Beruflich Dokumente

Kultur Dokumente

183 187 IVK3 2011 LJM TV ZR MJ MZ DD PDF

Hochgeladen von

nerminOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

183 187 IVK3 2011 LJM TV ZR MJ MZ DD PDF

Hochgeladen von

nerminCopyright:

Verfügbare Formate

The paper was presented at the Eleventh Meeting

“New Trends in Fatigue and Fracture” (NT2F11)

Polignano a Mare, Italy, 3–6 July, 2011

Ljubica Milović1, Tomaž Vuherer2, Zoran Radaković3, Blagoj Petrovski3, Miodrag Janković3, Milorad Zrilić1, Darko Daničić4

DETERMINATION OF FATIGUE CRACK GROWTH PARAMETERS IN WELDED JOINT OF

HSLA STEEL

ODREĐIVANJE PARAMETARA ZAMORNOG RASTA PRSLINE KOD ZAVARENIH SPOJEVA

OD HSLA ČELIKA

Originalni naučni rad / Original scientific paper Adresa autora / Author's address:

1)

UDK /UDC: 620.172.24: 669.15 University of Belgrade, Faculty of Technology and

620.172.24:66-988-112.81 Metallurgy, Belgrade, Serbia, acibulj@tmf.bg.ac.rs

2)

621.791.05:539.4.013 Welding Laboratory, University of Maribor, Faculty of

Rad primljen / Paper received: 9.10.2011 Mechanical Engineering, Maribor, Slovenia

3)

University of Belgrade, Faculty of Mechanical Engineering,

Belgrade, Serbia

4)

Kolubara Metal, Vreoci, Serbia

Keywords Ključne reči

• HSLA steel • HSLA čelik

• crack growth rate • brzina rasta prsline

• fatigue threshold • granica zamaranja

• Paris’ law • Parisov zakon

Abstract Izvod

The structural integrity and operational safety of welded Integritet konstrukcije i sigurnost u radu zavarenih posu-

pressure vessels primarily depends on the behaviour of da pod pritiskom uglavnom zavisi od ponašanja zavarenih

weldments. In spite of all efforts in material production and spojeva. Pored svih uloženih napora u proizvodnji i pobolj-

improvements in welding techniques, including strict codes, šanja postupaka zavarivanja, uključujući i stroge stan-

requirements and directives, the crack occurrence in welded darde, zahteve i smernice, pojava prslina u zavarenim

structures cannot be completely excluded. This is why frac- konstrukcijama se ne može u potpunosti izbeći. Zato je

ture mechanics analysis is inevitable in the structural integ- analiza mehanike loma neophodna u proceni integriteta

rity assessment of all welded structures. Examples of prac- svih zavarenih konstrukcija. Razmotreni su primeri praktič-

tical application of fracture mechanics parameters in ne primene parametara mehanike loma u integritetu posuda

cracked pressure vessel structural integrity are considered. pod pritiskom sa prslinom. Rad prikazuje određivanje para-

This paper shows the determination of parameters of the metara zamorne prsline za konstituente zavarenih spojeva

fatigue crack for constituents of welded joints produced of izrađenih od niskolegiranog čelika povišene čvrstoće Nioni-

high strength low alloyed steel Nionikral-70 (yield strength kral-70 (napona tečenja 700 MPa). Rezultati pokazuju da

700 MPa). Results have shown that the position of notch položaj zareza i inicijacija prsline utiču na vrednosti raspo-

and crack initiation affect the values of the stress intensity na napona za granicu zamora Kth i na parametre Parisove

range of fatigue threshold Kth and parameters in the relacije.

Paris’ equation.

fication, since a detected crack can initiate after a certain

INTRODUCTION

time. For safe operation, possible mechanisms of crack

The operation of a welded structure depends on its safety growth to critical size should be analysed and the condition

under the applied load. Requirements regarding the security of a fracture occurrence must be considered, /1-7/.

of the structure posed to the manufacturer are very strict Most frequent defects in welded structures are surface

when failure might endanger human lives. Nevertheless, cracks, caused by imperfections in the welded joint, as are

catastrophic failures still occur in exploitation of welded inclusions, overheating, corrosion damages, cracks in the

structures. In most cases failure is caused by the existence fusion region, welder’s markings. Surface crack propaga-

of cracks of critical size. Structural safety and integrity tion presents a significant problem, asking to consider also

analysis have to consider the influence of the fatigue crack the events immediately after its initiation /8/. Owing to this,

and its threshold value, eventually followed by in-service the relationship between crack growth rate per load cycle,

propagation through parent metal (PM), weld metal (WM) da/dN (where a is the crack length, and N represents the

and heat-affected-zone (HAZ) of the welded joint. The number of load cycles) and fracture mechanics parameter,

corresponding data have to be defined in the material speci- the stress intensity factor range, ΔK, has to be known.

INTEGRITET I VEK KONSTRUKCIJA 183 STRUCTURAL INTEGRITY AND LIFE

Vol. 11, br. 3 (2011), str. 183–187 Vol. 11, No. 3 (2011), pp. 183–187

Determination of fatigue crack growth parameters in Određivanje parametara zamornog rasta prsline kod

The paper is aimed at determining the complete relation- Paris, Gomez and Anderson (1961), and later Paris and

ship da/dN vs. ΔK for welded joint constituents (PM, WM Erdogan (1963) had supposed that the crack growth under

and HAZ) produced of high strength low-alloyed steel variable loads would follow the law, usually known as the

(HSLA) of nominal yield strength 700 MPa, for characteris- Paris’ law,

ing the properties, since they are not required in the basic da

steel specification. C K m (1)

dN

DETERMINATION OF CRACK GROWTH RATE Here the stress intensity factor range, ΔK, is defined as

Paris, Gomey and Anderson have first proposed in 1961 K Kmax Kmin (2)

that the crack growth rate, da/dN, might be correlated with

the stress intensity factor range, ΔK, when the material is Kmax and Kmin are maximum and minimum stress inten-

exposed to variable loading of constant amplitude, /9/. sity factors corresponding to the maximal load, Pmax (or

However, the leading journals in this area did not accept to maximal nominal stress, max) and minimal load, Pmin (or

publish the offered paper. This approach has been adopted minimal nominal stress, min) in a cycle. Values C and m in

for the characterisation of fatigue crack growth in the Eq.(1) are constants obtained empirically, and depend on

condition of small scale plastic deformation at the crack tip. the properties and material microstructure, fatigue frequency,

Linear elastic fracture mechanics (LEFM) has postulated mean stress, the environment, loading mode, stress state

that the stress intensity factor range, determined according and the applied temperature. The empirical law of crack

to remote stress and the cracked component geometry growth, expressed by Eq.(1) and presented in Fig. 1 as a

unambiguously characterize fatigue crack growth, even sigmoidal curve, is a most frequently used form for the

when the fatigue fracture mechanism is not known. characterisation of crack growth rate for a broad spectrum

Under variable loads, the crack can initiate from an of engineering materials and testing conditions.

existing defect or damage at maximum values of stress, Three different regimes of crack growth can be recog-

well below quasi-static fracture toughness. In the small- nised from the diagram in Fig. 1.

scale yielding condition, when the non-linear zone in fact

represents a disturbance in the otherwise elastic material,

Figure 1. Different regimes of stable fatigue crack propagation, /9/.

Slika 1. Različiti režimi stabilnog rasta zamorne prsline, /9/

In the regime A, the average increment of crack growth

MATERIAL

is smaller than one lattice spacing per cycle, connected to a

threshold stress intensity factor range, ΔKth. Below this The material used in the investigation is NIONIKRAL-

threshold, the crack either does not grow, or grows very 70 (NN-70), a high strength low-alloyed steel (HSLA), of

slowly, followed by a very steep increase of da/dN with ΔK. nominal yield strength 700 MPa and tensile strength

The law of Paris, Eq.(1), indicating the linear relation- 800 MPa, applied in the manufacture of welded pressure

ship in regime B between log(da/dN) and log(ΔK), is vessels for storing liquefied gas and also used in subma-

applied only on the segment of the growth curve related to rines. The chemical composition of NN-70 steel is presented

stable fatigue growth. in Table 1, and its mechanical properties are given in

Regime C corresponds to high ΔK values, when the Table 2. Tensile properties of the NN-70 steel are presented

crack propagates fast to final fracture, after reaching the in Fig. 2.

critical stress intensity factor value Kc.

INTEGRITET I VEK KONSTRUKCIJA 184 STRUCTURAL INTEGRITY AND LIFE

Vol. 11, br. 3 (2011), str. 183–187 Vol. 11, No 3 (2011), pp. 183–187

Determination of fatigue crack growth parameters in Određivanje parametara zamornog rasta prsline kod

Table 1. Chemical composition of NIONIKRAL-70 (weight %).

Tabela 1. Hemijski sastav NIONIKRAL-70 (tež. %)

C Si Mn P S Cr Ni Mo V Al

0.10 0.2 0.23 0.009 0.018 1.24 3.1 0.29 0.05 0.08

Table 2. Mechanical properties of NIONIKRAL-70.

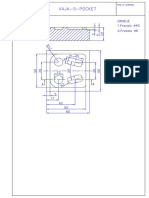

Tabela 2. Mehaničke osobine NIONIKRAL-70 Figure 3. Standard single-edge notch bend specimen SEN(B) used

Yield stress, Rp0.2 Tensile strength, Rm in the experiments.

Specimen Slika 3. Standardna epruveta sa ivičnim zarezom za savijanje

(MPa) (MPa)

PM, parallel to rolling SEN(B) koja je upotrebljena u eksperimentima

780 820

direction EXPERIMENTS

WM 718 791

HAZ 750 800 The crack growing rate da/dN and fatigue threshold ΔKth

are determined by moment controlled bending test on the

device RUMUL CRACTRONIC 160 Nm at the Welding

Laboratory of the Faculty of Mechanical Engineering, Uni-

versity of Maribor, Slovenia. Tests are performed with speci-

mens from parent metal (PM), weld metal (WM) and heat-

affected-zone (HAZ). Crack growth is monitored by meas-

uring potential drop by strain gauge RUMUL RMF A-5, meas-

uring 5 mm length, located on the specimen face surface.

The data about the tested steel and applied electrodes are

considered in Refs. /11-13/. Fatigue pre-cracks of 1.029 mm

length are produced with frequency of 90 Hz in all speci-

mens, applying the stress range in which the stress intensity

factor Kmax was lower than 15 MPam1/2 for the PM, and

12 MPam1/2 for WM, and 10 MPam1/2 for HAZ.

For further crack propagation of 0.9 mm the load ratio of

Figure 2. Stress vs. strain for steel NIONIKRAL-70. variable loading in tension is

Slika 2. Napon i deformacija za čelik NIONIKRAL-70 d

R 0

NIONIKRAL-70 steel is produced in the electric furnace, g

cast into ingots, rolled into slabs, and finally rolled into with frequency of 63 to 97 Hz, depending on the maximal

18 mm thick plates. High strength is achieved by combin- load. The strain gauge foil has fractured with fatigue crack

ing classical quenching and tempering, and additional grain growth, causing linear response of electrical resistance in

refining by an optimal combination of chemistry, micro- the foil with the change in crack length, /14/.

alloying and corresponding precipitation. Care is devoted to

obtain the best combination of strength, ductility, tough- ANALYSIS OF EXPERIMENTAL RESULTS

ness, crack resistance to initiation and growth, and the Experimental results are presented in diagrams log(da/dN)

stability of these properties at low temperatures, high resis- vs. logΔK, in Fig. 4 for PM, in Fig. 5 for WM, and in Fig. 6

tance to fatigue and stress corrosion, and in any case – good for HAZ. The results for the three welded joint constituents

workability and weldability, /10/. are summarised in Fig. 7.

SPECIMEN GEOMETRY From Figs. 4 to 6 it is possible to determine coefficients

C and m introduced in the Paris’ law, Eq.(1), for welded

The manufacture of welded structures using HSLA steels joint constituents, and also the threshold values for the

is recommended because the structural mass is reduced due stress intensity factor range, ΔKth. Results are listed in

to the high strength, saving both material and energy. How- Table 3. Table 3 also contains experimentally determined

ever, by increasing the strength, in general, the sensibility values of plane strain fracture toughness, KIc, /12/. It is clear

to cracking increases, what is of special importance for from the presented diagrams that the location of notch and

welded joints. Thus pre-cracked specimens are used for the fatigue pre-crack both affect the behaviour of the welded

determination of crack resistance and structural integrity joint under variable loading.

assessment.

The specimen applied in this analysis is shown in Fig. 3. Table 3. C and m in Paris’ law and fracture mechanics parameters

related to fatigue of welded joint constituents of NIONIKRAL 70.

Standard single-edge notch bend specimens SEN(B) are

Tabela 3. C i m u Parisovom zakonu i parametri mehanike loma sa

used, of rectangular cross section, with grinded and zamorom konstituenata zavarenog spoja NIONIKRAL-70

polished faces, taken from shielded manual arc butt welded

18 mm thick plates. Specimen dimensions are: length L = Crack Coeff. Coeff. ΔKth KIc (MPam1/2)

location C m (MPam1/2)

100 mm, width W = 16 mm and thickness B = 12 mm, with

PM 9.0510–14 4.76 5.85 158

2 mm deep notch.

WM 6.0710–12 2.393 5.82 120

HAZ 8.0610–12 3.054 4.3 147

INTEGRITET I VEK KONSTRUKCIJA 185 STRUCTURAL INTEGRITY AND LIFE

Vol. 11, br. 3 (2011), str. 183–187 Vol. 11, No 3 (2011), pp. 183–187

Determination of fatigue crack growth parameters in Određivanje parametara zamornog rasta prsline kod

Figure 4. Plot of crack growth rate da/dN vs. stress intensity factor Figure 7. Comparison of crack growth rate da/dN vs. stress

range ΔK for PM. intensity factor range ΔK for welded joint constituents.

Slika 4. Promena brzine rasta prsline da/dN sa rasponom faktora Slika 7. Poređenje brzine rasta prsline da/dN sa rasponom faktora

intenziteta napona K za PM intenziteta napona K za konstituente zavarenog spoja

CONCLUSION

In order to extend the characterisation of crack behaviour

for HSLA steel NN-70, the two fatigue parameters, fatigue

threshold, ΔKth, and coefficients C and m in the region of

validity of Paris’ law (so-called regime B, see Fig. 1) have

been experimentally determined for the SMAW welded

joint constituents (PM, WM and HAZ).

Fatigue threshold coincided well for PM and WM,

Fig. 7, Table 3. Its value for HAZ has been found to be

lower, ΔKth, indicating that in these constituents the fatigue

crack will initiate first. The slope of the crack growth rate is

approximately parallel for PM and WM, but indicates a

slower rate for WM. The crack growth rate line of HAZ

intersects that of PM, indicating faster rate for PM in the

Figure 5. Plot of crack growth rate da/dN vs. stress intensity factor first segment, the rate is the same for both PM and HAZ in

range ΔK for WM. the intersection region and the two lines are almost parallel

Slika 5. Promena brzine rasta prsline da/dN sa rasponom faktora in the final segment. For a crack growth rate in the HAZ the

intenziteta napona K za WM

change of slope can be revealed in Fig. 6, what is attributed

to different microstructures through which cracking has

developed.

The data for plane strain fracture toughness KIc, from

previous tests (Table 3), correspond to previously described

behaviour.

The behaviour of the welded joint has shown that fatigue

properties are not significantly reduced by welding, but for

a better understanding of the fatigue crack behaviour in

individual constituents of welded joints, a further investiga-

tion is necessary. It is also to remark that the tested speci-

mens had grinded and polished faces, so that no effects of

stress concentration from the weld overfill may contribute.

Overfill grinding is prescribed only for extremely loaded

pressure equipment, as are submarines and some reactors in

the chemical processing industry.

Figure 6. Plot of crack growth rate da/dN vs. stress intensity factor

range ΔK for HAZ. ACKNOWLEDGEMENTS

Slika 6. Promena brzine rasta prsline da/dN sa rasponom faktora Authors acknowledge the financial support of the Serbian

intenziteta napona K za HAZ Ministry of Science, project TR 35011, and the financial

support of international project EUREKA E! 5348.

INTEGRITET I VEK KONSTRUKCIJA 186 STRUCTURAL INTEGRITY AND LIFE

Vol. 11, br. 3 (2011), str. 183–187 Vol. 11, No 3 (2011), pp. 183–187

Determination of fatigue crack growth parameters in Određivanje parametara zamornog rasta prsline kod

REFERENCES

1. Božić, B., Sedmak, S., Petrovski, B., Sedmak, A., Resistance to 9. Suresh, S., Fatigue of materials, 2nd Ed., Cambridge University

crack growth of welded joint constituents in a real structure, Press, 1998.

(in Serbian) Glas CCCLIX Srpske akademije nauka i umet- 10. Grabulov, V., A contribution to the assessment of chemical

nosti, Odeljenje tehničkih nauka, 28, Beograd : 53-74, 1990. composition and plate thickness influence on crack initiation in

2. Radon, J.C., Study of Surface Fatigue Cracks, Structural Integ- welded joints made of NIONIKRAL 70 steel, MSc thesis (in

rity and Life, 6(3): 97-110, 2006. Serbian), University of Belgrade, Faculty of Technology and

3. Assoul, Y., Bacha, N., Semmar, D., Probabilistic model for Metallurgy, Belgrade, 1986.

pitting corrosion and fatigue life estimation of turbine blades, 11. Grabulov, V. Blačić, I., Radović, A., et al., Toughness and

Structural Integrity and Life, 8(1): 3-12, 2008. ductility of high strength steels welded joints, Structural Integ-

4. Manjgo, M., Sedmak, A., Grujić, B., Fracture and fatigue rity and Life, 8(3): 181-190, 2008.

behaviour of NIOMOL 490K welded joint, Structural Integrity 12. Zrilić, M., Grabulov, V., Burzić, Z., et al., Static and impact

and Life, 8(3): 149-158, 2008. crack properties of a high-strength steel welded joint, Intern J

5. Jodin, P., Zedira, H., Azari, Z., Gilgert, J., Fatigue life assess- Pres. Ves. & Piping, 84(3):139-150, 2007.

ment of an excavator arm box – Experiments and Computa- 13. Janković, M., Behaviour of low-alloyed steel and its manual

tions, Structural Integrity and Life, 9(1): 23-28, 2009. arc welded joint in fatigue loading, (in Serbian) IFMASS 3

6. Barter, S.A., Molent, L., White, P., Dixon, B., Recent Austra- Monograph ‘Fracture Mechanics of Welded Joints’, GOSA and

lian full-scale F/A-18 fatigue tests, Structural Integrity and TMF, Belgrade : 355-361, 1985.

Life, 9(2): 89-112, 2009. 14. Čamagić, I., Burzić, Z., Cvetković, S., Application of fracture

7. Petrašković, Z., The analysis of hysteresis in low cycle fatigue mechanics in the determination of fatigue crack growth

of steel dampers for earthquake application, Structural Integ- parameters for characteristic regions in the welded joint, (in

rity and Life, 9(3): 181-192, 2009. Serbian) Welding and Welded Structures, 3 : 83-90, 2008.

8. Radon, J., Fatigue surface crack growth in steel welded joints,

(in Serbian) IFMASS 3 Monograph ‘Fracture Mechanics of

Welded Joints’, GOSA and TMF, Belgrade : 177-210, 1985.

New Trends in Fatigue and Fracture NT2F12

27-30 May 2012, Brasov, Romania

Topics General information

Stress and strain analysis ABSTRACT SUBMISSION GUIDELINE

• experimental methods

• numerical analysis Authors are requested to electronically submit one page abstract of the

Materials paper by 30 JANUARY 2012 following instructions on website

• metallic materials, titanium alloys http://www.dimeg.poliba.it/NT2F/NT2F/Information_2.html

• sintered materials Only electronic submissions will be accepted: please do not fax, do not

• plastics and composites send duplicate submissions.

• biomaterials All files must be sent to NT2F12@poliba.it .

• nano-materials File dimension should not exceed 6 MB.

Structure Final manuscripts are due by 30 MARCH 2012.

• failure assessment English is the official language of the Conference.

• reliability and safety factors

• environemental effect ORGANIZING COMMITTEE

• hydrogen embrittlement Universitatea Transilvania din Brasov, Romania

• welded joints behaviour Sorin Vlase (Chairman), Mihai Ulea

• design codes and directives Politecnico di Bari, Italy

Defects assessment Carmine Pappalettere, Katia Casavola, Catalin Iulian Pruncu

• at macro, meso, micro and nano level

• size and location determination Université de Lille 1, France

• non destructive testing Moussa Nait-Abdeladiz

SCIENTIFIC COMMITTEE

Venue

Zitouni AZARI, Univ. de Metz, France

The Conference will be held at University Taoufik BOUKHAROUBA, Algeria

Transilvania of Brasov, AULA building in Strada Moussa NAIT-ABDELAZIZ, Univ. de Lille 1, France

Iuliu Maniu 41A. Marenglen GJONAJ, Polytechnic Univ. of Tirana, Albania

Dept. of Mechanics - Univ. Transilvania of Brasov, Nenad GUBELJAK, Univ. of Maribor, Slovenia

Str. Eroilor 29, 500036 – Brasov Paolo LAZZARIN, Univ. di Padova, Italy

Liviu MARSAVINA, Polytechnic Univ. of Timisoara, Romania

Contacts Yuri G. MATVIENKO, Mechanical Eng. Research Inst. of the Russian Academy

Prof S. Vlase of Sciences, Moscow, Russia

Tel. +40 268 418992 Lj. MILOVIC, Univ. of Belgrade, Serbia

Mobile: +40 722 643020 Carmine PAPPALETTERE, Politecnico di Bari, Italy

Fax +40 268 418992 Gheorghe PINTILIE, Univ. Vasile Alecsandri din Bacau, Romania

NT2F12@poliba.it Guy PLUVINAGE, Univ. de Metz, France

Dr C. Casavola Cetin M. SONSINO, Fraunhofer Institute for Structural Durability, Germany

Tel. +39 080 5962787 Vlad ULMANU, Univ. de Petrol Gaze Ploiesti, Romania

Fax +39 080 5962777

INTEGRITET I VEK KONSTRUKCIJA 187 STRUCTURAL INTEGRITY AND LIFE

Vol. 11, br. 3 (2011), str. 183–187 Vol. 11, No 3 (2011), pp. 183–187

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- v4 Pocket1i2Dokument1 Seitev4 Pocket1i2nerminNoch keine Bewertungen

- 037 IVK1 2007 IA DM ZupčaniciDokument10 Seiten037 IVK1 2007 IA DM ZupčanicizrosandNoch keine Bewertungen

- 181 TMT10 147 PDFDokument4 Seiten181 TMT10 147 PDFnerminNoch keine Bewertungen

- Parameter Optimization of Tube Hydroforming Using Genetic AlgorithmDokument7 SeitenParameter Optimization of Tube Hydroforming Using Genetic AlgorithmnerminNoch keine Bewertungen

- 149 Ivk2 2007 SS As MK PDFDokument10 Seiten149 Ivk2 2007 SS As MK PDFnerminNoch keine Bewertungen

- CATIA - FEM Solid 2 (FMD) PDFDokument4 SeitenCATIA - FEM Solid 2 (FMD) PDFnerminNoch keine Bewertungen

- 149 Ivk2 2007 SS As MK PDFDokument10 Seiten149 Ivk2 2007 SS As MK PDFnerminNoch keine Bewertungen

- Simbolička Matematika: M. Essert: Matlab InženjerskiDokument19 SeitenSimbolička Matematika: M. Essert: Matlab InženjerskinerminNoch keine Bewertungen

- Fortran Za Treci Razred Masinske Tehnicke SkoleDokument140 SeitenFortran Za Treci Razred Masinske Tehnicke SkoleMirhad SinanovicNoch keine Bewertungen

- FEM Utilities For CATIA Spec SheetDokument10 SeitenFEM Utilities For CATIA Spec Sheetklomps_jrNoch keine Bewertungen

- Advanced MaterialsDokument46 SeitenAdvanced MaterialsAnonymous FYDVlNDzuNoch keine Bewertungen

- CATIA - FEM Solid 2 (FMD) PDFDokument4 SeitenCATIA - FEM Solid 2 (FMD) PDFnerminNoch keine Bewertungen

- 1999 2 Spojen PDFDokument33 Seiten1999 2 Spojen PDFnerminNoch keine Bewertungen

- Analyzing the Structure and Processes of Technological SystemsDokument25 SeitenAnalyzing the Structure and Processes of Technological SystemsVasiljevic SlobodanNoch keine Bewertungen

- SolidWorks Flow SimulationDokument52 SeitenSolidWorks Flow SimulationMladen50% (2)

- Catia V5 Od Fred Karam I Charles KleismitDokument209 SeitenCatia V5 Od Fred Karam I Charles KleismitEdina Japić-HadžićNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 2016 IS 383 NSandDokument21 Seiten2016 IS 383 NSandproscokeNoch keine Bewertungen

- Eva Foam SpecificationsDokument5 SeitenEva Foam SpecificationsMada PerwiraNoch keine Bewertungen

- Fundamentals of Metal Forming: Fig 1.1 Fig 1.2Dokument45 SeitenFundamentals of Metal Forming: Fig 1.1 Fig 1.2Aparnesh MukhopadhyayNoch keine Bewertungen

- Bainite in SteelsDokument479 SeitenBainite in SteelsCharlie Chong100% (7)

- Indian Minerals Yearbook 2013 Report on Kaolin, Ball Clay, and Other Clays ProductionDokument24 SeitenIndian Minerals Yearbook 2013 Report on Kaolin, Ball Clay, and Other Clays ProductionPriyanka SareenNoch keine Bewertungen

- Case Study & Applications of Group TechnologyDokument29 SeitenCase Study & Applications of Group Technologybt19109019 Aditya VermaNoch keine Bewertungen

- Al2O3 ZrO2 FoamsDokument7 SeitenAl2O3 ZrO2 Foamspranaya_beheraNoch keine Bewertungen

- Hair Fibre Reinforced Concrete: Nila V. M, Raijan K.J, Susmitha Antony, Riya Babu M, Neena Rose DavisDokument8 SeitenHair Fibre Reinforced Concrete: Nila V. M, Raijan K.J, Susmitha Antony, Riya Babu M, Neena Rose Davisakanksha btceNoch keine Bewertungen

- T02 NsaDokument2 SeitenT02 NsaSanjay C BhattNoch keine Bewertungen

- Effect of Drawing Angle Size of A Die On Wire Drawing and Bunching ProcessDokument6 SeitenEffect of Drawing Angle Size of A Die On Wire Drawing and Bunching ProcessRaghavendra BetakerurNoch keine Bewertungen

- 3CREFORM Catalog English 2009Dokument101 Seiten3CREFORM Catalog English 2009TheBlackCat1977Noch keine Bewertungen

- Wooden PalletDokument5 SeitenWooden Palletneeshakothari31Noch keine Bewertungen

- Iron ProductionDokument8 SeitenIron ProductionVictor AlvarezNoch keine Bewertungen

- Me Automation & Robotics SyllabusDokument27 SeitenMe Automation & Robotics SyllabusweenniiNoch keine Bewertungen

- Major Project Report PDFDokument74 SeitenMajor Project Report PDFGaddam Sudheer100% (1)

- A Novel Tini/Alsi Composite With High Strength and High Damping CapacityDokument4 SeitenA Novel Tini/Alsi Composite With High Strength and High Damping CapacitypranithroyNoch keine Bewertungen

- Compatibility Test Pada PelumasDokument14 SeitenCompatibility Test Pada PelumasIzna YuniarNoch keine Bewertungen

- Amity University Production and Operations Management CourseDokument6 SeitenAmity University Production and Operations Management CourseSana KhanNoch keine Bewertungen

- 8th Edition NPCA QC ManualDokument181 Seiten8th Edition NPCA QC Manualjacobmill100% (2)

- NIOSH Lifting Equation (Single Task Analysis) : Step-by-Step GuideDokument16 SeitenNIOSH Lifting Equation (Single Task Analysis) : Step-by-Step Guidebudi utomoNoch keine Bewertungen

- How To Avoid Cracks in Plaster? (Plastic & Drying Shrinkage Cracks)Dokument3 SeitenHow To Avoid Cracks in Plaster? (Plastic & Drying Shrinkage Cracks)Ashish JainNoch keine Bewertungen

- HexWeb HRH10 DataSheet Eu PDFDokument6 SeitenHexWeb HRH10 DataSheet Eu PDFMatijaNoch keine Bewertungen

- Construction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckDokument12 SeitenConstruction and Cost Analysis of An FRP Reinforced Concrete Bridge DeckVergor Dominic Cueto EbiteNoch keine Bewertungen

- Edited Letter To DAS MOEDokument2 SeitenEdited Letter To DAS MOEapi-3832475Noch keine Bewertungen

- Fabric Properties Modification by Plasma ProcessDokument29 SeitenFabric Properties Modification by Plasma Processiwpda2009Noch keine Bewertungen

- Effect of Self Curing Agents On Mechanical Properties of ConcreteDokument5 SeitenEffect of Self Curing Agents On Mechanical Properties of ConcretesamiNoch keine Bewertungen

- HARDNESS TEST METHODSDokument13 SeitenHARDNESS TEST METHODShaizum_adamNoch keine Bewertungen

- Ansys Ls-Dyna Material ModelsDokument2 SeitenAnsys Ls-Dyna Material ModelsalfredohhbNoch keine Bewertungen

- Fatigue Analysis of Piping System Using Caesar IIDokument9 SeitenFatigue Analysis of Piping System Using Caesar IIHmd Mokhtari100% (1)

- Marshall Test WorksheetDokument5 SeitenMarshall Test WorksheetMoslem AghapourNoch keine Bewertungen