Beruflich Dokumente

Kultur Dokumente

Painting Inspection Report - 539 UV

Hochgeladen von

Rahul MoottolikandyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Painting Inspection Report - 539 UV

Hochgeladen von

Rahul MoottolikandyCopyright:

Verfügbare Formate

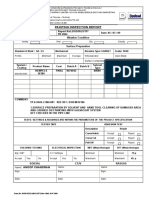

PROJECT : RASGAS ONSHORE EXPANSION PROJECT, PHASE 2 (RGX-2) /

AL KHALEEJ GAS PROJECT PHASE 2 (AKG-2)

COMPANY : RASGAS COMPANY LIMITED / EXXON MOBIL MIDDLE EAST GAS MARKETING

LIMITED

CONTRACTOR : CTJV (JV of Chiyoda – Technip)

SUB-CONTRACTOR : Dodsal Engineering & construction Pte Ltd

PROJECT NO. : RG6-CS-004 / AKG2-CS-001

PAINTING INSPECTION REPORT

Report Ref:DOD/RGX/TP/PR2069

Area: UTILITY/D943 Date: 06/03/09

to PR 2077

Weather Condition

Windy Wet Dry Cloudy

Surface Preparation

Standard of Blast : N/A Mechanical: ST-2 Abrasive Type: Grade:

Profile: Minimum Maximum Average Wheelabrator: N/A Open Blast:

Surface Contamination Removed Yes √

System / Solvent Solvent

Product Name Coat Batch A Batch B WFT DFT

Coating Type Batch

UV HEMPADUR 1 st 9010377 9010378 08450 8074365 70 µ 28 µ

15552 approx

HEMPADUR 2 nd 8042346 8084776 08080 8020875 50 µ 26 µ

55219 approx

COMMENT:

1) TP-6-820A-WSR-001 2) TP-6-820A-WSR-005 3) TP-6-820A-WSR-077

4) TP-6-820A-WSR-002 5) TP-6-820A-WSR-006 6) TP-6-820A-WSR-078

7) TP-6-820A-WSS-002 8) TP-6-820A-WSS-006 9) TP-6-820A-WSS-077

REF RFI : DOD/M/34401

1.SURFACE PREPARATION BY HAND TOOL AND CARRIED OUT PAINTING WITH

UV SYSTEM TO OBTAIN GOOD OPACITY.

TESTS / SETTINGS & READINGS ARE WITHIN THE PARAMETERS OF THE PROJECT SPECIFICATION

TESTEX TAPE ADHESION TEST

Description Result

Cross Hatch Accept Reject

Cross Cut Accept Reject

Pull Off Accept Reject

CHLORIDE TESTING ELECTRICAL INSPECTION WFT (Mean Average) DFT (Mean Average)

52 µ

Mg / CM2 K V Settings Minimum Minimum

approx

60 µ

Accept Yes No Accept Yes No Maximum Maximum

approx

DODSAL CTJV RASGAS

Name: ANOOP CHANDRAN Name: Name:

Sign: Sign: Sign:

Date: Date: Date:

Form No.:DOD-RGX2/AKG2-F072 Rev 4 Dtd. 20.07.2008

Das könnte Ihnen auch gefallen

- QAP For PQR'S - For Impact TestingDokument3 SeitenQAP For PQR'S - For Impact TestingDries VandezandeNoch keine Bewertungen

- Painting Procedure 4288 Danem 28-04-13Dokument24 SeitenPainting Procedure 4288 Danem 28-04-13Rejoy baby100% (1)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Dokument7 SeitenBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNoch keine Bewertungen

- Sandblasting & Painting Progress Daily Register ForDokument2 SeitenSandblasting & Painting Progress Daily Register Forsudeesh kumarNoch keine Bewertungen

- Bgas Paint Faults, BittinessDokument49 SeitenBgas Paint Faults, BittinessslxantoNoch keine Bewertungen

- SA 387 Grade 91 Class 2Dokument4 SeitenSA 387 Grade 91 Class 2briang-2Noch keine Bewertungen

- Painting ProcedureDokument4 SeitenPainting ProcedureRidoNoch keine Bewertungen

- 17-020-Ms-002 Welding For Fuel Gas r2Dokument53 Seiten17-020-Ms-002 Welding For Fuel Gas r2Alaa M. GhazalahNoch keine Bewertungen

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Dokument5 SeitenA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNoch keine Bewertungen

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- The NEW Company ProfileDokument26 SeitenThe NEW Company ProfilewisandhaNoch keine Bewertungen

- PipingDokument158 SeitenPipingmiteshmayurNoch keine Bewertungen

- Coke Crusher - Lubrication Pumps Run in TestDokument26 SeitenCoke Crusher - Lubrication Pumps Run in TestsayedNoch keine Bewertungen

- Approved Itp-Dss - 28 Sep 2016Dokument4 SeitenApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNoch keine Bewertungen

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDokument22 Seiten2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarNoch keine Bewertungen

- Wps Mig PDF FreeDokument3 SeitenWps Mig PDF Freehanz bermejoNoch keine Bewertungen

- QA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsDokument1 SeiteQA-R-05 - Fitup Inspection Report (SPL) LS & CS Joints For Pressure VesselsvinothNoch keine Bewertungen

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Dokument15 SeitenPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenNoch keine Bewertungen

- PWPS Eksperimen Super DuplexDokument33 SeitenPWPS Eksperimen Super Duplexryan.sNoch keine Bewertungen

- Welder and Welder Operator Qualification Record FormDokument1 SeiteWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNoch keine Bewertungen

- BRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Dokument10 SeitenBRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Ponaryo AnggaraNoch keine Bewertungen

- TopCoreBelco 101 FCDokument9 SeitenTopCoreBelco 101 FCCesar ArellanoNoch keine Bewertungen

- Liquid Penetrant Examination ReportDokument1 SeiteLiquid Penetrant Examination ReportBalmiki SinghNoch keine Bewertungen

- Tool Fab - WorkshopDokument347 SeitenTool Fab - Workshophrdsby100% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Dokument15 SeitenWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNoch keine Bewertungen

- Consumable Spec Rev 12Dokument24 SeitenConsumable Spec Rev 12megastar0604Noch keine Bewertungen

- INS T 004, Tol - OvalityDokument4 SeitenINS T 004, Tol - OvalityDeepakNoch keine Bewertungen

- TDC 004 CS Fittings r0Dokument1 SeiteTDC 004 CS Fittings r0samkarthik47Noch keine Bewertungen

- DRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFDokument36 SeitenDRP001-OUF-STA-MTS-L-000-030-O1 - WMS Pickling and Passivation PDFrodman823Noch keine Bewertungen

- O252-PI-SP-0126 - C04 - Specification For PaintingDokument26 SeitenO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedNoch keine Bewertungen

- Form Attchment - RFI PICTURE-2Dokument2 SeitenForm Attchment - RFI PICTURE-2Echik Kici100% (1)

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDokument16 SeitenHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamNoch keine Bewertungen

- SATIP-N-001-02 Rev. 4Dokument2 SeitenSATIP-N-001-02 Rev. 4Anonymous 4e7GNjzGW100% (1)

- APV STD Insp & Test Plan API6D ValvesDokument4 SeitenAPV STD Insp & Test Plan API6D ValvesdbmingoNoch keine Bewertungen

- MS For Fabrication of Above-Ground Storage TankDokument8 SeitenMS For Fabrication of Above-Ground Storage Tankdadz mingiNoch keine Bewertungen

- Welding Parameters Control PipelineDokument1 SeiteWelding Parameters Control PipelinemusheerNoch keine Bewertungen

- Ug PipingDokument1 SeiteUg PipingVinoth KumarNoch keine Bewertungen

- QAP For Conical StrainerDokument2 SeitenQAP For Conical StrainersatishchidrewarNoch keine Bewertungen

- Itp Structural SteelDokument4 SeitenItp Structural SteelkamlNoch keine Bewertungen

- Condensate Tank WELDING LOGDokument6 SeitenCondensate Tank WELDING LOGhasan shahriarNoch keine Bewertungen

- Field Hydrostatic Testing of Piping Systems-EGDokument9 SeitenField Hydrostatic Testing of Piping Systems-EGYusufNoch keine Bewertungen

- Duqm Refinery Project EPC Package 2 - Utilities and OffsitesDokument2 SeitenDuqm Refinery Project EPC Package 2 - Utilities and OffsitesDadaso Baburao JamdarNoch keine Bewertungen

- Quality ManualDokument37 SeitenQuality ManualDushan Lalithya GamaethigeNoch keine Bewertungen

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDokument26 SeitenNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNoch keine Bewertungen

- Fabrication Tracking Sheet (29-June 4.00 AmDokument9 SeitenFabrication Tracking Sheet (29-June 4.00 Amvishal bailurNoch keine Bewertungen

- Daily Fit-Up/Welding Inspection ReportDokument7 SeitenDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamNoch keine Bewertungen

- Interseal 670HDokument2 SeitenInterseal 670Hmadmax_mfpNoch keine Bewertungen

- Radiation Safety Distance DiagramDokument3 SeitenRadiation Safety Distance DiagramEswaranNoch keine Bewertungen

- Inspection and Test Plan FOR Filter Separator/CoalescerDokument6 SeitenInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNoch keine Bewertungen

- List of Inspection Tools (Qaqc)Dokument7 SeitenList of Inspection Tools (Qaqc)saffririzal4237Noch keine Bewertungen

- Test Package: Pt. TTN (Tambang Tondano Nusajaya)Dokument18 SeitenTest Package: Pt. TTN (Tambang Tondano Nusajaya)unto gunungNoch keine Bewertungen

- DRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Dokument61 SeitenDRP001-OUF-GAL-PRO-Q-000-067 Rev-S1Rafat KhanNoch keine Bewertungen

- 3500-00 Simathane Gloss (Finish Coat)Dokument3 Seiten3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNoch keine Bewertungen

- Company Profile - Rizhao Steel YingkouDokument41 SeitenCompany Profile - Rizhao Steel Yingkourashid isaarNoch keine Bewertungen

- Nde Map & Nde Procedure (Sudah Di Revisi)Dokument4 SeitenNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNoch keine Bewertungen

- Color Coding For MaterialsDokument1 SeiteColor Coding For Materialsvishal agrawalNoch keine Bewertungen

- Painting Inspection Report-534 - GALVACOATDokument1 SeitePainting Inspection Report-534 - GALVACOATRahul MoottolikandyNoch keine Bewertungen

- Gpti Qicl J931 Mut 019Dokument3 SeitenGpti Qicl J931 Mut 019uselessinstaid52Noch keine Bewertungen

- Gpti Qicl J931 Mut 041Dokument3 SeitenGpti Qicl J931 Mut 041uselessinstaid52Noch keine Bewertungen

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Dokument1 SeiteWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyNoch keine Bewertungen

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDokument6 SeitenPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyNoch keine Bewertungen

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokument3 SeitenItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNoch keine Bewertungen

- Need of Surface TreatmentDokument6 SeitenNeed of Surface TreatmentRahul MoottolikandyNoch keine Bewertungen

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokument3 SeitenMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNoch keine Bewertungen

- Inspection NotesDokument1 SeiteInspection NotesRahul MoottolikandyNoch keine Bewertungen

- Mass Earth's Atmosphere: DensityDokument23 SeitenMass Earth's Atmosphere: DensityRahul MoottolikandyNoch keine Bewertungen

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDokument3 SeitenMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyNoch keine Bewertungen

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDokument5 SeitenMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNoch keine Bewertungen

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDokument1 SeiteDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyNoch keine Bewertungen

- Mandays 100Dokument1 SeiteMandays 100Rahul MoottolikandyNoch keine Bewertungen

- 026 To 033test ReportsDokument40 Seiten026 To 033test ReportsRahul MoottolikandyNoch keine Bewertungen

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDokument7 SeitenMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyNoch keine Bewertungen

- Industrial Hose: Formerly Black Gold Choke & Kill HoseDokument4 SeitenIndustrial Hose: Formerly Black Gold Choke & Kill HoseRahul MoottolikandyNoch keine Bewertungen

- Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDokument5 SeitenMarking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyNoch keine Bewertungen

- Gate Pass Request FormDokument38 SeitenGate Pass Request FormRahul MoottolikandyNoch keine Bewertungen

- IZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportDokument1 SeiteIZZ-HAIMO-PTR-067!06!3inch Hose Pressure Test ReportRahul MoottolikandyNoch keine Bewertungen

- Gate Pass Request Form: Requested Date: Reference NoDokument1 SeiteGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyNoch keine Bewertungen

- Date Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Dokument1 SeiteDate Inspectors Mandays Rahul Sujai 7pm To 7am 7am To 7pm ### 1.5 - 1.5 ### - 1 1 Total 2.5Rahul MoottolikandyNoch keine Bewertungen

- Sheet 1Dokument3 SeitenSheet 1Kwaku AkostikNoch keine Bewertungen

- Ana Bruker Scion TQ Spec SheetDokument2 SeitenAna Bruker Scion TQ Spec SheetmdananicNoch keine Bewertungen

- Penicillin FermentationDokument30 SeitenPenicillin FermentationUlfia Al RahmaNoch keine Bewertungen

- 7 - ThermochemistryDokument31 Seiten7 - ThermochemistryLeslie MasiyandimaNoch keine Bewertungen

- GradeSlabsDesignandConstruction PresentationDokument34 SeitenGradeSlabsDesignandConstruction PresentationgemotorresNoch keine Bewertungen

- Jenis Suplementasi Oral Untuk HipoalbuminDokument5 SeitenJenis Suplementasi Oral Untuk HipoalbuminFauziyandaNoch keine Bewertungen

- 94 104 PDFDokument11 Seiten94 104 PDFpuvitta sudeshilaNoch keine Bewertungen

- OilCharacterization Adeyab PDFDokument18 SeitenOilCharacterization Adeyab PDFJhosymarSantosGutierrezNoch keine Bewertungen

- Dynisco LMI 5500 IV Test ProcedureDokument5 SeitenDynisco LMI 5500 IV Test ProcedureJaimeNoch keine Bewertungen

- 01-Crystals Fall2012 - Compatibility ModeDokument44 Seiten01-Crystals Fall2012 - Compatibility Modetrebor sllewNoch keine Bewertungen

- Metallurgy of Iron and SteelmakingDokument13 SeitenMetallurgy of Iron and SteelmakingAgustine SetiawanNoch keine Bewertungen

- Life Cycle of A StarDokument22 SeitenLife Cycle of A Starေအာင္ ေက်ာ္ စြာNoch keine Bewertungen

- Hartree-Fock For HeDokument19 SeitenHartree-Fock For HeAustin Yu LiuNoch keine Bewertungen

- 9step Pouring Ritual Poster1Dokument1 Seite9step Pouring Ritual Poster1Elias Ortiz UrrutiaNoch keine Bewertungen

- Buhler 2003-Vademecum For Vitamin FormulationsDokument144 SeitenBuhler 2003-Vademecum For Vitamin FormulationsRok Kopinč100% (1)

- HT14-IM2655 - Lecture 1 PDFDokument33 SeitenHT14-IM2655 - Lecture 1 PDFDiego Manuel Hernández AcostaNoch keine Bewertungen

- Uncovering the Silicon - ΜL914 - Evil Mad Scientist LaboratoriesDokument21 SeitenUncovering the Silicon - ΜL914 - Evil Mad Scientist LaboratoriesGulapo GapoNoch keine Bewertungen

- Gs01u10b02-00en-R CFMDokument150 SeitenGs01u10b02-00en-R CFMMoin- ud-dinNoch keine Bewertungen

- Accurate Rapid Analysis of Alkali Contents in Portland CementDokument4 SeitenAccurate Rapid Analysis of Alkali Contents in Portland CementyinglvNoch keine Bewertungen

- Dna Extraction and SpoolingDokument4 SeitenDna Extraction and SpoolingHas AlqisNoch keine Bewertungen

- White LED DatasheetDokument22 SeitenWhite LED DatasheettuzarahulNoch keine Bewertungen

- DPP 04 Ionic Equilibrium JH Sir-4172Dokument4 SeitenDPP 04 Ionic Equilibrium JH Sir-4172Shivam KumarNoch keine Bewertungen

- Physica E: Qianhui Yang, Liren Lou, Guanzhong WangDokument6 SeitenPhysica E: Qianhui Yang, Liren Lou, Guanzhong WangHabibi SaifuddinNoch keine Bewertungen

- EE669 Lecture Slides Module 1Dokument46 SeitenEE669 Lecture Slides Module 1sivanaresh14Noch keine Bewertungen

- Balancing Chemical Equations With KeyDokument4 SeitenBalancing Chemical Equations With Keyapi-298247873Noch keine Bewertungen

- (Edu - Joshuatly.com) Pahang STPM Trial 2010 Physics (W Ans) (9C9EAE7A)Dokument42 Seiten(Edu - Joshuatly.com) Pahang STPM Trial 2010 Physics (W Ans) (9C9EAE7A)HaRry ChgNoch keine Bewertungen

- Stabilization of Soil by Using Polypropylene FibersDokument7 SeitenStabilization of Soil by Using Polypropylene FibersIJRASETPublicationsNoch keine Bewertungen

- Ammonia Cracker PDFDokument8 SeitenAmmonia Cracker PDFpinky_y2kNoch keine Bewertungen

- P740JDokument2 SeitenP740JTan Chen TatNoch keine Bewertungen

- Emr439r White Mica PDFDokument41 SeitenEmr439r White Mica PDFGabriel Erazo FierroNoch keine Bewertungen