Beruflich Dokumente

Kultur Dokumente

Fatigue Finglow Calculation

Hochgeladen von

Govindan KrishnamoorthybashyamCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Fatigue Finglow Calculation

Hochgeladen von

Govindan KrishnamoorthybashyamCopyright:

Verfügbare Formate

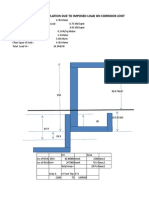

Finglow Software Verification Manual ASME VIII Div.

14. Cyclic Loading

14.1 FATIGUE ANALYSIS

Design data

Units - N mm degrees C

Fatigue Assessment - Yes

Bolted - No

Temperature deg.C 130.000

Design data

Material spec - A516-70:K02700

Fatigue curve - 5-110.1 (UTS <= 80)

Calculate stresses - Yes

Cylindrical shell - Yes

I/O Diameter - Internal

Inside diameter mm 2500.000

New thickness mm 15.000

Tolerance - Absolute

Thinning mm 0.000

Corrosion: int mm 0.000

Corrosion: ext mm 0.000

Calc nozzle SCF - Yes

Local SCF - 1.200

Nozzle data

Opening ident -

Nozzle OD-ID-NB - Internal

Nozzle ID mm 400.000

Nozzle thk mm 20.000

Tolerance - Absolute

Thinning mm 0.000

Issue 16 Document No. SP-6002-1 Page 14.1

ASME VIII Div.1 Cyclic Loading Finglow Software

Cyclic Loading data

Col.1

Description - Test

Pressure MPa 3.500

Pressure MPa 0.000

Reqd cycles n - 1.000

Col.2

Description - Upset

Pressure MPa 1.500

Pressure MPa 0.000

Reqd cycles n - 20.000

Col.3

Description - Oper

Pressure MPa 2.500

Pressure MPa 0.000

Reqd cycles n - 30000

Col.4

Description - Shut

Pressure MPa 1.300

Pressure MPa 0.000

Reqd cycles n - 50000

Page 14.2 Document No. SP-6002-1 Issue 16

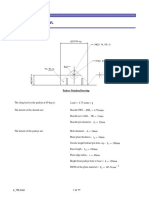

Finglow Software Cyclic Loading ASME VIII Div.1

Output data

Col.1

Description Test

Stress S.rij = D 2515 MPa 1050.5

= = 83.83

2t 2 × 15

3.5 × 83.83 × 3.58

Stress S.rij = MPa 0.0

Reqd cycles n = - 1.0

Col.2

Description Upset

Stress S.rij = 1.5 × 83.83 × 3.58 MPa 450.2

Stress S.rij = MPa 0.0

Reqd cycles n = - 20.0

Col.3

Description Oper

Stress S.rij = 2.5 × 83.83 × 3.58 MPa 750.3

Stress S.rij = MPa 0.0

Reqd cycles n = - 30000.0

Col.4

Description Shut

Stress S.rij = 1.3 × 83.83 × 3.58 MPa 390.2

Stress S.rij = MPa 0.0

Reqd cycles n = - 50000.0

Cyclic Loading data

From 5-110.1M (UTS <= 552)

E = 207000

E 207000

Ratio = = 1.055

196200 196200

Col.1

Stress S.alt = MPa 525.2

Reqd cycles n = - 1.0

Permitted cycles = S.alt × ratio = 525.2 × 1.055 = 554.15 MPa - 1088.0

From Table 5-110.1M = 1088

Usage factor = 1 percent 9.19E-02

× 100

1088

Col.2

Stress S.alt = MPa 375.2

Reqd cycles n = - 20.0

Issue 16 Document No. SP-6002-1 Page 14.3

ASME VIII Div.1 Cyclic Loading Finglow Software

Permitted cycles = S.alt × ratio = 375.2 × 1.055 = 395.83 MPa - 2824.0

From Table 5-110.1M = 2824.0

Usage factor = 20 percent 0.7

× 100

2842

Col.3

Stress S.alt = MPa 375.2

Reqd cycles n = - 29980.0

Permitted cycles = S.alt × ratio = 375.2 × 1.055 = 395.83 MPa - 2824.0

From Table 5-110.1M = 2824.0

Usage factor = 29980 percent 1061.6

× 100

2824

Col.4

Stress S.alt = MPa 195.1

Reqd cycles n = - 50000.0

Permitted cycles = S.alt × ratio = 195.1 × 1.055 = 205.82 MPa - 22551

From Table 5-110.1M = 22551

Usage factor = 50000 percent 221.7

× 100

22551

Miscellaneous data

Total SCF = D = 2500 + 15 = 2515 - 3.58

d = 400 + 20 = 420

T = 15

t = 20

d t D

2.0 + 2 d + 1.25

d

D D T T

D

=

t d t

1+

T DT

420 20 2515

2.0 + 2 × 420 × × + 1.25 ×

420

×

2515 15 15

2515 2515

20 420 20

1+ × ×

15 2515 15

= 2.98 × 1.2

Usage factor = 0.092 + 0.7 + 1061.6 + 221.7 percent 1285.00

Material data

Material spec - A516-70:K02700

Elastic mod E MPa 196200.0

Data: ASME II Part D Table TM-1 CS C <= 0.3% (M)

Warnings

Usage factor

Page 14.4 Document No. SP-6002-1 Issue 16

Das könnte Ihnen auch gefallen

- Discrete Element Method to Model 3D Continuous MaterialsVon EverandDiscrete Element Method to Model 3D Continuous MaterialsNoch keine Bewertungen

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceVon EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceNoch keine Bewertungen

- PV Elite ResultDokument239 SeitenPV Elite ResultChaitanya Sai TNoch keine Bewertungen

- SEISMIC ANALYSIS KazzincDokument14 SeitenSEISMIC ANALYSIS KazzincArees KhambattaNoch keine Bewertungen

- Stiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselDokument4 SeitenStiffening Ring Design On PV Elite For External Pressure Acting On Thin Walled Cylindrical Mounded VesselEstuardo Javier Gan RodríguezNoch keine Bewertungen

- PV Newsletter - Skirt Connections PDFDokument5 SeitenPV Newsletter - Skirt Connections PDFDivyesh PatelNoch keine Bewertungen

- V-340 OutDokument14 SeitenV-340 OutSachin5586Noch keine Bewertungen

- API Standard Storage Tank Data Sheet Rev 0Dokument3 SeitenAPI Standard Storage Tank Data Sheet Rev 0Guilherme B. BatistaNoch keine Bewertungen

- CR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFDokument3 SeitenCR4 - Thread - How To Calculate Flat Plate Thickness of Flat Bottom Storage Tank - PDFInamullah KhanNoch keine Bewertungen

- WRC Stress Analysis - NozzleDokument14 SeitenWRC Stress Analysis - NozzlevijayanmksNoch keine Bewertungen

- Wind Analysis ResultsDokument8 SeitenWind Analysis ResultsBrahim HammamiNoch keine Bewertungen

- Example 4Dokument4 SeitenExample 4dane05Noch keine Bewertungen

- 2400 Tema DCDokument7 Seiten2400 Tema DCMasoodMiyanNoch keine Bewertungen

- Lug Analysis - MechaniCalcDokument21 SeitenLug Analysis - MechaniCalcArunkumar RackanNoch keine Bewertungen

- BAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogieDokument7 SeitenBAEK Et Al. Fatigue Life Prediction Based On The Rainflow Cycle Counting Method For The End Beam of A Freight Car BogiePPNNoch keine Bewertungen

- 2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFDokument12 Seiten2015 - Finite Element Modelling of Debonding Failures in Steel Beams Flexurally Strengthened With CFRP Laminates - Teng Fernando Yu PDFvlad lupasteanuNoch keine Bewertungen

- Design of ShaftDokument8 SeitenDesign of ShaftPavan BabhaleNoch keine Bewertungen

- Sample21 SpreadsheetDokument20 SeitenSample21 SpreadsheetSivateja NallamothuNoch keine Bewertungen

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDokument4 Seiten3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNoch keine Bewertungen

- Power Correlation For Anchor and Helical Ribbon Impellers in Highly Viscous LiquidsDokument4 SeitenPower Correlation For Anchor and Helical Ribbon Impellers in Highly Viscous LiquidsJulián Jair Cadena Sánchez100% (1)

- Is 14812 2005Dokument12 SeitenIs 14812 2005JayDeep KhajureNoch keine Bewertungen

- Ce 5660: Design of Metal Structures Term Project: Design of A Pipe RackDokument10 SeitenCe 5660: Design of Metal Structures Term Project: Design of A Pipe RackFayaz HabeebNoch keine Bewertungen

- Spreaer Beam&Lifting Line Beam p3Dokument2 SeitenSpreaer Beam&Lifting Line Beam p3Sabrang LorNoch keine Bewertungen

- CHABOCHE, J. L. - Continuum Damage Mechanics P.2 - Damage Growth, Crack InitiationDokument8 SeitenCHABOCHE, J. L. - Continuum Damage Mechanics P.2 - Damage Growth, Crack InitiationhasmonteiroNoch keine Bewertungen

- Pin Base ModuleDokument16 SeitenPin Base ModuleMd Ahsanul KabirNoch keine Bewertungen

- Ansys Lug and Pin Stress AnalysesDokument30 SeitenAnsys Lug and Pin Stress AnalysesAmm WillulNoch keine Bewertungen

- Compress Manual 2.4.'Dokument19 SeitenCompress Manual 2.4.'sksiddiqueNoch keine Bewertungen

- PEC EN STN C 13619 17 Mar 2014Dokument169 SeitenPEC EN STN C 13619 17 Mar 2014Raja RamNoch keine Bewertungen

- 22BMJ 045 FEA 07 - Rev 0 - 23.07.05Dokument13 Seiten22BMJ 045 FEA 07 - Rev 0 - 23.07.05TEP DesignNoch keine Bewertungen

- USD T BeamDokument10 SeitenUSD T BeammanowarNoch keine Bewertungen

- Spring CalculationDokument3 SeitenSpring CalculationAkshay JadhavNoch keine Bewertungen

- Connecting Bolts Represented As Beam ElementsDokument19 SeitenConnecting Bolts Represented As Beam ElementsJoshua KarthikNoch keine Bewertungen

- Lecture 10 - MDPE - Design of Support - Bracket SupportDokument29 SeitenLecture 10 - MDPE - Design of Support - Bracket SupportPatel DhruvilNoch keine Bewertungen

- 6 - CE 511 - Base Plate Design PDFDokument33 Seiten6 - CE 511 - Base Plate Design PDFJayson RamosNoch keine Bewertungen

- Bolt Tensioning - E411 - GB PDFDokument2 SeitenBolt Tensioning - E411 - GB PDF4jawwy markme026Noch keine Bewertungen

- Wind Analysis For Vortex SheddingDokument14 SeitenWind Analysis For Vortex SheddingMakhzumi Muhammad UmarNoch keine Bewertungen

- Horizontal Vessel Support: Vertical Saddle ReactionsDokument12 SeitenHorizontal Vessel Support: Vertical Saddle ReactionsSanket BhaleraoNoch keine Bewertungen

- Deflection Calculation Due To Imposed Load On Corridor JoistDokument14 SeitenDeflection Calculation Due To Imposed Load On Corridor JoistranjitNoch keine Bewertungen

- PV Enineering EHX - OutDokument144 SeitenPV Enineering EHX - OutRAHUL KAVAR100% (1)

- PVEfea Assembly AnalysisDokument20 SeitenPVEfea Assembly AnalysisAnandh PsNoch keine Bewertungen

- PV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2Dokument15 SeitenPV Elite: Input Echo, Leg & Lug Item 1, Description: Trunnion 1-2SYedZYnAleNoch keine Bewertungen

- Vacuum Basics: Kinetic Theory of GasDokument19 SeitenVacuum Basics: Kinetic Theory of GasFederico LeonNoch keine Bewertungen

- CAEPIPE Users ManualDokument257 SeitenCAEPIPE Users ManualFATIMA TORRADO CASASNoch keine Bewertungen

- Comp 2Dokument9 SeitenComp 2YYo YudiNoch keine Bewertungen

- Calculations For Rectangular Storage TankDokument44 SeitenCalculations For Rectangular Storage TankSiva ShankarNoch keine Bewertungen

- Wind Load On Dish AntennaDokument1 SeiteWind Load On Dish AntennadovermanNoch keine Bewertungen

- Design-II, 2016 Bevel Gear Design ProcedureDokument1 SeiteDesign-II, 2016 Bevel Gear Design ProcedureenggsantuNoch keine Bewertungen

- WRC Loadings and Sign ConventionDokument9 SeitenWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamNoch keine Bewertungen

- Fatigue Analysis and Repair of A High Mast Light Pole: SynopsisDokument14 SeitenFatigue Analysis and Repair of A High Mast Light Pole: SynopsisjaffliangNoch keine Bewertungen

- H200141 - Calculation of Basering Rev 0 PDFDokument9 SeitenH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNoch keine Bewertungen

- Trunnion 6 TonDokument3 SeitenTrunnion 6 TonEngr Khurram Jaan RamayNoch keine Bewertungen

- Beams On Elastic FoundationsDokument3 SeitenBeams On Elastic FoundationsIgnatius SamrajNoch keine Bewertungen

- Shear Failure of Bolted Joints - ME 372 Lab: Bolt DataDokument1 SeiteShear Failure of Bolted Joints - ME 372 Lab: Bolt Databoo huNoch keine Bewertungen

- Mathcad - 4 - 75tDokument4 SeitenMathcad - 4 - 75tsereNoch keine Bewertungen

- ANSYS - Tips and TricksDokument84 SeitenANSYS - Tips and Tricksmanel_drNoch keine Bewertungen

- Tips For FEA AnalysisDokument6 SeitenTips For FEA Analysissagar1503Noch keine Bewertungen

- Seismic Load Calculation of The Tank As Per IS 1893Dokument1 SeiteSeismic Load Calculation of The Tank As Per IS 1893ParthibanNoch keine Bewertungen

- Fatigue Screeing StepsDokument2 SeitenFatigue Screeing StepsBashu PoudelNoch keine Bewertungen

- Design of Pressure VesselsDokument8 SeitenDesign of Pressure Vesselsanswer1Noch keine Bewertungen

- Rules For Classification: ShipsDokument17 SeitenRules For Classification: ShipsbrammiNoch keine Bewertungen

- Lec9 PDFDokument16 SeitenLec9 PDFGovindan KrishnamoorthybashyamNoch keine Bewertungen

- WRC Nozzle LoadsDokument3 SeitenWRC Nozzle LoadsGovindan KrishnamoorthybashyamNoch keine Bewertungen

- Intro To VA Terms & ConceptsDokument20 SeitenIntro To VA Terms & ConceptsGovindan KrishnamoorthybashyamNoch keine Bewertungen

- WRC Loadings and Sign ConventionDokument9 SeitenWRC Loadings and Sign ConventionGovindan KrishnamoorthybashyamNoch keine Bewertungen

- WRC Data-ModifiedDokument40 SeitenWRC Data-ModifiedGovindan KrishnamoorthybashyamNoch keine Bewertungen

- Nozzle LoadsDokument8 SeitenNozzle LoadsGovindan KrishnamoorthybashyamNoch keine Bewertungen

- Leveraging Competing and Complementary Roles For Success Inr&DDokument44 SeitenLeveraging Competing and Complementary Roles For Success Inr&DGovindan KrishnamoorthybashyamNoch keine Bewertungen

- PED Guideline 7-5Dokument1 SeitePED Guideline 7-5Govindan KrishnamoorthybashyamNoch keine Bewertungen

- Api 661 PDFDokument2 SeitenApi 661 PDFGovindan KrishnamoorthybashyamNoch keine Bewertungen

- Effect of Elemental Sulfur On Pitting Corrosion of SteelsDokument8 SeitenEffect of Elemental Sulfur On Pitting Corrosion of SteelsGovindan KrishnamoorthybashyamNoch keine Bewertungen

- TNY Cat6aDokument8 SeitenTNY Cat6aDávid DobóNoch keine Bewertungen

- Handbook of Driver Assistance SystemsDokument25 SeitenHandbook of Driver Assistance SystemsGeorge Florin CaraimanNoch keine Bewertungen

- STEM Education: MathsDokument28 SeitenSTEM Education: MathsChin Hua Chong100% (2)

- Water Cement RatioDokument16 SeitenWater Cement RatioNArendra REddyNoch keine Bewertungen

- 02 Compression TestDokument8 Seiten02 Compression TestWaleed ShakilNoch keine Bewertungen

- UEP Engineering Items of Interest 1998Dokument40 SeitenUEP Engineering Items of Interest 1998EIGENVAL249100% (1)

- NX CAD CAM AutomationDokument12 SeitenNX CAD CAM AutomationfalexgcNoch keine Bewertungen

- Labview BrochureDokument2 SeitenLabview BrochurebrittoajaychatNoch keine Bewertungen

- Module 3 Fields of Civil EngineeringDokument30 SeitenModule 3 Fields of Civil Engineeringtenya boostersNoch keine Bewertungen

- ALia ApartmentsDokument2 SeitenALia ApartmentsGeorge DanielNoch keine Bewertungen

- Vibrating Wire PiezometersDokument2 SeitenVibrating Wire Piezometerssatriaputra ekaNoch keine Bewertungen

- Construction Method Statement FOR RCC Boundry Wall With Precast Panel & ColumnDokument8 SeitenConstruction Method Statement FOR RCC Boundry Wall With Precast Panel & Columnkhurshidoman123Noch keine Bewertungen

- Constitutive Modelling of Granular MaterialsDokument556 SeitenConstitutive Modelling of Granular MaterialsAnupEkboteNoch keine Bewertungen

- NewRPP GradeCardDokument3 SeitenNewRPP GradeCardAmbuj KumarNoch keine Bewertungen

- WABO Bridge and Highway BrochureDokument20 SeitenWABO Bridge and Highway BrochureRiccardo MordecaNoch keine Bewertungen

- Finit Element Simulation Using ANSYSDokument429 SeitenFinit Element Simulation Using ANSYSNaseem Atia100% (1)

- Presentation PrefabDokument19 SeitenPresentation PrefabvuhalamNoch keine Bewertungen

- BOQ Piling WorksDokument4 SeitenBOQ Piling WorksRiffki Still Riffki50% (4)

- Analysis of Precast Multistoreyed Building - A Case Study: I J I R S E TDokument9 SeitenAnalysis of Precast Multistoreyed Building - A Case Study: I J I R S E TalexanderNoch keine Bewertungen

- Endorsed Mini Project Oct21 Feb22 Student Ver (With Rubric)Dokument5 SeitenEndorsed Mini Project Oct21 Feb22 Student Ver (With Rubric)Faiz JaafarNoch keine Bewertungen

- Design in Modular ConstructionDokument278 SeitenDesign in Modular ConstructionChristianJohandaCostaNoch keine Bewertungen

- Unti 1 WtledDokument2 SeitenUnti 1 WtledSajeevan SunthararrajahNoch keine Bewertungen

- Commentary To Assessment and Improvement of Unreinforced Masonry Buildings For Earthquake ResistanceDokument315 SeitenCommentary To Assessment and Improvement of Unreinforced Masonry Buildings For Earthquake ResistanceJuan Carlos Jiménez PachecoNoch keine Bewertungen

- Introduction To Project Chapter-1: 1.1 OverviewDokument27 SeitenIntroduction To Project Chapter-1: 1.1 OverviewNir PatelNoch keine Bewertungen

- Assignment-1 Computer Aided Manufacturing ME-418Dokument21 SeitenAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79Noch keine Bewertungen

- PVC Pipes & Fittings ManufacturerDokument5 SeitenPVC Pipes & Fittings ManufacturershandgroupNoch keine Bewertungen

- Habib Construction ServicesDokument16 SeitenHabib Construction ServicesShahid SaleemNoch keine Bewertungen

- Electrical Design & Detailed Engineering 1Dokument391 SeitenElectrical Design & Detailed Engineering 1Nasro100% (2)

- 400 Bad Request 400 Bad Request Nginx/1.2.9Dokument103 Seiten400 Bad Request 400 Bad Request Nginx/1.2.9Shobeir TabasiNoch keine Bewertungen

- Doubler JointsDokument3 SeitenDoubler JointsManoj Manoharan100% (1)