Beruflich Dokumente

Kultur Dokumente

Project

Hochgeladen von

JNfotoevents0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

62 Ansichten6 SeitenThis document provides a project execution plan for constructing a bridge, outlining general items like site facilities, traffic management, earthworks, concrete works, and reinforcement. It details the methods, equipment, and sequence that will be used, and how progress, safety, and quality will be monitored and controlled. The plan seeks to engage stakeholders and share knowledge for induction training.

Originalbeschreibung:

project execution for construction

Originaltitel

project

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides a project execution plan for constructing a bridge, outlining general items like site facilities, traffic management, earthworks, concrete works, and reinforcement. It details the methods, equipment, and sequence that will be used, and how progress, safety, and quality will be monitored and controlled. The plan seeks to engage stakeholders and share knowledge for induction training.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

62 Ansichten6 SeitenProject

Hochgeladen von

JNfotoeventsThis document provides a project execution plan for constructing a bridge, outlining general items like site facilities, traffic management, earthworks, concrete works, and reinforcement. It details the methods, equipment, and sequence that will be used, and how progress, safety, and quality will be monitored and controlled. The plan seeks to engage stakeholders and share knowledge for induction training.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

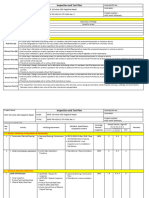

Project Execution Plan for Bridge Construction

. 1. Bridge Construction, Project Execution Plan Details of how a Bridge is

constructed, and how the progress, safety and quality will be monitored and

controlled. Also the measures to ensure that the site is environmentally friendly.

David H Moloney 8th August 2016 Brief Description The purpose of this

presentation is to give an understanding of the Methods, Plant and Sequence to

construct an insitu concrete bridge. This presentation can be used to engage

Stakeholders and to get the Site Teams commitment to the programme. Also can

be used for Induction Training and as a way to capture and share knowledge.

Project Execution Plan (PEP) details how a project will be executed, monitored and

controlled. High in Educational Value and easily understood. Recommended for

Continuing Professional Development (CPD) This Presentation is innovative and

has many beneficial uses.

. 2. Table of Contents

. 3. Introduction

. 4. Project Location & Nearby National Roads Introduction

. 5. Location of Bridge on Site Muscat Airport, Oman Introduction

. 6. Description & Scope Brief Description & Scope Four span insitu post-tensioned

deck, Piled foundations. Construction of the Bridge and Handover. Introduction

. 7. General Items

. 8. Contractor’s Temporary Site Facilities ⓒDavid H Moloney GeneralItems To see

animations, see my YouTube Film

. 9. Welfare Facilities ⓒDavid H Moloney GeneralItems Toilets – Washing Canteen,

Drying Room, Toilet & Generator

. 10. Temporary Roads & Entrances ⓒDavid H Moloney GeneralItems

. 11. Site Hoarding examples ⓒDavid H Moloney GeneralItems

. 12. Dust Suppression ⓒDavid H Moloney GeneralItems

. 13. Wheel Wash Drive-through ⓒDavid H Moloney GeneralItems

. 14. Temporary Electricity Supply & Tower Lights ⓒDavid H Moloney

GeneralItems

. 15. Contractor’s Temporary Site Facilities ⓒDavid H Moloney GeneralItems Brief

Description Contractors Site facilities comprise: Offices, Canteens, Toilets, Drying

Rooms, Stores, Plant Yard, generators and Workshops.

. 16. Dewatering ⓒDavid H Moloney GeneralItems Brief Description Construction

dewatering is the removal or drainage of groundwater and or surface / rain water

usually by pumping to keep the works dry.

. 17. Dewatering ⓒDavid H Moloney GeneralItems Brief Description Construction

dewatering is the removal or drainage of groundwater and or surface / rain water

usually by pumping to keep the works dry.

. 18. Dewatering ⓒDavid H Moloney GeneralItems

. 19. Temporary WorksGeneralItems

. 20. FalseworkGeneralItems Brief Description Falsework to support Bridge deck

formwork until the deck is post- tensioned and becomes self supporting

. 21. Sheet Pile Temporary Shaft ⓒDavid H Moloney GeneralItems Brief

Description Sheet Pile Temporary shaft is used to enable an excavation for a deep

structure. The construction sequence is: Install sheet-piles. Excavate and install

bracing. Excavate to final level. Construct concrete structure. Backfill, remove

bracing and sheet-piles

. 22. Sheet pile Temporary Shaft ⓒDavid H Moloney GeneralItems 3D Animation to

show Sequence

. 23. Sheet pile Cofferdam for Piers ⓒDavid H Moloney GeneralItems

. 24. Traffic Management ⓒDavid H Moloney GeneralItems Brief Description

Traffic management plans are necessary when working on or beside roads

. 25. Traffic Management – Work on Median ⓒDavid H Moloney GeneralItems

. 26. Earthworks

. 27. Much Shifting Brief Description Muck Shifting is the process of moving large

quantities of soil and rock. Earthworks

. 28. Excavate & Load, Cart, Tip & Return Brief Description Cycle Time for 7km

haulage distance using an Excavator 45 tonne weight and Dumper with a 40 tonne

capacity, the cycle time is 34 minutes Earthworks 7 minutes 14 minutes 3 minutes

14 minutes 7 km 7 km

. 29. Loading Tipper TrucksEarthworks

. 30. Tipping & Spreading FillEarthworks

. 31. Spreading & CompactionEarthworks

. 32. Spreading & CompactionEarthworks

. 33. Excavation for Trench with Stepped FacesEarthworks

. 34. Excavation for Trench with Battered FacesEarthworks

. 35. Backfill TrenchEarthworks

. 36. Rock - Excavability Brief Description The excavability of rock depends mainly

on the rock strength and the layer thickness. This diagram shows excavation

methods for rock of various strengths and thicknesses, with a free face. ⓒDavid H

Moloney Earthworks

. 37. Earthworks Excavator with Hydraulic Rock-breaker

. 38. Excavator with Hydraulic Rock-breakerEarthworks

. 39. Mass Haul DiagramEarthworks Brief Description Shows the quantities and

location of excavation and fill quantities for motorway.

. 40. Concrete

. 41. Concrete Full Scale Trial Castings of Pier ⓒDavid H Moloney Brief Description

The full-scale trial casting(s) shall demonstrate/document that all requirements to

the concrete and the execution of the work are fulfilled simultaneously using the

actual methods and performed by personnel as for the future production. Concrete

BIM 3D Model Shutter Fibreglass

. 42. Concrete Full Scale Trial Castings of Bridge Deck Brief Description The

full-scale trial casting(s) shall demonstrate/document that all requirements to the

concrete and the execution of the work are fulfilled simultaneously using the actual

methods and performed by personnel as for the future production. Concrete Fresh

Concrete Properties Tests Air Content, Consistence, Density, Initial and Final

Setting Time, Temperature and Bleeding Chloride Ion Content Hardening and

Hardened Concrete Properties Tests: Density and Compressive Strength for 1, 3,

7, 14 and 28 Days Concrete Core Compressive Strength Tensile Splitting Strength

Modulus of Elasticity Heat Development Chloride Migration Coefficient (28 Days)

Reinforcement Cover Measurement Survey

. 43. Concrete Tests ⓒDavid H Moloney Concrete

. 44. Trial Grouting of Post-tensioning Duct ⓒDavid H Moloney Brief Description

The full-scale trial of grouting operation shall demonstrate/document that all

requirements to the grout and the execution of the work are fulfilled simultaneously

using the actual methods and performed by personnel as for the future production.

Pre-trials were carried out in the site laboratory and by way of a mock-up to check

the following in accordance with BS EN 447: i Fluidity ii Bleeding and re-absorption

iii Compressive strength (3 cubes at 28 days, all > 30 N/mm2) iv Mixing ratio (w/c <

0.40) v Expansion (-1 % - +5 %). For grouts with expanding admixtures there shall

be no decrease in volume Concrete

. 45. Trial for Waterproofing to Bridge Deck ⓒDavid H Moloney Brief Description .

The trial for the deck waterproofing shall demonstrate/document that all

requirements to the waterproofing and the execution of the work are fulfilled

simultaneously using the actual methods and performed by personnel as for the

future production. Concrete

. 46. Trial for Waterproofing to Bridge Deck - Tests Concrete

.

47. Concrete Batching Plant David H Moloney ⓒDavid H Moloney Brief

Description Concrete batching plant comprises - concrete mixer, control cabin,

silos for cement and fly ash, aggregate bins and conveyor belt system to feed the

mixer. Also aggregate storage bays and water storage tanks. Concrete

. 48. Concrete Batching Plant ⓒDavid H Moloney Concrete

. 49. Concrete Batching Plant 3Nr. ⓒDavid H Moloney Concrete

. 50. Concrete Batching Plant – Computer Controlled ⓒDavid H Moloney Concrete

. 51. Concrete Batching Plant - Liebherr Betomix Animation Concrete

. 52. Concrete Batching Plant David H Moloney ⓒDavid H Moloney Brief

Description . The mixing is computer controlled and has a dynamic screen display,

showing the process. The material storage capacity is, to match two days concrete

production. Concrete

. 53. Concrete Mix Proportions per Cu M Brief Description . Details of Mix for C40 1.

Concrete Grade C40 2. Cement Type = OPC 3. Slump =125mm 4. Max size

aggregate = 20mm 5. Max water / Cementitious ration =0.42 Concrete Materials

Qty Units Cement 310 Kgs Fly ash 100 Kgs Micro-silica 12 Kgs Washed Sand 670

Kgs Fine Sand 106 Kgs 10mm Crushed aggregate 400 Kgs 20mm Crushed

aggregates 725 Kgs Water 145 Ltr. Additive Rheobuild 7.5 Ltr.

. 54. Concrete MixGeneralItems A concrete mix contains 5 major elements: cement,

water, coarse aggregates, fine aggregates (sand) and air in different proportion.

Additional elements such as pozzolanic materials (fly ash, silica fumes or slag) and

chemical admixtures can also be incorporated to the mix to increase its properties.

. 55. Quarry & Aggregate Production ⓒDavid H Moloney Concrete Brief

Description Quarry and Aggregate Production. Rock is blasted free from a quarry

face and fragmented. The blasted rock is crushed and screened to produce

different size ranges of aggregates

. 56. Quarry & Aggregate Production ⓒDavid H Moloney Concrete

. 57. Reinforcement Cutting & Bending Yard ⓒDavid H Moloney Concrete Brief

Description Reinforcement in 12 m lengths. Delivery in 3 ton Bundles

. 58. Reinforcement Cutting & Bending ⓒDavid H Moloney Concrete

. 59. Reinforcement Cutting & Bending ⓒDavid H Moloney Concrete

. 60. Reinforcement Cutting & Bending Yard David H Moloney ⓒDavid H Moloney

Reinforcement in 12 m lengths. Delivery in 3 ton Bundles Reinforcement cut to

length by Shearing Machine Reinforcement Bent to Shape by Bending Machine

Reinforcement that is cut and bent is Bundled for delivery to work site Concrete

. 61. Reinforced Wall Construction Sequence ⓒDavid H Moloney Concrete Brief

Description The sequence to construct a reinforced concrete wall is as follows: Tie

the reinforcement. Erect stop-ends and the wall shutters. Pour and vibrate the

concrete mix. Remove the shutters after the concrete has hardened. . Cycle Time

Pour per Day

. 62. Reinforced Wall Construction Sequence ⓒDavid H Moloney Concrete

. 63. Vibrating Concrete ⓒDavid H Moloney Concrete

. 64. Bridge & Post-tensioning Concrete Brief Description The sequence to

post-tension a bridge deck is as follows; Fix the ducts and anchorages. Install the

stressing strand. Concrete the deck. Stress the strands and lock at anchorages.

Grout the ducts.

. 65. Bridge & Post-tensioning Concrete

. 66. Bridge & Post-tensioning Concrete

. 67. Bridge Concrete Deck Concrete

. 68. Bridge Concrete Deck Concrete

. 69. Bridge Post Tensioning Deck – Install Strand Concrete

. 70. Bridge Post Tensioning Deck Concrete

. 71. Bridge Construction Sequence David H Moloney ⓒDavid H Moloney Concrete

. 72. Piling

. 73. Piling Construction - Plant & Methods Brief Description Piling Plant,

Equipment and Material; Crawler Crane, Piling Hammer, Temporary Casing, Piling

Rig, Concrete Pump, Concrete Mixer Trucks, Tremie Pipe and Reinforcement

Cage Piling

. 74. Piling Construction - Plant, Methods & SequencePiling

. 75. Piling Construction - Plant & MethodsPiling

. 76. Piling Construction - Vertical PilesPiling

. 77. Piling Construction - Raking PilesPiling

. 78. Piling Construction - Raking PilesPiling

. 79. Pile Load Test ⓒDavid H Moloney Piling Brief Description A jack is used to

load the pile in steps and gauges measure any settlement.

. 80. Pile Load Test ⓒDavid H Moloney Piling

. 81. Roads & Pavings

. 82. Asphalt Batching Yard Roads&Pavings Brief Description Asphalt Batching

Yard Capacity of main batching plant is 250 tonnes per hour .

. 83. Asphalt Batching Yard Roads&Pavings

. 84. Asphalt Batching Yard Roads&Pavings

. 85. Asphalt Batching Yard Roads&Pavings

. 86. Asphalt Batching Yard Roads&Pavings

. 87. Asphalt Batching Yard Roads&Pavings

. 88. Road Construction Brief Description Sequence, methods and plant to

construct a motorway on a high embankment Roads&Pavings

. 89. Road Construction Roads&Pavings

. 90. Road Construction Roads&Pavings

. 91. Asphalt Pavement - Tests Roads&Pavings

. 92. Miscellaneous Works

. 93. Fencing Miscellaneous Brief Description Fencing. Sequence of construction; 1.

Clear and grade the ground. 2. Fix corner and straining posts. 3. Fix intermediate

posts. 4. Fix line wire, chain-link and razor wire. 5. Construct concrete ground

beam

. 94. Fencing Miscellaneous

. 95. Fencing Miscellaneous

. 96. Fencing Miscellaneous

. 97. Fencing Miscellaneous

. 98. Setting out & Surveying

. 99. Setting out & Surveying

. 100. Setting out & Surveying

. 101. Safety & Environmental

. 102. Emergency Phone Numbers & Response Health,Safety&Environment

. 103. HSE Monitoring & Reporting - Dashboard Dashboard is a single page,

graphical representation of current HSE Issues and historical trends

Health,Safety&Environment

. 104. Site Safety Posters examples Health,Safety&Environment

. 105. Trench - Safety Measures ⓒDavid H Moloney Health,Safety&Environment

. 106. Safety Training on Site Miscellaneous The purpose of safety training is to

provide the knowledge necessary to perform a job safely

. 107. Safety Training Matrix Miscellaneous The purpose of safety training is to

provide the knowledge necessary to perform a job safely

. 108. Emergency Response Drill HSE Drills and exercises are used to rehearse

anticipated emergency scenarios

. 109. Safety Documents Health,Safety&Environment Safe System of Work. To

provide a safe system of work is a legal requirement. What this means is that

before you ask an employee to do a job. You ensure that he has received training,

has the appropriate personal protective equipment, the work area is safe and he is

unlikely to be injured or cause damage by carrying out the assigned task. Project

Management Plan for Health, Safety, Security and Environment. also Known as

(HSSE Plan) The Project HSSE Management Plan details how safety on site will

be managed. Project Procedures for Health, Safety, Security & Environment

Details the safe way to undertake a task Methods Statements Are prepared in

advance of starting work, to plan a Safe System of Work on site for all activities that

carries a risk. The contents of a Method Statement, typically include:- Scope &

Location of the Works, Programme, Roles & Responsibilities of Staff. Resources,

Work Methodologies and Risk Assessment. Slide 1 of 2

. 110. Safety Documents Health,Safety&Environment Safety Risk Assessments

Are prepared to identify and evaluate risks, to adopt control measures to reduce or

eliminate risks. COSHH Sheet The purpose of the Control Of Substances

Hazardous to Health sheet is to identify how to prevent or adequately control

workers exposure to hazardous substances. Permit to Work. Is a management

system used to control high risk activities by ensuring safety measures are in place

prior to starting work. Types of work for which permits will be required include:

Excavation and the digging of trenches. Working at height, including on roofs.

Working in confined spaces, for example entering a manhole. Hot work, which is

welding, soldering or cutting steel with angle grinders or by gas torch. Slide 2 of 2

. 111. Hazardous Substances Symbols Health,Safety&Environment COSHH

stands for the Control of Substances Hazardous to Health Shown are the new

hazard symbols

. 112. Safety Precautions Health,Safety&Environment

. 113. Signs Examples Health,Safety&Environment

. 114. Environmentally Friendly Site Air, Noise, Water & Soil

PollutionHealth,Safety&Environment

. 115. Segregation of WasteHealth,Safety&Environment Segregation of waste for

proper disposal and recycling. Less waste goes to landfill and hazardous waste is

treated to make it safe. Colour Code for Skips & Bins

. 116. Water Pollution PreventionHealth,Safety&Environment

. 117. Concrete Washout & Settlement TanksHealth,Safety&Environment

. 118. Existing Underground Utilities ⓒDavid H Moloney Brief Description Before

digging establish the location and route of underground utilities. Locator to find

Utilities Spray Paint to mark pavement Health,Safety&Environment

. 119. Existing Underground Utilities & Overhead Cables - Safety Measures ⓒ

David H Moloney Health,Safety&Environment

. 120. Trench - Safety Measures Health,Safety&Environment

. 121. Trench - Safety Measures ⓒDavid H Moloney Health,Safety&Environment

. 122. Quality Assurance

. 123. Quality Assurance Dashboard Dashboard is a single page, graphical

representation of current statistics and historical trends

. 124. Runway Asphalt Pavement - Tests Roads&Pavings

. 125. Quality Assurance Tests

. 126. Runway Concrete Pavement - Tests Roads&Pavings

. 127. Runway Laboratory Roads&Pavings

. 128. Laboratory ⓒDavid H Moloney AsphaltPaving

. 129. Administration

. 130. Staff Directory Brief Description List of staff and their contact details

. 131. Daily Work Record Brief Description Daily Work Records showing the

allocation of resources, materials and work activities carried out daily.

. 132. Organogram Brief Description Shown are the line and lateral relationships

between the various team members and their relative position in the site

organisation.

. 133. Staff Responsibility Matrix

. 134. Filing System

. 135. Quotations Comparison Sheet

. 136. Programme & Progress Monitoring

. 137. Progress Monthly, Monitoring & Reporting - Dashboard Dashboard is a

single page, graphical representation of current progress and historical trends

. 138. Programme for Construction Gantt Charts to plan and schedule projects

. 139. Bridge Construction Stages, Images & Timeline Concrete

. 140. Bridge Construction Stages, Images & Timeline Concrete

. 141. Bridge Construction Stages, Images & Timeline Concrete

. 142. Bridge Construction Stages, Images & Timeline Concrete

. 143. Bridge Construction Stages, Images & Timeline Concrete

. 144. Bridge Construction Stages, Images & Timeline Concrete

. 145. Bridge Construction Stages, Images & Timeline Concrete

. 146. Bridge Construction Stages, Images & Timeline Concrete

. 147. Bridge Construction Stages, Images & Timeline Concrete

. 148. Bridge Construction Stages, Images & Timeline Concrete

. 149. Bridge Construction Stages, Images & Timeline Concrete

. 150. Time Chainage Diagram Brief Description The chart has two axis: one for

time and the other for location A legend explains meaning of the colours, symbols

and line types Legend

. 151. Histogram Charts for Resources & Outputs Manpower per Discipline

Concrete per Location Man-hours for each month of the Project Quantity for each

month of the Project ⓒDavid H Moloney Brief Description Histograms shows

resources etc. for each month of a project.

. 152. Plant & Equipment List & Worker’s Job Titles ⓒDavid H Moloney

. 153. Other Bridge Projects

. 154. Other Projects – Kuwait Causeway Brief Description Marine Piling for

Causeway in Kuwait

. 155. Other Projects – Kuwait Causeway Brief Description Full Deck Span Precast

1,800 tonnes by 60m long Precast Yard Straddle Carriers loading Deck onto Multi

Wheeled Transporters Multi Wheeled Transporters moving deck to Jetty Jetty for

loading Barge Barge Crane Placing Deck Barge Crane Placing Deck

Das könnte Ihnen auch gefallen

- Project Execution Plan For Airport ConstructionDokument315 SeitenProject Execution Plan For Airport ConstructionCarl Williams100% (15)

- Bridge PlanDokument159 SeitenBridge PlanSoham BanerjeeNoch keine Bewertungen

- PEP2 Gas & Oil Processing Plant ConstructionDokument167 SeitenPEP2 Gas & Oil Processing Plant Constructiondavidhmoloney0% (1)

- Gas Oil Processing Plant-ConstructionDokument180 SeitenGas Oil Processing Plant-ConstructionDony RamdhaniNoch keine Bewertungen

- PEP1 Sea Port ConstructionDokument117 SeitenPEP1 Sea Port ConstructiondavidhmoloneyNoch keine Bewertungen

- Brief Description: David H Moloney 14 August 2016Dokument117 SeitenBrief Description: David H Moloney 14 August 2016vijayakumarjNoch keine Bewertungen

- Diaphragm Wall Quays For Myanmar Mega-PortDokument3 SeitenDiaphragm Wall Quays For Myanmar Mega-PortrakhbirNoch keine Bewertungen

- PEP5 Bridge ConstructionDokument132 SeitenPEP5 Bridge Constructiondavidhmoloney100% (3)

- Summer Internship ReportDokument17 SeitenSummer Internship ReportSiddh NayakNoch keine Bewertungen

- Completion Design (#2)Dokument57 SeitenCompletion Design (#2)Sayaf SalmanNoch keine Bewertungen

- Pile Foundation WorksDokument4 SeitenPile Foundation WorkstyraNoch keine Bewertungen

- BALJOT IndustrialDokument44 SeitenBALJOT IndustrialHarmeet Singh100% (1)

- CONCRETEDokument3 SeitenCONCRETEmarie.curie.0906Noch keine Bewertungen

- 9 Parliament BuildingDokument70 Seiten9 Parliament BuildingFuaad Abdirizak ElmiNoch keine Bewertungen

- MS # 00 Method Statement For Arch Culvert - C29 T218 - Rev.00Dokument12 SeitenMS # 00 Method Statement For Arch Culvert - C29 T218 - Rev.00Ahmed GamalNoch keine Bewertungen

- VICTORY VICTORY 1512032 Wells-Rosie Field 2638904 843650952Dokument22 SeitenVICTORY VICTORY 1512032 Wells-Rosie Field 2638904 843650952Agube VictoryNoch keine Bewertungen

- Da-1 CorrectDokument24 SeitenDa-1 CorrectSisay AmareNoch keine Bewertungen

- Crossrail TunnelsDokument15 SeitenCrossrail TunnelsPeter AyubaNoch keine Bewertungen

- Floating Concrete StructuresDokument10 SeitenFloating Concrete StructuresCyril LongtonNoch keine Bewertungen

- RMC Batching PlantDokument20 SeitenRMC Batching Plantaditishah20392Noch keine Bewertungen

- Presentation 8th SemDokument60 SeitenPresentation 8th SemZayan Khan100% (1)

- Self-Compacting Concrete in Bridge Construction PDFDokument59 SeitenSelf-Compacting Concrete in Bridge Construction PDFVladimir MilicevicNoch keine Bewertungen

- Guide Instruct US-mech+installation PavemDokument12 SeitenGuide Instruct US-mech+installation Pavemandrew_sfiNoch keine Bewertungen

- Fabrication of Mortar Mixer and CHB Filler PumpDokument15 SeitenFabrication of Mortar Mixer and CHB Filler PumpRenjo Kim VenusNoch keine Bewertungen

- Job Procedure Index: 01 Piling WorkDokument20 SeitenJob Procedure Index: 01 Piling WorkraghavaklNoch keine Bewertungen

- Honeycomb Rectification WorkDokument8 SeitenHoneycomb Rectification WorkToyEn MEgat100% (1)

- Anish Dhillon Report IndiabullsDokument72 SeitenAnish Dhillon Report IndiabullsAashi Mack100% (1)

- Well CompletionDokument37 SeitenWell Completionmusab doma100% (1)

- Wachemo UniversityDokument47 SeitenWachemo Universitynaoltekle11844279Noch keine Bewertungen

- Doc2 PDFDokument22 SeitenDoc2 PDFMohammad SayedNoch keine Bewertungen

- Em - 1110 2 3506Dokument159 SeitenEm - 1110 2 3506dannychacon27Noch keine Bewertungen

- 05-8 QCS 2014Dokument16 Seiten05-8 QCS 2014Raja Ahmed HassanNoch keine Bewertungen

- Duke and IvanDokument6 SeitenDuke and IvanJared CyrusNoch keine Bewertungen

- Cross Rail TunnelsDokument15 SeitenCross Rail TunnelsShiva KumarNoch keine Bewertungen

- Internship Report On 120 Mens Hostel ConstructionDokument47 SeitenInternship Report On 120 Mens Hostel ConstructionApollyon A100% (3)

- Method Statement FOR Concreting Work: ProjectDokument6 SeitenMethod Statement FOR Concreting Work: ProjectKelvin LauNoch keine Bewertungen

- Concrete ReportDokument11 SeitenConcrete ReportSANTOSH GAIKWADNoch keine Bewertungen

- Proposed Method Statement For Yangon CCRDokument31 SeitenProposed Method Statement For Yangon CCRMyo Lwin100% (1)

- Concrete: Various Terms Used / Steps For Concreting Operation A) BatchingDokument5 SeitenConcrete: Various Terms Used / Steps For Concreting Operation A) BatchingDARK KnightNoch keine Bewertungen

- Ground Improvement Technique - Grouting Technology (For Irrigation Projects and Tunnelling)Dokument109 SeitenGround Improvement Technique - Grouting Technology (For Irrigation Projects and Tunnelling)Sumanth GundetiNoch keine Bewertungen

- Prezentare Composite Materials - RCostinasDokument27 SeitenPrezentare Composite Materials - RCostinascostinasrazvanNoch keine Bewertungen

- Concrete Technologypart 1Dokument8 SeitenConcrete Technologypart 1Marmik JavareNoch keine Bewertungen

- Vacuum Dewatered Flooring: Mr. Kandavel Raja PDokument60 SeitenVacuum Dewatered Flooring: Mr. Kandavel Raja PKandavelrajaNoch keine Bewertungen

- Final Exam August 16, 2014Dokument9 SeitenFinal Exam August 16, 2014mulkeab11Noch keine Bewertungen

- Thabiso Dlamini - Vacation WorkDokument4 SeitenThabiso Dlamini - Vacation WorkThabiso Sihle DlaminiNoch keine Bewertungen

- Chapter 2Dokument16 SeitenChapter 2Kandasamy AsohanNoch keine Bewertungen

- Completion Design Manual (Shell)Dokument67 SeitenCompletion Design Manual (Shell)Davide Boreaneze93% (14)

- Construction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDokument23 SeitenConstruction of Rajive Gandhi Urja Bhawan, Ongc Energy Center & Corporate OfficeDevendra SharmaNoch keine Bewertungen

- Methodology ConstructionDokument35 SeitenMethodology ConstructionAnurag KumarNoch keine Bewertungen

- Scope of Work For Mining Contractor & Coal Production Schedule - Rev.1Dokument15 SeitenScope of Work For Mining Contractor & Coal Production Schedule - Rev.1setiawannm100% (1)

- Miss Design ManualDokument65 SeitenMiss Design Manualengsam777Noch keine Bewertungen

- Concret Mix Design (M10 To M100)Dokument65 SeitenConcret Mix Design (M10 To M100)Rajesh Kollipara93% (14)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringVon EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringBewertung: 4 von 5 Sternen4/5 (5)

- A Practical Guide to Concrete Pavement Technology for Developing CountriesVon EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNoch keine Bewertungen

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceVon EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNoch keine Bewertungen

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Concrete-Block Manufacture - Processes and MachinesVon EverandConcrete-Block Manufacture - Processes and MachinesBewertung: 5 von 5 Sternen5/5 (1)

- The Fabrication of Materials: Materials TechnologyVon EverandThe Fabrication of Materials: Materials TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Soil Investigation and Foundation DesignVon EverandSoil Investigation and Foundation DesignBewertung: 4.5 von 5 Sternen4.5/5 (9)

- 7 Medival ArchitectureDokument50 Seiten7 Medival ArchitectureRachana Muppala100% (3)

- Ceilings, Partitions & Raised FloorsDokument7 SeitenCeilings, Partitions & Raised FloorsMaddala Srinivasa RaoNoch keine Bewertungen

- Case Study On Ground Improvement by High Pressure Jet GroutingDokument6 SeitenCase Study On Ground Improvement by High Pressure Jet Groutingnagy_andor_csongorNoch keine Bewertungen

- St7016 Prefabricated StructuresDokument128 SeitenSt7016 Prefabricated StructuresSelva Raj77% (13)

- 000 - Tie Coat - Arabian Vermiculite - FIREBOND - Data SheetDokument2 Seiten000 - Tie Coat - Arabian Vermiculite - FIREBOND - Data SheetNizarHamrouniNoch keine Bewertungen

- Mozammel Hoque Momin: Hnial SkillsDokument3 SeitenMozammel Hoque Momin: Hnial SkillsEngr Mozammel Houqe MominNoch keine Bewertungen

- Astm C94-C94MDokument15 SeitenAstm C94-C94MRomeo Ramos MéndezNoch keine Bewertungen

- URS SpecsDokument248 SeitenURS SpecsIbrahim SNoch keine Bewertungen

- Opening of Bids Dorm 2, Ph1Dokument3 SeitenOpening of Bids Dorm 2, Ph1Laurie Carr LandichoNoch keine Bewertungen

- TEM4Dokument20 SeitenTEM4FranciscoNoch keine Bewertungen

- Technicalupdate ColdWeldingPolymersDokument63 SeitenTechnicalupdate ColdWeldingPolymersChris TeohNoch keine Bewertungen

- Manual Batch Records Mix Design ExcelDokument2 SeitenManual Batch Records Mix Design ExcelIswantoNoch keine Bewertungen

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Dokument168 Seiten(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)

- TF-450 Power EndDokument2 SeitenTF-450 Power EndppglNoch keine Bewertungen

- Authorisation For Layig GSB and WMM-Rev-R2Dokument1 SeiteAuthorisation For Layig GSB and WMM-Rev-R2Guna SekaranNoch keine Bewertungen

- Design Constants For Working Stress MethodDokument4 SeitenDesign Constants For Working Stress MethodArpit JaiswalNoch keine Bewertungen

- Cables Catalogue 2Dokument6 SeitenCables Catalogue 2fikih padliNoch keine Bewertungen

- HS PU Elastoseal PrimerDokument2 SeitenHS PU Elastoseal PrimergopipcuddaloreNoch keine Bewertungen

- Guidelines For The Use of Steel Piling For Bridge FoundationsDokument21 SeitenGuidelines For The Use of Steel Piling For Bridge FoundationsHermann PankowNoch keine Bewertungen

- 01 Suspension Bridge DrawingsDokument11 Seiten01 Suspension Bridge DrawingsNurali Mamen100% (1)

- Design: Rigid Solutions - Final CoachingDokument11 SeitenDesign: Rigid Solutions - Final CoachingEugene Ralph TimoteoNoch keine Bewertungen

- Technical Instruction Manual: Meva Formset MfsDokument20 SeitenTechnical Instruction Manual: Meva Formset MfspablopelaNoch keine Bewertungen

- MorenoHurtado Pedro MO6S2AI3Dokument7 SeitenMorenoHurtado Pedro MO6S2AI3PEDRO MORENO HURTADONoch keine Bewertungen

- Huamei Spec Sheets - 2018Dokument1 SeiteHuamei Spec Sheets - 2018Phan LongNoch keine Bewertungen

- The Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDokument6 SeitenThe Transformation of Vernacular Architecture in Indonesia in Relation To Colonisation by The DutchDavid TolentinoNoch keine Bewertungen

- TROX Chilled Beam Design GuideDokument60 SeitenTROX Chilled Beam Design GuideBRYMOENNoch keine Bewertungen

- Nmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)Dokument8 SeitenNmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)parangkilalakitaNoch keine Bewertungen

- Bomba Calpeda NM 25-160aeDokument12 SeitenBomba Calpeda NM 25-160aeMarvin TorresNoch keine Bewertungen

- Workplace Inspection Checklist TemplateDokument5 SeitenWorkplace Inspection Checklist Templatemyo lwinNoch keine Bewertungen

- V47 Components From Crank To Link Head (Conical) : Crank and Crank PlateDokument4 SeitenV47 Components From Crank To Link Head (Conical) : Crank and Crank PlatebalaNoch keine Bewertungen