Beruflich Dokumente

Kultur Dokumente

Triple Eccentric Metal Seated Valves

Hochgeladen von

Felipe Gamboa GálvezOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Triple Eccentric Metal Seated Valves

Hochgeladen von

Felipe Gamboa GálvezCopyright:

Verfügbare Formate

MV Series

Engineering

GREAT Solutions

Triple Eccentric Metal

Seated Valves

MV Series

Triple Eccentric Metal

Seated Valves

Customers worldwide specify our MV Series valves in their Tight shut-

applications because of their unique combination of control, reliability off sealing

and compactness. This makes them fit for purpose in critical high

pressure, tight shut-off, high temperature or cryogenic, throttling and

isolation duties.

Key features

> Resilient metal-to-metal seal > Integral external position indicator on Seal ring seated

valve shaft and body

> Full metal construction

> Wide range of materials and sizes

> Zero leakage bi-directional tight shut-off

> Triple eccentric design

> Quarter turn friction-free operation

> External anti-blowout device

> Fire-safe and fire-tested

Benefits

> Unique triple eccentric metal

seat design Seal ring prior to seating

- Prevents wear

- Zero leakage

- Longer service life

- Allows for lower operating torques

- Tight seal from bi-directional pressure

- Corrosion and erosion resistant

> One-piece seat integrated body

- Conical and inclined

- Ultimate rigidity

- Leak-free performance

- Uninterrupted flange sealing surface

> One-piece shaft and disc arrangement

- Minimal hysteresis Second

- Improves flow capability eccentricity

- Reduces pressure drop

> Special bushings offer immunity to dirt

and polymeric media creating a longer

service life

> Adjustable stuffing box allows flushing,

additional sealing, leakage control

or monitoring

Third First

eccentricity eccentricity

Unique triple eccentric design

Typical applications

> LNG > Blow down

> Process fluids > Sulphur recovery

> Hydrocarbons > Acid / caustic / chloride Full valve selection

> Steam / geothermal steam > Abrasive service available on our website

> Hot gas / sour gas (NACE)

www.imi-critical.com

> Oxygen / hydrogen

Product Specification

Materials Body styles Pressure limits

WCB See below From full vacuum – up to +450 bar

CF8M, CF3M (2200 psi)

LCB, LCC, LC3 Production range

Duplex ND 2” – 160” ANSI CI.50 Applicable standards

Superduplex ND 2” – 160” ANSI CI.300 ISO 15848-1

Monel ND 3” – 80” ANSI CI.600 Design: ANSI B16.34 / ASME VIII

Hastelloy ND 6” – 48” ANSI CI.900 Face to face: API/ ISO/ ANSI

254 SMO ND 6” – 48” ANSI body in ANSI CI.500 Flange: ANSI/ ISO/ DIN/ UNI/ JIS

Alloy steel WC6, WC9 ANSI CI.2500 with ANSI CI.900 trim Fire test: BS 6755–API607-ISO FDIS 10497

Inconel

Alloy 20 Temperature limits Rating

Aluminium bronze From -196°C (-320°F) up to NP 6 – 0 – 16 – 25

Titanium +818°C (+1600°F) ANSI CI.150 – 300 – 600 – 900 –

C5, C12 1500 – 2500

MVF: Double Flanged (Class 150) dimensions

Bore size A B C L I Y F Weight

2” 108 100 240 214 45 250 67 26

21/2” 112 130 240 214 45 250 67 26

3” 114 130 240 214 45 250 67 27

4” 127 135 255 214 45 250 67 31

5” 140 165 265 214 45 250 67 40

6” 140 190 280 214 45 250 67 49

8” 152 215 322 243 45 300 97 80

10” 165 250 380 243 45 300 97 106

12” 178 285 415 243 45 300 97 138

14” 190 315 462 380 48 500 88 182

16” 216 360 523 380 55 600 105 230

18” 222 395 554 440 55 500 123 287

Other body styles available

20” 229 438 592 475 60 600 140 262

Double flanged ISO 5752

24” 267 505 663 520 65 600 165 510

Double flanged ANSI B 16-10 (gate)

26” 292 530 686 510 65 600 159 600

Wafer & lugged API 609

28” 292 575 782 544 74 600 217 730

Butt-weld

30” 318 630 862 658 74 700 169 846

32” 318 630 862 658 74 700 169 970

34” 318 665 895 658 74 700 169 1186

36” 330 745 964 696 115 700 285 1337

40” 410 760 1014 696 115 700 285 1690

IMI Orton

Orton S.r.l.

Via dei Bazachi 50

29121

Piacenza

Italy

Tel: +39 0523 762 511

Fax: +39 0523 762 512

imiorton.sales@imi-critical.com

IMI Critical Engineering

Lakeside, Solihull Parkway

Birmingham Business Park

Birmingham B37 7XZ

United Kingdom

Tel: +44 (0)121 717 3700

Fax: +44 (0)121 717 3701

www.imi-critical.com

Das könnte Ihnen auch gefallen

- EVS en ISO 16137 2006 en PreviewDokument11 SeitenEVS en ISO 16137 2006 en PreviewMohamed MOUKHTARIANoch keine Bewertungen

- A338 Steel StandardDokument2 SeitenA338 Steel StandardguilhermehsssNoch keine Bewertungen

- Mech Malleable Iron Fittings Catalogue PDFDokument12 SeitenMech Malleable Iron Fittings Catalogue PDFics companyNoch keine Bewertungen

- Oooom Om Om: International StandardDokument32 SeitenOooom Om Om: International StandardNizarHamrouniNoch keine Bewertungen

- Instruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Dokument8 SeitenInstruction Manual Enardo 2000 2500 Series Emergency Pressure Relief Vents North America Only en 122600 3Ramon GarciaNoch keine Bewertungen

- Anodes in Cooling Water Exchangers PDFDokument12 SeitenAnodes in Cooling Water Exchangers PDFcbrittaivNoch keine Bewertungen

- Is 778 1984 Gate, Globe and Check Valves For Water Works Purposes (Fourth RevisionDokument32 SeitenIs 778 1984 Gate, Globe and Check Valves For Water Works Purposes (Fourth Revisionyesvvn100% (1)

- ASTM F1545 Plastic Lined Pipe 0803Dokument6 SeitenASTM F1545 Plastic Lined Pipe 0803JabranYounasNoch keine Bewertungen

- Sa 283Dokument3 SeitenSa 283AnilNoch keine Bewertungen

- AISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedDokument4 SeitenAISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedLinus LooNoch keine Bewertungen

- Open Book Testing - API 653Dokument9 SeitenOpen Book Testing - API 653EdisonCorderoNoch keine Bewertungen

- Data Source Book P-7475HDokument51 SeitenData Source Book P-7475HJoão13@Noch keine Bewertungen

- Sferova API6 Ball Valve CatalogueDokument27 SeitenSferova API6 Ball Valve CatalogueWong JowoNoch keine Bewertungen

- Previews - 2033457 PIP VEFV1100MDokument5 SeitenPreviews - 2033457 PIP VEFV1100Mabdulloh_99100% (1)

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Dokument31 SeitenStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNoch keine Bewertungen

- Is 210Dokument16 SeitenIs 210Debopriyo GhoshNoch keine Bewertungen

- Mss sp-71 1997 PDFDokument10 SeitenMss sp-71 1997 PDFChotiwan RattanasatienNoch keine Bewertungen

- Comparing ASME Code Fatigue Evaluation Methods for Nuclear PipingDokument65 SeitenComparing ASME Code Fatigue Evaluation Methods for Nuclear PipingOtso Cronvall100% (1)

- Pneumatic, Piston Type: Needle Valve ActuatorsDokument20 SeitenPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahNoch keine Bewertungen

- Hi - Temp 900Dokument5 SeitenHi - Temp 900bhavesh solankiNoch keine Bewertungen

- Nfa 49 310 Grade Tu 52 B Tubes PDFDokument1 SeiteNfa 49 310 Grade Tu 52 B Tubes PDFMitul MehtaNoch keine Bewertungen

- Astm A 335Dokument8 SeitenAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- PD Cen TS 12201-7-2014Dokument3 SeitenPD Cen TS 12201-7-20141100% (1)

- Standard Metric Bolt Shank Dimensions PDFDokument2 SeitenStandard Metric Bolt Shank Dimensions PDFbcvdocu100% (1)

- Kirloskar Valves Technical Specification CatalogueDokument24 SeitenKirloskar Valves Technical Specification CatalogueAbhinay SuratkarNoch keine Bewertungen

- Sfa-5.01 Filler Metal Procurement GuidelinesDokument10 SeitenSfa-5.01 Filler Metal Procurement GuidelinesCesar Agustin LimousinNoch keine Bewertungen

- API 6D Errata 10 UpdateDokument1 SeiteAPI 6D Errata 10 UpdateANANDNoch keine Bewertungen

- Astm A106 Ts EnglDokument4 SeitenAstm A106 Ts EnglxaviereduardoNoch keine Bewertungen

- ML 1015998765Dokument42 SeitenML 1015998765ডঃ শুভম চ্যাটার্জীNoch keine Bewertungen

- Cylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveDokument1 SeiteCylinders Shall Be Produced As Per IS 7285 and Approved by Chief Controller of ExplosiveAlanka Prasad100% (1)

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDokument1 SeiteThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1Noch keine Bewertungen

- Mi3530 B1820401Dokument1 SeiteMi3530 B1820401abinayaNoch keine Bewertungen

- ISO 15348 2002 Metal Bellows Expansion Joints PDFDokument8 SeitenISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezNoch keine Bewertungen

- Sa 961 PDFDokument10 SeitenSa 961 PDFaruntpeNoch keine Bewertungen

- Non-Asbestos Gasket Material Data SheetDokument1 SeiteNon-Asbestos Gasket Material Data Sheetheena jainNoch keine Bewertungen

- Drop Weight Tear Testing of High Toughness Pipeline MaterialDokument8 SeitenDrop Weight Tear Testing of High Toughness Pipeline MaterialKK SinghNoch keine Bewertungen

- OCS Prel WPS 007Dokument2 SeitenOCS Prel WPS 007vinothNoch keine Bewertungen

- Mil HDBK 695d Change 2Dokument45 SeitenMil HDBK 695d Change 2dhoo_babyNoch keine Bewertungen

- Design and Analysis of Disc Plate in Hot Blast Valve #DN1800Dokument8 SeitenDesign and Analysis of Disc Plate in Hot Blast Valve #DN1800MounicaRasagyaPallaNoch keine Bewertungen

- Astm A 450Dokument10 SeitenAstm A 450Telmo VianaNoch keine Bewertungen

- Astm F 541-04Dokument6 SeitenAstm F 541-04Jorge ToribioNoch keine Bewertungen

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDokument2 SeitenSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNoch keine Bewertungen

- Safety ValvesDokument3 SeitenSafety ValvesGiovanni LerasNoch keine Bewertungen

- VDM Data Sheet Nicrofer 6025 HT - e PDFDokument0 SeitenVDM Data Sheet Nicrofer 6025 HT - e PDFeugenio.gutenbertNoch keine Bewertungen

- Comco Pipe Supply Company Green BookDokument28 SeitenComco Pipe Supply Company Green BookinfoNoch keine Bewertungen

- Vecom - Japanese BlackDokument2 SeitenVecom - Japanese Blackdiaccessltd_17172961Noch keine Bewertungen

- Astm A181-2001 PDFDokument3 SeitenAstm A181-2001 PDFMohammed TariqNoch keine Bewertungen

- API 2H50 Data Sheet 2012 04 02Dokument2 SeitenAPI 2H50 Data Sheet 2012 04 02alvaedison00Noch keine Bewertungen

- Asme Section Ii A-2 Sa-592 Sa-592m PDFDokument4 SeitenAsme Section Ii A-2 Sa-592 Sa-592m PDFAnonymous GhPzn1xNoch keine Bewertungen

- EN10255 Pipe SizeDokument3 SeitenEN10255 Pipe SizeStefan CristescuNoch keine Bewertungen

- PASCAL Check Valves CatalogueDokument19 SeitenPASCAL Check Valves Cataloguecrys100% (1)

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionVon EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNoch keine Bewertungen

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- IMITruflo Rona - C-Rex ValveDokument4 SeitenIMITruflo Rona - C-Rex ValveDanielSchwaskiNoch keine Bewertungen

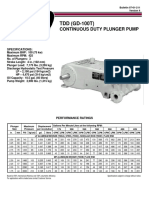

- Data Sheet TDD-GD100T PDFDokument2 SeitenData Sheet TDD-GD100T PDFjhon peñaNoch keine Bewertungen

- Mobile Phones in ChinaDokument9 SeitenMobile Phones in ChinaFelipe Gamboa GálvezNoch keine Bewertungen

- Stock CianuroDokument4 SeitenStock CianuroFelipe Gamboa GálvezNoch keine Bewertungen

- ID Task Mode Task Name Start Finish Text1 1 2 3 4: Project: Programa de Trabajo P Date: Fri 11/10/19Dokument2 SeitenID Task Mode Task Name Start Finish Text1 1 2 3 4: Project: Programa de Trabajo P Date: Fri 11/10/19Felipe Gamboa GálvezNoch keine Bewertungen

- Centro Materiales Tubos HDPE Geomembranas AceroDokument92 SeitenCentro Materiales Tubos HDPE Geomembranas AceroFelipe Gamboa GálvezNoch keine Bewertungen

- Material Inventory ListingDokument147 SeitenMaterial Inventory ListingFelipe Gamboa GálvezNoch keine Bewertungen

- Design Thinking 24-05-19Dokument1 SeiteDesign Thinking 24-05-19Felipe Gamboa GálvezNoch keine Bewertungen

- Cn-Consumption Control 2019Dokument10 SeitenCn-Consumption Control 2019Felipe Gamboa GálvezNoch keine Bewertungen

- Game-Changing Mineral Analysis Tech For Gold Miners - Mining MagazineDokument2 SeitenGame-Changing Mineral Analysis Tech For Gold Miners - Mining MagazineFelipe Gamboa GálvezNoch keine Bewertungen

- Wog General Service Ball ValvesDokument2 SeitenWog General Service Ball ValvesFelipe Gamboa GálvezNoch keine Bewertungen

- Atomac AKH3Dokument4 SeitenAtomac AKH3Felipe Gamboa GálvezNoch keine Bewertungen

- Partes Del TicketDokument1 SeitePartes Del TicketFelipe Gamboa GálvezNoch keine Bewertungen

- 77 1004 ConversionFactorsDokument2 Seiten77 1004 ConversionFactorsFelipe Gamboa GálvezNoch keine Bewertungen

- Triple Eccentric Metal Seated ValvesDokument4 SeitenTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezNoch keine Bewertungen

- Technical Manual: Register 3 Contents - Akh3Dokument29 SeitenTechnical Manual: Register 3 Contents - Akh3Felipe Gamboa GálvezNoch keine Bewertungen

- DPV EC Cert of ConformityDokument1 SeiteDPV EC Cert of ConformityFelipe Gamboa GálvezNoch keine Bewertungen

- 13747-TDS P2K Valves ExplainedDokument1 Seite13747-TDS P2K Valves ExplainedFelipe Gamboa GálvezNoch keine Bewertungen

- Flow Coeffi Cients: Catalog # 77-1006ADokument8 SeitenFlow Coeffi Cients: Catalog # 77-1006AFelipe Gamboa GálvezNoch keine Bewertungen

- Pin Honeywell Rtu2020 Nov2015Dokument5 SeitenPin Honeywell Rtu2020 Nov2015Felipe Gamboa GálvezNoch keine Bewertungen

- Wog General Service Ball ValvesDokument2 SeitenWog General Service Ball ValvesFelipe Gamboa GálvezNoch keine Bewertungen

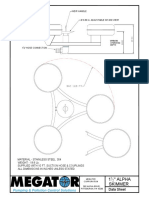

- 1.5 Inch Alpha Skimmer Data SheetDokument1 Seite1.5 Inch Alpha Skimmer Data SheetFelipe Gamboa GálvezNoch keine Bewertungen

- Oil Recovery & Treatment SystemDokument2 SeitenOil Recovery & Treatment SystemFelipe Gamboa GálvezNoch keine Bewertungen

- BTV 2000Dokument12 SeitenBTV 2000Felipe Gamboa GálvezNoch keine Bewertungen

- Argus FK 76M Ball Valve Material ListDokument2 SeitenArgus FK 76M Ball Valve Material ListFelipe Gamboa Gálvez100% (1)

- Triple Eccentric Metal Seated ValvesDokument4 SeitenTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezNoch keine Bewertungen

- HV3 Comparison - DotikiDokument1 SeiteHV3 Comparison - DotikiFelipe Gamboa GálvezNoch keine Bewertungen

- Argus FK75Dokument2 SeitenArgus FK75Felipe Gamboa GálvezNoch keine Bewertungen

- Argus HK35Dokument2 SeitenArgus HK35Felipe Gamboa GálvezNoch keine Bewertungen

- ABZolute Class 150 (+30% Safety)Dokument1 SeiteABZolute Class 150 (+30% Safety)Felipe Gamboa GálvezNoch keine Bewertungen

- Positioner Serie XL - Vlatb048Dokument16 SeitenPositioner Serie XL - Vlatb048Felipe Gamboa GálvezNoch keine Bewertungen

- Lecture 1 - IntroductionDokument30 SeitenLecture 1 - IntroductionNguyễn QuốcAnhNoch keine Bewertungen

- 1000 kVA Diesel Generator Set for Prime PowerDokument4 Seiten1000 kVA Diesel Generator Set for Prime PowerdkshtdkNoch keine Bewertungen

- Seminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyDokument17 SeitenSeminar ON Water Jet Cutting: Raj Kumar Goel Institute of TechnologyRahul kumarNoch keine Bewertungen

- Limit Switches: FeaturesDokument2 SeitenLimit Switches: FeaturesNoUserNameNoch keine Bewertungen

- Thermo-Chapter 17Dokument16 SeitenThermo-Chapter 17Patrick GareauNoch keine Bewertungen

- Fluid Machinery Syllabus PDFDokument3 SeitenFluid Machinery Syllabus PDFBajajNoch keine Bewertungen

- Mesurement and Inspection SheetDokument3 SeitenMesurement and Inspection SheetSaifur RahmanNoch keine Bewertungen

- Design ChimneyDokument30 SeitenDesign ChimneyKandavel Kandy50% (8)

- Module 2Dokument59 SeitenModule 2STEPHEN VILLARUZNoch keine Bewertungen

- Fiitjee: Answers, Hints & SolutionsDokument10 SeitenFiitjee: Answers, Hints & SolutionsZayanmalikNoch keine Bewertungen

- RCC 100 Important Questions 39Dokument33 SeitenRCC 100 Important Questions 39Engr Mehdi BugtiNoch keine Bewertungen

- Screw Air Compressors: SCR Belt DriveDokument2 SeitenScrew Air Compressors: SCR Belt DriveDelwin Jose HernandezNoch keine Bewertungen

- Elster Rotary Gas Meter: I Connected IndustrialDokument6 SeitenElster Rotary Gas Meter: I Connected IndustrialAlvaro Joel Quinteros RochaNoch keine Bewertungen

- Diesel Powered Generating Sets: Our Energy Working For YouDokument2 SeitenDiesel Powered Generating Sets: Our Energy Working For YouAndres Felipe Torres PradaNoch keine Bewertungen

- Keep 316Dokument68 SeitenKeep 316AdityaNoch keine Bewertungen

- The New Mercedes-Benz Medium Duty Engines OM 924 LA and OM 926 LA of The 900 Engine Series For Trucks and Buses.Dokument10 SeitenThe New Mercedes-Benz Medium Duty Engines OM 924 LA and OM 926 LA of The 900 Engine Series For Trucks and Buses.Erick Rodrigues0% (1)

- GATE 2007 CHEMICAL ENGINEERING EXAM REVIEWDokument23 SeitenGATE 2007 CHEMICAL ENGINEERING EXAM REVIEWVammsy Manikanta SaiNoch keine Bewertungen

- WavesDokument4 SeitenWavesMark ProchaskaNoch keine Bewertungen

- Daewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Dokument32 SeitenDaewoo - DWD m8041 m8042 m8043 DWD m1041 m1042 m1043 DWD m1241 m1242 m1243Mihai LunguNoch keine Bewertungen

- Chapter 2. Lagrangian Formalism: Essential Graduate Physics CM: Classical MechanicsDokument14 SeitenChapter 2. Lagrangian Formalism: Essential Graduate Physics CM: Classical MechanicsplfratarNoch keine Bewertungen

- Manufacturing MMMMMMMMMMMMM and Assembling of Drill RodsDokument24 SeitenManufacturing MMMMMMMMMMMMM and Assembling of Drill RodsGoturi KAMALAKAR REDDYNoch keine Bewertungen

- ZZ5371VDMB32100Dokument1 SeiteZZ5371VDMB32100Andy WangNoch keine Bewertungen

- Manual de Partes - Torito 2T FL PDFDokument54 SeitenManual de Partes - Torito 2T FL PDFJuan José Falcon PonceNoch keine Bewertungen

- Inelastic Analysis of StructuresDokument9 SeitenInelastic Analysis of StructuresNaim Demiri0% (1)

- H8.0FT, H8.0FT9, H9.0FT (B299) : 4053648 ©2012 Hyster Company 10/2012Dokument560 SeitenH8.0FT, H8.0FT9, H9.0FT (B299) : 4053648 ©2012 Hyster Company 10/2012pruhavNoch keine Bewertungen

- 14.production Optimization by Nodal Analysis PDFDokument31 Seiten14.production Optimization by Nodal Analysis PDFMuhammad Shehryar100% (1)

- Toyota GR Supra Brochure JulyDokument11 SeitenToyota GR Supra Brochure JulyAnthony Siew MengNoch keine Bewertungen

- GPG291 Designer's Guide To The Options For Ventilation and Cooling 2001Dokument40 SeitenGPG291 Designer's Guide To The Options For Ventilation and Cooling 2001IppiNoch keine Bewertungen

- Site Bumi Barito equipment status and repair updatesDokument1 SeiteSite Bumi Barito equipment status and repair updatesYulian GalihNoch keine Bewertungen

- 6M33 Maintain ManualDokument116 Seiten6M33 Maintain Manualteknisijarummas1Noch keine Bewertungen