Beruflich Dokumente

Kultur Dokumente

Zincalume Fire Performance CSIRO Opinion Letter Fire Performance 13july2011 PDF

Hochgeladen von

Dimas Saputra0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten2 SeitenOriginaltitel

Zincalume-Fire-Performance-CSIRO-Opinion-Letter-Fire-Performance-13July2011.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten2 SeitenZincalume Fire Performance CSIRO Opinion Letter Fire Performance 13july2011 PDF

Hochgeladen von

Dimas SaputraCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

14 Jutus Averue, Riverside Corxeta Pate

Non Rode NSW 2118,

PO Bax 10, Noah Ryde NSW 2113, Ausiraea

Telephone (02) 6400 S448 + Facsimile: (02) 400555 = ABN 41 607 119290 CSIRO

MatoatsSolence and Enghneting )

Our ref: FCO-1897/C04018

BlueScope Steel (Malaysia) Sdn. Bhd

Lot 1551, Jalan Bukit Kepar

42200 Kapar

Selangor D.E.

Malaysia

Attention: Mr Jack Chum Pak Kuan

Technical Specification Engineer

FIRE PERFORMANCE OF ZINCALUME AND COLORBOND SHEETING

Opinion Number FCO-1897

Your e-mail of 28 June

INTRODUCTION

We have re-examined the information referenced by you on the likely performance of your

steel sheeting if tested in accordance with ASTM E 136, ASTM E 84 and ASTM E 648, The

information included

‘+ CSIRO Sponsored Investigations test reports numbered £4957, E4958, £4959,

4960 E496%and FNE6657 being result of AS 1530.3 tests on your Zincalume

Colorbond steel sheeting,

‘+ CSIRO Sponsored Investigation test reports numbered C128, 0129, C131 and C134

being results of AS 1530.1 tests on your Zincalume Colorbond steel sheeting;

+ AS 1630.1 and AS 1830.3; and

© ASTME 136, ASTM E 84 and ASTM E 648.

We have retained these documents.

ANALYSIS

‘The materials under consideration are Zincalume, which is 4 Zinc/aluminium alloy coated

steel sheeting, and Colorbond, which is a pre-painted Zincalume. Both of these material have

been subjected to the test conditions of AS 1830.1, which is a test to determine combustibility

(equivalent to ASTM £136), and AS 1530.3, which is a test fo determine the ignition, flame

spread, heat evolved and smoke developed of a product.

Our report numbered C134 demonstrates that the bare Zincalume steel sheet is deemed not

combustible and would achieve the same result If tested to ASTM E 136. The pre-painted

sheets, due to the nature of the test, which requires the sample to be tested as a multi-layed

laminate, fall into the category of combustible material. This particular result is more an

indication of the unsuitability of the test procedure for these types of sheeting material than an

indication of the fire risk imposed by its use.

Calon #613 9545:2777 + Hghet +61 3 9252 6000 Lis #61 2.2473 7OCD + Nort Ryde +61 20400 Sass

‘Guceneland Cerra for Advanced Tectnaloges +61 73227 4444» Tidbiaila 6% 26204 7810 = Yarelumia + 61 26281 8502

Australian Science, Australia’s Future www.es

FCO-1807 Page 2 of 2 pages

ASTM E 648 is designed to determine flame spread for floor covering and is not applicable to your steel

sheeting although only low levels of flame travel would be exoectad if the sheeting was subjected to this

test. With regard to ASTM E 84, the test conditions of AS 130.3 are similar, in that the specimen is

subjected to an exposure of a heat source and is a measure of the ignition, burning and smoke

production of the sample. The test procedures differ in the size of the specimen, the orientation of the

‘specimen to the heat source and the characteristics. As such itis not possible to give a complete

correlation between specimens subjected to AS 1530.3 and ASTM E 84, What can be said with some

confidence is thal a product that has no or very litle reaction to the AS test would most likely achieve

equivalently low levels of flaming, spread and heat output if subjected the ASTM tests.

The products, being considered here, achieved test indices of 0:0:0:0-1 in AS 1530.3 where the

absolute best results possible are 0:0:0:0 and the worst possible Is 20:10:10:10. This indicates the

products would contribute litle to the spread of any fire exposure,

OPINION/CONCLUSION

Based on the factors detalled above and our experience with similar materials it is the opinion

of the Division that the proposed stee! sheeting materials would achieve the following results if

subjected to the specified test standards.

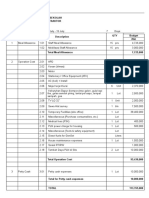

Material ASTME 736 ASTWE 64

Zincalume (bas | Not Combustibio Classification A

‘metal thickness (Flame Spread index

0.2-1.2 mm) <25)

Colotbond (base | Combustible Classification A 1

‘metal thickness (Flame Spread index

0.2-1.0 mm), <26)

Thus both sheeting materials would qualify as Class A under ASTM E 84 classification. Additionally

Zinealume is non-combustible, Also, changes in thickness would not only improve the performance, as it

is the non-combustible component (je the stee!) that is being increased.

PS Cll

Gory

Gafty Colins

Manager, Fire Testing and Assessment

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Data (3) - CSTDokument14 SeitenData (3) - CSTDimas SaputraNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Geo EnergyDokument13 SeitenGeo EnergyDimas SaputraNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Silika PenangananDokument6 SeitenSilika PenangananDimas SaputraNoch keine Bewertungen

- List TransactionDokument38 SeitenList TransactionDimas SaputraNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- DataDokument122 SeitenDataDimas SaputraNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- List TransactionDokument21 SeitenList TransactionDimas SaputraNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Actual CostDokument4 SeitenActual CostDimas SaputraNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Monitoring PO EM SandaiDokument1 SeiteMonitoring PO EM SandaiDimas SaputraNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Cas Flow by Year and MonthDokument1 SeiteCas Flow by Year and MonthDimas SaputraNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Apa Saja Item Pekerjaan Untuk Pembuatan..Dokument5 SeitenApa Saja Item Pekerjaan Untuk Pembuatan..Dimas SaputraNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Pt. Citramasjaya Teknikmandiri: Schedule Procurement Material E&M Gi 150Kv Sandai PLN Uip KalbagbarDokument1 SeitePt. Citramasjaya Teknikmandiri: Schedule Procurement Material E&M Gi 150Kv Sandai PLN Uip KalbagbarDimas SaputraNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- 37140M009200100Dokument2 Seiten37140M009200100Dimas SaputraNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- DataDokument85 SeitenDataDimas SaputraNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Distribution Contractor PSSP: Project Name Circuit Address Job Number CWA Number Est. Start DateDokument23 SeitenDistribution Contractor PSSP: Project Name Circuit Address Job Number CWA Number Est. Start DateDimas SaputraNoch keine Bewertungen

- RFQ DeksonDokument1 SeiteRFQ DeksonDimas SaputraNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- TDS Nitoflor Hardtop IDDokument5 SeitenTDS Nitoflor Hardtop IDDimas SaputraNoch keine Bewertungen

- Price List (Amada Elevator)Dokument2 SeitenPrice List (Amada Elevator)Dimas SaputraNoch keine Bewertungen

- RFQ Pipa PPRDokument4 SeitenRFQ Pipa PPRDimas SaputraNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Roofing Walkway Container: Garut, Jawabarat Indonesia Requested By: Customer ID: DepartmentDokument4 SeitenRoofing Walkway Container: Garut, Jawabarat Indonesia Requested By: Customer ID: DepartmentDimas SaputraNoch keine Bewertungen

- CA - Request 1st MonthDokument18 SeitenCA - Request 1st MonthDimas SaputraNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- W.O Borong Mandor UpahDokument1 SeiteW.O Borong Mandor UpahDimas SaputraNoch keine Bewertungen

- Idoc - Pub - Sample Manpower ScheduleDokument2 SeitenIdoc - Pub - Sample Manpower ScheduleDimas SaputraNoch keine Bewertungen

- Sika Solutions For Watertight Basement StructureDokument32 SeitenSika Solutions For Watertight Basement StructureDimas SaputraNoch keine Bewertungen

- Project ScheduleDokument7 SeitenProject ScheduleDimas SaputraNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)