Beruflich Dokumente

Kultur Dokumente

Manufacturing of Tablets by Direct Compression Method - Reader View

Hochgeladen von

Marta Halim0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

99 Ansichten1 SeiteTablets

Originaltitel

Manufacturing of Tablets by Direct Compression Method __ Reader View

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTablets

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

99 Ansichten1 SeiteManufacturing of Tablets by Direct Compression Method - Reader View

Hochgeladen von

Marta HalimTablets

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

9/28/2018 Manufacturing of Tablets by Direct Compression Method :: Reader View

www.pharmaguideline.com

Manufacturing of Tablets by Direct

Compression Method

Ankur Choudhary

4-5 minutes

In the past years, processing of drugs was mostly achieved through

wet granulation or related unit operations. Progressively, other methods

emerged that revolutionalized and gradually replaced the old tablet

manufacturing methods. Amongst the new techniques, the direct

compression method uses the most advanced technology.

From the term “direct compression“, this method can be defined as

basically mixing and processing of formulation ingredients then

compressing into tablets. The tablets are obtained directly from the

powder API or other excipients. The successful adaptation of this

method has lead to a reduction in units of operation, less machinery

involvement and minimized processing time.

Manufacturing of tablets using direct compression method involves

processes that can be condensed to three. The order following these

processes first involves using induced die feeders, dry binders and

lastly by using direct compression excipients.

In the process of using induced die feeders, a special feeding device is

used. The device prevents segregation and complements the powders

to flow down the die cavity of the pharmaceutical tablet press from the

hopper. Employing the induce die feeder usually minimizes entrapment

of air thereby increasing the density of the filling powder and its

susceptibility to compaction. Commonly used for a compact formulation

that does not fill the die cavity.

In pharmaceuticals, use of binders ensures that the active and inactive

ingredients are held together. The substances used as dry binders

must have the required cohesion properties so as to ensure that the

tablets are of the approved hardness and crispiness. It is also

recommended that a low binder to drug ratio should be maintained so

as to ensure satisfactory sizes of the tablets that contain high doses of

drugs. Microcrystalline cellulose and polyethylene glycol are some of

chrome-extension://ecabifbgmdmgdllomnfinbmaellmclnh/data/reader/index.html?id=645654975 1/1

Das könnte Ihnen auch gefallen

- Leukemia EssayDokument4 SeitenLeukemia EssaydanarajNoch keine Bewertungen

- How to Design and Implement Powder-to-Tablet Continuous Manufacturing SystemsVon EverandHow to Design and Implement Powder-to-Tablet Continuous Manufacturing SystemsFernando MuzzioNoch keine Bewertungen

- Liquid Based CytologyDokument51 SeitenLiquid Based CytologySonam Joshi100% (1)

- Hydralazine Drug StudyDokument1 SeiteHydralazine Drug Studymilkv71% (7)

- AssignmentDokument12 SeitenAssignmentAbdul Wahid OrakzaiNoch keine Bewertungen

- The Manufacturing Process of Tablets and CapsulesDokument12 SeitenThe Manufacturing Process of Tablets and CapsulesNico Hovagimian100% (1)

- GMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsVon EverandGMP in Pharmaceutical Industry: Global cGMP & Regulatory ExpectationsBewertung: 5 von 5 Sternen5/5 (2)

- Motivasi PajakDokument18 SeitenMotivasi PajakMarta HalimNoch keine Bewertungen

- Direct Compressible and Co-Processed Excipients - A ReviewDokument6 SeitenDirect Compressible and Co-Processed Excipients - A ReviewIJAR JOURNALNoch keine Bewertungen

- Recent Advances in Direct Compression Technique For Pharmaceutical Tablet FormulationDokument10 SeitenRecent Advances in Direct Compression Technique For Pharmaceutical Tablet FormulationUntoro DewantoNoch keine Bewertungen

- Recent Advances in Granulation Techniques: January 2014Dokument11 SeitenRecent Advances in Granulation Techniques: January 2014Hà Thanh TúNoch keine Bewertungen

- Factors That Influence The Choice of Manufacturing Process Used During Tablet FormulationDokument2 SeitenFactors That Influence The Choice of Manufacturing Process Used During Tablet Formulationabdelrhman aboodaNoch keine Bewertungen

- Manufacturing of Tablets PART-IIIDokument12 SeitenManufacturing of Tablets PART-IIIbalamuruganNoch keine Bewertungen

- Tablet GranulationDokument31 SeitenTablet GranulationIvenksNoch keine Bewertungen

- Report On Industrial Training at Goldfish: PHARMA PVT - LTD (Kukatpally, Hyderabad)Dokument25 SeitenReport On Industrial Training at Goldfish: PHARMA PVT - LTD (Kukatpally, Hyderabad)Ramya GNoch keine Bewertungen

- Tablet and Capsule ManufacturingDokument28 SeitenTablet and Capsule ManufacturingShibaprasad DandapatNoch keine Bewertungen

- Bi 5 55 PDFDokument9 SeitenBi 5 55 PDFKarine Jéssica SantanaNoch keine Bewertungen

- Review: Eksipien Untuk Pembuatan Tablet Dengan Metode Kempa LangsungDokument14 SeitenReview: Eksipien Untuk Pembuatan Tablet Dengan Metode Kempa LangsungRATNA DIYAN PANUNTUN RATNA DIYAN PANUNTUNNoch keine Bewertungen

- Web Site You Tube What App Telegram Face Book E-Mail Page - 1Dokument27 SeitenWeb Site You Tube What App Telegram Face Book E-Mail Page - 1Divyank GhadageNoch keine Bewertungen

- Articel Review: Journal of Pharmaceutical and Sciences (JPS)Dokument13 SeitenArticel Review: Journal of Pharmaceutical and Sciences (JPS)TAQWARARA SALSABILANoch keine Bewertungen

- Direct Compression - An Overview: - ReviewDokument4 SeitenDirect Compression - An Overview: - ReviewJim ColinsNoch keine Bewertungen

- Dry GranulationDokument1 SeiteDry Granulationnadira_rahmiNoch keine Bewertungen

- Direct Compression TabletDokument61 SeitenDirect Compression TabletMitul Shah100% (1)

- Recent Advances in Granulation TechnologyDokument8 SeitenRecent Advances in Granulation TechnologySadia AfrinNoch keine Bewertungen

- Granula TionDokument11 SeitenGranula TionIJRASETPublicationsNoch keine Bewertungen

- Act 3 Final Group 4Dokument2 SeitenAct 3 Final Group 4Jenesis Cairo CuaresmaNoch keine Bewertungen

- Review On Moisture Activated Dry Granulation Process: Pharmatutor December 2017Dokument11 SeitenReview On Moisture Activated Dry Granulation Process: Pharmatutor December 2017Md. JewelNoch keine Bewertungen

- Nisha NTDokument42 SeitenNisha NTNishant RaiNoch keine Bewertungen

- Pilot Plant Scale Up TechniquesDokument105 SeitenPilot Plant Scale Up TechniquesTý Nguyễn100% (2)

- Pilot Plant Scale Up Techniques: Prof. Dr. Basavaraj K. NanjwadeDokument105 SeitenPilot Plant Scale Up Techniques: Prof. Dr. Basavaraj K. Nanjwadesaikrishna645Noch keine Bewertungen

- TB and HeteroDokument20 SeitenTB and Heterokatta venkata vynateyaNoch keine Bewertungen

- Different Stages of Tablet Manufacturing Process - PharmaguidelineDokument2 SeitenDifferent Stages of Tablet Manufacturing Process - PharmaguidelinePrayag ThakarNoch keine Bewertungen

- Pharmaceutical Fluidized Bed GranulationDokument43 SeitenPharmaceutical Fluidized Bed GranulationDeepakraj Bansal0% (1)

- Pharmaceutical ManufacturingDokument12 SeitenPharmaceutical ManufacturingDeepakraj BansalNoch keine Bewertungen

- Hygroscopicity ClassificationDokument11 SeitenHygroscopicity ClassificationPardhasaradhi VobenaboinaNoch keine Bewertungen

- Sahil Saini ProjectDokument23 SeitenSahil Saini Projectpikurao1305Noch keine Bewertungen

- Acknowledgement: Industrial Training FileDokument24 SeitenAcknowledgement: Industrial Training FileGaurav Prabhakar100% (1)

- A Review On Co-Processed Excipients: Current and Future Trend of Excipient TechnologyDokument9 SeitenA Review On Co-Processed Excipients: Current and Future Trend of Excipient TechnologynadiraNoch keine Bewertungen

- Tablet Manufacturing: Industrial Pharmacy 5 Class 1 SemesterDokument23 SeitenTablet Manufacturing: Industrial Pharmacy 5 Class 1 SemesterShirzad HasanNoch keine Bewertungen

- Advanced Powder Technology: Kailas K. Moravkar, Tariq M. Ali, Jaywant N. Pawar, Purnima D. AminDokument11 SeitenAdvanced Powder Technology: Kailas K. Moravkar, Tariq M. Ali, Jaywant N. Pawar, Purnima D. AminSherly EvelinaNoch keine Bewertungen

- Review ArticleDokument20 SeitenReview Articleaishwarya bodkeNoch keine Bewertungen

- Formulation and Optimization of Immediate Release Tablet of An Anti Hypertensive Drug by Dry Granulation MethodDokument9 SeitenFormulation and Optimization of Immediate Release Tablet of An Anti Hypertensive Drug by Dry Granulation MethodEDI SAPUTRANoch keine Bewertungen

- Comrension Granulacion Fluidized BedDokument7 SeitenComrension Granulacion Fluidized Bedmaito2270Noch keine Bewertungen

- Tablet Technology StepsDokument9 SeitenTablet Technology StepsVikas JhawatNoch keine Bewertungen

- Ameyapaperjournal PDFDokument16 SeitenAmeyapaperjournal PDFKharisah AfifahNoch keine Bewertungen

- International Journal of Pharmtech ResearchDokument9 SeitenInternational Journal of Pharmtech ResearchTabare CostaNoch keine Bewertungen

- The Art and Science of Granulation PresentationDokument39 SeitenThe Art and Science of Granulation PresentationumarNoch keine Bewertungen

- Unit Operations in Secondary ManufacturingDokument11 SeitenUnit Operations in Secondary ManufacturingJoyce Marian BelonguelNoch keine Bewertungen

- Method of Preparation of Tabletdry GranulationDokument11 SeitenMethod of Preparation of Tabletdry GranulationChristopher LunaNoch keine Bewertungen

- Industrial AssignmentDokument5 SeitenIndustrial AssignmentM NoumanNoch keine Bewertungen

- Santhosh ManualDokument33 SeitenSanthosh Manualsanthoshsk27102002Noch keine Bewertungen

- Review Teknik GranulasiDokument6 SeitenReview Teknik GranulasiTanti MulyanaNoch keine Bewertungen

- Pharma ProcessDokument16 SeitenPharma ProcessDeepakraj BansalNoch keine Bewertungen

- A Review Article On - SuperdisintegrantsDokument12 SeitenA Review Article On - SuperdisintegrantsVhony Purnamasari HNoch keine Bewertungen

- Formulation and Evaluation of Tablets Containing Poorly Water Soluble Drug by Madg MethodDokument16 SeitenFormulation and Evaluation of Tablets Containing Poorly Water Soluble Drug by Madg MethodGudi OjhaNoch keine Bewertungen

- Roller Compactor Basic Principles and Applications in PharmaceuticalsDokument3 SeitenRoller Compactor Basic Principles and Applications in PharmaceuticalsTareq TareqNoch keine Bewertungen

- Ameya Paper JournalDokument16 SeitenAmeya Paper Journalkilari pavaniNoch keine Bewertungen

- Advanced Granulation Technology: Presented by Department of Pharmaceutics Faculty of Pharmacy Sri Ramachandra UniversityDokument24 SeitenAdvanced Granulation Technology: Presented by Department of Pharmaceutics Faculty of Pharmacy Sri Ramachandra UniversityAleeya rizviNoch keine Bewertungen

- Tumbling 1Dokument9 SeitenTumbling 1robiatulawaliyahNoch keine Bewertungen

- Advance Granulation TechnologyDokument81 SeitenAdvance Granulation TechnologysyeedNoch keine Bewertungen

- Introduction To Tableting by Wet GranulationDokument10 SeitenIntroduction To Tableting by Wet GranulationHuamán Diaz CuperNoch keine Bewertungen

- Granulation Process Basic UnderstandingDokument3 SeitenGranulation Process Basic UnderstandingRainMan75Noch keine Bewertungen

- SurbhiDokument21 SeitenSurbhiKashish MahajanNoch keine Bewertungen

- The 5 Anatomical Levels of The Human Body - DummiesDokument4 SeitenThe 5 Anatomical Levels of The Human Body - DummiesMarta HalimNoch keine Bewertungen

- Acetylcholine Receptors - Muscarinic and NicotinicDokument5 SeitenAcetylcholine Receptors - Muscarinic and NicotinicMarta HalimNoch keine Bewertungen

- Vanilin Ekstrak PDFDokument9 SeitenVanilin Ekstrak PDFMarta HalimNoch keine Bewertungen

- The Blood Harvest - Reader ViewDokument6 SeitenThe Blood Harvest - Reader ViewMarta HalimNoch keine Bewertungen

- Using Hawkeye From The Avengers To Communicate On The EyeDokument9 SeitenUsing Hawkeye From The Avengers To Communicate On The EyeGina SmithNoch keine Bewertungen

- Carisoprodol: Uses, Dosage, Side EffectsDokument8 SeitenCarisoprodol: Uses, Dosage, Side EffectsMarta HalimNoch keine Bewertungen

- 10 Rules For Writing Multiple Choice QuestionsDokument4 Seiten10 Rules For Writing Multiple Choice QuestionsMarta HalimNoch keine Bewertungen

- Format Label Tom Jerry (MS Word)Dokument3 SeitenFormat Label Tom Jerry (MS Word)Marta HalimNoch keine Bewertungen

- 4 Types of Chemical Bonds - DummiesDokument2 Seiten4 Types of Chemical Bonds - DummiesMarta HalimNoch keine Bewertungen

- Use of Qigong Therapy in Detoxification of Heroin AddictsDokument9 SeitenUse of Qigong Therapy in Detoxification of Heroin AddictsIvan Roca100% (1)

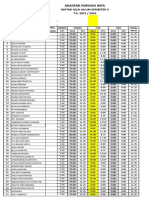

- Nilai Anfisman 2015 2016 MartaDokument20 SeitenNilai Anfisman 2015 2016 MartaMarta HalimNoch keine Bewertungen

- Our Right To Be Independent - Miras Oplosan Jadi Materi Wajib Rehabilitasi Pencandu NarkobaDokument3 SeitenOur Right To Be Independent - Miras Oplosan Jadi Materi Wajib Rehabilitasi Pencandu NarkobaMarta HalimNoch keine Bewertungen

- Cara Matematika SederhanaDokument92 SeitenCara Matematika SederhanaMarta HalimNoch keine Bewertungen

- Format Label Tom Jerry (MS Word)Dokument3 SeitenFormat Label Tom Jerry (MS Word)Marta HalimNoch keine Bewertungen

- Elementary School Diploma: This Diploma Is Proudly Presented ToDokument1 SeiteElementary School Diploma: This Diploma Is Proudly Presented ToMarta HalimNoch keine Bewertungen

- Galaxys7edge 3Dokument1 SeiteGalaxys7edge 3Marta HalimNoch keine Bewertungen

- AspirinDokument61 SeitenAspirinMarta Halim100% (1)

- Setup LGFlashTool 1.8.1.1023.zip at StockROMsDokument2 SeitenSetup LGFlashTool 1.8.1.1023.zip at StockROMsMarta HalimNoch keine Bewertungen

- Windows 8.1 1 Printed DocumentDokument2 SeitenWindows 8.1 1 Printed DocumentMarta HalimNoch keine Bewertungen

- P450 Drug Interaction TableDokument4 SeitenP450 Drug Interaction TableMarta HalimNoch keine Bewertungen

- Bahan Midtes Praktek Farmasetika 2015 MartaDokument12 SeitenBahan Midtes Praktek Farmasetika 2015 MartaMarta Halim100% (1)

- Cardiology PrescriptionDokument6 SeitenCardiology PrescriptionMarta HalimNoch keine Bewertungen

- Limulus Amebocyte LysateDokument44 SeitenLimulus Amebocyte LysateMarta HalimNoch keine Bewertungen

- Galaxys7edge 3Dokument1 SeiteGalaxys7edge 3Marta HalimNoch keine Bewertungen

- AIDS Dicampur Obat G PDFDokument2 SeitenAIDS Dicampur Obat G PDFMarta HalimNoch keine Bewertungen

- Drug and Alcohol Abuse. Antisocial PersonalityDokument9 SeitenDrug and Alcohol Abuse. Antisocial PersonalityMarta HalimNoch keine Bewertungen

- Interaksi HipertensiDokument17 SeitenInteraksi HipertensiMarta HalimNoch keine Bewertungen

- Health Literacy Toolkit Tool #9 Pharmacist Consultation - Tool9Dokument2 SeitenHealth Literacy Toolkit Tool #9 Pharmacist Consultation - Tool9Marta HalimNoch keine Bewertungen

- Wellness Check PrintableDokument2 SeitenWellness Check PrintablethubtendrolmaNoch keine Bewertungen

- Systematic Review - The Effectiveness ofDokument15 SeitenSystematic Review - The Effectiveness ofSabrinaNoch keine Bewertungen

- BIODDokument5 SeitenBIODJedan TopiagonNoch keine Bewertungen

- Tinnitus EpidemiologyDokument149 SeitenTinnitus EpidemiologyTheodoros Kontogiannis100% (1)

- CV Stoskopf 12 06Dokument52 SeitenCV Stoskopf 12 06shinevoiceNoch keine Bewertungen

- J&J CompanyDokument127 SeitenJ&J CompanyRam TyagiNoch keine Bewertungen

- GUY Et Al 1994 - Regulation of Colostrum Formation in Beef and Dairy CowsDokument6 SeitenGUY Et Al 1994 - Regulation of Colostrum Formation in Beef and Dairy CowsMonique IndNoch keine Bewertungen

- Multicare MC in ManualDokument28 SeitenMulticare MC in ManualTom TamponNoch keine Bewertungen

- CVS Examination EditedDokument134 SeitenCVS Examination EditedThilak JayalathNoch keine Bewertungen

- RP-HPLC Method Development and Validation of Gallic Acid in Polyherbal Tablet FormulationDokument6 SeitenRP-HPLC Method Development and Validation of Gallic Acid in Polyherbal Tablet FormulationLela MirelaNoch keine Bewertungen

- Harmony Provider Directory 2011Dokument156 SeitenHarmony Provider Directory 2011Todd HedgesNoch keine Bewertungen

- L10 ToleranceDokument19 SeitenL10 Tolerancesara garciaNoch keine Bewertungen

- BestDokument25 SeitenBestAlejandro Lopez OsorioNoch keine Bewertungen

- Interpretation of MriDokument12 SeitenInterpretation of Mrijimitkapadia100% (1)

- Home Private ServiceDokument4 SeitenHome Private ServiceTubagus Adil AL AminNoch keine Bewertungen

- DRUGSDokument4 SeitenDRUGSHoney Grace L LemorenasNoch keine Bewertungen

- DotDokument2 SeitenDotahsanraja123Noch keine Bewertungen

- A Report On Depression: Mental HealthDokument12 SeitenA Report On Depression: Mental HealthArchiev KumarNoch keine Bewertungen

- ES V 0281 001 FinalSPCDokument4 SeitenES V 0281 001 FinalSPCPankaj BeniwalNoch keine Bewertungen

- Modell SkellefteaDokument96 SeitenModell SkellefteaMan ManNoch keine Bewertungen

- The Tactical Combat Casualty Care Casualty Card - TCCC Guidelines - Proposed Change 1301Dokument9 SeitenThe Tactical Combat Casualty Care Casualty Card - TCCC Guidelines - Proposed Change 1301Paschalis DevranisNoch keine Bewertungen

- Case GNApsDokument47 SeitenCase GNApsAndhika Hadi WirawanNoch keine Bewertungen

- Autonomic Nervous System: Rodina Rivera-Gorospe, M.DDokument44 SeitenAutonomic Nervous System: Rodina Rivera-Gorospe, M.DPogo LocoNoch keine Bewertungen

- Hazardous Materials Management Plan SMDokument26 SeitenHazardous Materials Management Plan SMdarmayunitaNoch keine Bewertungen

- 11 NCP Pressure UlcerDokument6 Seiten11 NCP Pressure UlcerICa MarlinaNoch keine Bewertungen

- BibliopocDokument4 SeitenBibliopocKarlo ReyesNoch keine Bewertungen

- Oral CavityDokument79 SeitenOral CavityueumanaNoch keine Bewertungen