Beruflich Dokumente

Kultur Dokumente

Speed and Feed - Roughers PDF

Hochgeladen von

David BumbaloughOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Speed and Feed - Roughers PDF

Hochgeladen von

David BumbaloughCopyright:

Verfügbare Formate

ROUGHING END MILLS

Speed and Feed Data

TECHNICAL INFORMATION

Chip Load per Tooth LIST OF SYMBOLS

Material SFM 1/8” 1/4” 1/2” 1”

Aluminum Alloys 125-250 .0010 .0020 .0025 .0030 F = NUMBER OF FLUTES

Magnesium 125-250 .0010 .0020 .0025 .0030 D = DIAMETER OF CUTTER

Copper 75-100 .0008 .0015 .0030 .0060 R.P.M. = REVOLUTIONS PER MINUTE

Brass 85-110 .0008 .0015 .0030 .0060 S.F.M. = SURFACE FEET PER MINUTE

Bronze 75-100 .0008 .0015 .0030 .0060 I.P.M. = FEED RATE: INCHES PER MINUTE

Cast Iron 100-125 .0008 .0015 .0025 .0050 I.P.R. = FEED RATE: INCHES PER REVOLUTION

Cast Steel 75-100 .0008 .0015 .0025 .0050

Malleable Iron 80-120 .0008 .0015 .0025 .0050

Stainless Steel MACHINING FORMULAS

Free Machining 75-90 .0005 .0007 .0012 .0020

Other 50-75 .0005 .0007 .0012 .0020

S.F.M. = 0.262 x D x R.P.M.

Steel

Annealed 100-125 .0010 .0020 .0040 .0060

R.P.M. = 3.82 x S.F.M.

Rc 18-24 75-100 .0070 .0012 .0030 .0050

D

Rc 25-37 40-75 .0005 .0010 .0020 .0040

Titanium

I.P.R. = I.P.M. or CHIP LOAD x F

Up to Rc 30 40-75 .0005 .0012 .0025 .0050

R.P.M.

Rc 30+ 20-25 .0005 .0010 .0020 .0035

High Temp Alloys

I.P.M. = R.P.M. x I.P.R.

Austenitic 12-20 * .0007 .0015 .0030

Ferritic 50-75 .0004 .0007 .0020 .0050

CHIP LOAD = I.P.M. or I.P.R.

Nickel Base 20-25 .0004 .0007 .0015 .0030

R.P.M. x F F

Cobalt Base 8-15 * .0007 .0015 .0030

www.endmill.com n Phone 800/521-1078 n 216/362-4200 n Fax 800/521-1558 n 216/362-4230

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Tortort Manufacturing 80% Milled Receivers AK47Dokument6 SeitenTortort Manufacturing 80% Milled Receivers AK47David BumbaloughNoch keine Bewertungen

- Exercises After Abdominal SurgeryDokument5 SeitenExercises After Abdominal SurgeryDavid BumbaloughNoch keine Bewertungen

- The Complete Guide To Growing Corn in Containers - Garden and HappyDokument17 SeitenThe Complete Guide To Growing Corn in Containers - Garden and HappyDavid BumbaloughNoch keine Bewertungen

- 44-01 Machining With TailstockDokument1 Seite44-01 Machining With TailstockDavid BumbaloughNoch keine Bewertungen

- Scaling Exercise: Use T01 Ø20 End MillDokument1 SeiteScaling Exercise: Use T01 Ø20 End MillDavid BumbaloughNoch keine Bewertungen

- Feedrate Q+A: # Answer 1Dokument2 SeitenFeedrate Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- HK94, MP5, Parts KitsDokument6 SeitenHK94, MP5, Parts KitsDavid BumbaloughNoch keine Bewertungen

- CNC Machining Q+A: # Answer 1Dokument2 SeitenCNC Machining Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- Scaling Function Q+A: # Answer 1Dokument2 SeitenScaling Function Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- Verifying Programs Q+A: # Answer 1Dokument2 SeitenVerifying Programs Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- 53-02 Locators PDFDokument1 Seite53-02 Locators PDFDavid BumbaloughNoch keine Bewertungen

- 49-01 Documenting Programs Q+A PDFDokument1 Seite49-01 Documenting Programs Q+A PDFDavid BumbaloughNoch keine Bewertungen

- 46-01 Horizontal MachiningDokument1 Seite46-01 Horizontal MachiningDavid BumbaloughNoch keine Bewertungen

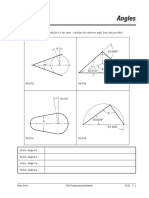

- Angles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDokument1 SeiteAngles: in The Four Exercises, The Objective Is The Same - Calculate The Unknown Angle From Data ProvidedDavid BumbaloughNoch keine Bewertungen

- Trig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDokument1 SeiteTrig Calculations: XY Contour Points On The Part Only, Along The Contour, Back To The StartDavid BumbaloughNoch keine Bewertungen

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDokument1 SeiteBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNoch keine Bewertungen

- Unknown Radius: Chine Shop MagazineDokument1 SeiteUnknown Radius: Chine Shop MagazineDavid BumbaloughNoch keine Bewertungen

- 53-03 Contour Points 1Dokument1 Seite53-03 Contour Points 1David BumbaloughNoch keine Bewertungen

- 22 00 IntroductionDokument2 Seiten22 00 IntroductionDavid BumbaloughNoch keine Bewertungen

- Blend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDokument1 SeiteBlend Radius 2: Compare With Project 53-06, Which Is Similar, But The Arc Is Dimensioned To Its Sharp CornerDavid BumbaloughNoch keine Bewertungen

- 23-03 Skipped Holes With ObstaclesDokument1 Seite23-03 Skipped Holes With ObstaclesDavid BumbaloughNoch keine Bewertungen

- 22-01 Simple Linear Motion 1Dokument1 Seite22-01 Simple Linear Motion 1David BumbaloughNoch keine Bewertungen

- 25-01 Fixed Cycles Q+A PDFDokument2 Seiten25-01 Fixed Cycles Q+A PDFDavid BumbaloughNoch keine Bewertungen

- Machine Zero Return Q+A: # Answer 1Dokument2 SeitenMachine Zero Return Q+A: # Answer 1David BumbaloughNoch keine Bewertungen

- 23-02 Trial Cut For Turning PDFDokument1 Seite23-02 Trial Cut For Turning PDFDavid BumbaloughNoch keine Bewertungen

- 23-02 Trial Cut For Turning PDFDokument1 Seite23-02 Trial Cut For Turning PDFDavid BumbaloughNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Toll PlazaDokument13 SeitenToll PlazaNARAYAN DASNoch keine Bewertungen

- Masterglenium Sky 8632 TdsDokument3 SeitenMasterglenium Sky 8632 TdsVenkat Eswar KuruvaNoch keine Bewertungen

- Congruent Transformation: No Change in Composition Upon PhaseDokument21 SeitenCongruent Transformation: No Change in Composition Upon PhaseTuna ÇelikNoch keine Bewertungen

- Steel AlloyDokument4 SeitenSteel AlloyRuffy OiraNoch keine Bewertungen

- Heucophos Zcp-Plus / Heucorin RZ: Solvent BasedDokument2 SeitenHeucophos Zcp-Plus / Heucorin RZ: Solvent BasedXuxo XuxitoNoch keine Bewertungen

- Beams, Steel I Beams, Structural Beams, Wide FlangeDokument4 SeitenBeams, Steel I Beams, Structural Beams, Wide Flangeanon_795652448Noch keine Bewertungen

- Versa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesDokument2 SeitenVersa-Matic Pump Company: Pump Model Model E4 Elima-Matic Bolted SeriesdeepaNoch keine Bewertungen

- 2 Construction WorkDokument53 Seiten2 Construction WorkShuvam AdhikariNoch keine Bewertungen

- Mud BrickDokument3 SeitenMud Brickabc50% (2)

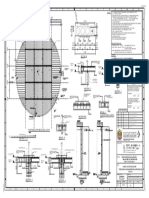

- 1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelDokument1 Seite1M05 (B) TECTON-C-010 (REV-AB-1) SHEET No.1 OF 3-ModelmannshiNoch keine Bewertungen

- Competitors of Maple LeafDokument4 SeitenCompetitors of Maple Leafmarwah rafiqNoch keine Bewertungen

- FBE PowderDokument8 SeitenFBE PowderJoseph CortezNoch keine Bewertungen

- Window & Door Schedule: StudioDokument1 SeiteWindow & Door Schedule: StudioBatWing ZNoch keine Bewertungen

- Astm C270 10Dokument14 SeitenAstm C270 10MustafaMahdi100% (2)

- API RP 14J MMS ApprovalsDokument2 SeitenAPI RP 14J MMS ApprovalsBrent FraserNoch keine Bewertungen

- California Building CodeDokument21 SeitenCalifornia Building Codez15tea33% (3)

- 12 Samss 007Dokument33 Seiten12 Samss 007marghoobNoch keine Bewertungen

- Class Designation Code: Page 8 of 8Dokument1 SeiteClass Designation Code: Page 8 of 8Yemmina Madhusudhan100% (2)

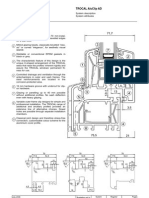

- Aluclip A5 EngDokument238 SeitenAluclip A5 EngSid SilviuNoch keine Bewertungen

- Rimseal Pu40r Jun16Dokument3 SeitenRimseal Pu40r Jun16LEONARDONoch keine Bewertungen

- Chemistry Investigatory Project Study of Constituent of AlloysDokument19 SeitenChemistry Investigatory Project Study of Constituent of AlloysVaishnavi.V NathanNoch keine Bewertungen

- Tabelle Gewicht Rundstahl PDFDokument1 SeiteTabelle Gewicht Rundstahl PDFCécé Charles KoliéNoch keine Bewertungen

- VRCDokument9 SeitenVRCMishal LimbuNoch keine Bewertungen

- Two Way Slab at 16.006 - Floor RoomDokument3 SeitenTwo Way Slab at 16.006 - Floor RoomRamakanth PuttyNoch keine Bewertungen

- White Cement - ReportDokument15 SeitenWhite Cement - ReportSai PujithNoch keine Bewertungen

- Shear Strength Between Concrete LayerDokument6 SeitenShear Strength Between Concrete LayerAndrian FirmansyahNoch keine Bewertungen

- Annular Cutter Feeds and SpeedsDokument1 SeiteAnnular Cutter Feeds and SpeedsAnonymous JzEb8CXErNoch keine Bewertungen

- Bolts and Nuts Torque Table1Dokument2 SeitenBolts and Nuts Torque Table1Ibama MirillaNoch keine Bewertungen

- Catalog AccuraDokument88 SeitenCatalog AccuraAndika YonitraNoch keine Bewertungen

- MethodologyDokument3 SeitenMethodologyjonar taliptip0% (1)