Beruflich Dokumente

Kultur Dokumente

Tittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself Apparatus

Hochgeladen von

Chathura Chamikara0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

44 Ansichten6 SeitenStandard test method for sand cone test.

Originaltitel

Sand-cone Test

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenStandard test method for sand cone test.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

44 Ansichten6 SeitenTittle: Field Density Test. Scope: To Determine Density of Soil at The Field Itself Apparatus

Hochgeladen von

Chathura ChamikaraStandard test method for sand cone test.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

TITTLE: FIELD DENSITY TEST.

SCOPE : TO DETERMINE DENSITY OF SOIL AT THE FIELD ITSELF

APPARATUS:

1 Sampling tools; large spoon, dibber, hammer, chisel, a scraper to make leveled surface.

2 Containers.

3 Balance, readable to 1g.

4 Glass plate, at least 10mm thickness and 500 mm2 areas.

5 Metal tray or container, to take excavated soil. Diameter shall be 300mm and the height

shall be 40mm.

6 A cylindrical steel core cutter 130mm long and 100+/- 2mm internal diameter with 3mm

wall thickness, for fine grained cohesive soils.

7 Sand cone density apparatus

8 A metal tray with 300mm2 area and 40mm depth with 100mm diameter hole in the

centre.

PROCEDURE:

-The site was selected to test at random.

-All loose material was removed and scraped at the location.

-The surface of 450mm square area was exposed and leveled.

-The base plate was pined securely in position with spikes provided.

-Metal tray was laid with the hole over the portion of the soil to be tested & hole

was excavated to have 100mm diameter to maximum depth of 150mm.

-Excavated material was then carefully removed and weigh was taken to the nearest 1g.

After that, the pouring cylinder which is filled to constant mass was placed, concentrically

to cover the hole by the base of the cylinder.

-Subsequently the shutter was opened & allows sand to run out.

-Cylinder was removed & the mass was measured to the nearest 1g.

CALCULATION:

Volume of cone = weight of sand to fill cone/ unit weight of sand

Volume of density hole and cone = weight of sand to fill hole and cone/unit weight of sand

Density of soil = weight material removed/ volume of density hole

Moisture content = weight of moisture /weight of dry sample x100

Degree of Compaction = Field Dry Density / Maximum Dry Density

Refer attached sheet.

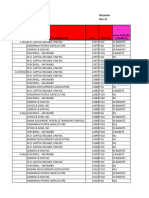

Weight of sand +container =8562g

Weight of sand residue + container =4388g

Weight of sand used =8562g-4388g

=4174g

Volume of sand used =4174g/ 1.37 g/ cm3

=3047cm3

Volume of hole =3047 cm3 - 1092 cm3

=1955 cm3

Weight of wet soil =3472g

Wet density of soil =3472g/1955 cm3

=1.78 g/ cm3

Dry density of soil =1.78 g/ cm3/ (1+1.105)

=1.61 g/ cm3

DISCUSSION:

Most of the construction sites normally do the field density test because it helps to continuing

the construction process. When doing the field density test, the site chosen must be flat and

smooth as possible the test.

When place removing materials from the hole, larger stone particles (12.5mm) should be

excepted. These stones can be replaced in the hole during the volume measurement with

density sand.

And also great care must be taken to get the walls of the holes as smooth as possible as this

affects the volume measurement and the test should be done in such a way that sand cone is

free from any vibrations or disturbances during the flowing of the sand as this affects the

volume of the hole.

Replacement sand should be cleaned closely grained silica sand (Bulk density is reasonably

consistent). Grading, 100% passing 600µm sieve and 100% retained in 63µm sieve. Sand

shall be free from flaky particles, silt, clay and organic matter. It shall be oven dried before

use and keep in closed container to reach equilibrium with atmospheric humidity (7 days).

This test method is specified for fine and medium grained soils. The layer thickness shall not

be greater than 150mm. large pouring cylinder can be used for soils with layer thickness from

150 to 250 mm.

If the testing soil is pavement or embankment fill, degree of compaction can be found after

a standard compaction test. In that case OMC and MDD shall be found and the degree

of compaction can be found

There are number of field test methods such as, water replacement method, core cutter

method, nuclear method, etc.

Most of the available methods depend upon the removal of a representative sample of soil

from the pits and determining its mass and the volume is occupied before being removed.

Mass determination is common and volume determination varies depending on the nature of

the soil being tested.

Periodic calibration of sand density should be carried out.

Location preparation and collecting sample

DISCUSSION:

Most of the construction sites normally do the field density test because it helps to continuing

the construction process. When doing the field density test, the site chosen must be flat and

smooth as possible the test.

When place removing materials from the hole, larger stone particles (12.5mm) should be

excepted. These stones can be replaced in the hole during the volume measurement with

density sand.

And also great care must be taken to get the walls of the holes as smooth as possible as this

affects the volume measurement and the test should be done in such a way that sand cone is

free from any vibrations or disturbances during the flowing of the sand as this affects the

volume of the hole.

Replacement sand should be cleaned closely grained silica sand (Bulk density is reasonably

consistent). Grading, 100% passing 600µm sieve and 100% retained in 63µm sieve. Sand

shall be free from flaky particles, silt, clay and organic matter. It shall be oven dried before

use and keep in closed container to reach equilibrium with atmospheric humidity (7 days).

This test method is specified for fine and medium grained soils. The layer thickness shall not

be greater than 150mm. large pouring cylinder can be used for soils with layer thickness from

150 to 250 mm.

If the testing soil is pavement or embankment fill, degree of compaction can be found after

a standard compaction test. In that case OMC and MDD shall be found and the degree

of compaction can be found

There are number of field test methods such as, water replacement method, core cutter

method, nuclear method, etc.

Most of the available methods depend upon the removal of a representative sample of soil

from the pits and determining its mass and the volume is occupied before being removed.

Mass determination is common and volume determination varies depending on the nature of

the soil being tested.

Compaction is the most popular technique of improving soils. Compaction increases the

strength, lowers the compressibility and reduces the permeability of a soil by rearranging its

fabric. The soil fabric is forced into a denser configuration by the mechanical effort used in

compaction.

Knowledge of the optimum water content and the maximum dry unit weight of soils very

important for construction specifications of soil improvement by compaction. Specifications

for earth structures usually call for a minimum of 95% of maximum dry unit weight. This

level of compaction can be attained at two water contents, one before the attainment of the

maximum dry unit weight, the other after attainment of the maximum dry unit weight.

Normal practice is to compact the soil at lower water content value except for swelling soils.

When embankments construct by spreading the material in relatively thin layers and

compacting it at moisture content close to the optimum. This improvement results largely

because a greater dry density is obtained, which in turn results in higher strength in the soil

mass and decreased settlement and rutting. Layered construction also produced greater

uniformity in the material itself and in its density and moisture contents. Uniformity of

compaction is of prime importance in preventing uneven settlement. Some settlements can be

tolerated it is important that they are minimized, especially on the approaches to bridges and

culverts where adequate compaction is essential.

Compaction trials should always be carried out to determine the best way to achieve the

specified density with the available compacting equipment.

REFERENCE:

1. Soil mechanics and foundations, by Muni Budhu, Professor, University of Arizona.

Das könnte Ihnen auch gefallen

- Determine Soil Density Using Sand Pouring CylindersDokument14 SeitenDetermine Soil Density Using Sand Pouring Cylindersabood buriahiNoch keine Bewertungen

- C 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Dokument6 SeitenC 0) C' and ' C' and ' C' ' C C' Effective Undrained Cohesion C' Undrained Angle of Friction ' Effective Undrained Angle of Friction 'Dr Wong Kim YuenNoch keine Bewertungen

- ICBP Paving Provides Durability and Flexibility at Low CostDokument24 SeitenICBP Paving Provides Durability and Flexibility at Low CostAbhishek RanaNoch keine Bewertungen

- Direct Shear TestDokument11 SeitenDirect Shear TestKrishna KumarNoch keine Bewertungen

- Mix Design by Marshall MethodDokument27 SeitenMix Design by Marshall MethodS K SinghNoch keine Bewertungen

- CIVL354 Notes 1 Soil CompactionDokument20 SeitenCIVL354 Notes 1 Soil Compactionmusiomi2005Noch keine Bewertungen

- Jamuni River Geotech ReportDokument58 SeitenJamuni River Geotech ReportRoshan KejariwalNoch keine Bewertungen

- Compacting Factor TestDokument3 SeitenCompacting Factor TestRahul SharmaNoch keine Bewertungen

- Shear TestDokument3 SeitenShear TestRajesh Kumar SrivastavaNoch keine Bewertungen

- Half-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskDokument3 SeitenHalf-Cell Potential Method for Measuring Reinforcing Bar Corrosion RiskBIPL REPORTNoch keine Bewertungen

- Percolation TestDokument3 SeitenPercolation TestKothiyal MukeshNoch keine Bewertungen

- OCW Marshall Mix Design MethodDokument25 SeitenOCW Marshall Mix Design MethodPacifique NicholasNoch keine Bewertungen

- UU Triaxial Test - Lab ManualDokument6 SeitenUU Triaxial Test - Lab ManualmmNoch keine Bewertungen

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Dokument11 SeitenOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- External Development Qty For Luxor 11-09-2019 - Bifurcation For Package-1 Package - 2Dokument57 SeitenExternal Development Qty For Luxor 11-09-2019 - Bifurcation For Package-1 Package - 2raviNoch keine Bewertungen

- Standard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Dokument3 SeitenStandard Test Method For Measurement of Collapse Potential of Soils - ASTM D 5333-92Gusti PaganiniNoch keine Bewertungen

- Sample Plate Load Test Field DataDokument3 SeitenSample Plate Load Test Field DatampvfolloscoNoch keine Bewertungen

- Experiment 7: Field Density (Sand Cone Method)Dokument8 SeitenExperiment 7: Field Density (Sand Cone Method)Thanaa' Marabeh100% (1)

- Swelling IndexDokument3 SeitenSwelling IndexjitenderNoch keine Bewertungen

- NT Build 492Dokument3 SeitenNT Build 492pavan6595Noch keine Bewertungen

- Marshall Mix Design Test ProcedureDokument3 SeitenMarshall Mix Design Test Procedureshafiqz_4Noch keine Bewertungen

- 4.bulk Density of AggregatesDokument3 Seiten4.bulk Density of AggregatesRahul SharmaNoch keine Bewertungen

- JSTU civil engineering student's Marshall mix design experimentDokument20 SeitenJSTU civil engineering student's Marshall mix design experimentali100% (1)

- Name: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Dokument17 SeitenName: Yanik Lubin CVNG 3009 - Marshall Mix Design Lab I.D.#: 809100024Deoraj ToolsieNoch keine Bewertungen

- Soil Stabilization by Using: Fly AshDokument12 SeitenSoil Stabilization by Using: Fly AshRavi HirulkarNoch keine Bewertungen

- L1-Physical Characteristic of SoilDokument78 SeitenL1-Physical Characteristic of SoilTAN PANG ZORNoch keine Bewertungen

- Conrete Mix Design & Making and Curing of Test SpecimenDokument15 SeitenConrete Mix Design & Making and Curing of Test SpecimenBlesNoch keine Bewertungen

- 3 Constant HeadDokument12 Seiten3 Constant HeadWHfamilyNoch keine Bewertungen

- Lab ReportDokument44 SeitenLab ReportNepali Kanchoo100% (1)

- Hilti HKV DatasheetDokument5 SeitenHilti HKV DatasheetozkanhasanNoch keine Bewertungen

- Triaxial Compression TestDokument53 SeitenTriaxial Compression TestAndyra Jaiz BadduNoch keine Bewertungen

- Mechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Dokument10 SeitenMechanical and Physical Properties of Aggregates Aggregate Crushing Value (Acv)Kamukwema johnNoch keine Bewertungen

- Ev2 Test PDFDokument1 SeiteEv2 Test PDFBinod SharmaNoch keine Bewertungen

- Plate Bearing Load TestDokument1 SeitePlate Bearing Load TestTk Kendrick Lau100% (1)

- Plate Load Test ResultsDokument4 SeitenPlate Load Test ResultsDeepak100% (1)

- BTM Soil Laboratory ProfileDokument36 SeitenBTM Soil Laboratory Profilebtmsoil100% (1)

- NDT - Acoustic Emission TestingDokument26 SeitenNDT - Acoustic Emission TestingAshwini SinghNoch keine Bewertungen

- Mix Design Report - Malkangiri-311Dokument1 SeiteMix Design Report - Malkangiri-311KanhaNoch keine Bewertungen

- The Effect of Excess Water in ConcreteDokument2 SeitenThe Effect of Excess Water in ConcreteKevin NacalabanNoch keine Bewertungen

- Direct Shear TestDokument2 SeitenDirect Shear TestUtkarsh KumarNoch keine Bewertungen

- Experiment No 3a Sieve Analysis of SoilDokument7 SeitenExperiment No 3a Sieve Analysis of Soillance adrian del rosarioNoch keine Bewertungen

- 13-HPCL Vizag Soil Report-VOL.VDokument28 Seiten13-HPCL Vizag Soil Report-VOL.VDhananjay KumarNoch keine Bewertungen

- Concrete Methods of Test Fresh ConcreteDokument4 SeitenConcrete Methods of Test Fresh Concretecevivekt0% (1)

- Field Density Test Subgrade A. Weight of Sand in Cone in GMDokument6 SeitenField Density Test Subgrade A. Weight of Sand in Cone in GMratheeshNoch keine Bewertungen

- Density For Soil by Sand Displacement Method: Scope Is Code ApparatusDokument2 SeitenDensity For Soil by Sand Displacement Method: Scope Is Code ApparatusMastani BajiraoNoch keine Bewertungen

- R-12-090 - Pressure Meter Test ReportDokument30 SeitenR-12-090 - Pressure Meter Test ReportRaghu Prakash ANoch keine Bewertungen

- UU TestDokument7 SeitenUU TestVenu Gopal Mudhiraj100% (1)

- DBM Job MixDokument3 SeitenDBM Job MixSOIGNE ENGINEERING CONSULTANTSNoch keine Bewertungen

- Plate Load Test Air PortDokument4 SeitenPlate Load Test Air PortSimone GuarnacciaNoch keine Bewertungen

- Concrete Quality Non-Destructive TestsDokument5 SeitenConcrete Quality Non-Destructive TestsNadhirah LnfNoch keine Bewertungen

- Extraction Test BitumenDokument2 SeitenExtraction Test BitumenAbhishek AbNoch keine Bewertungen

- Concrete Mix Design C 25 For KamoaDokument9 SeitenConcrete Mix Design C 25 For KamoaMitendra Kumar ChauhanNoch keine Bewertungen

- Lecture 5 Highway Construction MaterialsDokument15 SeitenLecture 5 Highway Construction MaterialsCherylNoch keine Bewertungen

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Von EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Noch keine Bewertungen

- Report Field Density - Sand Replacement MethodDokument9 SeitenReport Field Density - Sand Replacement Methodwanfaiz12382% (11)

- Field Density TestDokument11 SeitenField Density TestNimish Madanan100% (1)

- Sand ReplacementDokument14 SeitenSand ReplacementMuniey Aziz75% (8)

- Sand Replacement TESTDokument15 SeitenSand Replacement TESTNurul Adha100% (2)

- Mi Drone Mini Instruction ManualDokument73 SeitenMi Drone Mini Instruction ManualFlavio BraboNoch keine Bewertungen

- Title: Density Test Scope: Determine The Density of Cement ApparatusDokument4 SeitenTitle: Density Test Scope: Determine The Density of Cement ApparatusChathura ChamikaraNoch keine Bewertungen

- Tittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatDokument7 SeitenTittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatChathura ChamikaraNoch keine Bewertungen

- Tittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatDokument7 SeitenTittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatChathura ChamikaraNoch keine Bewertungen

- Flakiness IndexDokument6 SeitenFlakiness IndexChathura ChamikaraNoch keine Bewertungen

- Concrete Mix Design GuideDokument7 SeitenConcrete Mix Design GuideChathura ChamikaraNoch keine Bewertungen

- Saybolt Furol VisosityDokument3 SeitenSaybolt Furol VisosityChathura ChamikaraNoch keine Bewertungen

- Modified Compaction Test: MDD and OMCDokument5 SeitenModified Compaction Test: MDD and OMCChathura ChamikaraNoch keine Bewertungen

- DCP TestDokument10 SeitenDCP TestChathura ChamikaraNoch keine Bewertungen

- Tittle: Standard Compaction Test Scope: To Determine The Maximum Dry Density and OptimumDokument8 SeitenTittle: Standard Compaction Test Scope: To Determine The Maximum Dry Density and OptimumChathura ChamikaraNoch keine Bewertungen

- Elongation Index of Coarse Aggregate TestDokument4 SeitenElongation Index of Coarse Aggregate TestChathura ChamikaraNoch keine Bewertungen

- Tittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatDokument7 SeitenTittle: Consistancy Limits Test Scope: To Determine The Plasticity Index of Fine Grained Soils ThatChathura ChamikaraNoch keine Bewertungen

- WBS Task Name Duration Start FinishDokument2 SeitenWBS Task Name Duration Start FinishChathura ChamikaraNoch keine Bewertungen

- Slump Test (Rath)Dokument3 SeitenSlump Test (Rath)Chathura ChamikaraNoch keine Bewertungen

- Flakiness IndexDokument6 SeitenFlakiness IndexChathura ChamikaraNoch keine Bewertungen

- Elongation Index of Coarse Aggregate TestDokument4 SeitenElongation Index of Coarse Aggregate TestChathura ChamikaraNoch keine Bewertungen

- Soundness AggregateDokument4 SeitenSoundness AggregateChathura ChamikaraNoch keine Bewertungen

- DCP TestDokument10 SeitenDCP TestChathura ChamikaraNoch keine Bewertungen

- Flakiness IndexDokument6 SeitenFlakiness IndexChathura ChamikaraNoch keine Bewertungen

- Determination of Compressive Strenght of Concrete CubesDokument3 SeitenDetermination of Compressive Strenght of Concrete CubesChathura ChamikaraNoch keine Bewertungen

- LBP 3500 ManualDokument56 SeitenLBP 3500 ManualChathura ChamikaraNoch keine Bewertungen

- Traffic Calming and Road Safety DesignsDokument9 SeitenTraffic Calming and Road Safety DesignsChathura ChamikaraNoch keine Bewertungen

- The Parachute Problem: Ronald Phoebus and Cole ReillyDokument23 SeitenThe Parachute Problem: Ronald Phoebus and Cole ReillyChathura ChamikaraNoch keine Bewertungen

- Manual Series 3Dokument16 SeitenManual Series 3Chathura ChamikaraNoch keine Bewertungen

- DCT Dual Clutch TransmissionDokument16 SeitenDCT Dual Clutch TransmissionSudharshan SrinathNoch keine Bewertungen

- Lighting SchemesDokument7 SeitenLighting SchemesSharath CherryNoch keine Bewertungen

- Decision Model Using ExcelDokument236 SeitenDecision Model Using Excelসামিউল ইসলাম রাজু100% (3)

- Nov. AbwDokument50 SeitenNov. Abwjbyarkpawolo70Noch keine Bewertungen

- MC0081Dokument385 SeitenMC0081Purushottam KumarNoch keine Bewertungen

- Auditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearDokument6 SeitenAuditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearJosé MorenoNoch keine Bewertungen

- Kidney AnatomyDokument55 SeitenKidney AnatomyMohammad zreadNoch keine Bewertungen

- Order Change Management (OCM)Dokument19 SeitenOrder Change Management (OCM)Debasish BeheraNoch keine Bewertungen

- Oracle Database JDBC Developer Guide and ReferenceDokument432 SeitenOracle Database JDBC Developer Guide and Referenceapi-25919427100% (1)

- Class 9 Sample Paper 2020-21Dokument3 SeitenClass 9 Sample Paper 2020-21sasta jiNoch keine Bewertungen

- Test 2Dokument16 SeitenTest 2edwardNoch keine Bewertungen

- Design of Three Span Steel Composite FlyoverDokument85 SeitenDesign of Three Span Steel Composite FlyoverStructural SpreadsheetsNoch keine Bewertungen

- State Standards: Common CoreDokument24 SeitenState Standards: Common CoreEddy R. VélezNoch keine Bewertungen

- Collet Chuck Catalog 2007 PDFDokument28 SeitenCollet Chuck Catalog 2007 PDFAlexandru Marius-catalinNoch keine Bewertungen

- Alcohols, Phenols and Ethers Worksheet Answer Grade 12Dokument6 SeitenAlcohols, Phenols and Ethers Worksheet Answer Grade 12sethu100% (1)

- Week 10 TelecommunicationsDokument7 SeitenWeek 10 TelecommunicationsGuido MartinezNoch keine Bewertungen

- Connector Python En.a4Dokument98 SeitenConnector Python En.a4victor carreiraNoch keine Bewertungen

- Chapter 6 Basic Heat TransferDokument7 SeitenChapter 6 Basic Heat TransferGabo MarquezNoch keine Bewertungen

- Gas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 ADokument33 SeitenGas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 APélagie DAH SERETENONNoch keine Bewertungen

- Chapter 13: The Electronic Spectra of ComplexesDokument42 SeitenChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniNoch keine Bewertungen

- LAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Dokument13 SeitenLAB REPORT-Rock Pore Volume and Porosity Measurement by Vacuum Saturation-GROUP - 5-PETE-2202Jeremy MacalaladNoch keine Bewertungen

- Saravel Air Hanling UnitDokument92 SeitenSaravel Air Hanling UnitClaire ApapNoch keine Bewertungen

- Medical Oxygen Cylinder Filling System User ManualDokument57 SeitenMedical Oxygen Cylinder Filling System User ManualAldo Tolaba QuirogaNoch keine Bewertungen

- VeEX OTN Quick Reference GuideDokument12 SeitenVeEX OTN Quick Reference GuideDewan H S SalehinNoch keine Bewertungen

- Java 8 Interview QuestionsDokument31 SeitenJava 8 Interview QuestionsAmit Sharma100% (2)

- GBE Version 3: API: New API SpecificationDokument44 SeitenGBE Version 3: API: New API SpecificationAdi BauNoch keine Bewertungen

- Post GreeDokument15 SeitenPost GreeDwi PraptiNoch keine Bewertungen

- Mechanical Engineering Conference ProgramDokument40 SeitenMechanical Engineering Conference Programirinuca12Noch keine Bewertungen

- SQL SlidesDokument65 SeitenSQL SlidescopsamostoNoch keine Bewertungen

- IMS2 Manual EngDokument61 SeitenIMS2 Manual EngJhonatan BuenoNoch keine Bewertungen