Beruflich Dokumente

Kultur Dokumente

Tek 5-5B Integrating Concrete Masonry Walls With Metal Building Systems

Hochgeladen von

clam2014Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tek 5-5B Integrating Concrete Masonry Walls With Metal Building Systems

Hochgeladen von

clam2014Copyright:

Verfügbare Formate

An information series from the national authority on concrete masonry technology

INTEGRATING

CONCRETE MASONRY WALLS TEK 5-5B

WITH METAL BUILDING SYSTEMS Details (2011)

INTRODUCTION steel and masonry, careful consideration must be given to ac-

commodating differential movement between the two materials

Metal buildings are used extensively for warehouses and and their assemblies. In Serviceability Design Considerations

other structures requiring large, open floor spaces. Part of their for Low-Rise Buildings (ref. 2), a lateral drift limit of H/100 for

design flexibility comes from the ability to clad metal buildings a ten year recurrence wind loading based on main wind force

with a variety of materials to provide different appearances or resisting system loads is suggested for low rise buildings with

functions to the buildings. Concrete masonry walls are popular exterior masonry walls reinforced vertically. See Table 12.12.1 of

enclosure systems for metal buildings because of masonry's ASCE 7 (ref. 4) for the allowable story drift for seismic loading.

aesthetic appeal, impact resistance, strength, and fire resistance. Most reinforced masonry walls for metal buildings are designed

The durability of concrete masonry resists incidental impacts to span vertically, supported by a steel spandrel at the top and by

from hand carts and forklifts, provides maximum protection in the foundation at the bottom.

disasters such as earthquakes and hurricanes, as well as superior

security, fire resistance, and noise control. Wall Base

Concrete masonry walls used for metal buildings can include: Because of stiffness and deformation incompatibilities between

exterior full-height walls, either with or without a parapet; exterior flexible steel and rigid masonry assemblies, and consequently, to

partial-height or wainscot walls; and interior loadbearing walls or control the location of cracking in the masonry walls that may result

nonloadbearing walls or partitions. Architectural concrete masonry from relatively larger steel frame deflections at the top of the structure,

units, such as colored, split faced, burnished, or scored units, can

be used to provide an almost limitless array of textures and

patterns to the walls. These units can be used for the entire Ridge Roof purlin

facade or for banding courses to achieve specific patterns Eave strut

Roof System

or highlight certain design aspects of the building. Rigid frame

A more detailed discussion of the system, along Gutter column

with structural design and construction considerations, is Rigid frame

included in Concrete Masonry Walls for Metal Building

height

Systems (ref. 1). The manual is intended to bridge the gap

Eave

n

between the engineer who designs the metal building system

r spa

a

and the engineer who designs the concrete masonry walls Cle

to unify their respective knowledge.

CMU wall

DETAILS Spandrel Ba End wall frame

ys

Bracing pac End wall column

ing

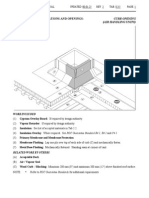

A typical metal building clad with masonry is shown End wall roof beam

in Figure 1. Figures 2 - 6 show some typical details used End wall

Sidewall

for exterior concrete masonry cladding on a metal building. End wall corner column

These details may need to be modified to meet individual

design conditions. Figure 1—Schematic of Metal Building Clad with

Because of the inherent material differences between Concrete Masonry Walls

Related TEK: Keywords: anchorage, architectural details, cladding, connectors,

construction details, deflection, drift, lateral loads, lateral support, metal

building, shear walls, veneer, wall movement

NCMA TEK 5-5B 1

a “hinge” can be incorporated at the base of

the masonry assembly to allow out-of-plane

Rigid frame column Concrete masonry

wall rotation.

Two such hinge connections are shown

Flashing adhered to Extend foundation dowel 2 in.

concrete masonry (51 mm) into grouted cell of in Figures 2 and 3. The construction shown in

wall. Tape bar above flashing Figure 2 uses through-wall flashing to break

"Hairpin" reinforcement to reduce bond to grout the bond at the base of the wall providing a

as required by design simply supported condition allowing shear

Mastic seal around transfer but no moment for out-of-plane

reinforcing bar

loading. In many cases the shear force can

be adequately transferred by friction through

Continuous flashing the flashed bed joint. However, it is recom-

with drip mended that a positive shear connection be

provided by extending foundation dowels

Column footing as Concrete column across the joint. It is recommended that the

required by design number of bars extended across the horizontal

Wall strip footing joint be minimized, and that the extension be

beyond limited to 2 in. (51 mm), to ensure that the

joint will behave as assumed. Therefore, every

Footing

reinforcement as vertical bar otherwise required for strength at

required by design critical sections does not necessarily need to

be extended through the joint.

Masonry shear walls are very strong

Figure 2—Vertically Spanning Reinforced Concrete Masonry Side Wall at and stiff and are often used to resist lateral

Foundation for Other than Shear Wall Segment loads. However, masonry wall sections used

as shear wall segments must have vertical

reinforcement continuous into the foundation as shown in Figure

3. Flashing is also incorporated at the floor level to allow the wall

some out-of-plane rotation due to building drift. Design aids are

included in Concrete Masonry Walls for Metal Building Systems

(ref. 1) for in-plane and out-of-plane reinforced masonry walls

as well as for lintels and anchor bolts.

Appendix C also presents design ex-

Rigid frame column Concrete masonry wall amples using NCMA’s popular, easy

to use Structural Masonry Design

Lap splice per design System Software (ref. 3). As shown

Flashing adhered to in Figure 4, these walls normally span

concrete masonry Continuous flashing vertically and are laterally supported

"Hairpin" reinforcement with drip by a spandrel at the top of the masonry

as required by design

portion of the wall.

Foundation dowel-extend past When the masonry is designed

flashing and lap with vertical with a base hinge, it is important to

reinforcement in masonry shear properly detail the building corners

wall segment where required by to accommodate the movements.

design to maintain continuity and A vertical isolation joint should be

resist in-plane overturning forces

placed near the building corner and

Column footing as proper consideration should be given

required by design Concrete column to the masonry and steel connections

Wall strip footing at corner columns. Flexible anchors

beyond and/or slotted connections should be

used.

Footing

reinforcement as Wainscot Walls

required by design

Although full height masonry walls

provide the most benefit particularly

when the masonry is used for shear

Figure 3—Vertically Spanning Reinforced Concrete Masonry walls, partial-height walls, or wain-

Side Wall Shear Wall Segment Detail at Foundation scots, are sometimes used. These walls

are commonly 4 to 10 ft (1.2 to 3.0 m)

2 NCMA TEK 5-5B

high with metal panel walls extending from the top of

the masonry to the roof. The masonry provides strength

and impact resistance for the portion of the wall most

susceptible to damage.

Column Detail Rigid frame

Figure 5 shows the connection of a rigid frame

column to concrete masonry sidewalls with a coinci- Bond beam

dent vertical control joint. The details show vertically Anchor bolts at 17 in.

adjustable column anchors connecting the wall to the (432 mm) o.c., or 34 in.

column. For walls designed to span vertically, it is (864 mm) o.c. max.

good practice to provide a nominal number of anchors Reinforced bond

connecting the wall to the column to add stiffness and beam at spandrel

strength to the edge of the wall. If rigid enough, these

Grout cell at anchor Spandrel

anchors can assist in laterally bracing the outside col-

bolt locations

umn flange. For larger lateral loads, more substantial

connections may be required. Anchorage to end wall Mesh to confine grout

columns is very similar. Reinforced concrete

masonry wall

Spandrel Detail (reinforcement not

A typical spandrel detail is shown in Figure 6. shown for clarity)

Spandrels should be placed as high as possible to re-

duce the masonry span above the spandrel, especially Note: A standardized punching of 9/16 in. (14 mm) diameter holes at 17 in.

on walls with parapets. Depending on the rigid frame (432 mm) centers for ½ in. (13 mm) masonry anchors is recommended

configuration used, rigid frame connection plates and The masonry engineer may choose to place the anchors farther apart than

diagonal stiffeners may restrict the spandrel location. 17 in. (432 mm) o.c.; however, anchors should not be spaced more than 34

The spandrel is designed by the metal building manu- in. (864 mm) as this could affect lateral stability of the steel member being

facturer. If the inner flange of the spandrel needs to connected to prevent torsional buckling (ref. 1).

be braced, the metal building manufacturer will show

on the drawings where the braces are required along

Figure 4—Single Wythe Wall Without Parapet at

with the information needed for the masonry engineer

Low Side Wall or Eave (see also Figure 6)

to design them and their anchorage to the wall.

Shim plates should be used at spandrel/masonry connections

to allow for camber in the spandrel and other construction toler-

ances (see Figure 6). The steel spandrel should never be pulled

to the masonry wall by tightening the anchor bolts.

CONSTRUCTION SEQUENCE

Rigid frame column

Vertical reinforcement

Typically, construction of metal buildings as required by wall Inside flange brace as

with concrete masonry walls proceeds as fol- design required by metal

lows: concrete footing and column placement; building manufacturer

concrete masonry foundation wall construction (typ.)

to grade; concrete slab placement; steel erec- Anchor bolt (typ.)

tion; and concrete masonry wall construction. Shim as

Note, however, that this sequence may need to required (typ.)

be modified to meet the needs of a particular

project. For example, this construction sequence

changes when loadbearing end walls are used.

In this case, the steel supported by the masonry

is erected after the masonry wall is in place.

Coordination between the various trades Contol joint Grout cell at anchor

is essential for efficient construction. Precon- Sash unit location (typ.)

struction conferences are an excellent way for Preformed gasket Adjustable anchors

contractors and subcontractors to coordinate Rake joint, fill with sealant

construction scheduling and to avoid conflicts on closed-cell backer rod

and delays.

Figure 5—Adjustable Anchor Connection to Rigid Frame Column

and Control Joint Detail

NCMA TEK 5-5B 3

Concrete masonry wall

A Reinforced bond beam at

Anchor bolt spandrel. 6 in.(152 mm) min.

grout on all sides of anchor which

Spandrel flange may require a two or more course

high bond beam as shown

Anchor bolt

21 2 in.

(64 mm) Spandrel

min. Brace if required by metal

building manufacturer (may be

under spandrel or on top of

spandrel)

Section A-A

A Shim plates as required

Grout cell at anchor bolt for

brace

Figure 6—Structural Spandrel for Lateral Load Detail

REFERENCES

1. Concrete Masonry Walls for Metal Building Systems, TR 149A. National Concrete Masonry Association, Metal Building Manufacturers As-

sociation, International Code Council, 2011.

2. Serviceability Design Considerations for Steel Buildings, AISC Steel Design Guide #3. American Institute of Steel Construction, 2003.

3. Structural Masonry Design System Software. National Concrete Masonry Association, Western States Clay Products Association, The Brick

Industry Association, and the International Code Council, 2010.

4. Minimum Design Loads for Buildings and Other Structures, ASCE 7-05. American Society for Civil Engineers, 2005.

NCMA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy

and the application of the information contained in this publication.

NATIONAL CONCRETE MASONRY ASSOCIATION

13750 Sunrise Valley Drive, Herndon, Virginia 20171

www.ncma.org

To order a complete TEK Manual or TEK Index, contact NCMA Publications (703) 713-1900

4 NCMA TEK 5-5B

Das könnte Ihnen auch gefallen

- Ducker Window ReportDokument38 SeitenDucker Window Reportschloo0% (1)

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- TBA 09 Detailing of Clay MasonryDokument42 SeitenTBA 09 Detailing of Clay MasonryHenderson CheungNoch keine Bewertungen

- Seismic Technical Guide Seismic Expansion Joints en SC2496Dokument15 SeitenSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11Noch keine Bewertungen

- Hebel Tech Manual 3Dokument79 SeitenHebel Tech Manual 3subhaschandraNoch keine Bewertungen

- TemperedGlassBible PDFDokument698 SeitenTemperedGlassBible PDFengineering masatalsahraaNoch keine Bewertungen

- Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteVon EverandStructural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced ConcreteNoch keine Bewertungen

- Trusses English PDFDokument12 SeitenTrusses English PDFPrakash SharmaNoch keine Bewertungen

- Design of Concrete Masonry Walls For Blast Loading: TEK 14-21ADokument9 SeitenDesign of Concrete Masonry Walls For Blast Loading: TEK 14-21Afoush bashaNoch keine Bewertungen

- STP1453 - Structural Glazing Failure - 5 Case StudyDokument8 SeitenSTP1453 - Structural Glazing Failure - 5 Case Studygionobilli100% (1)

- Entrances Storefronts Window Walls Curtain Walls (PDFDrive)Dokument226 SeitenEntrances Storefronts Window Walls Curtain Walls (PDFDrive)liquid snakeNoch keine Bewertungen

- 14 Masonry ConstructionMethodsDokument78 Seiten14 Masonry ConstructionMethodsMaverick LastimosaNoch keine Bewertungen

- Seismic Rehabilitation Methods for Existing BuildingsVon EverandSeismic Rehabilitation Methods for Existing BuildingsNoch keine Bewertungen

- Joist Design GuideDokument98 SeitenJoist Design GuidemtNoch keine Bewertungen

- WoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFDokument4 SeitenWoodWorks - 2017-01 - 5-Over-2 Podium Design - Part 1 PDFtdegrobertNoch keine Bewertungen

- 2011-Bes-Peevey Common Installation Problems Foraluminum Framed Curtain Wall SystemsDokument12 Seiten2011-Bes-Peevey Common Installation Problems Foraluminum Framed Curtain Wall SystemsMurat PizanNoch keine Bewertungen

- CSSBI 59 05 IntroductionDokument8 SeitenCSSBI 59 05 IntroductionrigaschNoch keine Bewertungen

- Exterior Cladding DetailsDokument13 SeitenExterior Cladding DetailsMuhammad irfan javaidNoch keine Bewertungen

- Braced Frameworks: An Introduction to the Theory of StructuresVon EverandBraced Frameworks: An Introduction to the Theory of StructuresNoch keine Bewertungen

- RCABC Roof Curb Pentrations and OpeningsDokument13 SeitenRCABC Roof Curb Pentrations and OpeningsdomcristiniNoch keine Bewertungen

- The Importance of Proper Roof Slope: Tech TodayDokument1 SeiteThe Importance of Proper Roof Slope: Tech TodayGiri DharanNoch keine Bewertungen

- Managing Building Movement With JointsDokument57 SeitenManaging Building Movement With JointsDavid Alexander Calderón ArreguiNoch keine Bewertungen

- Foamglas For The Building Envelope: Cellular Glass Insulation GuideDokument48 SeitenFoamglas For The Building Envelope: Cellular Glass Insulation GuideAlejandro Vargas CalderonNoch keine Bewertungen

- Earthquake Resistant Design and Risk ReductionVon EverandEarthquake Resistant Design and Risk ReductionBewertung: 4 von 5 Sternen4/5 (1)

- Illustrated Guide to Door Hardware: Design, Specification, SelectionVon EverandIllustrated Guide to Door Hardware: Design, Specification, SelectionNoch keine Bewertungen

- Chapter 5 Staircase Types, Analysis and DesignDokument15 SeitenChapter 5 Staircase Types, Analysis and Designzeru32611720% (1)

- 2016 Cts Buccellato HenshellDokument10 Seiten2016 Cts Buccellato HenshellSoe PaingNoch keine Bewertungen

- ASTM B 69 Rolled ZN - 1998Dokument4 SeitenASTM B 69 Rolled ZN - 1998ecsuperalNoch keine Bewertungen

- NCMA TEK 19-4A Water Penetration Resistance (2008)Dokument4 SeitenNCMA TEK 19-4A Water Penetration Resistance (2008)B0B_PNoch keine Bewertungen

- Building Facades: San Francisco Inspection Requirements: by Carolyn Searls, Matthew WorsterDokument2 SeitenBuilding Facades: San Francisco Inspection Requirements: by Carolyn Searls, Matthew WorsterANoch keine Bewertungen

- Bor11999 QLD Manual Bk12Dokument58 SeitenBor11999 QLD Manual Bk12Vinh DuongNoch keine Bewertungen

- Architectural Precast JointsDokument28 SeitenArchitectural Precast JointsFalgun HindochaNoch keine Bewertungen

- Differences Between Galvalume and Galvanized in Metal RoofingDokument2 SeitenDifferences Between Galvalume and Galvanized in Metal RoofingPPM100% (1)

- Profiled Metal Roofing DesignDokument32 SeitenProfiled Metal Roofing DesignEJourDNoch keine Bewertungen

- 2013 Mason Ancon MDC BracketsDokument36 Seiten2013 Mason Ancon MDC BracketsalwezalokNoch keine Bewertungen

- Construction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceDokument13 SeitenConstruction and Performance of Curtain Wall Systems For Super Highrise Buildings - The Hong Kong's ExperienceHeronijosh DgNoch keine Bewertungen

- AAMA 320-10: General Guidelines For Troubleshooting Welded Thermoplastic CornersDokument17 SeitenAAMA 320-10: General Guidelines For Troubleshooting Welded Thermoplastic CornersDavidNoch keine Bewertungen

- Civil Engineer (Planning): Passbooks Study GuideVon EverandCivil Engineer (Planning): Passbooks Study GuideNoch keine Bewertungen

- Ncma Tek: Segmental Retaining Wall Units TEK 2-4BDokument4 SeitenNcma Tek: Segmental Retaining Wall Units TEK 2-4BJorge Luis Arevalo LopezNoch keine Bewertungen

- BarChip Fibres Replace Steel in Chilean HousingDokument2 SeitenBarChip Fibres Replace Steel in Chilean HousingPedro Augusto Delgado NascimentoNoch keine Bewertungen

- Writing SpecificationDokument86 SeitenWriting SpecificationVinicius AlvesNoch keine Bewertungen

- Tek 10-03Dokument4 SeitenTek 10-03Thai DamNoch keine Bewertungen

- CS Hafele EbookDokument40 SeitenCS Hafele EbookAjrod RodNoch keine Bewertungen

- Curtain Wall Manual - Section 8 InstallationDokument32 SeitenCurtain Wall Manual - Section 8 InstallationphilipNoch keine Bewertungen

- Unified Facilities Criteria Ufc 4 721 10Dokument96 SeitenUnified Facilities Criteria Ufc 4 721 10hamz786Noch keine Bewertungen

- Metal Building Vehicular-Access Door Wind Analysis and DesignDokument6 SeitenMetal Building Vehicular-Access Door Wind Analysis and DesignSimon TileNoch keine Bewertungen

- Good Faith Best Practices - Facade Maintenance InspectionsDokument7 SeitenGood Faith Best Practices - Facade Maintenance InspectionsANoch keine Bewertungen

- Presentation - Slides MALONE Mass Timber Connections Webinar 210609Dokument91 SeitenPresentation - Slides MALONE Mass Timber Connections Webinar 210609AntonNoch keine Bewertungen

- TFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresDokument6 SeitenTFEC Timber Design Guide 17 Fire Resistance of Mass Timber StructuresVelmohanaNoch keine Bewertungen

- Galvalume Brochure Web2Dokument24 SeitenGalvalume Brochure Web2amitNoch keine Bewertungen

- 2014 CTS Wind UpliftDokument11 Seiten2014 CTS Wind Upliftluca bragliaNoch keine Bewertungen

- Tank Farm Construction Extent of Condition Review For Tank IntegrityDokument179 SeitenTank Farm Construction Extent of Condition Review For Tank Integrityclam2014Noch keine Bewertungen

- STI HSS Column Load Tables LRFD PDFDokument123 SeitenSTI HSS Column Load Tables LRFD PDFAhmed Ali MohammedNoch keine Bewertungen

- Office Prototype FinalDokument16 SeitenOffice Prototype Finalclam2014Noch keine Bewertungen

- Overview Plastic Hinge Analysis PDFDokument34 SeitenOverview Plastic Hinge Analysis PDFclam2014Noch keine Bewertungen

- Stiffness Reduction MethodDokument34 SeitenStiffness Reduction Methodclam2014Noch keine Bewertungen

- CFS Compression Member Design PDFDokument2 SeitenCFS Compression Member Design PDFclam2014Noch keine Bewertungen

- Lateral Torsional Buckling of Cellular Steel Beams PDFDokument16 SeitenLateral Torsional Buckling of Cellular Steel Beams PDFclam2014Noch keine Bewertungen

- AISC-EJ Unreinforced Web Openings in Steel BeamsDokument14 SeitenAISC-EJ Unreinforced Web Openings in Steel BeamsBala SrikanthNoch keine Bewertungen

- General Solution Eccentric Loads Weld Groups PDFDokument10 SeitenGeneral Solution Eccentric Loads Weld Groups PDFclam2014Noch keine Bewertungen

- Unmasking Weld Ductility HandoutDokument112 SeitenUnmasking Weld Ductility Handoutclam2014Noch keine Bewertungen

- Trapezoidal Steel Box Girder Bridge - Design Guides and MethodsDokument84 SeitenTrapezoidal Steel Box Girder Bridge - Design Guides and MethodsDavid A. BurrowsNoch keine Bewertungen

- Application of AISC Design Provisions For Tapered Members PDFDokument13 SeitenApplication of AISC Design Provisions For Tapered Members PDFclam2014Noch keine Bewertungen

- EJ 2005 JMFisher V42 - 04 - 247 PDFDokument14 SeitenEJ 2005 JMFisher V42 - 04 - 247 PDFSitananNoch keine Bewertungen

- Unmasking Weld Ductility HandoutDokument112 SeitenUnmasking Weld Ductility Handoutclam2014Noch keine Bewertungen

- Unmasking Weld Ductility HandoutDokument112 SeitenUnmasking Weld Ductility Handoutclam2014Noch keine Bewertungen

- Bolted Field Splices For Steel Bridge Flexural Members May2017Dokument62 SeitenBolted Field Splices For Steel Bridge Flexural Members May2017clam2014Noch keine Bewertungen

- Design CFSL Portal Frame Buildings Including Joint Effects Secondary MembersDokument31 SeitenDesign CFSL Portal Frame Buildings Including Joint Effects Secondary Membersclam2014Noch keine Bewertungen

- Tips For Avoiding Crane Runway ProblemsDokument25 SeitenTips For Avoiding Crane Runway ProblemsAshishNoch keine Bewertungen

- Steel DuctilityDokument18 SeitenSteel DuctilityGeorge KinaNoch keine Bewertungen

- STI HSS Column Load Tables LRFD PDFDokument123 SeitenSTI HSS Column Load Tables LRFD PDFAhmed Ali MohammedNoch keine Bewertungen

- AISC Field Fixes PDFDokument153 SeitenAISC Field Fixes PDFfegenbush93% (15)

- Local Buckling Strength of Steel Foam Sandwich PanelsDokument26 SeitenLocal Buckling Strength of Steel Foam Sandwich Panelsclam2014Noch keine Bewertungen

- Experience Use Heavy W Shapes in Tension PDFDokument15 SeitenExperience Use Heavy W Shapes in Tension PDFclam2014Noch keine Bewertungen

- SEAU Practical Uses of Nonlinear Pushover AnalysisDokument95 SeitenSEAU Practical Uses of Nonlinear Pushover Analysisclam2014Noch keine Bewertungen

- Seismic Non West Coast Part 1 HandoutDokument49 SeitenSeismic Non West Coast Part 1 Handoutclam2014Noch keine Bewertungen

- Practical Implementation Stability Bracing Strength Stiffness Guidelines Steel I-Girder BridgeDokument14 SeitenPractical Implementation Stability Bracing Strength Stiffness Guidelines Steel I-Girder Bridgeclam2014Noch keine Bewertungen

- Seismic Non West Coast Part 2 HandoutDokument63 SeitenSeismic Non West Coast Part 2 Handoutclam2014Noch keine Bewertungen

- Practical Three Dimensional Nonlinear Static Pushover AnalysisDokument4 SeitenPractical Three Dimensional Nonlinear Static Pushover AnalysisArvin Edsel SiosonNoch keine Bewertungen

- Plastic Design Multistory FramesDokument290 SeitenPlastic Design Multistory Framesclam2014Noch keine Bewertungen

- Seismic Drift Control and Building Periods PDFDokument9 SeitenSeismic Drift Control and Building Periods PDFclam2014Noch keine Bewertungen

- Slides Arrays Two Dimensional ArraysDokument12 SeitenSlides Arrays Two Dimensional ArraysPratham MishraNoch keine Bewertungen

- BJT Common Emitter Characteristics: Experiment 6Dokument5 SeitenBJT Common Emitter Characteristics: Experiment 6beesahNoch keine Bewertungen

- Quiz13 130630200754 Phpapp02Dokument10 SeitenQuiz13 130630200754 Phpapp02anukrititiwaNoch keine Bewertungen

- What Is New in API 610 11th EdDokument6 SeitenWhat Is New in API 610 11th EdAnonymous 1XHScfCINoch keine Bewertungen

- Honda Bikes and ScootersDokument6 SeitenHonda Bikes and ScootersShamrjit AgrahariNoch keine Bewertungen

- A Butterfly Effect Volume 1 (Years 1 - 2)Dokument362 SeitenA Butterfly Effect Volume 1 (Years 1 - 2)xdyj2005Noch keine Bewertungen

- Green Revolution: It's Acheivements and FailuresDokument24 SeitenGreen Revolution: It's Acheivements and FailuresSingh HarmanNoch keine Bewertungen

- Commissioning Valve Product BrochureDokument14 SeitenCommissioning Valve Product BrochureblindjaxxNoch keine Bewertungen

- Euroncap 2017 Audi q5 DatasheetDokument13 SeitenEuroncap 2017 Audi q5 DatasheetCosmin AnculiaNoch keine Bewertungen

- P1 - Duct Design IntroductionDokument30 SeitenP1 - Duct Design IntroductionAndryx MartinezNoch keine Bewertungen

- Renault Gearbox and Final Drive OilsDokument10 SeitenRenault Gearbox and Final Drive OilsPhat0% (1)

- A. Desplat: Godzilla (2014) - Film Score AnalysisDokument18 SeitenA. Desplat: Godzilla (2014) - Film Score AnalysisR.PercacciNoch keine Bewertungen

- Envgeo D 17 00052 - R1Dokument42 SeitenEnvgeo D 17 00052 - R1Recep AkanNoch keine Bewertungen

- Bravo Petroleum ProfileDokument8 SeitenBravo Petroleum ProfileJacob Thom ZiwahwaNoch keine Bewertungen

- Dimensional Stability After MoldingDokument14 SeitenDimensional Stability After MoldingpgovindaiahNoch keine Bewertungen

- Ffu 0000034 01Dokument8 SeitenFfu 0000034 01Karunia LestariNoch keine Bewertungen

- RAJPUT - Gokul IndustryDokument76 SeitenRAJPUT - Gokul IndustryrajputvjNoch keine Bewertungen

- Concrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIDokument3 SeitenConcrete Tunnel Design and Calculation Spreadsheet Based On AASHTO and ACIFirat PulatNoch keine Bewertungen

- Laura Gentile Letter On Hampden County CourthouseDokument6 SeitenLaura Gentile Letter On Hampden County CourthouseMassLiveNoch keine Bewertungen

- Papr114 SpectralDokument4 SeitenPapr114 Spectrallilivaca28Noch keine Bewertungen

- Research Paper On TurbojetDokument6 SeitenResearch Paper On Turbojetqptwukrif100% (1)

- Nuitration in Human 3Dokument2 SeitenNuitration in Human 3Usman AmeenNoch keine Bewertungen

- Specifications: Louie Jean Mabanag Ar - 3BDokument8 SeitenSpecifications: Louie Jean Mabanag Ar - 3BLouie Jean100% (1)

- Colegio de San Gabriel Arcangel of Caloocan, IncDokument7 SeitenColegio de San Gabriel Arcangel of Caloocan, IncKIRITO SALINASNoch keine Bewertungen

- DuranDuran OrdinaryWorldDokument1 SeiteDuranDuran OrdinaryWorldEduardo LuzNoch keine Bewertungen

- B2 First For Schools 4, Test 4 Answer Key, Reading and Use of EnglishDokument7 SeitenB2 First For Schools 4, Test 4 Answer Key, Reading and Use of EnglishAlejandro Iglesias Peón0% (1)

- Sandvik DD210Dokument4 SeitenSandvik DD210Lener Elvin Lopez LavadoNoch keine Bewertungen

- 017 - Chapter 3 - L13Dokument6 Seiten017 - Chapter 3 - L13nanduslns07Noch keine Bewertungen

- L 7 Thermal Death Time DataDokument21 SeitenL 7 Thermal Death Time DataVaibhav GuptaNoch keine Bewertungen