Beruflich Dokumente

Kultur Dokumente

ASTM D95-05 (Metodo de Prueba Estandar para Agua en Productos Del Petroleo y Materiales Bituminosos Por Destilación) PDF

Hochgeladen von

Daniel FelipeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASTM D95-05 (Metodo de Prueba Estandar para Agua en Productos Del Petroleo y Materiales Bituminosos Por Destilación) PDF

Hochgeladen von

Daniel FelipeCopyright:

Verfügbare Formate

Highway Transportation Standard

Designation: D95 – 05 (Reapproved 2010) AASHTO No. T55

Designation: Manual of Petroleum Measurement Standards (MPMS), Chapter 10.5

Designation: 74/82 (88)

Standard Test Method for

Water in Petroleum Products and Bituminous Materials by

Distillation1

This standard is issued under the fixed designation D95; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D1796 Test Method for Water and Sediment in Fuel Oils by

1.1 This test method covers the determination of water in the Centrifuge Method (Laboratory Procedure) (API

the range from 0 to 25 % volume in petroleum products, tars, MPMS Chapter 10.6)

and other bituminous materials by the distillation method. D4006 Test Method for Water in Crude Oil by Distillation

(API MPMS Chapter 10.2)

NOTE 1—Volatile water-soluble material, if present, may be measured D4057 Practice for Manual Sampling of Petroleum and

as water.

Petroleum Products (API MPMS Chapter 8.1)

1.2 The specific products considered during the develop- D4177 Practice for Automatic Sampling of Petroleum and

ment of this test method are listed in Table 1. For bituminous Petroleum Products (API MPMS Chapter 8.2)

emulsions refer to Test Method D244. For crude oils, refer to D5854 Practice for Mixing and Handling of Liquid Samples

Test Method D4006 (API MPMS Chapter 10.2). of Petroleum and Petroleum Products (API MPMS Chapter

NOTE 2—With some types of oil, satisfactory results may be obtained 8.3)

from Test Method D1796 (API MPMS Chapter 10.6). E123 Specification for Apparatus for Determination of Wa-

ter by Distillation

1.3 The values stated in SI units are to be regarded as the

2.2 API Standards:3

standard. The values in parentheses are for information only.

MPMS Chapter 8.1 Manual Sampling of Petroleum and

1.4 This standard does not purport to address all of the

Petroleum Products (ASTM Practice D4057)

safety concerns, if any, associated with its use. It is the

MPMS Chapter 8.2 Automatic Sampling of Petroleum and

responsibility of the user of this standard to establish appro-

Petroleum Products (ASTM Practice D4177)

priate safety and health practices and determine the applica-

MPMS Chapter 8.3 Mixing and Handling of Liquid Samples

bility of regulatory limitations prior to use. For specific hazard

of Petroleum and Petroleum Products (ASTM Practice

statements, see Section 6.

D5854)

2. Referenced Documents MPMS Chapter 10.2 Determination of Water in Crude Oil

2.1 ASTM Standards:2 by the Distillation Method (ASTM Test Method D4006)

D244 Test Methods and Practices for Emulsified Asphalts MPMS Chapter 10.6 Test Method for Water and Sediment in

Fuel Oils by the Centrifuge Method (Laboratory Proce-

dure) (ASTM Test Method D1796)

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and the API Committee on Petroleum Measure- 3. Terminology

ment, and is the direct responsibility of Subcommittee D02.02 /COMQ, the joint

ASTM-API Committee on Hydrocarbon Measurement for Custody Transfer (Joint 3.1 Definitions:

ASTM-API).

Current edition approved May 1, 2010. Published May 2010. Originally

approved in 1921. Last previous edition approved in 2005 as D95–05. DOI:

10.1520/D0095-05R10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Published as Manual of Petroleum Measurement Standards. Available from

Standards volume information, refer to the standard’s Document Summary page on American Petroleum Institute (API), 1220 L. St., NW, Washington, DC 20005-4070,

the ASTM website. http://www.api.org..

Copyright (C) ASTM International, 100 Barr Harbor Dr. PO Box C-700, West Conshohocken, PA. USA

Copyright by ASTM Int'l (all rights reserved); 1

D95 – 05 (2010)

3.1.1 bituminous material, n—in petroleum technology, a 6.1.3.2 Iso-octane, of 95% purity or better. (Warning—

black or dark-colored very viscous liquid or semi-solid com- Extremely flammable. Harmful if inhaled. Vapors may cause

posed principally of high molecular weight condensed aro- fire.)

matic, or naphthenic compounds, or both. 6.2 Solvent Blank—The water content of the solvent shall

be determined by distilling an equivalent amount of the same

4. Summary of Test Method solvent used for the test sample in the distillation apparatus and

4.1 The material to be tested is heated under reflux with a testing as outlined in Section 10. The blank shall be determined

water-immiscible solvent, which co-distills with the water in to the nearest scale division and used to correct the volume of

the sample. Condensed solvent and water are continuously water in the trap in Section 11.

separated in a trap, the water settling in the graduated section

of the trap and the solvent returning to the still. 7. Apparatus

5. Significance and Use 7.1 General—The apparatus comprises a glass or metal

still, a heater, a reflux condenser, and a graduated glass trap.

5.1 A knowledge of the water content of petroleum products

The still, trap, and condenser may be connected by any suitable

is important in the refining, purchase, sale, and transfer of

method that produces a leakproof joint. Preferred connections

products.

are ground joints for glass and O-rings for metal to glass.

5.2 The amount of water as determined by this test method

Typical assemblies are illustrated in Fig. 1, Fig. 2, and Fig. 3.

(to the nearest 0.05 or 0.1 volume %, depending on the trap

The stills and traps should be chosen to cover the range of

size used) may be used to correct the volume involved in the

materials and water contents expected. On assembly, care shall

custody transfer of petroleum products and bituminous mate-

be taken to prevent the joints from freezing or sticking. Always

rials.

apply a very thin film of stopcock grease to prevent the

5.3 The allowable amount of water may be specified in

glassware joints from seizing.

contracts.

7.2 Still—A glass or metal vessel with a short neck and

6. Solvent-Carrier Liquid suitable joint for accommodating the reflux tube of the trap

6.1 A solvent-carrier liquid appropriate to the material being shall be used. Vessels of 500, 1000, and 2000-mL nominal

tested (see Table 1) shall be used. capacity have proved satisfactory.

6.1.1 Aromatic Solvent—The following aromatic solvents 7.3 Heater—A suitable gas burner or electric heater may be

are acceptable: used with the glass still. A gas ring burner with ports on the

6.1.1.1 Industrial Grade Xylene—(Warning—Flammable. inside circumference shall be used with the metal still. The gas

Vapor harmful.) ring burner shall be of such dimensions that it may be moved

6.1.1.2 A blend of 20 volume % industrial grade toluene and up and down the vessel when testing materials that are likely to

80 volume % industrial grade xylene. (Warning—Flammable. foam or solidify in the still.

Vapor harmful.) 7.4 Glassware—Dimensions and descriptions of typical

6.1.1.3 Petroleum Naphtha or Coal Tar Naphtha, free of glassware for use in this test method are provided in Specifi-

water, yielding not more than 5% distillates at 125°C (257°F) cation E123.

and not less than 20% at 160°C (320°F) and with a relative NOTE 3—Instead of standardizing on a particular apparatus specifica-

density (specific gravity) not lower than 0.8545 at 15.56/ tion with respect to dimensions and style, a given apparatus will be

15.56°C (60/60°F). (Warning—Extremely flammable. Harm- deemed satisfactory when accurate results are obtained by the standard

ful if inhaled. Vapors may cause fire.)

6.1.2 Petroleum Distillate Solvent—A petroleum distillate

solvent, 5% boiling between 90 and 100°C (194 and 212°F)

and 90% distilling below 210°C (410°F), shall be used. Percent

may be determined by mass or by volume. (Warning—

Flammable. Vapor harmful.)

6.1.3 Volatile Spirits Solvent—The following volatile spirits

solvents are acceptable:

6.1.3.1 Petroleum Spirit, with a boiling range from 100 to

120°C (212 to 248°F). (Warning—Flammable. Vapor harm-

ful.)

TABLE 1 Type of Solvent-Carrier Liquid Versus Material to Be

Tested

Type of Solvent-Carrier Liquid Material to be Tested

Aromatic asphalt, tar, coal tar, water gas tar, road

tar, cut-back bitumin, liquid asphalt, tar

acid

Petroleum distillate road oil, fuel oil, lubricating oil, petroleum

sulfonates

Volatile spirits lubricating grease

FIG. 1 Typical Assembly with Glass Still

Copyright by ASTM Int'l (all rights reserved); 2

D95 – 05 (2010)

9.1.2 In styles E and F, as specified in Table 2, each major

subdivision (0.1 mL, 1.0 mL, 2.0 mL, 4.0 mL, and 5.0 mL in

the case of Style E; 0.05 mL, 0.5 mL, 1.0 mL, 1.5 mL, and 2.0

mL in the case of Style F) shall be verified.

9.2 The entire glassware assembly shall be verified prior to

first use and at a regular frequency thereafter as follows.

9.2.1 Put 400 mL of dry (0.02 % water maximum) xylene or

the solvent to be utilized in the analysis of unknown samples

into the apparatus and test in accordance with Section 10.

When complete, discard the contents of the trap and add the

volume of water as specified as first test in Table 3 directly to

the distillation flask and test in accordance with Section 10.

9.2.2 Repeat the test in 9.2.1, and add the volume specified

as second test in Table 3 directly to the flask. The assembly of

the apparatus is satisfactory only if the trap readings are within

the tolerances specified in Table 3.

9.3 A reading outside the permissible limits suggests a

malfunction resulting from vapor leaks, too rapid boiling,

inaccuracies in calibration of the trap, or ingress of extraneous

FIG. 2 Two-millilitre Receiver Showing Alternative Connections to moisture. Eliminate these factors before repeating the verifica-

Glass Still tion.

addition technique described in Section 9. 10. Procedure

NOTE 4—The precision of this test method will be affected by water

8. Sampling

droplets adhering to surfaces in the apparatus and therefore not settling

8.1 Sampling is defined as all steps required to obtain an into the water trap to be measured. To minimize the problem, all apparatus

aliquot of the contents of any pipe, tank, or other system and to must be cleaned chemically at least daily to remove surface films and

place the sample into the laboratory test container. Only debris, which hinder free drainage of water in the test apparatus. More

representative samples obtained as specified in Practices frequent cleaning is recommended if the nature of samples being run

causes persistent contamination.

D4057 (API MPMS Chapter 8.1) and D4177 (API MPMS

Chapter 8.2) shall be used for this test method. 10.1 Measure a suitable amount of sample to an accuracy of

8.2 The size of the test portion should be based on the 6 1% and transfer it to the still.

expected water content of the sample, such that the water yield 10.2 Measure ordinary liquid samples in a graduated cylin-

does not exceed the capacity of the trap (unless a trap with a der of an appropriate size. Rinse the material adhering to the

stopcock is used permitting excess water to be withdrawn into cylinder with one 50-mL and two 25-mL portions of the

a graduated cylinder). solvent-carrier liquid (see Section 6 and Table 1). Drain the

8.3 Practice D5854 (API MPMS Chapter 8.3) contains cylinder thoroughly after the sample transfer and each rinsing.

information on sampling and homogenization efficiency of 10.3 Weigh solid or viscous materials directly into the still

unknown mixers. This test method should not be followed and add 100 mL of the selected solvent-carrier liquid. In cases

without strict adherence to Practice D5854 (API MPMS of material with a low-water content when large samples must

Chapter 8.3). be used, a solvent-carrier liquid volume in excess of 100 mL

may be necessary.

9. Verification 10.4 Glass beads or other boiling aids may be added, if

9.1 The accuracy of the graduation marks on the trap shall necessary, to reduce bumping.

be certified or verified, using only national or international 10.5 Assemble the components of the apparatus, as illus-

standards, such as National Institute of Standards and Technol- trated in Fig. 1, Fig. 2, and Fig. 3, choosing the trap in

ogy (NIST)4 traceable equipment. Verification shall be with a accordance with the expected water content of the sample and

traceable 5 mL Micro Burette or Micro Pipette, readable to the making all connections vapor and liquid tight. If a metal still

nearest 0.01 mL. with a removable cover is used, insert a gasket of heavy paper,

9.1.1 In styles A, B, C, and D, as specified in Table 2 moistened with solvent, between the still body and the cover.

(Table 1 in Specification E123), each subdivision (that is, 0.1 The condenser tube and trap must be chemically clean to

mL through 1.0 mL) in the conical portion of the tube shall be ensure free drainage of water into the bottom of the trap. Insert

verified. Thereafter, each major subdivision (that is, 2.0 mL, a loose cotton plug in the top of the condenser to prevent

3.0 mL, 4.0 mL, and up to the total volume of the trap) shall be condensation of atmospheric moisture inside it. Circulate cold

verified. water through the jacket of the condenser.

10.6 Apply heat to the still, adjusting the rate of boiling so

that condensed distillate discharges from the condenser at the

4

National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop rate of two to five drops per second. If the metal still is used,

1070, Gaithersburg, MD 20899-1070, http://www.nist.gov. start heating with the ring burner about 76 mm (3 in.) above the

Copyright by ASTM Int'l (all rights reserved); 3

D95 – 05 (2010)

NOTE—Trap shall be 15 to 16 mm in inside diameter.

FIG. 3 Typical Assemblies with Metal Still

TABLE 2 Specifications and Sizes of Traps

Description

Smallest

Top of Bottom of Scale Error

Bottom of Size of Trap Range Scale

Style Graduated Graduated Maximum,

Vapor Tube mL mL Division,

Tube Tube mL

mL

A ST Joint Conical ST Joint 10 0 to 1.0 0.1 0.05

>1.0 to 10.0 0.2 0.1

B ST Joint Conical ST Joint 25 0 to 1.0 0.1 0.05

C ST Joint Conical Plain 25 >1.0 to 25 0.2 0.1

D ST Joint Conical Plain 25 1.0 to 25 0.2 0.1

E ST Joint Round ST Joint 5 0 to 5.0 0.1 0.05

5 0 to 5.0 0.05 0.025

10 0 to 10.0 0.1 0.1

F ST Joint Round ST Joint 2 0 to 2.0 0.05 0.025

Copyright by ASTM Int'l (all rights reserved); 4

D95 – 05 (2010)

TABLE 3 Permissible Limits in Millilitres ~Volume of water in trap, mL! 2 ~Water in solvent blank, mL!

Mass of test sample, g 3 100

Volume of Water Permissible Limits for

Capacity of Receiver at 20°C Added to Flask at Recovered Water at (2)

20°C 20°C

Round trap 12. Report

2 1st Test 1 1 6 0.05

2 2nd Test 1.9 1.9 6 0.05

12.1 Report the results as the water content to the nearest

0.05% if the 2-mL receiver has been used and to the nearest

5 (0.05 mL 1st Test 1 1 6 0.05 0.1% if the 10-mL or 25-mL receiver has been used and to the

subdivisions)

5 (0.05 mL 2 nd

Test 4.5 4.5 6 0.05

nearest subdivision if a 5-mL receiver has been used with a

subdivisions) 100-mL or 100-g sample.

5 (0.1 mL 1st Test 1 1 6 0.1 13. Precision and Bias

subdivisions)

5 (0.1 mL 2 nd

Test 4.5 4.5 6 0.1 13.1 Precision—The criteria described in 13.1.1 and 13.1.2

subdivisions) should be used to judge the acceptability of results when using

10 1st Test 5 5 6 0.1

the 10 or 25-mL traps. The precision when using the 2-mL trap

10 2nd Test 9 9 6 0.1 or a 5–mL trap has not been established.

Conical trap NOTE 5—Practice D6300 was not used in obtaining precision data.

10 1st Test 1 1 6 0.1

10 2nd Test 9 9 6 0.2

13.1.1 Repeatability—The difference between successive

test results, obtained by the same operator with the same

25 1st Test 12 12 6 0.2 apparatus under constant operating conditions on identical test

25 2nd Test 24 24 6 0.2

material, would, in the long run, in the normal and correct

operation of the test method, exceed the values in Table 4 in

only one case in twenty.

bottom of the still and gradually lower the burner as the 13.1.2 Reproducibility—The difference between two single

distillation proceeds. Continue distillation until no water is and independent test results obtained by different operators

visible in any part of the apparatus except in the trap and the working in different laboratories on identical test material,

volume of water in the trap remains constant for 5 min. If there would, in the long run, in the normal and correct operation of

is a persistent ring of water in the condenser tube, carefully the test method, exceed the values in Table 4 in only one case

increase the rate of distillation or cut off the condenser water in twenty.

for a few minutes. 13.2 Bias—As there is no accepted reference material

10.7 When the evolution of water is complete, allow the trap suitable for determining bias for the procedure described in this

and contents to cool to room temperature. Dislodge any drops test method for measuring water in petroleum products and

of water adhering to the sides of the trap with a glass or bituminous materials by distillation, no statement about bias is

polytetrafluoroethylene (PTFE) rod or other suitable means and made.

transfer them to the water layer. Read the volume of the water

in the trap to the nearest scale division. 14. Keywords

10.8 A solvent blank shall be established, as outlined in 6.2. 14.1 bituminous materials; distillation; petroleum products;

solvent carrier liquid; water by distillation; water content

11. Calculation

11.1 Calculate the water in the sample, as weight or volume TABLE 4 Precision

percent, in accordance with the basis on which the sample was Type

Water Collected,

Difference, mL

taken, as follows: mL

11.1.1 Water, % (V/V) = Repeatability 0.0–1.0 0.1

1.1–25 0.1 mL or 2 % of the mean, whichever is

~Volume in water trap, mL! 2 ~Water in solvent blank, mL! greater

Volume in test sample, mL 3 100 Reproducibility 0.0–1.0 0.2

(1) 1.1–25 0.2 mL or 10 % of the mean, whichever is

greater

11.1.2 Water, % (V/m) =

Copyright by ASTM Int'l (all rights reserved); 5

D95 – 05 (2010)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 6

Das könnte Ihnen auch gefallen

- Astm D7224-18Dokument15 SeitenAstm D7224-18Vu HungNoch keine Bewertungen

- D7279-08 Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon ViscometerDokument6 SeitenD7279-08 Kinematic Viscosity of Transparent and Opaque Liquids by Automated Houillon ViscometerLuis Alberto Ramirez PerezNoch keine Bewertungen

- D893Dokument5 SeitenD893rpajaro75Noch keine Bewertungen

- Indice de Viscosidad d2270.35676Dokument5 SeitenIndice de Viscosidad d2270.35676Vanne ParraNoch keine Bewertungen

- Astm D445-17Dokument16 SeitenAstm D445-17ridermateNoch keine Bewertungen

- D2896-11 Standard Test Method For Base Number ofDokument9 SeitenD2896-11 Standard Test Method For Base Number ofAswindana Ibnu SenaNoch keine Bewertungen

- Astm TBN 2011Dokument9 SeitenAstm TBN 2011Tria Hikma100% (1)

- Norma D4378-03 Monitoreo AceitesDokument11 SeitenNorma D4378-03 Monitoreo AceitesSebastian DimianNoch keine Bewertungen

- D 1120 - 94 R04 RdexmjaDokument3 SeitenD 1120 - 94 R04 RdexmjaGeorge HdlcNoch keine Bewertungen

- D5002 Densidad Por Densimetro Digital PDFDokument5 SeitenD5002 Densidad Por Densimetro Digital PDFkarfer78Noch keine Bewertungen

- Astm 1500 2012Dokument5 SeitenAstm 1500 2012Hugo MtzaNoch keine Bewertungen

- Measurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryDokument14 SeitenMeasurement of Remaining Primary Antioxidant Content in In-Service Industrial Lubricating Oils by Linear Sweep VoltammetryJuan F AlvarezNoch keine Bewertungen

- Astm d2709 Agua CDokument3 SeitenAstm d2709 Agua CDiana ÁlvarezNoch keine Bewertungen

- E2412 3213 PDFDokument24 SeitenE2412 3213 PDFEsteban CorderoNoch keine Bewertungen

- Acid and Base Number by Color-Indicator Titration: Standard Test Method ForDokument7 SeitenAcid and Base Number by Color-Indicator Titration: Standard Test Method ForLuis EnriqueNoch keine Bewertungen

- Base Number of Petroleum Products by Potentiometric Perchloric Acid TitrationDokument8 SeitenBase Number of Petroleum Products by Potentiometric Perchloric Acid TitrationKatty AtocheNoch keine Bewertungen

- Foaming Characteristics of Lubricating Oils: Standard Test Method ForDokument10 SeitenFoaming Characteristics of Lubricating Oils: Standard Test Method ForDennise ChicaizaNoch keine Bewertungen

- ASTM - D7684 EditedDokument10 SeitenASTM - D7684 Editedanandagholap100% (1)

- Measurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryDokument6 SeitenMeasurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryMohanadNoch keine Bewertungen

- ASTM-D974 - No. de Acido Por ColorDokument7 SeitenASTM-D974 - No. de Acido Por ColorIvan Pulido100% (2)

- D7220-06 MEDXRF Sulfur AutomotiveDokument6 SeitenD7220-06 MEDXRF Sulfur AutomotiveVladimir KrzalicNoch keine Bewertungen

- Astm D7112 Estabilidad de AsfaltenosDokument11 SeitenAstm D7112 Estabilidad de AsfaltenosYiliana Piña100% (1)

- Electrical Conductivity of Aviation and Distillate Fuels: Standard Test Methods ForDokument11 SeitenElectrical Conductivity of Aviation and Distillate Fuels: Standard Test Methods ForMuhammad KhairuddinNoch keine Bewertungen

- Ash From Petroleum Products: Standard Test Method ForDokument4 SeitenAsh From Petroleum Products: Standard Test Method ForNelson GomesNoch keine Bewertungen

- ASTMD1500.11975 ColorDokument5 SeitenASTMD1500.11975 ColorKaren DayanaNoch keine Bewertungen

- D5967Dokument42 SeitenD5967jbaquerizo31Noch keine Bewertungen

- MPC Oil Varnish Potential Testing ASTM D-7843 - White - Paper - Sep - 2016 PDFDokument5 SeitenMPC Oil Varnish Potential Testing ASTM D-7843 - White - Paper - Sep - 2016 PDFMauro MLRNoch keine Bewertungen

- D 7640 - 16Dokument2 SeitenD 7640 - 16mgamal1080Noch keine Bewertungen

- Astm D 97Dokument5 SeitenAstm D 97Ivan AlanizNoch keine Bewertungen

- D5293Dokument8 SeitenD5293Carlos Olivares ZegarraNoch keine Bewertungen

- Astm D 664 - 07Dokument8 SeitenAstm D 664 - 07Alfonso MartínezNoch keine Bewertungen

- D 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Dokument21 SeitenD 3241-14a Thermal Oxidation Stability of Aviation Turbine Fuels1Ruben Perez Ayo100% (1)

- Set-Up Ftir - d7418Dokument8 SeitenSet-Up Ftir - d7418Sofia Fasolo CunhaNoch keine Bewertungen

- (Thiol Mercaptan) Sulfur in Gasoline, Kerosine, Aviation Turbine, and Distillate Fuels (Potentiometric Method)Dokument8 Seiten(Thiol Mercaptan) Sulfur in Gasoline, Kerosine, Aviation Turbine, and Distillate Fuels (Potentiometric Method)Dennise ChicaizaNoch keine Bewertungen

- Astm - ASTM D 2270 PDFDokument7 SeitenAstm - ASTM D 2270 PDFthuandiemNoch keine Bewertungen

- D 1744 PDFDokument4 SeitenD 1744 PDFmilecsa50% (2)

- Astm D445 PDFDokument12 SeitenAstm D445 PDFrodrigo50% (2)

- Astm D721Dokument7 SeitenAstm D721ebalideNoch keine Bewertungen

- ASTM D6079.dvfr3720 PDFDokument8 SeitenASTM D6079.dvfr3720 PDFangel100% (2)

- Astm D 1121-07 Rezerva Alcalinitate AntigelDokument3 SeitenAstm D 1121-07 Rezerva Alcalinitate AntigelCorina StanculescuNoch keine Bewertungen

- Astm D 91 - 02Dokument3 SeitenAstm D 91 - 02Edwin RamirezNoch keine Bewertungen

- Determination of Metals in Lubricating Greases by Inductively Coupled Plasma Atomic Emission SpectrometryDokument7 SeitenDetermination of Metals in Lubricating Greases by Inductively Coupled Plasma Atomic Emission SpectrometryNguyen Hoang QuanNoch keine Bewertungen

- Astm d1319 2003 PDFDokument10 SeitenAstm d1319 2003 PDFJeffreyCheleNoch keine Bewertungen

- TNRCC Method 1005 Determinación de Hidrocarburos de Pretoleo PresentesDokument26 SeitenTNRCC Method 1005 Determinación de Hidrocarburos de Pretoleo PresentesSusana DiazNoch keine Bewertungen

- Astm D 2711Dokument8 SeitenAstm D 2711aleiviNoch keine Bewertungen

- SARA Method D4124Dokument9 SeitenSARA Method D4124mahamuninaresh1Noch keine Bewertungen

- IndexDokument90 SeitenIndexAlfonso MartínezNoch keine Bewertungen

- ASTM D2272-09 - Oxidation StabilityDokument19 SeitenASTM D2272-09 - Oxidation StabilityDr. Minhaj Uddin MonirNoch keine Bewertungen

- Middle Distillate Fuel Storage Stability at 43 °C (110 °F) : Standard Test Method ForDokument6 SeitenMiddle Distillate Fuel Storage Stability at 43 °C (110 °F) : Standard Test Method ForFlavia AliceNoch keine Bewertungen

- Astm D 2896 - 03Dokument8 SeitenAstm D 2896 - 03rod3662Noch keine Bewertungen

- Insolubles in Used Lubricating Oils: Standard Test Method ForDokument5 SeitenInsolubles in Used Lubricating Oils: Standard Test Method ForDennise Chicaiza100% (1)

- D6443Dokument7 SeitenD6443rimi7al100% (1)

- Astm D95Dokument6 SeitenAstm D95bryan Javier100% (1)

- ASTM D4006 - 16e1Dokument11 SeitenASTM D4006 - 16e1Angel MurilloNoch keine Bewertungen

- Water in Crude Oil by Distillation: Standard Test Method ForDokument11 SeitenWater in Crude Oil by Distillation: Standard Test Method ForMercedes de LarenaNoch keine Bewertungen

- Astm - 4006Dokument11 SeitenAstm - 4006CarlosJayaNoch keine Bewertungen

- ASTM D 4007 (Porcentaje de S&W)Dokument5 SeitenASTM D 4007 (Porcentaje de S&W)Shirley GutierrezNoch keine Bewertungen

- D95 - Water in Petroleum Products and Bituminous Materials byDokument5 SeitenD95 - Water in Petroleum Products and Bituminous Materials byNavneet YadavNoch keine Bewertungen

- ASTM D95 13e1Dokument3 SeitenASTM D95 13e1EdwinNoch keine Bewertungen

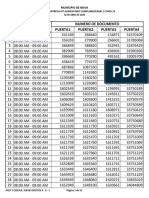

- Puerta1 Puerta2 Puerta3 Puerta4 Numero de Documento HoraDokument52 SeitenPuerta1 Puerta2 Puerta3 Puerta4 Numero de Documento HoraDaniel FelipeNoch keine Bewertungen

- Uydt 5 YudDokument4 SeitenUydt 5 YudDaniel FelipeNoch keine Bewertungen

- Possible Role of Asphaltenes in Stabilization of Water-In-Crude Oil EmulsionsDokument2 SeitenPossible Role of Asphaltenes in Stabilization of Water-In-Crude Oil EmulsionsDaniel FelipeNoch keine Bewertungen

- Rheological Response of Viscoelastic Asphaltene Films and The Effect On Drop Coalescence.Dokument31 SeitenRheological Response of Viscoelastic Asphaltene Films and The Effect On Drop Coalescence.Daniel FelipeNoch keine Bewertungen

- SPE-190057-MS Asphaltenes Contribution in Emulsion Formation During Solvent-Steam ProcessesDokument12 SeitenSPE-190057-MS Asphaltenes Contribution in Emulsion Formation During Solvent-Steam ProcessesDaniel FelipeNoch keine Bewertungen

- WerhdgukdtyjDokument75 SeitenWerhdgukdtyjDaniel FelipeNoch keine Bewertungen

- 3 2 2 0 Diploma Examination, 2010: 130. Petroleum Refinery EngineeringDokument2 Seiten3 2 2 0 Diploma Examination, 2010: 130. Petroleum Refinery EngineeringdhasdjNoch keine Bewertungen

- Boeing 727 - 71 (Gen Fam)Dokument15 SeitenBoeing 727 - 71 (Gen Fam)ElLoko Martines100% (2)

- Fire Quiz QuestionsDokument22 SeitenFire Quiz Questionssauravsinhaa50% (2)

- Caterpillar 3054Dokument2 SeitenCaterpillar 3054Mas Inyeccion Electronica88% (8)

- Biodiesel From Micro AlgaeDokument3 SeitenBiodiesel From Micro Algaeraanja2Noch keine Bewertungen

- Fuel System PrimeDokument4 SeitenFuel System PrimebejoythomasNoch keine Bewertungen

- Tale of Piracy Unfolds On Facebook: Farewell To Panamah Peat'Dokument52 SeitenTale of Piracy Unfolds On Facebook: Farewell To Panamah Peat'Tad WoottonNoch keine Bewertungen

- Vacuum Brake ReportDokument65 SeitenVacuum Brake ReportsasikumarNoch keine Bewertungen

- 2017 Catalysis PDFDokument68 Seiten2017 Catalysis PDFnurlianaNoch keine Bewertungen

- Catalogo Compresor NuevoDokument119 SeitenCatalogo Compresor NuevoDAVE100% (2)

- Bituplus PDokument2 SeitenBituplus Pveera_chapoNoch keine Bewertungen

- Report MegDokument17 SeitenReport MegKrishnamoorthy VijayalakshmiNoch keine Bewertungen

- JSA For KAHSDokument6 SeitenJSA For KAHSFrancis Enriquez TanNoch keine Bewertungen

- ASTM D1250 08 Use of The Petroleum Measurement Tables PDFDokument7 SeitenASTM D1250 08 Use of The Petroleum Measurement Tables PDFAhmed IsmailNoch keine Bewertungen

- Sizing of Steam Coil of Insulated Tank Rev 3Dokument2 SeitenSizing of Steam Coil of Insulated Tank Rev 3ypatels50% (2)

- Termotehnica Part2Dokument95 SeitenTermotehnica Part2Cirstea AlexandruNoch keine Bewertungen

- Ud QuesterDokument21 SeitenUd QuesterBintang Tamago100% (2)

- Operation and Safety Manual: Boom Lift Models 600S 660SJDokument118 SeitenOperation and Safety Manual: Boom Lift Models 600S 660SJABF ETSNoch keine Bewertungen

- Centralita 1Dokument32 SeitenCentralita 1pepe ruizNoch keine Bewertungen

- Model 274 Regulator General Description GD274 - nonUSA PDFDokument16 SeitenModel 274 Regulator General Description GD274 - nonUSA PDFAntonio VelardeNoch keine Bewertungen

- Calculations Based On Fuel AnalysisDokument3 SeitenCalculations Based On Fuel AnalysisBrille Adrian FernandoNoch keine Bewertungen

- Air Standard Power CycleDokument24 SeitenAir Standard Power Cycle24sandeep24Noch keine Bewertungen

- Is 12056-1987 PDFDokument6 SeitenIs 12056-1987 PDFObuli KarthikeyanNoch keine Bewertungen

- SPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisDokument16 SeitenSPE 26647 Application of Variable Formation Compressibility For Improved Reservoir AnalysisglsancorNoch keine Bewertungen

- Company Profile Manufacturer PT BMI PDFDokument17 SeitenCompany Profile Manufacturer PT BMI PDFJo FrancescNoch keine Bewertungen

- LG Dryer - Owner ManualDokument125 SeitenLG Dryer - Owner Manualjer0923Noch keine Bewertungen

- Biogas Fuel Agri WasteDokument5 SeitenBiogas Fuel Agri WasteDinesh HindujaNoch keine Bewertungen

- Generator Datasheet C2500D5ADokument3 SeitenGenerator Datasheet C2500D5AQuang PhamNoch keine Bewertungen

- Astm TestingDokument7 SeitenAstm TestingFallo SusiloNoch keine Bewertungen

- Ducati Desmodromic Variable Timing (DVT) EngineDokument3 SeitenDucati Desmodromic Variable Timing (DVT) EngineRushLaneNoch keine Bewertungen