Beruflich Dokumente

Kultur Dokumente

WQT - WPS 03

Hochgeladen von

Gururaj P KundapurOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WQT - WPS 03

Hochgeladen von

Gururaj P KundapurCopyright:

Verfügbare Formate

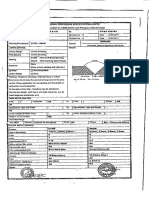

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-04-3

WELDER NAME : GULAB CHAUHAN WPS NO. : DAPL-QC-WPS-03

WELDER I/D No. : W - 04 TEST COUPON NO.: DAPL-QC-WPS-03/

ADDRESS : DAPL SITE, JAJPUR DAPL-QC-PQR-03

PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/30 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW + FCAW THROUGH REPAIR DATE OF TEST : 08.03.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 70 - 91 22 - 34 62.50 - 65.93

HOT PASS BOHLER ( E 8010) 4.0 128 - 159 27 - 37 162.16 - 171.43

FILLER BOHLER (E 81T8-FD) 2.0 203 - 279 22 - 28 136.36 - 230.77

CAPPING BOHLER (E 81T8-FD) 2.0 204 - 266 22 - 29 176.47 - 193.55

ELECTRICAL CHARACTERISTICS : DCEP & DCEN ELECTRODE : R & HP - POSITIVE, F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Uphill

Hot Pass : Vertical Down

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : - N.A. -

Removal of clamp after : - N.A. -

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/006 Dtd 11.03.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T.

IN ACCORDANCE WITH THE REQUIREMENTS OF THE W.P.S., API 1104 & MECON SPECIFICATION

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

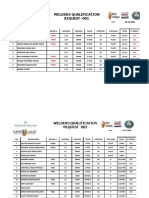

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-03-5

WELDER NAME : AMARJEET KR PRASAD WPS NO. : DAPL-QC-WPS-03

WELDER I/D No. : W - 03

TEST COUPON NO.: KM 116 / M 15 R

ADDRESS : DAPL SITE, JAJPUR PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/30 LOCATION : DAPL CAMP

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW + FCAW THROUGH REPAIR DATE OF TEST : 05.07.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 15.9 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 72 - 91 22 - 34 171.42 - 187.50

HOT PASS BOHLER ( E 8010) 4.0 128 - 159 27 - 37 187.50 - 193.54

FILLER BOHLER (E 81T8-FD) 2.0 203 - 279 22 - 28 146.34 - 166.66

CAPPING BOHLER (E 81T8-FD) 2.0 204 - 266 22 - 29 157.89 - 171.42

ELECTRICAL CHARACTERISTICS : DCEP & DCEN ELECTRODE : R & HP - POSITIVE, F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Uphill

Hot Pass : Vertical Down

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : - N.A. -

Removal of clamp after : - N.A. -

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/305 Dtd 06.07.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T.

IN ACCORDANCE WITH THE REQUIREMENTS OF THE W.P.S., API 1104 & MECON SPECIFICATION

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

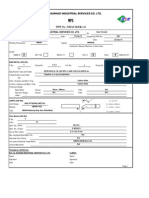

WELDER QUALIFICATION TEST RECORD

(API 1104)

Doc. No. :

PLL/DAPL/QA/MS/020-F-02

CLIENT : GAIL/ MECON CONTRACTOR : PUNJ LLOYD LTD. WQT NO. : DAPL-QC-WQT-44-1

WELDER NAME : BIKAS SAMANTO WPS NO. : DAPL-QC-WPS-03

WELDER I/D No. : W - 44

TEST COUPON NO.: KM 128 / M 19 R

ADDRESS : DAPL SITE, JAJPUR ROAD PLACE FOR

PHOTOGRAPH WELDING M/C TYPE / SIZE : RECTIFIER

PASSPORT / I/C No. : DAPL/INPL003/W/ LOCATION : DAPL 2, at CH 128

NATIONALITY : INDIAN WEATHER CONDITIONS : SUNNY

WELDING PROCESS : SMAW + FCAW THROUGH REPAIR DATE OF TEST : 11.09.2018

PIPE AND FITTING MATERIALS : Linepipe API 5L Gr. X 70, PSL 2 TO API 5L Gr. X 70 , PSL 2

PIPE OUTSIDE DIAMETER : 914.4 MM Range Qualified : Ø > 323.85 MM

PIPE WALL THICKNESS : 19.1 MM Range Qualified : 4.8 MM ≤ T ≤ 19.1 MM

JOINT DESIGN

Make and Type of Diameter Current Voltage Travel Speed

Pass

Filler Material MM (Amps) (Volts) MM/Min

ROOT BOHLER ( E 6010) 3.2 71 - 91 25 - 31 125.00 - 130.43

HOT PASS BOHLER ( E 8010) 4.0 122 - 152 27 - 34 157.89 - 171.42

FILLER BOHLER (E 81T8-FD) 2.0 209 - 265 21 - 27 142.85 - 157.89

CAPPING BOHLER (E 81T8-FD) 2.0 204 - 261 22 - 28 176.47 - 187.50

ELECTRICAL CHARACTERISTICS : DCEP & DCEN ELECTRODE : R & HP - POSITIVE, F & C - NEGATIVE

WELD POSITION: 5G SHIELDING FLUX: CELLULOSIC

DIRECTION OF WELDING :

Root Pass: Vertical Uphill

Hot Pass : Vertical Down

Subsequent Passes : Vertical Down

Minimum Number of runs before joint as allowed to cool : Minimum 2 Pass

Maximum time between commencement and completion of weld : Not Applicable

TYPE OF LINE UP CLAMP : - N.A. -

Removal of clamp after : - N.A. -

CLEANING : Power Brushing, Grinding & Chipping

INEPSCTION / NON DESTRUCTIVE EXAMINATION Applicable Code Required Remarks

Visual Inspection API 1104 (Section 6) Yes ACCEPTABLE

Radiography (Rep. No. DAPL/QC/RT/339 Page 02/02 Dtd 12.09.18) API 1104 (Section 8) Yes ACCEPTABLE

THE STATEMENTS IN THE RECORD ARE CORRECT. THE WELDER HAS COMPLETED THE W.Q.T.

IN ACCORDANCE WITH THE REQUIREMENTS OF THE W.P.S., API 1104 & MECON SPECIFICATION

PLL PLL CLIENT AUTHORITY

SIGN : SIGN : SIGN :

NAME : NAME : NAME :

DATE : DATE : DATE :

Das könnte Ihnen auch gefallen

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDokument3 SeitenDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNoch keine Bewertungen

- WPS - Smaw - 2Dokument6 SeitenWPS - Smaw - 2Harkesh RajputNoch keine Bewertungen

- WQT - WPS 02Dokument33 SeitenWQT - WPS 02Gururaj P KundapurNoch keine Bewertungen

- WQT - WPS 01Dokument71 SeitenWQT - WPS 01Gururaj P Kundapur100% (1)

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Dokument1 SeiteWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNoch keine Bewertungen

- Welding Procedure Specification (WPS) : in The Outer TubeDokument1 SeiteWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNoch keine Bewertungen

- WPS PQR PDFDokument23 SeitenWPS PQR PDFtomj9104Noch keine Bewertungen

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDokument1 SeiteWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNoch keine Bewertungen

- WPS PQR PDFDokument23 SeitenWPS PQR PDFAhmad Daniel100% (1)

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDokument1 SeiteWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Dokument2 SeitenWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNoch keine Bewertungen

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDokument1 SeiteWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345Noch keine Bewertungen

- Welders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJDokument3 SeitenWelders Qualification REQUEST - 001: TSM02 ACC TSM04 ACC TSM01 ACC - REJ - REJ TSM03 ACC TSM06 ACC TSM05 ACC - REJel_sharkawy2011Noch keine Bewertungen

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Dokument2 SeitenLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNoch keine Bewertungen

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDokument2 SeitenASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNoch keine Bewertungen

- WPQDokument1 SeiteWPQjuda823Noch keine Bewertungen

- Joints (Qw-402) DetailsDokument3 SeitenJoints (Qw-402) DetailsNaqqash SajidNoch keine Bewertungen

- Wps Pip Gtaw - ArabianDokument1 SeiteWps Pip Gtaw - ArabianIshack MohammedNoch keine Bewertungen

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDokument4 Seiten163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDokument1 SeiteD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Noch keine Bewertungen

- Sample of WQP/PQR/WQT ProgrammeDokument1 SeiteSample of WQP/PQR/WQT ProgrammeMorjhan MJNoch keine Bewertungen

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDokument2 SeitenName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiNoch keine Bewertungen

- P. WpsDokument14 SeitenP. WpsIsmiArdyNoch keine Bewertungen

- WOPQ Form English1Dokument2 SeitenWOPQ Form English1oaperuchenaNoch keine Bewertungen

- d1.1 Fcaw Unlimited Test Plate ConfigurationDokument77 Seitend1.1 Fcaw Unlimited Test Plate ConfigurationJuan Martinez100% (1)

- PQR Is7307Dokument1 SeitePQR Is7307Tridib Dey100% (1)

- WpsDokument2 SeitenWpssamer8saifNoch keine Bewertungen

- WPS PQR FormatsDokument22 SeitenWPS PQR Formatsmdharmaraj28Noch keine Bewertungen

- PQR Editable SampleDokument2 SeitenPQR Editable SampleKoya ThangalNoch keine Bewertungen

- NSH-DALM-JERP-WPS-11-P2 Rev.00Dokument10 SeitenNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNoch keine Bewertungen

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDokument5 SeitenWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNoch keine Bewertungen

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Dokument2 SeitenProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNoch keine Bewertungen

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDokument3 SeitenWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNoch keine Bewertungen

- WPS 204 NewDokument6 SeitenWPS 204 Newarockiyathass100% (1)

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDokument9 Seiten2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNoch keine Bewertungen

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Dokument6 SeitenMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNoch keine Bewertungen

- WPS002 312Dokument2 SeitenWPS002 312proxywarNoch keine Bewertungen

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDokument4 Seiten170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- 2G +5GDokument1 Seite2G +5GRahul Moottolikandy0% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDokument1 SeitePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNoch keine Bewertungen

- Welding Proposed Pwps For Our Jubail WorkDokument2 SeitenWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPQ-1083 3G PDFDokument2 SeitenWPQ-1083 3G PDFduendex360100% (1)

- Gtaw 106Dokument2 SeitenGtaw 106ganeshkumarg_1Noch keine Bewertungen

- WPS PQR FormatDokument1 SeiteWPS PQR FormatJatin Kamdar100% (2)

- Welding Procedure Specification For GTAW & GMAWDokument4 SeitenWelding Procedure Specification For GTAW & GMAWanh thoNoch keine Bewertungen

- WPS - 020Dokument15 SeitenWPS - 020MAT-LION100% (2)

- Visual Inspection of Weld Joints Welding and NDTDokument7 SeitenVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Dokument2 SeitenWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNoch keine Bewertungen

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Dokument18 SeitenWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNoch keine Bewertungen

- ASME 9 Multi Process Welding Procedures QW200Dokument2 SeitenASME 9 Multi Process Welding Procedures QW200Teodor EzaruNoch keine Bewertungen

- WPS AMC-0195 Rev 01Dokument3 SeitenWPS AMC-0195 Rev 01umer.shariff87Noch keine Bewertungen

- Dokumen - Tips Wqt-FormatDokument2 SeitenDokumen - Tips Wqt-FormatMr Pie100% (1)

- WPQT CertificateDokument104 SeitenWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- Gtaw Smaw 6 Inch 6G CSDokument1 SeiteGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- Wps - Asme Ix - Gtaw - Plat SteDokument6 SeitenWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNoch keine Bewertungen

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlDokument1 SeiteIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayNoch keine Bewertungen

- Welding Procedure SpecificationsDokument2 SeitenWelding Procedure SpecificationsIOT ISPRLNoch keine Bewertungen

- 7.14 CP14571 Blower PackageDokument29 Seiten7.14 CP14571 Blower PackageIsaias de la CruzNoch keine Bewertungen

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Dokument6 SeitenPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonNoch keine Bewertungen

- Gpti Qicl J931 Mut 041Dokument3 SeitenGpti Qicl J931 Mut 041uselessinstaid52Noch keine Bewertungen

- BG - Chapter 12Dokument2 SeitenBG - Chapter 12Gururaj P KundapurNoch keine Bewertungen

- Vishal Pipe S Test CertificatesDokument24 SeitenVishal Pipe S Test CertificatesGururaj P KundapurNoch keine Bewertungen

- Ctod Test OffshoreDokument20 SeitenCtod Test OffshoreGururaj P KundapurNoch keine Bewertungen

- Ctod TestDokument20 SeitenCtod TestGururaj P KundapurNoch keine Bewertungen

- Chapter 6Dokument3 SeitenChapter 6Gururaj P KundapurNoch keine Bewertungen

- BG - Chapter 5Dokument1 SeiteBG - Chapter 5Gururaj P KundapurNoch keine Bewertungen

- Vol II of II - Technical VolDokument21 SeitenVol II of II - Technical VolGururaj P KundapurNoch keine Bewertungen

- 19.05 X 2.41 MTCDokument3 Seiten19.05 X 2.41 MTCGururaj P KundapurNoch keine Bewertungen

- THINK GAS WITNESS REPORT - Vishal PipesDokument10 SeitenTHINK GAS WITNESS REPORT - Vishal PipesGururaj P KundapurNoch keine Bewertungen

- Curriculum Vitae: Gururaj P KundapurDokument5 SeitenCurriculum Vitae: Gururaj P KundapurGururaj P KundapurNoch keine Bewertungen

- JP-12 - HDPE Duct Laying-Rev.0Dokument10 SeitenJP-12 - HDPE Duct Laying-Rev.0Gururaj P Kundapur100% (1)

- JHBDPL Project (Phase - Ii, Section - 2A) : Combined Daily Progress Report (Laying Works of Main Line & Spur Lines)Dokument2 SeitenJHBDPL Project (Phase - Ii, Section - 2A) : Combined Daily Progress Report (Laying Works of Main Line & Spur Lines)Gururaj P KundapurNoch keine Bewertungen

- Qap - Mdpe - 19-08-2021 - AwcDokument3 SeitenQap - Mdpe - 19-08-2021 - AwcGururaj P KundapurNoch keine Bewertungen

- JP-12 - HDPE Duct Laying-Rev.0Dokument9 SeitenJP-12 - HDPE Duct Laying-Rev.0Gururaj P KundapurNoch keine Bewertungen

- Ilovepdf MergedDokument4 SeitenIlovepdf MergedGururaj P KundapurNoch keine Bewertungen

- JP-12 - HDPE Duct Laying-Rev.0Dokument9 SeitenJP-12 - HDPE Duct Laying-Rev.0Gururaj P KundapurNoch keine Bewertungen

- Marching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Dokument2 SeitenMarching Chart JHBDPL, DAPL Section - II, ORISSA Region (118.23 To 206.59 KM)Gururaj P Kundapur100% (1)

- Is1200 (Part2) 1974Dokument14 SeitenIs1200 (Part2) 1974Gururaj P KundapurNoch keine Bewertungen

- BGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Dokument48 SeitenBGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Gururaj P KundapurNoch keine Bewertungen

- Signed PQT - Field Joint CoatingDokument12 SeitenSigned PQT - Field Joint CoatingGururaj P Kundapur100% (1)

- Cebex 112 PDFDokument2 SeitenCebex 112 PDFGururaj P KundapurNoch keine Bewertungen

- Is1200 (Part1) 1992Dokument5 SeitenIs1200 (Part1) 1992Gururaj P KundapurNoch keine Bewertungen

- BGA-EnG-MATL-TS-0008 Materials of Construction Requirements Rev 01Dokument38 SeitenBGA-EnG-MATL-TS-0008 Materials of Construction Requirements Rev 01Gururaj P KundapurNoch keine Bewertungen

- BGA ENG MATL TS 0006 Cathodic Protection Rev 02aDokument26 SeitenBGA ENG MATL TS 0006 Cathodic Protection Rev 02aGururaj P KundapurNoch keine Bewertungen

- BG ST OPS OPS 043 Offshore Marine OperationsDokument34 SeitenBG ST OPS OPS 043 Offshore Marine OperationsGururaj P Kundapur100% (1)

- BGA-EnG-MATL-TS-0007 Fabrication of Equipment and Piping Rev 02aDokument44 SeitenBGA-EnG-MATL-TS-0007 Fabrication of Equipment and Piping Rev 02aGururaj P Kundapur100% (1)

- Fittings SwagelokDokument16 SeitenFittings SwagelokFernando OlaveoNoch keine Bewertungen

- Surface Vehicle Recommended Practice: Issued OCT1999Dokument19 SeitenSurface Vehicle Recommended Practice: Issued OCT1999Eduardo100% (1)

- Observation of Defects in Cast Iron Castings by Surface AnalysisDokument19 SeitenObservation of Defects in Cast Iron Castings by Surface Analysisgonzalo gimenez100% (1)

- DIN en 10085 2001 Nitriding SteelsDokument27 SeitenDIN en 10085 2001 Nitriding SteelsjorgeNoch keine Bewertungen

- MIL-HDBK-756 Manufacture of Projectiles, Projectile Components, and Cartridge Cases For Artillery, Tank Main Armament, and Mortars PDFDokument147 SeitenMIL-HDBK-756 Manufacture of Projectiles, Projectile Components, and Cartridge Cases For Artillery, Tank Main Armament, and Mortars PDF劉永賢Noch keine Bewertungen

- Welding 304HDokument29 SeitenWelding 304Hclaude.bouillot3566Noch keine Bewertungen

- WPS & PQRDokument7 SeitenWPS & PQRRanjan KumarNoch keine Bewertungen

- Delta Mks (Zinc Flake) - Pea ProjectDokument32 SeitenDelta Mks (Zinc Flake) - Pea ProjectTAEWARAT RAKRUANGNoch keine Bewertungen

- Detailed Lesson Plan (Jor)Dokument6 SeitenDetailed Lesson Plan (Jor)Pebbles ParedesNoch keine Bewertungen

- Ions ChargeDokument1 SeiteIons Chargeshashankshukla676100% (1)

- 34 CR Mo 4Dokument2 Seiten34 CR Mo 4fsfunbNoch keine Bewertungen

- Usb 3100Dokument2 SeitenUsb 3100terenceNoch keine Bewertungen

- Journal of Alloys and Compounds: A. Yarmou Shamsabadi, R. Bakhtiari, G. Eisaabadi BDokument10 SeitenJournal of Alloys and Compounds: A. Yarmou Shamsabadi, R. Bakhtiari, G. Eisaabadi BJustin DixonNoch keine Bewertungen

- Febby Fauziah - Pengaruh Persentase Reduksi Terhadap Sifat Mekanik Dan Struktur Mikro FixDokument11 SeitenFebby Fauziah - Pengaruh Persentase Reduksi Terhadap Sifat Mekanik Dan Struktur Mikro FixAmmi AndamNoch keine Bewertungen

- DocumentDokument25 SeitenDocumentRodolfo GarciaNoch keine Bewertungen

- Gatting SystemDokument7 SeitenGatting SystemANIDHANoch keine Bewertungen

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Dokument3 SeitenAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- TABLE 6.1 General Characteristics of Bulk Deformation ProcessesDokument63 SeitenTABLE 6.1 General Characteristics of Bulk Deformation Processesharlow6winfield6adamNoch keine Bewertungen

- Is 1285 2002Dokument14 SeitenIs 1285 2002Eldho VargheseNoch keine Bewertungen

- Data Sheet-CF.S10Dokument1 SeiteData Sheet-CF.S10nicolasNoch keine Bewertungen

- Saph 440Dokument1 SeiteSaph 440rinkumax2003100% (1)

- DIN en 10270-1 - Engl - Januar 2012Dokument27 SeitenDIN en 10270-1 - Engl - Januar 2012Mesquita VictorNoch keine Bewertungen

- Tentative Calendar of Events INDOCOR 2017Dokument2 SeitenTentative Calendar of Events INDOCOR 2017Firlan MaulanaNoch keine Bewertungen

- Element Six Metalworking-BrochureDokument18 SeitenElement Six Metalworking-BrochureGuilherme TrettelNoch keine Bewertungen

- Titanium Grade 1 Vs Grade 2: ASTM B338/ASTM B337 Seamless and Welding TubingDokument4 SeitenTitanium Grade 1 Vs Grade 2: ASTM B338/ASTM B337 Seamless and Welding Tubingaman131Noch keine Bewertungen

- Material Science Objective QuestionsDokument44 SeitenMaterial Science Objective Questionspurushothamkr82% (45)

- GostDokument4 SeitenGostPinkuNoch keine Bewertungen

- Corrosion Resistant Enclosures HOFFMANDokument231 SeitenCorrosion Resistant Enclosures HOFFMANMario GuzmanNoch keine Bewertungen

- Section Guillotine: Title SawDokument4 SeitenSection Guillotine: Title SawIsabel TorresNoch keine Bewertungen