Beruflich Dokumente

Kultur Dokumente

Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....

Hochgeladen von

Shijumon KpOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Torque Values For Isolating Gaskets On ASME B16.5 and ASME B16.47 Series....

Hochgeladen von

Shijumon KpCopyright:

Verfügbare Formate

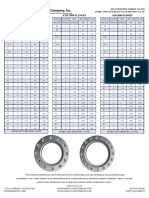

Torque Values for Isolating Gaskets on ASME B16.5 and ASME B16.

47

Series A & B, Class 150 through Class 2500 Flange

Stud Bolt Size Torque Value

Inch Ft- Lb

½ 30

9/16 45

5/8 60

¾ 100

7/8 160

1 245

1-1/8 355

1-1/4 500

1-3/8 680

1-1/2 800

1-5/8 1100

1-3/4 1500

1-7/8 2000

2 2200

2-1/4 3180

2-1/2 4400

2-3/4 5920

3 7720

3-1/4 8400

3-1/2 9000

3-3/4 9600

4 10000

Note: Torque values based on 30,000 psi tension load and 0.16 Friction Factor from API BULL 5A2

thread compound. See Table-SAEP-351-01 Notes.

Commentary Notes:

a) For ASME Class 900 through Class 2500, API-6B and API-6BX Class 2000 through Class 15000,

and RTJ Flanges, the maximum compressive stresses induced during installation should not

exceed 25,000 psi. Design to 12,500 psi when possible.

b) Calculations for compressive stresses applied during torque-up procedures must account for

ring joint grooves, gasket seal grooves, raised face diameters, and gasket inside diameter.

(See PIKOTEK Gasket User's manual).

c) Bolt tensioning equipment may be used for class 900 and above resulting in a minimum

residual bolt stress of 30000 psi and a maximum of 50,000 psi. Refer to PIKOTEK Gasket User's

manual for specific bolting instructions.

Das könnte Ihnen auch gefallen

- Pressure Test Chart API 598Dokument1 SeitePressure Test Chart API 598John0% (1)

- TDC 516 GR 70Dokument2 SeitenTDC 516 GR 70I Kailash Rao100% (1)

- ASME B16 Welding EndsDokument2 SeitenASME B16 Welding Endsf_riseNoch keine Bewertungen

- Table UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1Dokument4 SeitenTable UCS-56-1 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 1MechanicalNoch keine Bewertungen

- Torque Values B7 Studs PDFDokument1 SeiteTorque Values B7 Studs PDFipsthethiNoch keine Bewertungen

- Torque Chart For ASTM A193 Grade B7 StudsDokument3 SeitenTorque Chart For ASTM A193 Grade B7 StudsEmmanuel100% (1)

- WPS SUMMARYDokument10 SeitenWPS SUMMARYbhavin178Noch keine Bewertungen

- Bolt torque requirements for gasketsDokument2 SeitenBolt torque requirements for gasketsrached100% (2)

- UCS-79 - ASME VIII Div 1 (Fiber Elongation)Dokument2 SeitenUCS-79 - ASME VIII Div 1 (Fiber Elongation)Asep Darojat0% (1)

- Check Safety Requirements For Clutch Door According To ASMEDokument3 SeitenCheck Safety Requirements For Clutch Door According To ASMEtranhonghakd5533Noch keine Bewertungen

- WPQ WELDER PERFORMANCE QUALIFICATIONDokument2 SeitenWPQ WELDER PERFORMANCE QUALIFICATIONalokbdasNoch keine Bewertungen

- External Template UG-29 UG-80 - 81 Calculation - Rev.0Dokument5 SeitenExternal Template UG-29 UG-80 - 81 Calculation - Rev.0souren1975100% (1)

- Torqueo Pikotek PDFDokument4 SeitenTorqueo Pikotek PDFjast111100% (1)

- Dimensions Weldolet® Size On Size STD MSS SP97Dokument2 SeitenDimensions Weldolet® Size On Size STD MSS SP97Musslih Yulianto100% (1)

- BS 3293 1960Dokument1 SeiteBS 3293 1960Santhosh ThekkethottiyilNoch keine Bewertungen

- Asme Sec I PWHT RequirementDokument6 SeitenAsme Sec I PWHT RequirementSajin ChandranNoch keine Bewertungen

- Tube Expansion Report Format r.0Dokument1 SeiteTube Expansion Report Format r.0fizanlamin100% (2)

- API 650 Water Storage TankDokument60 SeitenAPI 650 Water Storage TankHgagselim Selim100% (1)

- API Valve Trim ChartDokument2 SeitenAPI Valve Trim ChartkhaireddinNoch keine Bewertungen

- Wall thickness table for steel pipe standardsDokument1 SeiteWall thickness table for steel pipe standardsMukesh Kumar Jha100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDokument2 SeitenElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- Weldolet DimensionDokument4 SeitenWeldolet DimensionabhishekNoch keine Bewertungen

- Torque Values RTJ (B16.5) PDFDokument3 SeitenTorque Values RTJ (B16.5) PDFAnonymous cCS6Xz67% (3)

- WPS GTAW Stainless SteelDokument7 SeitenWPS GTAW Stainless SteelVarun MalhotraNoch keine Bewertungen

- Lesson 09 UW16 UG37 New2Dokument38 SeitenLesson 09 UW16 UG37 New2Kandregula Mohan BabuNoch keine Bewertungen

- Flange Bolt Tightening ProcedureDokument5 SeitenFlange Bolt Tightening ProcedureArya100% (1)

- 2"NS M/V FLANGE MOUNTED UNISIGDokument1 Seite2"NS M/V FLANGE MOUNTED UNISIGPrajwal ShettyNoch keine Bewertungen

- B1a1 Pipe ClassDokument1 SeiteB1a1 Pipe Classbrujula27Noch keine Bewertungen

- Straddle Principle For FlangesDokument1 SeiteStraddle Principle For Flangesameybarve67% (3)

- Stud Bolts For Flange JIS B2222Dokument1 SeiteStud Bolts For Flange JIS B2222Masih BelajarNoch keine Bewertungen

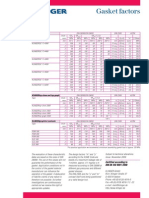

- Klinger - Gasket FactorsDokument4 SeitenKlinger - Gasket FactorsFelip PrietoNoch keine Bewertungen

- API 650 Technical Inquiries SummaryDokument28 SeitenAPI 650 Technical Inquiries SummaryIgnatios Staboulis0% (1)

- 7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFDokument1 Seite7-12-0008 Rev6 (Lug Support For Vertical Vessel) PDFsumit kumar100% (1)

- Hmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Dokument81 SeitenHmel GGSRP Bathinda 16/43: Piping Material Specification 6922-6-44-0005 Rev. 0Krunal Shaj100% (1)

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Dokument1 SeiteMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (2)

- Technical Datasheet For Monorail With Chain HoistDokument5 SeitenTechnical Datasheet For Monorail With Chain HoistvuongNoch keine Bewertungen

- Torque values for ICP flange insulation gasketsDokument2 SeitenTorque values for ICP flange insulation gasketsYasser MahmoudNoch keine Bewertungen

- Hot Insulation Hot InsulationDokument1 SeiteHot Insulation Hot InsulationFarshid KhoshkarNoch keine Bewertungen

- 7-12-0006 Rev6 (Angle Leg Support)Dokument2 Seiten7-12-0006 Rev6 (Angle Leg Support)sumit kumarNoch keine Bewertungen

- Asme U1 FormsDokument4 SeitenAsme U1 FormsoberaiNoch keine Bewertungen

- AES Type Heat ExchangerDokument8 SeitenAES Type Heat ExchangerSudhanshu67100% (1)

- LARGE DIAMETER FLANGES & FITTINGS GUIDEDokument38 SeitenLARGE DIAMETER FLANGES & FITTINGS GUIDEAshfaq Anwer100% (1)

- Blind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGDokument1 SeiteBlind Thickness Calculation: Refer Section 304.5.3 ASME B31.3 Diam, NB Class Diam, DGVarun MalhotraNoch keine Bewertungen

- TAYLOR FORGE - Catalog 722 PDFDokument79 SeitenTAYLOR FORGE - Catalog 722 PDFMiguel Martinez Guerrero0% (1)

- Pipe Fitting Weight ChartDokument1 SeitePipe Fitting Weight Chartab5918590Noch keine Bewertungen

- Torque Values RTJ (B16.5)Dokument3 SeitenTorque Values RTJ (B16.5)Dave Donohue100% (9)

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDokument2 SeitenSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNoch keine Bewertungen

- Astm-A707 CS As LTS PDFDokument5 SeitenAstm-A707 CS As LTS PDFGoutam Kumar DebNoch keine Bewertungen

- Bolt Pocket ChartDokument2 SeitenBolt Pocket ChartAlex LaraNoch keine Bewertungen

- Material With Electrode SelectionDokument2 SeitenMaterial With Electrode SelectionJithuJohn100% (3)

- Bleed & Flushing Ring GuideDokument1 SeiteBleed & Flushing Ring GuideRatna Giridhar KavaliNoch keine Bewertungen

- Outlet Pipe FittingsDokument13 SeitenOutlet Pipe FittingspetromatcompanyNoch keine Bewertungen

- Ramco Recommended Torque ChartDokument2 SeitenRamco Recommended Torque ChartMohamed ElmoghazyNoch keine Bewertungen

- Flanged "Y" Strainers Steel / Stn. Stl. - 300YF Series: Ratings MaterialsDokument1 SeiteFlanged "Y" Strainers Steel / Stn. Stl. - 300YF Series: Ratings MaterialsNitin ZoreNoch keine Bewertungen

- Stud Bolt Length For UploadDokument1 SeiteStud Bolt Length For UploadDan PastorNoch keine Bewertungen

- Stud bolt length chartDokument1 SeiteStud bolt length chartRyan Goh Chuang HongNoch keine Bewertungen

- Stud Bolt Length For Upload PDFDokument1 SeiteStud Bolt Length For Upload PDFvishnu300022Noch keine Bewertungen

- Stud bolt length chartDokument1 SeiteStud bolt length chartPat AuffretNoch keine Bewertungen

- Stud bolt length chartDokument1 SeiteStud bolt length chartTharindu JeewanaNoch keine Bewertungen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Single & Headered Relief Vent Piping Analysis: Todd Jekel, PH.D., P.E. Industrial Refrigeration ConsortiumDokument32 SeitenSingle & Headered Relief Vent Piping Analysis: Todd Jekel, PH.D., P.E. Industrial Refrigeration ConsortiumShijumon KpNoch keine Bewertungen

- Stroke (Brain Attack) : Frontal Lobe (Blue)Dokument6 SeitenStroke (Brain Attack) : Frontal Lobe (Blue)Rizky SutrisnoNoch keine Bewertungen

- pressureProcedTest PDFDokument7 SeitenpressureProcedTest PDFfaizal azizNoch keine Bewertungen

- 3-5400 GB PDFDokument16 Seiten3-5400 GB PDFShijumon KpNoch keine Bewertungen

- 1083ch2 10 PDFDokument17 Seiten1083ch2 10 PDFShijumon KpNoch keine Bewertungen

- Pipe Conversion ChartDokument7 SeitenPipe Conversion ChartramyzottyNoch keine Bewertungen

- SMART Transmitter Power Supply Technical SpecsDokument3 SeitenSMART Transmitter Power Supply Technical SpecsMichael Adu-boahenNoch keine Bewertungen

- 55Dokument6 Seiten55pacifficNoch keine Bewertungen

- B31.1 Vs B31.3Dokument18 SeitenB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- Vapor Pressure and EquilibriumDokument5 SeitenVapor Pressure and EquilibriumShijumon KpNoch keine Bewertungen

- PSV ManualDokument326 SeitenPSV Manualrichardsemper100% (2)

- Aca 0101Dokument24 SeitenAca 0101jabraneNoch keine Bewertungen

- SMART Transmitter Power Supply Technical SpecsDokument3 SeitenSMART Transmitter Power Supply Technical SpecsMichael Adu-boahenNoch keine Bewertungen

- Recommended Torque Values.Dokument1 SeiteRecommended Torque Values.Shijumon KpNoch keine Bewertungen

- EISDokument4 SeitenEISShijumon KpNoch keine Bewertungen

- Control valve sizing handbookDokument21 SeitenControl valve sizing handbooktiwarishailendra2198Noch keine Bewertungen

- Cooper - Intrinsic Safety GuideDokument20 SeitenCooper - Intrinsic Safety Guidetkdrt2166100% (2)

- Process Piping Guide R2.Dokument1 SeiteProcess Piping Guide R2.Shijumon KpNoch keine Bewertungen

- Hazardous Zone, Class, DivisionDokument26 SeitenHazardous Zone, Class, DivisionHạo Nam-Born To WinNoch keine Bewertungen

- Corrosion and Climatic Effects in Electronics: Risto HienonenDokument420 SeitenCorrosion and Climatic Effects in Electronics: Risto HienonenShijumon KpNoch keine Bewertungen

- Aca 0101Dokument24 SeitenAca 0101jabraneNoch keine Bewertungen

- 1.1 Austenitic Stainless SteelDokument29 Seiten1.1 Austenitic Stainless SteelTarek MohamedNoch keine Bewertungen

- Cp01195den 0117.Dokument124 SeitenCp01195den 0117.Shijumon KpNoch keine Bewertungen

- VALTEK Valve Size PDFDokument16 SeitenVALTEK Valve Size PDFalbahbahaneeNoch keine Bewertungen

- B31.1 Vs B31.3Dokument18 SeitenB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDokument57 SeitenAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNoch keine Bewertungen

- 800 wp004 - en P.Dokument19 Seiten800 wp004 - en P.Shijumon KpNoch keine Bewertungen

- Flange Calculations As Per en 1591.Dokument44 SeitenFlange Calculations As Per en 1591.Shijumon Kp100% (3)

- Development of Multicomponent Vaporization/condensation Model For A Reactor Safety Analysis Code SIMMER-III Theoretical Modeling and Basic VerificationDokument16 SeitenDevelopment of Multicomponent Vaporization/condensation Model For A Reactor Safety Analysis Code SIMMER-III Theoretical Modeling and Basic VerificationShijumon KpNoch keine Bewertungen

- 0 40a Fuel Injection SystemDokument10 Seiten0 40a Fuel Injection SystemRusmansyahNoch keine Bewertungen

- Turbine Flowmeter DatasheetDokument7 SeitenTurbine Flowmeter DatasheetRanaIfteeNoch keine Bewertungen

- FMC Flowline Products & Services Catalog PDFDokument80 SeitenFMC Flowline Products & Services Catalog PDFsekead67% (3)

- CT344 EngineDokument69 SeitenCT344 EngineSaMos AdRiianNoch keine Bewertungen

- WP320L WP460LDokument59 SeitenWP320L WP460Ljohn smithNoch keine Bewertungen

- ASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bDokument13 SeitenASME B16.21 Ring and Full Face Dimensions 150 2500# B16.5 & 16.47 Series A&bMONoch keine Bewertungen

- Meter ®: Dual Chamber Orifice FittingDokument2 SeitenMeter ®: Dual Chamber Orifice FittingEnamul KhanNoch keine Bewertungen

- WRT 1 FlangesDokument2 SeitenWRT 1 FlangesShyam BambalNoch keine Bewertungen

- Horizontal Tank ChecklistDokument3 SeitenHorizontal Tank ChecklistA.P.100% (1)

- Astm D5685 PDFDokument5 SeitenAstm D5685 PDFprateekmuleNoch keine Bewertungen

- Catalogue Pressure GaugesDokument50 SeitenCatalogue Pressure GaugesIra MartianiNoch keine Bewertungen

- Instruction Manual Geislinger Damper ENDokument42 SeitenInstruction Manual Geislinger Damper ENingprijon100% (2)

- FP 400e-6dDokument4 SeitenFP 400e-6dRICHINoch keine Bewertungen

- JX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionDokument21 SeitenJX Nippon Oil & Gas Exploration (Malaysia) Limited INSPECTION TEST RECORD (ITR) - A Piping Work CompletionAmyNoch keine Bewertungen

- HPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Dokument29 SeitenHPX-SL - Semi-Open Impeller Pump: Desio Pump Catalog Typical Photo Z 1 of 1Ashwin NarayanNoch keine Bewertungen

- Copper Alloy C95200Dokument11 SeitenCopper Alloy C95200Lin DouaiNoch keine Bewertungen

- MSS 89 PDFDokument21 SeitenMSS 89 PDFkjhgNoch keine Bewertungen

- Tapping FittingsDokument4 SeitenTapping FittingsKharim MarNoch keine Bewertungen

- Flexmaster Joints: Section Pages Section Pages Section PagesDokument16 SeitenFlexmaster Joints: Section Pages Section Pages Section Pageseduardo HernandezNoch keine Bewertungen

- Grundfos CR 5 4 A A A e HqqeDokument10 SeitenGrundfos CR 5 4 A A A e HqqePrejit RadhakrishnaNoch keine Bewertungen

- API 570 Exam QuastionsDokument18 SeitenAPI 570 Exam QuastionsBernathTurnipNoch keine Bewertungen

- Armstrong Model FTV: Hard Flanged Flo-Trex Combination Valve Installation and Operating InstructionsDokument8 SeitenArmstrong Model FTV: Hard Flanged Flo-Trex Combination Valve Installation and Operating InstructionsMarco Antonio Robles BetancourtNoch keine Bewertungen

- Pipe Routing InstructionsDokument37 SeitenPipe Routing InstructionsDANLIN ENGINEERS100% (1)

- Pneumatic ActuatorDokument64 SeitenPneumatic Actuatorsyed khalilNoch keine Bewertungen

- Coating ProcedureDokument43 SeitenCoating ProcedureMerko67% (3)

- Cummins Isde245 30 So40149 Parts CatalogueDokument10 SeitenCummins Isde245 30 So40149 Parts CatalogueChen CarolineNoch keine Bewertungen

- ONIXline BJ Series Dimensions GuideDokument5 SeitenONIXline BJ Series Dimensions Guidemarcusa85Noch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument11 SeitenDisclosure To Promote The Right To InformationBhavin PatelNoch keine Bewertungen

- Flowserve - CPX Chemical Process Reference Manual PDFDokument125 SeitenFlowserve - CPX Chemical Process Reference Manual PDFthod3r100% (4)

- TruckFit Nadgradnja Cisterne MAN 18.310Dokument28 SeitenTruckFit Nadgradnja Cisterne MAN 18.310Anto BanašNoch keine Bewertungen