontal force under Seismic condition

Sls = Hls x 1000

Ae

= 199250

2495.7504

= 79.84 < 153 N/mm2 88.79234

Confidential Tefcon Bearings P. Ltd. 6 of 8

08/21/2018

Confidential Tefcon Bearings P. Ltd. 7 of 8

Grade 4.6 80

Grade 8.8 160

Grade 9.8 180

Grade 10.9 200

Das könnte Ihnen auch gefallen

- Bearing Pot Cum 27-08-2020Dokument48 SeitenBearing Pot Cum 27-08-2020Hymavathi MNoch keine Bewertungen

- FB. 60M - Free Bearing DesignDokument10 SeitenFB. 60M - Free Bearing DesignBasava SowmyaNoch keine Bewertungen

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementDokument9 Seiten2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilNoch keine Bewertungen

- Type FRB1. 333 Ton Free Sliding Bearing DesignDokument8 SeitenType FRB1. 333 Ton Free Sliding Bearing DesignAnkush SharmaNoch keine Bewertungen

- POT Design R0Dokument9 SeitenPOT Design R0VB665Noch keine Bewertungen

- Detailed Design of Free Pot BearingDokument7 SeitenDetailed Design of Free Pot BearingDevesh SinghNoch keine Bewertungen

- Longitudinal BearingDokument6 SeitenLongitudinal BearingDPJAIN INFRASTRUCTURENoch keine Bewertungen

- Final Pot Ptfe Design Sheet - 02.01.13Dokument47 SeitenFinal Pot Ptfe Design Sheet - 02.01.13Sandeep Kumar75% (4)

- RDSO B 11754 4R1 (Mod)Dokument1 SeiteRDSO B 11754 4R1 (Mod)shibnath lahiriNoch keine Bewertungen

- Calculate spherical bearing loadsDokument5 SeitenCalculate spherical bearing loadsSHARATH VASUPRADA100% (1)

- ELASTOMERIC and POT PTFEDokument10 SeitenELASTOMERIC and POT PTFESwapnil KNoch keine Bewertungen

- Design of Elastomeric Bearing: (For Effective Span of 20.95M)Dokument8 SeitenDesign of Elastomeric Bearing: (For Effective Span of 20.95M)vivekNoch keine Bewertungen

- Elastomeric Bearing DesignDokument22 SeitenElastomeric Bearing DesignRudra Sharma50% (2)

- PSC Girder-25m R0Dokument148 SeitenPSC Girder-25m R0infra120100% (1)

- Extradosed Cable Stayed Bridge Design in BSDokument111 SeitenExtradosed Cable Stayed Bridge Design in BSSANDIPNoch keine Bewertungen

- Prof Ashok Jain - Example On Bi-Axial Bending IRC SP 114-App A3Dokument10 SeitenProf Ashok Jain - Example On Bi-Axial Bending IRC SP 114-App A3Ankit GuptaNoch keine Bewertungen

- Cable stayed bridge analysis and designDokument80 SeitenCable stayed bridge analysis and designamir100% (2)

- 1.0 Bearing-38.973 (Skew)Dokument37 Seiten1.0 Bearing-38.973 (Skew)vinoraamNoch keine Bewertungen

- Design of Laminated Elastomeric Bearing for 20m SpanDokument8 SeitenDesign of Laminated Elastomeric Bearing for 20m Spannaresh KUMARNoch keine Bewertungen

- Rdso B-11753 5R1Dokument1 SeiteRdso B-11753 5R1shibnath lahiriNoch keine Bewertungen

- Typical Design Calculations of PierDokument40 SeitenTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- Design of Elastomeric Bearing Based On IRC 083-2-1987Dokument4 SeitenDesign of Elastomeric Bearing Based On IRC 083-2-1987Babita SharmaNoch keine Bewertungen

- STUP Consultants P. LTD.: Input DataDokument35 SeitenSTUP Consultants P. LTD.: Input Dataraja mistryNoch keine Bewertungen

- RDSO composite girder Web and flange splice designDokument8 SeitenRDSO composite girder Web and flange splice designAnonymous sfkedkymNoch keine Bewertungen

- Load Combinations Section 12Dokument23 SeitenLoad Combinations Section 12avikshit yNoch keine Bewertungen

- PipeDokument30 SeitenPipepudumai100% (1)

- DESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFDokument33 SeitenDESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFShashibhushan SinghNoch keine Bewertungen

- ISO-Certified HDPE Pipe ManufacturerDokument4 SeitenISO-Certified HDPE Pipe Manufacturerdhopat kalpeshNoch keine Bewertungen

- Design of Thrust Bed: Proposed Construction of Rubs in Lieu of LC NO. 293A AT KM 882/700-800Dokument11 SeitenDesign of Thrust Bed: Proposed Construction of Rubs in Lieu of LC NO. 293A AT KM 882/700-800Saurabh PandeyNoch keine Bewertungen

- Design of Gap SlabDokument15 SeitenDesign of Gap Slabvivek100% (1)

- Fatigue Check in Prestressed GirderDokument3 SeitenFatigue Check in Prestressed GirderViplawNoch keine Bewertungen

- Box Culvert Design ParametersDokument18 SeitenBox Culvert Design ParametersPrafulla MallaNoch keine Bewertungen

- NHAI Bridge Design StagingDokument9 SeitenNHAI Bridge Design StagingMasud AminNoch keine Bewertungen

- Paradip Port Connectivity Project Temperature Gradient CalculationsDokument79 SeitenParadip Port Connectivity Project Temperature Gradient CalculationsSM ConsultantsNoch keine Bewertungen

- Amendment To IRC 24 - 2010Dokument6 SeitenAmendment To IRC 24 - 2010mrraee4729100% (1)

- IRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFDokument4 SeitenIRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFJayantNoch keine Bewertungen

- RDSO Guidelines On Seismic Design of Railway Bridges PDFDokument95 SeitenRDSO Guidelines On Seismic Design of Railway Bridges PDFSreeraja Sreevilasan57% (7)

- IRC 6-2017 Ammendment (Nov-17)Dokument9 SeitenIRC 6-2017 Ammendment (Nov-17)avisek_basuNoch keine Bewertungen

- Design of Pot Ptfe Bearing (Fixed Bearing) As Per Irc 83:2002 (Part 3)Dokument7 SeitenDesign of Pot Ptfe Bearing (Fixed Bearing) As Per Irc 83:2002 (Part 3)DPJAIN INFRASTRUCTURE100% (1)

- Superstructure Design: Maligaon R.O.B Design of PSC Superstructure Superstructure/1Dokument47 SeitenSuperstructure Design: Maligaon R.O.B Design of PSC Superstructure Superstructure/1Er Arabinda Kumar DharNoch keine Bewertungen

- Return Wall 10mDokument23 SeitenReturn Wall 10mAkhil Singhal100% (2)

- Creep and shrinkage calculations for concrete memberDokument5 SeitenCreep and shrinkage calculations for concrete memberNabeel Ahmad50% (2)

- Design of Abutment A2 for Road Project in GujaratDokument44 SeitenDesign of Abutment A2 for Road Project in GujaratNilay Gandhi100% (5)

- Loads On Pot - Ptfe Bearing - 3x17m SpanDokument12 SeitenLoads On Pot - Ptfe Bearing - 3x17m SpanMalayKumarDebNoch keine Bewertungen

- Government of Odisha National Highways: Rajlaxmi Constructions LimitedDokument4 SeitenGovernment of Odisha National Highways: Rajlaxmi Constructions LimitedSaudagar Biswal100% (1)

- Design of Abutment on Open FoundationDokument22 SeitenDesign of Abutment on Open FoundationAnonymous wosn1lyNoch keine Bewertungen

- Steel Plate Girder (41.38m) - R0Dokument58 SeitenSteel Plate Girder (41.38m) - R0ShaileshRastogiNoch keine Bewertungen

- Design of PSC Cross Girder As Per IRC 112Dokument2 SeitenDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- Design of centering for pier cap beamDokument10 SeitenDesign of centering for pier cap beamSantosh ReddyNoch keine Bewertungen

- Scour Depth and Bearing Pressure CalculationDokument46 SeitenScour Depth and Bearing Pressure Calculationinfra120Noch keine Bewertungen

- DN-101A-Design of Friction Slab-R1Dokument4 SeitenDN-101A-Design of Friction Slab-R1jithinNoch keine Bewertungen

- Commentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersDokument3 SeitenCommentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersNarayanan Jayachandran100% (3)

- Type FXB1. 333 Ton Fixed Bearing DesignDokument7 SeitenType FXB1. 333 Ton Fixed Bearing DesignAnkush SharmaNoch keine Bewertungen

- Free POT/PTFE BearingDokument25 SeitenFree POT/PTFE BearingZakee MohamedNoch keine Bewertungen

- 4.3.5.tap BS ConnectionDokument30 Seiten4.3.5.tap BS ConnectionAnh KyNoch keine Bewertungen

- Project Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Dokument30 SeitenProject Code: 719002 Document No.: CAL-1-004-C-0001 Date: 30/08/2023 REV: 2Anh KyNoch keine Bewertungen

- Pile Cap 10P-PC7Dokument6 SeitenPile Cap 10P-PC7balaji gmscNoch keine Bewertungen

- Design of Square Footing For A Recta Sloped Footing: Check For Development LengthDokument44 SeitenDesign of Square Footing For A Recta Sloped Footing: Check For Development LengthSwarna LathaNoch keine Bewertungen

- Column Splice Plate DesignDokument4 SeitenColumn Splice Plate Designinnovativekarthi100% (1)

- Idn - 3Dokument6 SeitenIdn - 3Anh KyNoch keine Bewertungen

- Amendment No 1 To IRC 112 2014 PDFDokument3 SeitenAmendment No 1 To IRC 112 2014 PDFNONGTHONNoch keine Bewertungen

- Interview Question and AnswerDokument1 SeiteInterview Question and AnswerNONGTHONNoch keine Bewertungen

- SP 071 2006 PDFDokument28 SeitenSP 071 2006 PDFTranslink BilaspurNoch keine Bewertungen

- SP 071 2006 PDFDokument28 SeitenSP 071 2006 PDFTranslink BilaspurNoch keine Bewertungen

- Continous Beam SFD BMD DEFLECTIONDokument2 SeitenContinous Beam SFD BMD DEFLECTIONNONGTHONNoch keine Bewertungen

- Reinforced Concrete Column Interaction DiagramDokument34 SeitenReinforced Concrete Column Interaction DiagramNONGTHONNoch keine Bewertungen

- Spcolumn Engineering Software Program Manual V6.50: F ' 5000 Psi FDokument1 SeiteSpcolumn Engineering Software Program Manual V6.50: F ' 5000 Psi FNONGTHONNoch keine Bewertungen

- Amendment No. 1 To IRC 112 - 2014 PDFDokument3 SeitenAmendment No. 1 To IRC 112 - 2014 PDFmrraee4729100% (3)

- Ammendment To IRC 112 - 2Dokument2 SeitenAmmendment To IRC 112 - 2NONGTHONNoch keine Bewertungen

- Interview Question and Answer 6Dokument2 SeitenInterview Question and Answer 6NONGTHONNoch keine Bewertungen

- Circular Column Interaction Diagram (ACI 318-14Dokument1 SeiteCircular Column Interaction Diagram (ACI 318-14NONGTHONNoch keine Bewertungen

- Aci 209 R21Dokument44 SeitenAci 209 R21Hao LuoNoch keine Bewertungen

- Circular-Reinforced-Concrete-Column-Interaction-Diagram-ACI318-14 3Dokument1 SeiteCircular-Reinforced-Concrete-Column-Interaction-Diagram-ACI318-14 3NONGTHONNoch keine Bewertungen

- Interaction Diagram - Circular Reinforced Concrete Column (ACI 318-14)Dokument1 SeiteInteraction Diagram - Circular Reinforced Concrete Column (ACI 318-14)NONGTHONNoch keine Bewertungen

- Interview Question and Answer 5Dokument2 SeitenInterview Question and Answer 5NONGTHONNoch keine Bewertungen

- Interview Question and Answer3Dokument2 SeitenInterview Question and Answer3NONGTHONNoch keine Bewertungen

- 5 LossesDokument11 Seiten5 LossesJohn Michael SubionNoch keine Bewertungen

- Prestressed Concrete BasicsDokument2 SeitenPrestressed Concrete BasicsNONGTHONNoch keine Bewertungen

- Shear Connector BehaviourDokument10 SeitenShear Connector BehaviourNONGTHONNoch keine Bewertungen

- Concrete Bridge V K RainaDokument788 SeitenConcrete Bridge V K RainaNONGTHONNoch keine Bewertungen

- Wrana 2015 4 PDFDokument11 SeitenWrana 2015 4 PDFarslanpasaNoch keine Bewertungen

- Prestressed Concrete StructuresDokument35 SeitenPrestressed Concrete StructuresAmar WadoodNoch keine Bewertungen

- Piles DesignDokument15 SeitenPiles Designvenkatesh19701Noch keine Bewertungen

- Socketing Details-IsO 7595Dokument8 SeitenSocketing Details-IsO 7595NONGTHONNoch keine Bewertungen

- Comportamiento y Diseño de Puentes Extradosados PDFDokument176 SeitenComportamiento y Diseño de Puentes Extradosados PDFJulio Rafael Terrones Vásquez100% (1)

- Ijser: Design of Well FoundationDokument6 SeitenIjser: Design of Well FoundationKARAN SINGLA 15BCL0073Noch keine Bewertungen

- Pile Dynamic Test Report PDFDokument61 SeitenPile Dynamic Test Report PDFNONGTHONNoch keine Bewertungen

- Cable Stay Bridge RFPDokument67 SeitenCable Stay Bridge RFPNONGTHONNoch keine Bewertungen

- LRB Non-LinearDokument24 SeitenLRB Non-LinearGeEs AnggaNoch keine Bewertungen

- Design and Construction of Cable Stayed Bridges in The Czech RepublicDokument20 SeitenDesign and Construction of Cable Stayed Bridges in The Czech Republicwcano94Noch keine Bewertungen

- ALD Doping ReviewDokument18 SeitenALD Doping ReviewbismuthsunilNoch keine Bewertungen

- MINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSDokument17 SeitenMINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSAris TesoroNoch keine Bewertungen

- Cooling TowerDokument12 SeitenCooling Towernhalieza1067Noch keine Bewertungen

- Aramid Dyeing CHT PDFDokument18 SeitenAramid Dyeing CHT PDFno1gandhi9770Noch keine Bewertungen

- Metalkraft - Decking and Roofing Brochure - NEWDokument6 SeitenMetalkraft - Decking and Roofing Brochure - NEWParthasarathi H RNoch keine Bewertungen

- Beseva Group Product Listing for Bleaching, Dyeing, Finishing and Printing ChemicalsDokument9 SeitenBeseva Group Product Listing for Bleaching, Dyeing, Finishing and Printing ChemicalsNoumanKhanNoch keine Bewertungen

- PDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVDokument34 SeitenPDQXDO GH LDYDYDMLOODV LQVWUXFFLRQHVjarroyojNoch keine Bewertungen

- A Detailed Lesson Plan in ScienceDokument4 SeitenA Detailed Lesson Plan in SciencemarigoldNoch keine Bewertungen

- V0L2 PDFDokument4 SeitenV0L2 PDFJohannie Nina ClaridadNoch keine Bewertungen

- Subgrade Rutting Flexible PavementDokument5 SeitenSubgrade Rutting Flexible PavementPalak ShivhareNoch keine Bewertungen

- Concrete Works Method StatementDokument6 SeitenConcrete Works Method StatementmemekenyaNoch keine Bewertungen

- Junction-Box-Para Instalaciones EléctricasDokument3 SeitenJunction-Box-Para Instalaciones EléctricasOSCAR EDGARDO ARIAS CABEZANoch keine Bewertungen

- Test 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleDokument13 SeitenTest 1 Paper2 - Grade 10-11 IGCSE - 2020 - MoodleJadNoch keine Bewertungen

- Underwater Concreting With Rescon TDokument12 SeitenUnderwater Concreting With Rescon TPrateek JainNoch keine Bewertungen

- Cotton ListDokument22 SeitenCotton ListL.N.CHEMICAL INDUSTRYNoch keine Bewertungen

- Water Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaDokument8 SeitenWater Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaVijay PanchalNoch keine Bewertungen

- CH 5 Coordination CompoundsDokument53 SeitenCH 5 Coordination Compoundsgerawop972Noch keine Bewertungen

- Astm F 442-99Dokument7 SeitenAstm F 442-99JORGE ARTURO TORIBIO HUERTA100% (2)

- CH1104 Chapter 8Dokument90 SeitenCH1104 Chapter 8Chuah Chong YangNoch keine Bewertungen

- KHKKKDokument39 SeitenKHKKKdaney67299Noch keine Bewertungen

- AP Chemistry Unit 6 worksheet key conceptsDokument5 SeitenAP Chemistry Unit 6 worksheet key conceptsburcak gecNoch keine Bewertungen

- Eye ShadowDokument40 SeitenEye ShadowYuni WidyastutiNoch keine Bewertungen

- Dow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in PolyethyleneDokument1 SeiteDow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in Polyethylenefengshaohua_gmailNoch keine Bewertungen

- Advanced Level Problems: Q. No. 1 To 3 (3 Questions)Dokument78 SeitenAdvanced Level Problems: Q. No. 1 To 3 (3 Questions)Saravanan BNoch keine Bewertungen

- Beton Dizayn ProgramiDokument4 SeitenBeton Dizayn Programibarış sökeNoch keine Bewertungen

- Tanginl SeawallDokument12 SeitenTanginl SeawallKing LemuelNoch keine Bewertungen

- Disperse DyeDokument8 SeitenDisperse DyeSifat RaihanNoch keine Bewertungen

- UPVC Litaflex Conduit & FittingDokument10 SeitenUPVC Litaflex Conduit & FittingSara NuonNoch keine Bewertungen

- Carbon Steel Ball Valve: Code # 50 (Aksctk)Dokument1 SeiteCarbon Steel Ball Valve: Code # 50 (Aksctk)thilina lakhithaNoch keine Bewertungen

- THEORITICAL RAW MIX DESIGNDokument3 SeitenTHEORITICAL RAW MIX DESIGNVaibhav Khodake100% (4)