Beruflich Dokumente

Kultur Dokumente

Bosch CR Pumps Test Data PDF

Hochgeladen von

Inyectronix VyhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bosch CR Pumps Test Data PDF

Hochgeladen von

Inyectronix VyhCopyright:

Verfügbare Formate

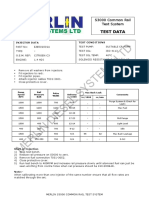

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 002

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FIAT 4645 2567

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

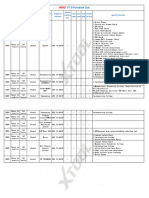

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 003

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FIAT 4643 2242

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 006

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- FIAT 4652 2786

Test Oil Temperature- 40 C

EM

Engine:- 185A 6 000 2.4JTD

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

N

Mm3st/ccmin

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 007

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 540/54

LI

2 500 300 510/225

3 1000 500 510/510

ER

4 1000 1000 340/340

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 510/1020

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 008

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031-3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031-3051 to Fuel Pump.

Connect Fuel Pump Cable T031-3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 550/275

3 1000 500 550/550

ER

4

5 1000 1000 Max 10% less More Than

than 3 500/500

M

6 2000 1350 550/1100

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 009

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R70/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- BMW 13 51 2 247 798

Test Oil Temperature- 40 C

EM

Engine:- 30 6 D1

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

3. RESISTANCES

MERLIN S3000 COMMON RAIL TEST SYSTEM

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 - 20

2 - 3.5-3.7 - 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 010

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 16S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- PSA 1920 CY

Test Oil Temperature- 40 C

EM

Engine:- PSA RHY/RHZ 2.0 HDi

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4 1000 500 Activate Aux >400/400

Button

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 011

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

LI

1 500 300 510/255

2 1000 500 510/510

ER

3 1000 500 Activate Aux n/a

Button

4 1000 1000 Max 10% less More Than

than 3 460/460

M

5 2000 1350 510/1020

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 013

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031-3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031-3051 to Fuel Pump.

Connect Fuel Pump Cable T031-3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 550/275

3 1000 500 550/550

ER

4

5 1000 1000 Max 10% less More Than

than 3 500/500

M

6 2000 1350 550/1100

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 018

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT 7700101016

Test Oil Temperature- 40 C

EM

Engine:- F9Q- 732 1.9 DCi Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

N

mm3st/ccmin

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 019

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1K3/L70/10- 6S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB 612 070 00 01

Test Oil Temperature- 40 C

EM

Engine:- OM612- 961/962/963/967

Direction of Rotation - L

ST

Fit T016- 693 fuel inlet kit to pump.

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type PCV to test rail (ie 0281002873).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 - 20

2 - 3.5-3.7 - 40

D

- -

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 021

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R70/10- 16S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- PSA 1920 AL

Test Oil Temperature- 40 C

EM

Engine:- PSA 4HX /RHW 2.2 HDi

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4 1000 500 Activate Aux >420/420

Button

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 024

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031-3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031-3051 to Fuel Pump.

Connect Fuel Pump Cable T031-3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 550/275

3 1000 500 550/550

ER

4

5 1000 1000 Max 10% less More Than

than 3 500/500

M

6 2000 1350 550/1100

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 028

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/L70/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT 8200 010 076

Test Oil Temperature- 40 C

EM

Engine:- G9T- 710 2.2DCi

Direction of Rotation - L

ST

Fit T016- 693 fuel inlet kit to pump.

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type PCV to test rail (ie 0281002873).

Connect Fuel Pump Cable T031- 3002 to PCV

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 - 20

2 - 3.5-3.7 - 40

D

- -

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 029

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L110/30- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB 628 070 01 01

Test Oil Temperature- 40 C

EM

Engine:- OM628.960/961

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

Pressure BAR

LI

1 350 250 1.5-2.0

ER

2 1000 500 4.0-5.0

3 2000 1350 2.5-3.0

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

1 100 300 970/97

2 500 300 1100/550

3 1000 500 1100/1100

D

4 1000 1000 Max 10% less More Than

than 3 950/950

LT

5 2000 1350 1000/2000

S

3. RESISTANCES

EM

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

Resistance TEMP °C

1 - 2.8-3.2 - 20

ST

2 - 3.2-3.6 - 40

- - SY

4. SCV Operation

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

EL

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Cm/1000

S

1 1000 NOM Pump Drv 100% 1100/1100

2 1000 NOM Pump Drv 50% Nil

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 030

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1K3/L70/10- 6S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB 612 070 01 01

Test Oil Temperature- 40 C

EM

Engine:- OM612- 981

Direction of Rotation - L

ST

Fit T016- 693 fuel inlet kit to pump.

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type PCV to test rail (ie 0281002873).

Connect Fuel Pump Cable T031- 3002 to PCV And shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4 1000 500 Activate Aux <420/420

Button

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

D

- -

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 031

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT 8200 037 472

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 032

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1K3/L70/10- 6S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB 612 070 02 01

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Fit T016- 693 fuel inlet kit to pump.

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type PCV to test rail (ie 0281002873).

Connect Fuel Pump Cable T031- 3002 to PCV And shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4 1000 500 Activate Aux <420/420

Button

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

D

- -

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Pump Designation:- 0 445 010 033 Testing Prerequisites

LT

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L70/

0- 8911S Test Oil Specification- ISO 4113

Manufacturer I.D.:-

S

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

S

5 2000 1350 600/1200

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 034

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- VM 3502 2087F

Test Oil Temperature- 40 C

EM

Engine:- CHRYSLER 2.5CRDI

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 038

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1K3/R70/10S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- HYUNDAI 33100 27000

Test Oil Temperature- 40 C

EM

Engine:- D4EA

Direction of Rotation - R

ST

Fit T016- 693 fuel inlet kit to pump.

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type PCV to test rail (ie 0281002873).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 500/50

LI

2 500 300 640/320

3 1000 500 650/650

ER

4

5 1000 1000 Max 10% less More Than

than 3 580/580

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 - 20

2 - 3.5-3.7 - 40

D

- -

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 039

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- ISUZU 897227 0264

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 042

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- PSA 1920 EC 96373173

Test Oil Temperature- 40 C

EM

Engine:- 8HX / 8HZ

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 045

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 89S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- BMW 1351 7 787199

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 046

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 16S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- PSA 1920 EA

Test Oil Temperature- 40 C

EM

Engine:- PSA RHY/RHS 2.0 HDi

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

N

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4 1000 500 Activate Aux >400/400

Button

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 047

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- TOYOTA

Test Oil Temperature- 40 C

EM

Engine:- D- 4D 1.4

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 048

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L70/20- 89S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB611 070 14 01

Test Oil Temperature- 40 C

EM

Engine:- OM646- 962/982

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 052

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- KIA/HYUNDAI

33100- 4A000 Test Oil Temperature- 40 C

EM

Engine:- D4CB

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 071

Inlet Feed Pressure - 1.5 BAR

Type Designation:-

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:-

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

N

1 100 300 540/54

LI

2 500 300 510/225

3 1000 500 510/510

ER

4 1000 1000 340/340

5 1000 1000 Max 10% less More Than

than 3 540/540

M

6 2000 1350 510/1020

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 072

Inlet Feed Pressure - 1.5 BAR

Type Designation:- CR/CP1S3/R65/10- 1S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- LANCIA 75301003

Test Oil Temperature- 40 C

EM

Engine:- 841 M 000 THESIS 2.4 JTD

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Remove Fuel Pump PCV and fit to test rail. Fit Blank T031- 3051 to Fuel Pump.

Connect Fuel Pump Cable T031- 3002 to PCV and element Shut off valve.

SY

1. RUNNING IN/LEAK TEST

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

EL

1 350 250 15 Secs No Unusual noise

2 2000 500 3 Mins No Leaks and

S

3 2000 1500 No abnormal

IE

Temperature rise.

2. FUEL DELIVERY

D

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

N

mm3st/ccmin

1 100 300 560/56

LI

2 500 300 600/300

3 1000 500 600/600

ER

4

5 1000 1000 Max 10% More Than

less than 3 540/540

M

6 2000 1350 600/1200

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. RESISTANCES

Test Bench Speed - RPM PCV Resistance Shut off Valve INLET FUEL

Resistance TEMP °C

1 - 2.5-2.7 23-24 20

2 - 3.5-3.7 26-27 40

- -

D

LT

S

EM

ST

SY

S EL

IE

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 075

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT 8200 108 225

OPEL 9109268 Test Oil Temperature- 40 C

EM

Engine:- 1.9DCI

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 076

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- ISUZU 897227 0264

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 082

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L110/30- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- VW 057 130 755 G

Test Oil Temperature- 40 C

EM

Engine:- AUDI 4.0 ASE

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

Pressure BAR

LI

1 350 250 1.5-2.0

ER

2 1000 500 4.0-5.0

3 2000 1350 2.5-3.0

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

1 100 300 970/97

2 500 300 1100/550

3 1000 500 1100/1100

D

4 1000 1000 Max 10% less More Than

than 3 950/950

LT

5 2000 1350 1000/2000

S

3. RESISTANCES

EM

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

Resistance TEMP °C

1 - 2.8-3.2 - 20

ST

2 - 3.2-3.6 - 40

- - SY

4. SCV Operation

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

EL

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

S

1 1000 NOM Pump Drv 1100/1100

100%

IE

2 1000 NOM Pump Drv Nil

50%

D

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 084

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- VM 35022103F

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% More Than

less than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 085

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- TOYOTA

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 086

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- OPEL 97327924

Test Oil Temperature- 40 C

EM

Engine:- Z17 DTL/DTH

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

Mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 087

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- RENAULT 8200 229 004

Test Oil Temperature- 40 C

EM

Engine:- F9Q803/804

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv Nil

50%

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 088

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- TOYOTA 22100- ON010

Test Oil Temperature- 40 C

EM

Engine:- D- 4D 1.4

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 089

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/R70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- PSA 1920 FL

FORD3M5Q 9A 543AA Test Oil Temperature- 40 C

EM

Engine:- 9HZ/9HY

Direction of Rotation - R

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

S

5 2000 1350 600/1200

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 093

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L70/20- 789S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- HONDA 16410RBDE000

Test Oil Temperature- 40 C

EM

Engine:-

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N

Remove one suction valve cover from fuel pump and fit T016- 702 Transfer pressure

adaptor and connect to bench pressure gauge.

LI

Test Bench Speed - RPM Rail Pressure - BAR Comments Transfer

ER

Pressure BAR

1 350 250 1.5-2.0

2 1000 500 4.0-5.0

M

3 2000 1350 2.5-3.0

MERLIN S3000 COMMON RAIL TEST SYSTEM

3. FUEL DELIVERY

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

mm3st/ccmin

D

1 100 300 500/50

2 500 300 640/320

LT

3 1000 500 650/650

4 1000 1000 Max 10% less More Than

than 3 580/580

5 2000 1350 600/1200

S

EM

3. RESISTANCES

Test Bench Speed - RPM SCV Resistance Temp Sender INLET FUEL

ST

Resistance TEMP °C

1 - 2.8-3.2 - 20

2 - 3.2-3.6 - 40

SY

- -

4. SCV Operation

EL

Connect lead T031- 3002 to fuel pump Suction Control Valve

Set test unit T031- 3000 to SCV.

S

Test Bench Speed - RPM Rail Pressure - BAR Comments Delivery

IE

Mm3st/ccmin

1 1000 NOM Pump Drv 650/650

100%

D

2 1000 NOM Pump Drv 50% Nil

N

LI

ER

M

MERLIN S3000 COMMON RAIL TEST SYSTEM

S3000 Common Rail

Test System

TEST DATA

D

Testing Prerequisites

LT

Pump Designation:- 0 445 010 096

Inlet Feed Pressure - 0.2 BAR

Type Designation:- CR/CP3S3/L70/20- 8911S

Test Oil Specification- ISO 4113

S

Manufacturer I.D.:- DB 640 070 06 01

Test Oil Temperature- 40 C

EM

Engine:- OM640- 940/941/942

Direction of Rotation - L

ST

Remove injector pipes from test rail and blank off with T031- 3005

Fit Bosch type Pressure control valve to test rail (ie 0 281 200 872).

Connect Fuel Pump Cable T031- 3002 to PCV.

SY

Set S3000 test unit to ‘PCV’

1. RUNNING IN/LEAK TEST

EL

Test Bench Speed - RPM Rail Pressure - BAR Conditions Comments

1 350 250 15 Secs No Unusual noise

S

2 2000 500 3 Mins No Leaks and

3 2000 1500 No abnormal

IE

Temperature rise.

D

2. Transfer Pressure

N