Beruflich Dokumente

Kultur Dokumente

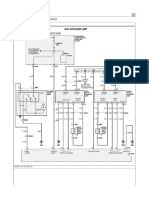

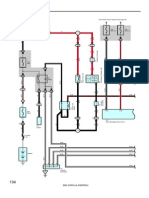

Instrument Panel Nissan Note

Hochgeladen von

Wilmer Elias Quiñonez HualpaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Instrument Panel Nissan Note

Hochgeladen von

Wilmer Elias Quiñonez HualpaCopyright:

Verfügbare Formate

BODY INTERIOR

IP

A

B

SECTION

INSTRUMENT PANEL C

E

CONTENTS

PRECAUTION ............................................... 2 Removal and Installation .........................................15 F

PRECAUTIONS ................................................... 2 STEERING COLUMN COVERS ....................... 17

Precaution for Supplemental Restraint System Removal and Installation .........................................17

G

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................... 2

CENTER CONSOLE ASSEMBLY .................... 18

Exploded View .........................................................18

Precaution for Work .................................................. 2

Removal and Installation .........................................18 H

PREPARATION ............................................ 3

CENTER CONSOLE LOWER ........................... 20

PREPARATION ................................................... 3 Removal and Installation .........................................20

I

Special Service Tools .............................................. 3

CLUSTER LID A ............................................... 21

Commercial Service Tools ....................................... 3

Removal and Installation .........................................21

CLIP LIST ............................................................ 4 IP

CLUSTER LID C ............................................... 22

Descriptions for Clips ................................................ 4

Removal and Installation .........................................22

SYMPTOM DIAGNOSIS ............................... 8 FRONT AIR CONTROL FINISHER ................... 23 K

SQUEAK AND RATTLE TROUBLE DIAG- Removal and Installation .........................................23

NOSES ................................................................ 8 INSTRUMENT LOWER PANEL LH .................. 24

Work Flow ................................................................. 8 L

Removal and Installation .........................................24

Generic Squeak and Rattle Troubleshooting ............ 9

Diagnostic Worksheet ............................................. 12 GLOVE BOX ASSEMBLY ................................ 25

Removal and Installation .........................................25 M

REMOVAL AND INSTALLATION ............... 14

UPPER GLOVE BOX ........................................ 26

INSTRUMENT PANEL ASSEMBLY ..................14 Removal and Installation .........................................26

Exploded View ........................................................ 14 N

Revision: April 2013 IP-1 2014 Note

PRECAUTIONS

< PRECAUTION >

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000009472925

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Work INFOID:0000000009472926

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: April 2013 IP-2 2014 Note

PREPARATION

< PREPARATION >

PREPARATION A

PREPARATION

Special Service Tools INFOID:0000000009472927

B

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number Description

(Kent-Moore No.) C

Tool name

— Locating the noise

(J-39570) D

Chassis Ear

SIIA0993E

F

— Repairing the cause of noise

(J-50397)

NISSAN Squeak and Rattle

Kit G

H

ALJIA1232ZZ

— Removing trim components

(J-46534)

Trim Tool Set I

IP

AWJIA0483ZZ

Commercial Service Tools INFOID:0000000009472928 K

(Kent-Moore No.) Description L

Tool name

(J-39565) Locating the noise

Engine Ear

M

SIIA0995E

( — ) Loosening nuts, screws and bolts O

Power Tool

PIIB1407E

Revision: April 2013 IP-3 2014 Note

CLIP LIST

< PREPARATION >

CLIP LIST

Descriptions for Clips INFOID:0000000009472929

Replace any clips which are damaged during removal or installation.

SIIA0315E

Revision: April 2013 IP-4 2014 Note

CLIP LIST

< PREPARATION >

IP

SIIA0316E

Revision: April 2013 IP-5 2014 Note

CLIP LIST

< PREPARATION >

SIIA0317E

Revision: April 2013 IP-6 2014 Note

CLIP LIST

< PREPARATION >

ALJIA0564GB I

IP

Revision: April 2013 IP-7 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

SYMPTOM DIAGNOSIS

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Work Flow INFOID:0000000009671285

SBT842

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to IP-12, "Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

• The customer may not be able to provide a detailed description or the location of the noise. Attempt to obtain

all the facts and conditions that exist when the noise occurs (or does not occur).

• If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer is

concerned about. This can be accomplished by test driving the vehicle with the customer.

• After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

• Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard surfaces

= higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

• Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch depen-

dent on materials/often brought on by activity.

• Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

• Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

• Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

• Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

• Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

• Often the degree of acceptable noise level will vary depending upon the person. A noise that you may judge

as acceptable may be very irritating to the customer.

• Weather conditions, especially humidity and temperature, may have a great effect on noise level.

DUPLICATE THE NOISE AND TEST DRIVE

Revision: April 2013 IP-8 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to A

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

B

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”. C

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs. D

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS E

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

F

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope). G

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be H

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily. I

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise. IP

• looking for loose components and contact marks.

Refer to IP-9, "Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE K

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible. L

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-50397) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION: M

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information. N

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered separately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will O

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement. P

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting INFOID:0000000009671286

Refer to Table of Contents for specific component removal and installation information.

Revision: April 2013 IP-9 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

Revision: April 2013 IP-10 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose. A

3. Loose screws at console attachment points.

SEATS B

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include: C

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

D

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area. E

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then F

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

G

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins H

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best I

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine rpm or

load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise. IP

Revision: April 2013 IP-11 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

Diagnostic Worksheet INFOID:0000000009671287

LAIA0072E

Revision: April 2013 IP-12 2014 Note

SQUEAK AND RATTLE TROUBLE DIAGNOSES

< SYMPTOM DIAGNOSIS >

IP

LAIA0071E

Revision: April 2013 IP-13 2014 Note

INSTRUMENT PANEL ASSEMBLY

< REMOVAL AND INSTALLATION >

REMOVAL AND INSTALLATION

INSTRUMENT PANEL ASSEMBLY

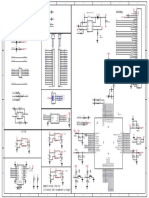

Exploded View INFOID:0000000009567640

AWJIA1105ZZ

Revision: April 2013 IP-14 2014 Note

INSTRUMENT PANEL ASSEMBLY

< REMOVAL AND INSTALLATION >

1. Instrument side finisher (RH) 2. Passenger air bag module 3. Instrument panel assembly A

4. Instrument side finisher (LH) 5. Side ventilator grille (LH) 6. Combination meter

7. Cluster lid A 8. Instrument lower panel LH 9. Steering column upper cover

10. Steering column lower cover 11. Steering lock escutcheon 12. Center console lower B

13. Front air control finisher 14. Front air control 15. Center ventilator grille (RH)

16. Center ventilator grille (LH) 17. Cluster lid C 18. Audio unit/AV control unit

19. Glove box lid 20. Glove box assembly 21. Glove box striker C

22. Side ventilator grille (RH) 23. Upper glove box Pawl

Metal clip Clip

D

Removal and Installation INFOID:0000000009567641

CAUTION: E

• Be careful not to scratch instrument panel pad or other parts.

• Before servicing, turn the ignition switch off, disconnect both battery terminals and wait at least

three minutes.

• Do not tamper with or force air bag lid open, as this may adversely affect air bag performance. F

REMOVAL

1. Disconnect the negative and positive battery terminals, then wait at least three minutes. Refer to PG-69, G

"Removal and Installation (Battery)".

2. Remove front pillar finishers (LH/RH). Refer to INT-19, "FRONT PILLAR FINISHER : Removal and Instal-

lation". H

3. Remove dash side finishers (LH/RH). Refer to INT-22, "DASH SIDE FINISHER : Removal and Installa-

tion".

4. Partially remove front body side welts (LH/RH). Refer to INT-22, "BODY SIDE WELT : Removal and I

Installation".

5. Release the pawls using a suitable tool (A) and then remove

instrument side finisher (LH) as shown.

IP

: Pawl

AWJIA1130ZZ

M

6. Release the pawls using a suitable tool (A) and then remove

instrument side finisher (RH) as shown.

: Pawl

N

P

AWJIA1131ZZ

7. Remove center console lower. Refer to IP-20, "Removal and Installation".

8. Remove steering wheel. Refer to ST-8, "Removal and Installation".

9. Remove steering column covers. Refer to IP-17, "Removal and Installation".

10. Remove combination switch. Refer to EXL-112, "Removal and Installation".

11. Remove combination meter. Refer to MWI-48, "Removal and Installation".

Revision: April 2013 IP-15 2014 Note

INSTRUMENT PANEL ASSEMBLY

< REMOVAL AND INSTALLATION >

12. Remove audio unit. Refer to AV-33, "Removal and Installation" (BASE AUDIO) or AV-93, "Removal and

Installation" (DISPLAY AUDIO).

13. Remove AV control unit (NAVIGATION). Refer to AV-178, "Removal and Installation".

14. Remove front air control. Refer to HAC-47, "Removal and Installation".

15. Remove glove box assembly. Refer to IP-25, "Removal and Installation".

16. Remove front passenger air bag module. Refer to SR-17, "Removal and Installation".

17. Remove instrument panel assembly.

a. Remove instrument panel assembly screws (A).

ALJIA1252ZZ

b. Disconnect the harness connectors from the instrument panel assembly.

c. Remove instrument panel assembly through passenger door opening.

CAUTION:

• Cover shift selector assembly with a shop cloth to prevent damage to instrument panel assem-

bly.

• When removing instrument panel assembly, two people are required to prevent from damage.

18. Removal of the following components is only necessary if replacing the instrument panel assembly.

• Side ventilator grille (LH/RH): Refer to VTL-6, "SIDE VENTILATOR GRILLE : Removal and Installation".

• Center ventilator duct (LH/RH): Refer to VTL-6, "CENTER VENTILATOR DUCT : Removal and Installa-

tion".

• Side defroster duct (LH/RH): Refer to VTL-7, "SIDE DEFROSTER DUCT : Removal and Installation".

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

If replacing instrument panel, transfer all the necessary parts to the new instrument panel.

Revision: April 2013 IP-16 2014 Note

STEERING COLUMN COVERS

< REMOVAL AND INSTALLATION >

STEERING COLUMN COVERS

A

Removal and Installation INFOID:0000000009567642

REMOVAL B

1. Remove instrument lower panel LH. Refer to IP-24, "Removal and Installation".

2. Remove steering column cover screws (A).

NOTE: C

Rotate steering wheel to access steering column cover screws.

3. Pull steering column upper cover (1) upward to disengage steer-

ing column upper cover pawls. D

: Pawl

4. Remove steering column upper cover (1) and lower cover (2).

E

AWJIA0707ZZ

F

INSTALLATION

Installation is in the reverse order of removal.

G

IP

Revision: April 2013 IP-17 2014 Note

CENTER CONSOLE ASSEMBLY

< REMOVAL AND INSTALLATION >

CENTER CONSOLE ASSEMBLY

Exploded View INFOID:0000000009567643

TYPE 1

AWJIA1134ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. USB connector (if equipped)

4. Power socket A. Clip B. Screw

TYPE 2

AWJIA1135ZZ

1. Shift selector boot (5MT: RS5F91R) 2. Center console assembly 3. Power socket

4. USB connector (if equipped) 5. Heated seat switch (RH) (if equipped) 6. Heated seat switch (LH)

(if equipped)

A. Clip B. Screw

Removal and Installation INFOID:0000000009567644

REMOVAL

1. Move shift selector to “N” position (CVT: RE0F11A).

2. Remove shift selector handle (5MT: RS5F91R). Refer to TM-19, "Exploded View".

3. Raise parking brake lever.

Revision: April 2013 IP-18 2014 Note

CENTER CONSOLE ASSEMBLY

< REMOVAL AND INSTALLATION >

4. Remove center console assembly clips (A).

A

JMJIA6093ZZ

D

5. Remove the center console assembly rear screws.

6. Slide driver side seat to the full rearward position and recline.

7. Slide passenger side seat to the full rearward position and recline. E

8. Lift rear right corner of center console assembly, rotating slightly,

making sure to lift assembly upward over the parking brake han-

dle.

F

9. Disconnect the harness connectors from the center console

assembly.

10. Remove center console assembly.

G

H

AWJIA0695ZZ

INSTALLATION

Installation is in the reverse order of removal. I

IP

Revision: April 2013 IP-19 2014 Note

CENTER CONSOLE LOWER

< REMOVAL AND INSTALLATION >

CENTER CONSOLE LOWER

Removal and Installation INFOID:0000000009567645

REMOVAL

1. Remove center console assembly. Refer to IP-18, "Removal and Installation".

2. Remove center console lower.

a. Remove center console lower clips (LH/RH) (A).

JMJIA6052ZZ

b. Release center console lower pawls using a suitable tool and

remove.

: Pawl

AWJIA0706ZZ

INSTALLATION

Installation is in the reverse order of removal.

Revision: April 2013 IP-20 2014 Note

CLUSTER LID A

< REMOVAL AND INSTALLATION >

CLUSTER LID A

A

Removal and Installation INFOID:0000000009567646

REMOVAL B

1. Remove steering column covers. Refer to IP-17, "Removal and Installation".

2. Remove cluster lid C. Refer to IP-22, "Removal and Installation".

C

3. Remove cluster lid A.

AWJIA1075ZZ

F

Pawl Metal clip

G

a. Remove combination meter finisher and cluster lid A as an assembly by pulling rearward to release pawls

and metal clips.

b. Disconnect the harness connector and remove cluster lid A. H

c. Separate cluster lid A (2) from combination meter finisher (1) by releasing the metal clips (If necessary).

INSTALLATION

Installation is in the reverse order of removal. I

IP

Revision: April 2013 IP-21 2014 Note

CLUSTER LID C

< REMOVAL AND INSTALLATION >

CLUSTER LID C

Removal and Installation INFOID:0000000009567647

REMOVAL

1. Release the cluster lid C (1) clips using a suitable tool.

: Metal clip

ALJIA1231ZZ

2. Disconnect harness connectors from cluster lid C and remove.

INSTALLATION

Installation is in the reverse order of removal.

Revision: April 2013 IP-22 2014 Note

FRONT AIR CONTROL FINISHER

< REMOVAL AND INSTALLATION >

FRONT AIR CONTROL FINISHER

A

Removal and Installation INFOID:0000000009567648

REMOVAL B

1. Remove cluster lid C. Refer to IP-22, "Removal and Installation".

2. Remove intake door lever knob (2).

C

3. Release the front air control finisher (1) clips using a suitable

tool and remove.

: Metal clip

D

ALJIA1234ZZ

F

INSTALLATION

Installation is in the reverse order of removal.

G

IP

Revision: April 2013 IP-23 2014 Note

INSTRUMENT LOWER PANEL LH

< REMOVAL AND INSTALLATION >

INSTRUMENT LOWER PANEL LH

Removal and Installation INFOID:0000000009567649

REMOVAL

1. Remove data link connector from instrument lower panel LH.

2. Remove bolts (A) and position hood lock/fuel filler door release

handle aside.

JMKIA7998ZZ

3. Remove instrument lower panel LH.

a. Release instrument lower panel LH metal clips and pawls using a suitable tool.

CAUTION:

Release pawls and metal clips slowly so that they are not damaged.

b. Disconnect the harness connectors from instrument lower panel LH and remove.

INSTALLATION

Installation is in the reverse order of removal.

Revision: April 2013 IP-24 2014 Note

GLOVE BOX ASSEMBLY

< REMOVAL AND INSTALLATION >

GLOVE BOX ASSEMBLY

A

Removal and Installation INFOID:0000000009567650

REMOVAL B

1. Remove glove box lid.

a. Open glove box lid.

C

b. Pull glove box lid rearward and glove box lid hinges down and

rearward to release, then remove the glove box lid.

E

JMJIA6060ZZ

2. Remove glove box assembly. F

a. Remove glove box assembly screws (A).

b. Pull glove box assembly rearward to release pawls and remove.

: Pawl G

AWJIA0714ZZ I

INSTALLATION

Installation is in the reverse order of removal. IP

Revision: April 2013 IP-25 2014 Note

UPPER GLOVE BOX

< REMOVAL AND INSTALLATION >

UPPER GLOVE BOX

Removal and Installation INFOID:0000000009667864

REMOVAL

1. Remove upper glove box screws (A).

ALJIA1253ZZ

2. Release the clips and pawls using a suitable tool and remove upper glove box.

INSTALLATION

Installation is in the reverse order of removal.

Revision: April 2013 IP-26 2014 Note

Das könnte Ihnen auch gefallen

- Mercedes 722.6Dokument2 SeitenMercedes 722.6Kelvin Tan Boon Lork100% (5)

- Repairs and Maintenance: Service ManualDokument136 SeitenRepairs and Maintenance: Service ManualGustavo PaezNoch keine Bewertungen

- Binder1 1998 Honda Accord 2.2L 2.3LDokument98 SeitenBinder1 1998 Honda Accord 2.2L 2.3LAgustin Chaparro Tirado100% (1)

- Automatic Transaxle: SectionDokument754 SeitenAutomatic Transaxle: SectionElias SerranoNoch keine Bewertungen

- DatasheetDokument50 SeitenDatasheetLuis BarbosaNoch keine Bewertungen

- Automatic Transmission PDFDokument334 SeitenAutomatic Transmission PDFAriel MercochaNoch keine Bewertungen

- Aston Martin DB9 PDFDokument41 SeitenAston Martin DB9 PDFMauricio SabinoNoch keine Bewertungen

- Body Electrcal System PDFDokument112 SeitenBody Electrcal System PDFNenad Jovanic100% (1)

- Prius High Voltage Battery Diagnosis and UpgradeDokument36 SeitenPrius High Voltage Battery Diagnosis and UpgradevicdiaNoch keine Bewertungen

- Wt/Control/Dispatcherapplic Wd&Command Getcgm&Arguments P10641.Cgm 8/27/2015Dokument1 SeiteWt/Control/Dispatcherapplic Wd&Command Getcgm&Arguments P10641.Cgm 8/27/2015Virgolici CatalinNoch keine Bewertungen

- Pfp13080 Isobus User Guide enDokument40 SeitenPfp13080 Isobus User Guide ensuper_facaNoch keine Bewertungen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- Adaptronic Blacktop Installation NotesDokument6 SeitenAdaptronic Blacktop Installation NotesRayz GsrNoch keine Bewertungen

- 2-Wire Serial EEPROM: FeaturesDokument23 Seiten2-Wire Serial EEPROM: FeaturesgillupilluNoch keine Bewertungen

- 2006 Nissan Almera Classic B10 Service Repair Manual PDFDokument10 Seiten2006 Nissan Almera Classic B10 Service Repair Manual PDFfjskedmmsme0% (2)

- Sfi System: PrecautionDokument60 SeitenSfi System: PrecautionChristian Linares AbreuNoch keine Bewertungen

- Body Electrical SystemDokument360 SeitenBody Electrical Systemsebastião SantosNoch keine Bewertungen

- 2-Wire Serial EEPROM: FeaturesDokument26 Seiten2-Wire Serial EEPROM: FeaturesLinkyNoch keine Bewertungen

- Holden CommodoreDokument22 SeitenHolden CommodoreFlorent NduwayoNoch keine Bewertungen

- Racecar Engineering 2013 09Dokument100 SeitenRacecar Engineering 2013 09freddyonnimi100% (1)

- 2003 Nissan Altima 2.5 Serivce Manual EIDokument36 Seiten2003 Nissan Altima 2.5 Serivce Manual EIAndy DellingerNoch keine Bewertungen

- Body Electrical System - PDF - LIL EVODokument107 SeitenBody Electrical System - PDF - LIL EVOShannon AsimNoch keine Bewertungen

- Apexi PowerFC WikipediaDokument9 SeitenApexi PowerFC WikipediarxhughesNoch keine Bewertungen

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDokument16 SeitenInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeSalah Al-AbsiNoch keine Bewertungen

- Low Boy Ganzo DollyDokument55 SeitenLow Boy Ganzo DollyDaniel Vargas RibeiroNoch keine Bewertungen

- 1541383764248Dokument85 Seiten1541383764248draNoch keine Bewertungen

- 2004 Corolla Electrcal Diagram - TroubleshootingDokument5 Seiten2004 Corolla Electrcal Diagram - TroubleshootingNick Baptiste100% (1)

- EVO9 Link Manual PDFDokument24 SeitenEVO9 Link Manual PDFviktorNoch keine Bewertungen

- Boost Pressure Sensor (BPS)Dokument50 SeitenBoost Pressure Sensor (BPS)Gian Fran0% (1)

- Terex RDT Product Bro ENGLISH LO RES OriginalDokument15 SeitenTerex RDT Product Bro ENGLISH LO RES OriginalRasoolKhadibiNoch keine Bewertungen

- Rolls Royce JourneyDokument3 SeitenRolls Royce JourneyLEX-57 the lex engineNoch keine Bewertungen

- 2014 BMW M3 M4 CatalogueDokument27 Seiten2014 BMW M3 M4 CatalogueJohn BandaNoch keine Bewertungen

- MahindraDokument104 SeitenMahindraAakashSharmaNoch keine Bewertungen

- A6Dokument67 SeitenA6Ashraff AudiNoch keine Bewertungen

- Interior: SectionDokument26 SeitenInterior: SectionJUAN CARLOS PAZNoch keine Bewertungen

- ESCL Tpi Diagnosis FlowchartDokument36 SeitenESCL Tpi Diagnosis FlowchartCristian SindieNoch keine Bewertungen

- Typical LED SymbolDokument4 SeitenTypical LED Symbolthy thy thyNoch keine Bewertungen

- Quick Start Platinum 2000 V11 PDFDokument20 SeitenQuick Start Platinum 2000 V11 PDFSarif AkbarNoch keine Bewertungen

- Sequential Fuel Injection SystemDokument66 SeitenSequential Fuel Injection SystemCậu TúNoch keine Bewertungen

- Can Communication: Can Communication System: Terminals ofDokument11 SeitenCan Communication: Can Communication System: Terminals ofKiddNoch keine Bewertungen

- LG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202Dokument42 SeitenLG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202noguri25Noch keine Bewertungen

- TOMO 4 Ajuste de KM PDFDokument647 SeitenTOMO 4 Ajuste de KM PDFMax Bike MartinezNoch keine Bewertungen

- 4M4 Gr13E PDFDokument36 Seiten4M4 Gr13E PDFcristian garciaNoch keine Bewertungen

- Meter / Gauge System: PrecautionDokument76 SeitenMeter / Gauge System: PrecautionlogammicNoch keine Bewertungen

- X 431 Pro3 User Manual PDFDokument64 SeitenX 431 Pro3 User Manual PDFsamsularief03Noch keine Bewertungen

- Understanding Wiring Diagrams: ToyotaDokument6 SeitenUnderstanding Wiring Diagrams: ToyotaThang TongNoch keine Bewertungen

- Tvip PDFDokument6 SeitenTvip PDFamart79196Noch keine Bewertungen

- 2004 Legacy Service Manual Quick Reference Index Wiring System SectionDokument116 Seiten2004 Legacy Service Manual Quick Reference Index Wiring System SectionspelectronNoch keine Bewertungen

- Plug Pin Symbol Input / OutputDokument5 SeitenPlug Pin Symbol Input / OutputOsman GutierrezNoch keine Bewertungen

- Aie R Conditioning Sysatem TeierDokument72 SeitenAie R Conditioning Sysatem TeierDinsosnakertrans KudusNoch keine Bewertungen

- Chap5 Series DC CircuitsDokument60 SeitenChap5 Series DC Circuitsbree789Noch keine Bewertungen

- (##) Anti Theft Steering SystemDokument85 Seiten(##) Anti Theft Steering SystemstarNoch keine Bewertungen

- Avensis Intake System PDFDokument19 SeitenAvensis Intake System PDFMladen VidovićNoch keine Bewertungen

- N13 Manual PDFDokument238 SeitenN13 Manual PDFignitionyemiNoch keine Bewertungen

- Project 15 MOTOR BASICSDokument7 SeitenProject 15 MOTOR BASICSDarwin VargasNoch keine Bewertungen

- Tang NANO 2704 (Schematic)Dokument1 SeiteTang NANO 2704 (Schematic)June Anthony Asistio100% (1)

- 4 EngineDokument14 Seiten4 EngineSoeAyeNoch keine Bewertungen

- Ec PDFDokument1.061 SeitenEc PDFRicardo CarbajalNoch keine Bewertungen

- Nissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETDokument2 SeitenNissan 1991-1993 Silvia S13 SR20DET, 1991-1995 180SX SR20DETElectronica Ave FenixNoch keine Bewertungen

- Charging System Leture and Quiz1Dokument5 SeitenCharging System Leture and Quiz1Mae CherryNoch keine Bewertungen

- TV Philips LC4.2HE-Service ManualDokument0 SeitenTV Philips LC4.2HE-Service ManualAnonymous RCPxaonfvNoch keine Bewertungen

- MTCDokument64 SeitenMTCAnonymous tBqr2pRo1100% (1)

- Product Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Dokument4 SeitenProduct Introduction Product Introduction: LEXUS LS600h/LS600hL Hybrid System Power Control Unit (PCU)Вячеслав ГлушакNoch keine Bewertungen

- Supplemental Restraint System (SRS) PDFDokument64 SeitenSupplemental Restraint System (SRS) PDFruanm_1Noch keine Bewertungen

- Maintenance Manual ABS PDFDokument39 SeitenMaintenance Manual ABS PDFPedro Emilio Miguez CastrillonNoch keine Bewertungen

- Multiport Fuel System (Mfi) : Group 13ADokument64 SeitenMultiport Fuel System (Mfi) : Group 13Ajagjitemir6014Noch keine Bewertungen

- Galant CH 2 Engine Electrical PDFDokument14 SeitenGalant CH 2 Engine Electrical PDFjustcheerfulNoch keine Bewertungen

- Instrument Panel: SectionDokument26 SeitenInstrument Panel: SectiontecnicofigueroaNoch keine Bewertungen

- Instrument Panel (Section IP)Dokument23 SeitenInstrument Panel (Section IP)Gleydson Bahiense RamosNoch keine Bewertungen

- Instrument Panel: SectionDokument23 SeitenInstrument Panel: Sectionak_adamNoch keine Bewertungen

- Instrument PanelDokument24 SeitenInstrument PaneldiegoNoch keine Bewertungen

- Exterior & Interior: SectionDokument34 SeitenExterior & Interior: SectionAnonymous 64HDY7IiN0Noch keine Bewertungen

- Engine Lubrication System: SectionDokument10 SeitenEngine Lubrication System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Exhaust System: SectionDokument6 SeitenExhaust System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Section: Driver ControlsDokument6 SeitenSection: Driver ControlsWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Exterior: SectionDokument34 SeitenExterior: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Lan System: SectionDokument98 SeitenLan System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Glass & Window System: SectionDokument28 SeitenGlass & Window System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Exhaust System: SectionDokument7 SeitenExhaust System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- FL PDFDokument18 SeitenFL PDFWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- VtlnissanDokument8 SeitenVtlnissanWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Exterior Lighting System: SectionDokument123 SeitenExterior Lighting System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Front Suspension: SectionDokument21 SeitenFront Suspension: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Mir NissanDokument18 SeitenMir NissanWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Front Axle: SectionDokument28 SeitenFront Axle: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Charging System: SectionDokument25 SeitenCharging System: SectionWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Simbologia Equipos Cat PDFDokument82 SeitenSimbologia Equipos Cat PDFWilmer Elias Quiñonez HualpaNoch keine Bewertungen

- Nomenclatura para LlantasDokument4 SeitenNomenclatura para LlantassybamxNoch keine Bewertungen

- Catalogo de Palas Retro Terex - pdf1231185670 PDFDokument8 SeitenCatalogo de Palas Retro Terex - pdf1231185670 PDFRobinson GuanemeNoch keine Bewertungen

- Renault Captur Press KitDokument28 SeitenRenault Captur Press KitMsMoab100% (1)

- Altima: Nissan. Innovation That ExcitesDokument4 SeitenAltima: Nissan. Innovation That ExcitesJayvee Amoy AmolatoNoch keine Bewertungen

- Ford Tourneo CustomDokument27 SeitenFord Tourneo CustomAlex RaduțăNoch keine Bewertungen

- Design Presentation: Virtual Baja Saeindia 2015Dokument12 SeitenDesign Presentation: Virtual Baja Saeindia 2015goldencomet100% (1)

- Reference PointsDokument36 SeitenReference PointsYangNoch keine Bewertungen

- Porsche Stradali OBDII 100 EngDokument9 SeitenPorsche Stradali OBDII 100 EngJoseph TogoNoch keine Bewertungen

- Captiva Manual MY13Dokument380 SeitenCaptiva Manual MY13David PomaNoch keine Bewertungen

- A Report On Design Approach For FSAE Car..Dokument8 SeitenA Report On Design Approach For FSAE Car..Sandeep Kr. Mishra100% (1)

- 55 Mazda 1 F3A PDFDokument8 Seiten55 Mazda 1 F3A PDFAlexander Neyra0% (1)

- AcknowledgmentDokument3 SeitenAcknowledgmentഹരി നീലാംബരിNoch keine Bewertungen

- Toyota Corolla 1997 Ignition Switch Transmission and Parking BrakeDokument12 SeitenToyota Corolla 1997 Ignition Switch Transmission and Parking Brakeairtarlac100% (1)

- Seat ExeoDokument15 SeitenSeat ExeoCosmin Mihai KiritaNoch keine Bewertungen

- Volkswagen China (Revise)Dokument33 SeitenVolkswagen China (Revise)vera1999Noch keine Bewertungen

- L00090 ABA Parts and Cross Reference Guide 9-09Dokument12 SeitenL00090 ABA Parts and Cross Reference Guide 9-09CellblocXNoch keine Bewertungen

- Mitsubishi Recalls 50K SUVs Rear Hatches Can Fall On PeopleDokument2 SeitenMitsubishi Recalls 50K SUVs Rear Hatches Can Fall On Peoplecbs6albanyNoch keine Bewertungen