Beruflich Dokumente

Kultur Dokumente

Piques Y Chimeneas

Hochgeladen von

yo puesOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Piques Y Chimeneas

Hochgeladen von

yo puesCopyright:

Verfügbare Formate

1

PIQUES

PIQUES yy CHIMENEAS:

CHIMENEAS:

Diseño,

Diseño, Construcción

Construcción yy Operación

Operación

Ph. D., P. Eng. TADEUSZ S. GOLOSINSKI

tgolosinski@expo.intercade.org

Consultor INTERCADE

Junio 2008

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

2

6. EXCAVACION MECHANICA

DE PIQUES

(Shaft Boring)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

3

SHAFT VS. RAISE

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

4

SHAFT BORING

• Use raiseborer for smaller diameter shafts.

• Use specialized shaft boring machines.

– Wirth, Robbins (Atlas Copco).

– V-Mole (rodless).

• Applies to vertical shafts only.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

5

PROCEDURE

• Drill pilot hole (see ”Raises”).

– Use directional drilling tools.

• Ream the pilot hole to diameter of between 1.83 and

2.4 m.

– The center pilot hole to drop the cuttings down.

– Sufficient verticality of the reamed hole is of

essence (a challenge if over 1,300 m.)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

6

MORE ON PROCEDURE

• Ream shaft downwards to the final diameter.

– Boring diameter from 5.0 to 8.5 m.

– Assembly of the borer some 6 weeks.

• Foreshaft needed to start the shaft drilling operation.

– To place the drilling mchine and associated

equipment.

– Slipped and lined to the depth of ca.11 m.

• Install the hoisting facilities.

– Needed to hoist the people and material to/from the

stage.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

7

MORE ON PROCEDURE (3)

• Shaft support and equipping.

– Robotic arm installed on the stage.

• Reaming, muck disposal, shaft support, permanent

shaft equipping performed continuously and

concurrently.

• Feasible performance.

– 7 m/d for concrete lined, 7 mm. dia shaft.

• Removal of the boring machine from the shaft bottom.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

8

REQUIREMENTS

• Relatively competent rock.

– Unsupported core center to stand up.

– See above for geomechanics evaluations.

• Reamed pilot hole required.

– 1.83 to 2.4 m in diameter.

– Sufficient verticality.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

9

RVDS: ROTARY VERTICAL

DRILLING SYSTEM Tubular Housings

And Stabilizer

Bearing Section

Assembly

Transmission

Unit

Power Unit

(Rotor and Stator)

Dump Sub

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

10

V-MOLE

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

11

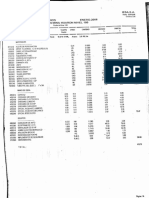

TABLE 3-STATISCAL DATA ON SHAFT BORERS

1971 1977 1980

Machine V.Mole 1 V.Mole 2 V.Mole 3

Drive Elec/Hydr. Elec/Mech. Elec/Mech.

Drill diam 4.5-5.0 m 5.0-6.5 m 6.5-8.0 m

Cutter head 3 x 75 kw 4 x 110 kw 6 x 110 kw

Total kw 230 kw 490 kw 7450 kw

Torque mkp 27 000 76 000 141 000

Thrust 300 Mp 550 Mp 740 Mp

Load/disc App. 4 Mp App. 12 Mp App. 12 Mp

Cutters Two discs One disc One disc

Disc spacing 48 mm 70 mm 70 mm

Head angle 30º 45º 45º

Gripper pressure 12 kp/cm2 12 kp/cm2 12 kp/cm2

Weight App. 100 Mp App. 150 Mp App. 237 Mp

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

12

PERMANENT LINING INSTALLATION

(ROCK REINFORCMENT)

Support Deck

(independent

of rotational

& vertical

mole motion)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

13

AUTOMATED SHOTCRETING

Initial support:

Segmented steel

ring pushed against

rock by hydraulic

Jacks.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

14

FULL-FACE SHAFT BORER

- No pilot hole.

- Hydraulic muck

disposal.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

15

SHAFT BORING MACHINE

(NO PILOT POLE)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

16

Large diameter

Drill rig

(Hughes)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

17

A COMPARISON

In relatively hard rock, the speed of the various operations

might be as follows:

• Pilot hole drilling: 15 m/day.

• Enlarging pilot hole to 1.8 metres: 7.5 m/day.

• Enlarging to 6.5 metres with V-mole: 6 m/day.

Assuming a 1,000-metre deep shaft and neglecting the

time to set up the V-mole, a completed shaft would take

368 days — an advance rate of 2.7 m/day — which is no

faster than conventional sinking.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

18

ADVANCES

• In relatively hard rock, the speed of the various

operations might be as follows:

– pilot hole drilling — 15 m/day.

– enlarging pilot hole to 1.8 metres — 7.5 m/day.

– enlarging to 6.5 metres with V-mole — 6 m/day.

• Assuming a 1,000-metre deep shaft and neglecting the

time to set up the V-mole, a completed shaft would take

368 days — an advance rate of 2.7 m/day — which is no

faster than conventional sinking.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

19

FEATURES

Advantages:

• Shaft walls remain smooth.

• The overbreak is eliminated.

– Less rock to handle (15%+ ?)

• No rock damage by blasting.

• Less manpower / people involved.

Problems:

• Independent access to shaft bottom is a must.

• Cost and expertise.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

20

MECHANICAL

SHAFT

EXCAVATOR

(Gewerkschaft

Walter)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

21

Comparison Items Conventional Shaft Bore

Blind Sink

Competitively

1 Depth Restrictions None Economical from

600 m

2 Diameter None 4.5 m to 8.5 m in

Restrictions diameter

3 Speed of sink Faster up Faster from 600 m

to 600m onwards

4 Blasting All sinking None

5 Need bottom No Yes

access

6 Lining thickness Thicker Thinner

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

22

Comparison Items Conventional Shaft Bore

Blind Sink

Thinner

6 Lining thickness Thicker

Comparison,

7 Safety aspects Poorer Best

cont ….

8 Stage requiriment Large Small

Large hoist

9 Kibble hoist Small hoist for men

for rock &

requeriment & material only

material

10 Stage hoist Large Smaller

11 Sinking crew Larger Smaller

size

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

23

Additional

Available Data

Data

Compatability of raise

Raise Geotechnical Preliminary Site Specific

specification With Ground Monitoring

Information Evaluation Investigations

Conditions Investigations

Proceed

Acceptable

With Raise

Raise General Major

MONITOR

Diameter Geology Features -Pilot hole

Air Photo

Interpretation -Advance Input

Assess Acceptable For

-Delays Future

Underground Contracts

Risk

-Falis of

Mapping Re Assess Ground

Variability

Raise Regional

-Strenght

Lenght Structure Possibly Risk -Bit Life

Structure

Acceptable/ Orientated

Unacceptable Core Drilling Machine

-Machine

Perfromance

Acceptable

Premeability

Testing

Groundwater Local Stability

Structure

Material

Property

Machine Tetsing

Groundwater Boreability

Characteristics

In-Situ RE DESIGN

Stress -Relocate

Measurement -Amend

Location In-Situ Inflows Specification

Stress

-Diameter

-Method

Unacceptable -Sink

Conventionally

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

24

“Q” VALUE

(MSUS – MAX STABLE UNSUPPORTED SPAN)

RQD Jr Jw

• Q= ------------ x -------- x ---------

Jn Ja SFR

Where:

RQD – Rock Quality Designation. 1. Estimate of rock

Jn - Joint set number. block size.

2. Discontinuity shear

Jr - Joint roughness number.

strength.

Ja - Joint alteration number. 3. Condition of active

Jw - Joint water reduction factor. stress around the

SFR - Stress reduction factor. excavation.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

25

“QR” VALUE FOR SHAFTS

Apply adjustment factors (cumulative):

1. Wall condition adjustment factor.

2. Discontinuity orientation adjustment factor.

3. Weathering and alteration adjustment factor.

Note:

Qr does not predict stand-up times. These need to be

based on RMR rating.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

26

STABILITY OF SHAFT EXCAVATION

(AFTER MCCRACKEN & STACEY)

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

27

SUGGESTED LEVELS OF

RELIABILITY

(MCCRACKEN & STACEY)

Service Reliability Probability

Excavation Type Life R of Failure

(Years) (%) P(f)

Unlined hoisting Shaft >15 99 0,01

Ventilation Shaft 10 95 0,05

Ore Pass >2 85 0,15

Ore Pass 1 75 0,25

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

28

HOW TO TREAT ADVERSE

CONDITIONS?

Control of ground conditions:

• Cement grouting prior to shaft boring.

• Provide immediate rock support.

Others:

• Keep the pilot hole and open during shaft boring.

• Watch for potential scaling and deterioration of the

center core pilot shaft.

Ph. D. Eng. TADEUSZ S. GOLOSINSKI - tgolosinski@expo.intercade.org - Consultor Intercade

Das könnte Ihnen auch gefallen

- Truncation of Post-Tensioned Tendons - H KirrageDokument45 SeitenTruncation of Post-Tensioned Tendons - H KirrageAnonymous 8pw0Il0Dsy100% (1)

- Rotary Products 5632Dokument40 SeitenRotary Products 5632Pablo AbalosNoch keine Bewertungen

- Westco Product Catalog 2019Dokument16 SeitenWestco Product Catalog 2019DiegoCaicedo1982100% (2)

- Bearings: A Tribology HandbookVon EverandBearings: A Tribology HandbookM. J. NealeBewertung: 3 von 5 Sternen3/5 (8)

- Pullers & Puller Sets Proto PDFDokument24 SeitenPullers & Puller Sets Proto PDFMauricio GarciaNoch keine Bewertungen

- Impact Sockets ProtoDokument35 SeitenImpact Sockets ProtoMauricio Garcia100% (1)

- Invert Heave in Operation TunnelDokument9 SeitenInvert Heave in Operation TunnelKen LiewNoch keine Bewertungen

- DR560Dokument3 SeitenDR560yo puesNoch keine Bewertungen

- 26.techtips Sheavesgrooves enDokument5 Seiten26.techtips Sheavesgrooves enVinit AhluwaliaNoch keine Bewertungen

- Tube Fitters ManualDokument275 SeitenTube Fitters ManualBrian Aplin100% (2)

- Downhole Motors PDFDokument15 SeitenDownhole Motors PDFarasquare100% (1)

- Sct1375 Technical SpecDokument315 SeitenSct1375 Technical SpecMUTHUKKUMARAMNoch keine Bewertungen

- Alta Mimi 2015Dokument11 SeitenAlta Mimi 2015Félix Gallo CruzNoch keine Bewertungen

- Linear 2 Manual CompleteDokument115 SeitenLinear 2 Manual CompleteDjvionico PerezNoch keine Bewertungen

- ASBP 7 17-26 26-32 CurrentDokument10 SeitenASBP 7 17-26 26-32 CurrentJhonathan MirandaNoch keine Bewertungen

- CE199 2L 1Q1819 HGE 1st Take PDFDokument8 SeitenCE199 2L 1Q1819 HGE 1st Take PDFCristal Haze VictoriaNoch keine Bewertungen

- 26th March 2002 Room and Pillar Mechanised MiningDokument59 Seiten26th March 2002 Room and Pillar Mechanised MiningCraig ThomasNoch keine Bewertungen

- Spe 30364 Seebty Ofpotrebum Endnws: Platform Concept OutlineDokument12 SeitenSpe 30364 Seebty Ofpotrebum Endnws: Platform Concept Outlinebr_fdm1604100% (1)

- What Is VersaFlex® Liner Hanger SystemDokument24 SeitenWhat Is VersaFlex® Liner Hanger Systemadvantage025Noch keine Bewertungen

- Report On Design of RCC Retaining Wall Between Ch. Km. 54.342 & 54.504 (Old Ch. Km. 53.625 & 53.787)Dokument76 SeitenReport On Design of RCC Retaining Wall Between Ch. Km. 54.342 & 54.504 (Old Ch. Km. 53.625 & 53.787)shashibhushan singhNoch keine Bewertungen

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingVon EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNoch keine Bewertungen

- 1620015541geotech Practice DTalk Yan Adriansyah2021Dokument18 Seiten1620015541geotech Practice DTalk Yan Adriansyah2021MaruliTobingNoch keine Bewertungen

- Analysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisDokument6 SeitenAnalysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisJournal of Computer Science and EngineeringNoch keine Bewertungen

- Blow Out PreventorDokument6 SeitenBlow Out PreventorCesar Valdivia MontañoNoch keine Bewertungen

- PILES Analysis and DesignDokument2 SeitenPILES Analysis and DesignJC Agbuya100% (1)

- MPDDokument19 SeitenMPDeriantoelonNoch keine Bewertungen

- I2 Piques Profundización 2Dokument0 SeitenI2 Piques Profundización 2Bryan CisnerosNoch keine Bewertungen

- Draft Specification of Various Items of TunnelsDokument29 SeitenDraft Specification of Various Items of TunnelsDEBASIS BARMANNoch keine Bewertungen

- Scaffolding & Form Works For SlabsDokument27 SeitenScaffolding & Form Works For Slabssaleh ehmouda99Noch keine Bewertungen

- DSI Ground Support Mechanical RockboltsDokument14 SeitenDSI Ground Support Mechanical RockboltscuteshivNoch keine Bewertungen

- Size Effect of The Concrete Cone Failure LoadDokument10 SeitenSize Effect of The Concrete Cone Failure LoadFatin Amilin MustaparNoch keine Bewertungen

- Power Transmission Using Elbow MechanismDokument17 SeitenPower Transmission Using Elbow MechanismsarathNoch keine Bewertungen

- PoleAttachmentCracking MooreDokument8 SeitenPoleAttachmentCracking MooreSirish ShresthaNoch keine Bewertungen

- Modal Shaker FAQ RevaDokument20 SeitenModal Shaker FAQ RevaHOD MECHNoch keine Bewertungen

- 316 - Recent Advances in Overburden and Down-The-Hole Drilling TechniquesDokument10 Seiten316 - Recent Advances in Overburden and Down-The-Hole Drilling Techniquessoja2009Noch keine Bewertungen

- Lab Manual Strata ControlDokument14 SeitenLab Manual Strata ControlPiyush Tiwari100% (1)

- TONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithDokument4 SeitenTONGS: Large-Capacity, Self-Locking Wrenches Used To Grip Drill String Components and Apply Torque. As WithAhmed AmirNoch keine Bewertungen

- Gearless Power-Transmission-Project Report 4Dokument2 SeitenGearless Power-Transmission-Project Report 4A-2011 AKASH DUTTANoch keine Bewertungen

- Stress Analysis of Bevel Gear Tool, Using FEA Tool ANSYS V.14Dokument6 SeitenStress Analysis of Bevel Gear Tool, Using FEA Tool ANSYS V.14IjrtsNoch keine Bewertungen

- Autoset MK7 ManualDokument6 SeitenAutoset MK7 ManualRobinson SanchezNoch keine Bewertungen

- Studyofstrengtho00crai PDFDokument76 SeitenStudyofstrengtho00crai PDFRodrigo MachadoNoch keine Bewertungen

- SSI AFTS21000 Tube Diffusers: What Makes The A Worldwide Choice?Dokument2 SeitenSSI AFTS21000 Tube Diffusers: What Makes The A Worldwide Choice?JOHNNY CALERONoch keine Bewertungen

- Frame Saw Manual 1902Dokument111 SeitenFrame Saw Manual 1902wolf143Noch keine Bewertungen

- Design Procedure For Concrete AnchorDokument36 SeitenDesign Procedure For Concrete AnchorYan Yan100% (1)

- Automatic Motorized Bench-ViceDokument24 SeitenAutomatic Motorized Bench-Vicekaran pitrodaNoch keine Bewertungen

- Design and Fabrication of Diamond JackDokument31 SeitenDesign and Fabrication of Diamond JacksachinNoch keine Bewertungen

- Synopsis Pedal HacksawDokument13 SeitenSynopsis Pedal Hacksawbalbir100% (1)

- Tutorial Sheet 1: - Eme 602 (Submitted by Achintya Mehrotra, 0802740006)Dokument12 SeitenTutorial Sheet 1: - Eme 602 (Submitted by Achintya Mehrotra, 0802740006)Achintya MehrotraNoch keine Bewertungen

- Design and Analysis of Belt Conveyor Roller ShaftDokument5 SeitenDesign and Analysis of Belt Conveyor Roller ShaftGogy100% (1)

- Bookchapter2012 Chapter16SolidStateNanoGearsManipulationsDokument11 SeitenBookchapter2012 Chapter16SolidStateNanoGearsManipulationshurmakmuhNoch keine Bewertungen

- Catalogo de AnchorsDokument28 SeitenCatalogo de Anchorspavito1986Noch keine Bewertungen

- Pipe Sticks SupportDokument8 SeitenPipe Sticks SupportAmitNoch keine Bewertungen

- DSI Ground Support Catalogue-V3 UsDokument84 SeitenDSI Ground Support Catalogue-V3 UsJustin CorbettNoch keine Bewertungen

- Design of Castelleated Beam by British CodeDokument8 SeitenDesign of Castelleated Beam by British Codemsn sastryNoch keine Bewertungen

- Spe/Iadc 79915 Gyrostab Project: The Missing Link Azimuth and Inclination Mastered With New Principles For Standard Rotary BhasDokument11 SeitenSpe/Iadc 79915 Gyrostab Project: The Missing Link Azimuth and Inclination Mastered With New Principles For Standard Rotary BhasJohnSmithNoch keine Bewertungen

- Encyclopedia of AnchoringDokument74 SeitenEncyclopedia of Anchoringgutter1Noch keine Bewertungen

- Understanding The Pile Stress Wave What The PDA Test Shows: December 2015Dokument38 SeitenUnderstanding The Pile Stress Wave What The PDA Test Shows: December 2015exowilzNoch keine Bewertungen

- MKT Vibratory Hammer Selection and Soils TrainingDokument24 SeitenMKT Vibratory Hammer Selection and Soils Traininggustavo caicedoNoch keine Bewertungen

- PulvoMatic AzulDokument5 SeitenPulvoMatic AzulGABRIEL RONDO CUBA (PSICOLOGO-INVESTIGADOR)Noch keine Bewertungen

- I10Cables PDFDokument60 SeitenI10Cables PDFyo puesNoch keine Bewertungen

- Gearless Transmission: College of Engineering &technology Ghatikia, Bhubaneswar, Odisha - 751003, IndiaDokument32 SeitenGearless Transmission: College of Engineering &technology Ghatikia, Bhubaneswar, Odisha - 751003, IndiahiteshNoch keine Bewertungen

- Structure Analysis-1: Lab ManualDokument18 SeitenStructure Analysis-1: Lab ManualUsman HaiderNoch keine Bewertungen

- Ring Pocket RRS Rev008bDokument22 SeitenRing Pocket RRS Rev008bPaul BarriosNoch keine Bewertungen

- How To Perform Low Strain Pile Integrity TestDokument6 SeitenHow To Perform Low Strain Pile Integrity TestAamirShabbirNoch keine Bewertungen

- Spe-168301-Ms-Composite Is Multi-Plug Milling That fast-SLBDokument7 SeitenSpe-168301-Ms-Composite Is Multi-Plug Milling That fast-SLBfkong16688Noch keine Bewertungen

- Apex Catlogue A43010-MinDokument24 SeitenApex Catlogue A43010-Minfaisal kingNoch keine Bewertungen

- NEXO Sliding SleeveDokument3 SeitenNEXO Sliding SleevetongsabaiNoch keine Bewertungen

- LINK Shop ExerciseDokument15 SeitenLINK Shop ExerciseNicole MilanNoch keine Bewertungen

- I10Cables PDFDokument60 SeitenI10Cables PDFyo puesNoch keine Bewertungen

- SimposiumDokument57 SeitenSimposiumyo puesNoch keine Bewertungen

- Relleno Pasta TesisDokument126 SeitenRelleno Pasta Tesisyo puesNoch keine Bewertungen

- I11Cierre PDFDokument13 SeitenI11Cierre PDFyo puesNoch keine Bewertungen

- Logistic ADokument10 SeitenLogistic Ayo puesNoch keine Bewertungen

- Documento CompletoDokument16 SeitenDocumento CompletoJuan Carlos Rodriguez EnriquezNoch keine Bewertungen

- AmbumentDokument7 SeitenAmbumentGaurav MadgaonkarNoch keine Bewertungen

- End - For TilesDokument171 SeitenEnd - For Tilesxinlok007Noch keine Bewertungen

- Introduction To Unsaturated Soil MechanicsDokument3 SeitenIntroduction To Unsaturated Soil MechanicsReginald HammahNoch keine Bewertungen

- Unified Soil Classification System (ASTM D 2487) : PI Is 7.5. HenceDokument6 SeitenUnified Soil Classification System (ASTM D 2487) : PI Is 7.5. HenceImad HabeebNoch keine Bewertungen

- Ret-Wall B 20211105 7.5m (4 - No Toe)Dokument4 SeitenRet-Wall B 20211105 7.5m (4 - No Toe)Ahmad NasriNoch keine Bewertungen

- DamDokument6 SeitenDamDG GarciaNoch keine Bewertungen

- Soil ReportDokument10 SeitenSoil Reportsubramanyam kumarNoch keine Bewertungen

- Types of FoundationDokument18 SeitenTypes of FoundationJoshua SainiNoch keine Bewertungen

- Geotechnical Engineering 1: Soil Investigation PresentationDokument19 SeitenGeotechnical Engineering 1: Soil Investigation PresentationMohamed SubiyeNoch keine Bewertungen

- Silt Factor-229Dokument24 SeitenSilt Factor-229SM ConsultantsNoch keine Bewertungen

- Lecture #-1aDokument11 SeitenLecture #-1aAbdullahNoch keine Bewertungen

- GDM Ch-12 EmbankmentsDokument118 SeitenGDM Ch-12 EmbankmentstonaalaniNoch keine Bewertungen

- Application For Building PermitsDokument8 SeitenApplication For Building PermitsTracey DeeNoch keine Bewertungen

- T 17ayeDokument17 SeitenT 17ayeDaniel Santillan GarzaNoch keine Bewertungen

- 3.lab Test Stress Anlysis - WEEK 3 PDFDokument90 Seiten3.lab Test Stress Anlysis - WEEK 3 PDFAnanda GautamaNoch keine Bewertungen

- Qater SeismicDokument1 SeiteQater SeismicobadaehNoch keine Bewertungen

- Pile Group Settlement Analysis On The Basis of Static Load TestDokument9 SeitenPile Group Settlement Analysis On The Basis of Static Load TestKam PaolinoNoch keine Bewertungen

- Part 1. Technical Report StructureDokument5 SeitenPart 1. Technical Report StructurenenaddimNoch keine Bewertungen

- Laboratory 4 - Rock Slope StabilityDokument14 SeitenLaboratory 4 - Rock Slope StabilityTikar Mengkuang0% (7)

- 01 - Mine Geotechnics - Supandi - IntroductionDokument43 Seiten01 - Mine Geotechnics - Supandi - IntroductionN Kusuma WardhanaNoch keine Bewertungen

- TERREMOTO E PERFORAZIONE RAPPORTO ICHESE - ReportDokument213 SeitenTERREMOTO E PERFORAZIONE RAPPORTO ICHESE - ReportPrimaDaNoi.itNoch keine Bewertungen

- Permeability - Simple ProblemDokument11 SeitenPermeability - Simple ProblemDhananjay ShahNoch keine Bewertungen