Beruflich Dokumente

Kultur Dokumente

Risk Assessment Check List - Condensate Project

Hochgeladen von

MugeshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Assessment Check List - Condensate Project

Hochgeladen von

MugeshCopyright:

Verfügbare Formate

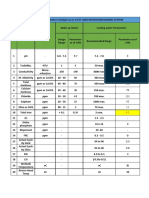

INITIAL RISK ASSESSMENT CHECKLIST

Review Date: 18.04.2018

Note: Explicit recommendations may be evident from application of this checklist. If a YES answer is made to any of the questions below a further more detailed risk analysis/evaluation (

shall check the type of more detailed risk assessment required and assign a responsible person to ensure it is completed. If the Functional Review Team determines that a more detailed r

Team will list the risk assessed, the risk mitigation measures required and then assign a responsible person to complete the task.

Item Will this change potentially………. Yes/ No Risk Assessed Risk Mitigation available

Allow operation outside design limits? (i.e. pressure, Safety relief valve, Excess flow check valve,

Risk of reaching high/ low LPG level, pressure

1 vacuum, temperature, flow, inventory, level, phase, YES pressure gauge, temperature gauge are

and temperature.

relief load)? provided in the vessel.

Require additional safety devices or systems (e.g.

alarms, interlocks, fire suppression) or cause existing

2 YES LPG leak risk and BLEVE,UVCE Deluge activation from field is available.

safety devices or systems to become unavailable, or

not function as required?

Introduce hazardous substances or noise levels to

new areas within a facility or in closer proximity to Sudden release of LPG liquid from T402 inlet EFCVs available at liquid inlet and outlet

3 YES

the public (e.g. hazardous area classification, siting and out let flanges. nozzles.

study)?

Require new or temporary procedures, or require

deviation from safety, operating or maintenance In adequate knowledge level about the

4 YES NIL

procedures, including preventive maintenance operation and maintanance.

programs?

Create a high risk or unusual situation during Fire hazard,LPG/Vapor leakage may occur

5 implementation that may not be identified and YES Adequate fire fighting system is available

during implementation

addressed by existing safe work practices?

Affect the integrity of dedicated product or utility

6 systems by creating cross connections or new flow NO

paths?

Deviate from governing regulations, applicable No changes envisaged in the PESO licensed

7 industry standards, or recognized and generally NO vessel

accepted good engineering practices?

Proper work completion and good

Cause temporary abnormal conditions or unusual Possible of mis communication during work communication (logbook) during the change

8 situations to persist across shift change (e.g. road yes completion and during shift change. over.

closure, controlled safety system bypass)?

Increase potential for erosive/corrosive conditions,

9 plugging, or potential creation of dead legs in piping No

circuits?

Affect upstream or downstream operations and or

10 No

products?

11 Introduce contamination to products? YES Oil carry over with LPG. Drain provision available for checking

12 Create new sources of emissions to environment? NO

Involve a major Organizational Change that could Organisational Change is not applicable for this

13 NO

impact Safety or productivity? job

Involve a level of complexity and risk that warrants a Hazop study conducted to identify the risk

14 more detailed hazards analysis (e.g. Riskman II, QRA, Yes involved in the operation of the equipment.

Hazop, What-if checklist)?

Is Further Risk Assessment Required? NO No

IST

MOC #

sk analysis/evaluation (e.g. Hazops, What-If, Riskman II, etc.) may be required. If so, then the Functional Review Team

that a more detailed risk assessment is not required for each question checked as YES below the Functional Review

Additional Risk Mitigation Required Responsible Person Completion Date Initials

Level and pressure indications with

alarm are to be provided in the Control Jayaprakash

Room and loading bay.

Gas sensors are to be installed at both

ends of the vessel. Deluge activation Jayaprakash

from control room is to be given.

EFCV is to be provided in the spare Shift Incharge

nozzle

SOP is to be prepared to carry out Shift Incharge

condensate collection process.

Writtern procedure is to be prepared

along with check list before taking the Shift Incharge

hookup work and ensure the all works

are to be in the safe manner

Prabaharan

All Shift Incharge

Periodical check for presence of oil and

water. All shift incharges

NA NA

1) High level indication and alarm will

be provided in the control room .

2) LCV to be provided at inlet of T 402

to control T 402 level.3) deluge

operation from control room.

If YES, Check Additional Assessment

Y/N Responsible Person Completion Date Initials

Required

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Auto Parts Industry MexicoDokument39 SeitenAuto Parts Industry MexicoAna Celene RojasNoch keine Bewertungen

- Wiring Diagram - C3Dokument3 SeitenWiring Diagram - C3dardo100% (1)

- Standards Followed in Design of Oil JettyDokument12 SeitenStandards Followed in Design of Oil JettyMugeshNoch keine Bewertungen

- Dfe 29 JGDokument91 SeitenDfe 29 JGKale ArbroughNoch keine Bewertungen

- Classic 750VDC Rail ElectrificationDokument17 SeitenClassic 750VDC Rail ElectrificationSemifallen100% (1)

- HP LP BYPASS SYSTEM ADVANTAGESDokument3 SeitenHP LP BYPASS SYSTEM ADVANTAGESkaruna346Noch keine Bewertungen

- Infrastructure Planning for Proposed 314-Acre IT Township in KolkataDokument92 SeitenInfrastructure Planning for Proposed 314-Acre IT Township in KolkataManjunath Hrm100% (2)

- Cummins Engine Company, Inc M-90196 4BT3.9-MDokument2 SeitenCummins Engine Company, Inc M-90196 4BT3.9-Mคุณชายธวัชชัย เจริญสุข100% (1)

- Improve manufacturing performance through loop checkingDokument8 SeitenImprove manufacturing performance through loop checkingOhaneje Uzoma67% (3)

- Strama PaperDokument28 SeitenStrama PaperHiezll Wynn R. Rivera100% (1)

- AC Machinery Fundamentals ExplainedDokument38 SeitenAC Machinery Fundamentals ExplainedDicky Andra Irawan100% (1)

- Water Hammer Arrestor (Handbook JR Smith) PDFDokument22 SeitenWater Hammer Arrestor (Handbook JR Smith) PDFLubyanka100% (1)

- Centrifugal: CompressorsDokument98 SeitenCentrifugal: CompressorsMugesh100% (1)

- Unloading HosesDokument8 SeitenUnloading HosesMugeshNoch keine Bewertungen

- 14-08 Microchem ReportDokument1 Seite14-08 Microchem ReportMugeshNoch keine Bewertungen

- OISD Standard for Optimized Oil and Gas Installation LayoutsDokument29 SeitenOISD Standard for Optimized Oil and Gas Installation LayoutsMugeshNoch keine Bewertungen

- OISD Recommended Practices for Storing and Handling Bulk LPGDokument40 SeitenOISD Recommended Practices for Storing and Handling Bulk LPGMugeshNoch keine Bewertungen

- Design standards for cross-country pipelinesDokument14 SeitenDesign standards for cross-country pipelinesMugeshNoch keine Bewertungen

- On Industrial Hazards and Safe Handling of Hazardous MaterialsDokument34 SeitenOn Industrial Hazards and Safe Handling of Hazardous MaterialsMugeshNoch keine Bewertungen

- Six Sigma Green Belt: (Weekend-Centred GB - 51 Batch)Dokument4 SeitenSix Sigma Green Belt: (Weekend-Centred GB - 51 Batch)MugeshNoch keine Bewertungen

- For More BPCL Papers - : Click HereDokument4 SeitenFor More BPCL Papers - : Click HereMugeshNoch keine Bewertungen

- Shift Incharge ResponsibilitiesDokument1 SeiteShift Incharge ResponsibilitiesMugeshNoch keine Bewertungen

- Report On Loss of Compressor Oil From Primary Oil Seperator: ProblemDokument2 SeitenReport On Loss of Compressor Oil From Primary Oil Seperator: ProblemMugeshNoch keine Bewertungen

- (II) S.No. Technical Assistant Trainees (TAT) / Lab Analyst Trainees (LAT) Qualification No. of PostsDokument7 Seiten(II) S.No. Technical Assistant Trainees (TAT) / Lab Analyst Trainees (LAT) Qualification No. of Postssurendar kohliNoch keine Bewertungen

- CanteenDokument1 SeiteCanteenMugeshNoch keine Bewertungen

- Vapour PR Vs TemperatureDokument5 SeitenVapour PR Vs TemperatureMugeshNoch keine Bewertungen

- Shift Schedule Intercom NumbersDokument11 SeitenShift Schedule Intercom NumbersMugeshNoch keine Bewertungen

- Tuticorin Terminal Wins Best Terminal Award for 2016Dokument2 SeitenTuticorin Terminal Wins Best Terminal Award for 2016MugeshNoch keine Bewertungen

- CHE 31 Chemical Engineering CalculationsDokument13 SeitenCHE 31 Chemical Engineering CalculationsxxkooonxxNoch keine Bewertungen

- A1 Side Suction NRVDokument4 SeitenA1 Side Suction NRVMugeshNoch keine Bewertungen

- Butane Propane SL No N-Butane Isobutane Propane Butane WT% Propane WT%Dokument9 SeitenButane Propane SL No N-Butane Isobutane Propane Butane WT% Propane WT%MugeshNoch keine Bewertungen

- LPG Storage Terminal,: TuticorinDokument1 SeiteLPG Storage Terminal,: TuticorinMugeshNoch keine Bewertungen

- Hazop Condesate LoadingDokument9 SeitenHazop Condesate LoadingMugeshNoch keine Bewertungen

- EB Power Consumption & Cost For April'18: LT /HT DG Power Generation & It's CostDokument4 SeitenEB Power Consumption & Cost For April'18: LT /HT DG Power Generation & It's CostMugeshNoch keine Bewertungen

- LPG Physical PropertiesDokument6 SeitenLPG Physical PropertiesMugeshNoch keine Bewertungen

- Volume Correction Factors-Liquefied Petroleum Gas or PropaneDokument5 SeitenVolume Correction Factors-Liquefied Petroleum Gas or PropaneDadang Ibnu SetyawanNoch keine Bewertungen

- Lect12 Recycle Bypass PurgeDokument1 SeiteLect12 Recycle Bypass PurgeMugeshNoch keine Bewertungen

- Our Valued Client: Presented ToDokument65 SeitenOur Valued Client: Presented ToMugeshNoch keine Bewertungen

- LPG Storage Terminal,: TuticorinDokument1 SeiteLPG Storage Terminal,: TuticorinMugeshNoch keine Bewertungen

- INVERTER FREEZER CHEAT SHEET EpcDokument3 SeitenINVERTER FREEZER CHEAT SHEET EpcHeco Hek Hek CanapiNoch keine Bewertungen

- Coil Gun Design Considerations - Based On Capacitor Configuration, and ESR.20140625.221528Dokument2 SeitenCoil Gun Design Considerations - Based On Capacitor Configuration, and ESR.20140625.221528output33hatNoch keine Bewertungen

- 6284 4 10 PDFDokument14 Seiten6284 4 10 PDFnps100% (1)

- D Regulators enDokument52 SeitenD Regulators enmasakpNoch keine Bewertungen

- WPS-Starting Point Rev1Dokument170 SeitenWPS-Starting Point Rev1Taufiq Sunar50% (2)

- Unit 5.1 GB11 HSDokument5 SeitenUnit 5.1 GB11 HSwinterflowervNoch keine Bewertungen

- Amte 126 MidtermsDokument4 SeitenAmte 126 MidtermsJan Patrick VelosoNoch keine Bewertungen

- 6th Sem Institution Electives_2023-24Dokument3 Seiten6th Sem Institution Electives_2023-24bhuvankumar3877Noch keine Bewertungen

- Contactor FinderDokument10 SeitenContactor FinderEfrain Valiente RiveraNoch keine Bewertungen

- Report On Tech Talk Series: School of Mech & Civil EnggDokument2 SeitenReport On Tech Talk Series: School of Mech & Civil Enggmpatilboy25Noch keine Bewertungen

- Transient Response of RC CircuitDokument5 SeitenTransient Response of RC CircuitJayesh Ruikar100% (1)

- Quotation of Pass Box For ACI 2017 12 28Dokument2 SeitenQuotation of Pass Box For ACI 2017 12 28Lucas khanNoch keine Bewertungen

- Business Ethics Question PaperDokument27 SeitenBusiness Ethics Question PaperPoonamlims100% (1)

- India Genset DemandDokument139 SeitenIndia Genset DemandYanyan2009Noch keine Bewertungen

- Complete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWDokument64 SeitenComplete Range of BBL Crane & Hoist Duty Motors (0.12kW to 1250kWgayathrikanduriNoch keine Bewertungen

- Major Environmental Issues of Pakistan Prevention and SolutionsDokument29 SeitenMajor Environmental Issues of Pakistan Prevention and SolutionssaadNoch keine Bewertungen

- Susol-UL-ACB E 1903 10Dokument100 SeitenSusol-UL-ACB E 1903 10miguelpaltinoNoch keine Bewertungen

- A Systems Approach To Multiphase Reactor SelectionDokument49 SeitenA Systems Approach To Multiphase Reactor SelectionClarence AG YueNoch keine Bewertungen

- Heat Pure 1500 Infrared Heater Owners ManualDokument10 SeitenHeat Pure 1500 Infrared Heater Owners ManualInfraredHeatStoreNoch keine Bewertungen

- First Law of Thermodynamics ExplainedDokument62 SeitenFirst Law of Thermodynamics ExplainedTUSHIT JHANoch keine Bewertungen