Beruflich Dokumente

Kultur Dokumente

Marshall Test Worksheet

Hochgeladen von

Moslem AghapourOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Marshall Test Worksheet

Hochgeladen von

Moslem AghapourCopyright:

Verfügbare Formate

Print Form Reset Form

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

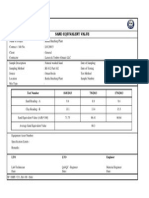

WORKSHEET FOR A MARSHALL MIX DESIGN

AASHTO T 245

Project: Date:

Contractor: Class & Grading of mixture:

Asphalt supplier: Grade of asphalt:

Sources for: Aggregates: Mineral filler:

Testing laboratory name: Phone:

Testing performed by:

Testing reported by:

English ✔ Metric

SUMMARY OF THE PROPOSED JOB-MIX-FORMULA

1. Percent asphalt by mass of total mix1, (Pb) 9. Specific gravity of binder (Gb)

2. Air voids (Va) 10. Specific gravity of mineral filler

3. Voids in mineral aggregate (VMA) 11. Dust-to-Binder ratio (DP)

4. Maximum specific gravity (Gmm ) 12. Moisture susceptibility test results: 2

5. Recommended plant mixing temperature, °C a. Dry strength, kPa

(Attach Temperature Viscosity Curve)

b. Wet strength, kPa

6. Effective specific gravity of aggregate (Gse)

c. Index of retained strength, %

7. Marshall stability, N

8. Marshall flow, 0.25 mm

Gradation Designation: Is RAP included in Mix Design? ✔ Yes No

GRADATION TARGET VALUES AND

ALLOWABLE DEVIATIONS SPECIFIC GRAVITY AND ABSORPTION

Job Mix Target Value Allowable Fine Coarse

Combined

Sieve Sizes Formula Specification Deviation4 Aggregate Aggregate Aggregate

Target Value 3 Range % % (AASHTO T 84) (AASHTO T 85)

Bulk SG (Gsb )

Bulk SSD SG

Apparent SG (Gsb)

Absorption % % %

1

Establish asphalt cement content (percent by mass of mix) to the nearest 0.01 percent.

2

See contract for moisture susceptibility test method: AASTHO T 165/T 167 or AASTHO T 283.

Virgin Aggregate and

3

Establish target values to the nearest 0.1 percent as a part of the job mix formula.

RAP Combined Gsb

4

Allowable deviations plus or minus from established target values.

Form FHWA 1622 (Rev 03-11) Page 1 of 5

WORKSHEET FOR A MARSHALL MIX DESIGN (Continued)

Material Stockpile Description Blend Ratio

Stockpile

A %

B %

C %

D %

E %

Total 0 %

Stockpile Gradation

Stockpile Stockpile Stockpile Stockpile Stockpile Blended Job Mix

Sieve A B C D E Stockpile Formula Specification

Size % % % % % Gradation Target Values Limits

Aggregate Properties

Property Result Specification Property Result Specification

LA Abrasion, % - Grading Fractured Faces, % - Select

AASHTO T 96 ASTM D 5821

Sand Equivalent

Sodium Sulfate Soundness, %

AASHTO T 176, Alt method

AASHTO T 104

#2, reference method

Durability index (Coarse)

Other:

AASHTO T 210

Durability index (Fine)

Other:

AASHTO T 210

Form FHWA 1622 (Rev 03-11) Page 2 of 5

WORKSHEET FOR A MARSHALL MIX DESIGN (Continued)

Trial Number 1 2 3

% Asphalt by mass of total mix, (Pb)

Effective Binder Content (Pbe)

Specimen height, mm

Marshall Stability, N

Marshall Flow, 0.25 mm

Bulk specific gravity, (Gmb)

Bulk unit mass, kg/m³

Max. specific gravity, (Gmm )

Dust-to-Binder ratio, (DP)

% Air voids, (Va )

% Voids in mineral aggregate, (VMA)

Average Marshall Stability value, N

Average Marshall Flow value, 0.25 mm

Average % Air voids, (Va )

Average % Voids in mineral aggregate, (VMA)

Trial Number 4 5 6

% Asphalt by mass of total mix, (Pb)

Effective Binder Content (Pbe)

Specimen height, mm

Marshall Stability, N

Marshall Flow, 0.25 mm

Bulk specific gravity, (Gmb)

Bulk unit mass, kg/m³

Max. specific gravity, (Gmm )

Dust-to-Binder ratio, (DP)

% Air voids, (Va )

% Voids in mineral aggregate, (VMA)

Average Marshall Stability value, N

Average Marshall Flow value, 0.25 mm

Average % Air voids, (Va )

Average Voids in mineral aggregate, (VMA)

Test Results for Each of the Individual Moisture Susceptibility Test Specimens

Percent asphalt binder: AASHTO T 165/T 167 AASHTO T 283

Specimen Dia: 6 inch 4 inch

Antistrip, type, amount:

Freeze cycle: Yes No

Sample I.D. Average

Height Dry

mm Wet

Bulk Specific Dry

Gravity Wet

Air Dry

Voids Wet

Dry

Strength kPa Wet

Retained Strength, %

Form FHWA 1622 (03-11) Page 3 of 5

WORKSHEET FOR A HVEEM MIX DESIGN (Continued)

graph it

Design Curves for Proposed Job Mix Formula (JMF)

AIR VOIDS (Va) MARSHALL FLOW

% Air voids (Va )

0.25 mm

% Asphalt binder (Pb) % Asphalt binder (Pb)

MARSHALL STABILITY VMA

Voids in mineral aggregate

N

% Asphalt binder (Pb) % Asphalt binder (Pb)

Form FHWA 1622 (Rev 03-11) Page 4 of 5

U.S. Department of Transportation

Federal Highway Administration

Federal Lands Highway

RECLAIMED ASPHALT PAVEMENT (RAP) DATA SHEET

Location: Sampled by:

Tested by: Date: _____________________

RAP 1 RAP 2

% of RAP in Mixture

T 308 T 308

Dry Dry

Sieve Size Burned Burned

Gradation Gradation

Gradation Gradation

AC by % mix, Pb

Specific Gravity Specific Gravity

Gmm

Gse

Gse = (100 – Pb)/(10/Gmm – Pb/Gb)

Gsb

Gsb = Gse/(((Pba*Gse)/(100*Gb)) + 1)

Pba = (assumed) 1.00 1.00

Gb = (assumed) 1.010 1.010

Remarks:

Form FHWA 1622 (Rev 03-11) Page 5 of 5

Das könnte Ihnen auch gefallen

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementVon EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNoch keine Bewertungen

- Bitumen ExtractionDokument7 SeitenBitumen ExtractionArjun Raj100% (1)

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDokument7 SeitenStandard Test Procedures Manual: 1. Scope 1.1. Description of TestMuhsin KhanNoch keine Bewertungen

- Calculating and Determining Volumetric Properties of Hot Mix Asphalt SuperPaveDokument4 SeitenCalculating and Determining Volumetric Properties of Hot Mix Asphalt SuperPavefaragahmed707756Noch keine Bewertungen

- Specific Gravity of Filler: Determination Trial No AverageDokument1 SeiteSpecific Gravity of Filler: Determination Trial No AveragePrasanna S KulkarniNoch keine Bewertungen

- ASTM C88 Soundness of AggregateDokument3 SeitenASTM C88 Soundness of AggregateShaher Abo Meazer100% (1)

- Is 15462 2004 Modified Rubber BItumen PDFDokument16 SeitenIs 15462 2004 Modified Rubber BItumen PDFrajeshji_000100% (3)

- Highway RehabilitationDokument31 SeitenHighway Rehabilitationketh patrickNoch keine Bewertungen

- Lesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008Dokument37 SeitenLesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008akmeez100% (1)

- Design of Hot Mix Asphalt Using Bailey Method of GradationDokument8 SeitenDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- D7113 tcxp6531 DensityDokument3 SeitenD7113 tcxp6531 DensityDasarathaNoch keine Bewertungen

- Warm Mix Asphalt: "National Perspective"Dokument46 SeitenWarm Mix Asphalt: "National Perspective"Royhan RizkyNoch keine Bewertungen

- Aashto T 201Dokument3 SeitenAashto T 201Mohammed AliNoch keine Bewertungen

- 75 81 EngDokument84 Seiten75 81 Engmehrdad_so1981Noch keine Bewertungen

- Astm E1170Dokument10 SeitenAstm E1170Mutyaba Johnson100% (1)

- Bulk Specific GravityDokument9 SeitenBulk Specific Gravityelnaqa176Noch keine Bewertungen

- ASTM D2940 Agregates For Base CourseDokument1 SeiteASTM D2940 Agregates For Base Courseتوفيق عبداللهNoch keine Bewertungen

- HMA Mix Design Report-2Dokument11 SeitenHMA Mix Design Report-2yustinokwingwa100% (1)

- D2489Dokument2 SeitenD2489reefreef100% (1)

- Astm d4123 PDFDokument4 SeitenAstm d4123 PDFShantale Andrión100% (2)

- D4867 PDFDokument5 SeitenD4867 PDFAdderly Ortega100% (1)

- M 17-07 Filler For Bituminous Paving Mix PDFDokument3 SeitenM 17-07 Filler For Bituminous Paving Mix PDFWalticoZegarraHerrera100% (1)

- ASTM (Los Angeles Test)Dokument4 SeitenASTM (Los Angeles Test)Efri DwiyantoNoch keine Bewertungen

- Marshall Mix DesignDokument3 SeitenMarshall Mix DesignHasanur Rahman Mishu33% (3)

- Sma PMB40Dokument114 SeitenSma PMB40Er Thyagaraj Gowda100% (1)

- Asphalt Module AASHTO T-269 2003 PDFDokument1 SeiteAsphalt Module AASHTO T-269 2003 PDFguru nathNoch keine Bewertungen

- Astm D 4318Dokument16 SeitenAstm D 4318Camilo OrozcoNoch keine Bewertungen

- WMM Calibration 05.01.2016Dokument8 SeitenWMM Calibration 05.01.2016SRR QAQCNoch keine Bewertungen

- D6857Dokument5 SeitenD6857DannyChaconNoch keine Bewertungen

- Highway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik PahariDokument2 SeitenHighway Material Testing & Quality Control, 1/e: G. Venkatappa Rao, D.V. Bhavanna Rao, K. Ramachandra Rao & Kausik Paharisunil777tvpm100% (2)

- Rubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodDokument8 SeitenRubber Content of Crumb Rubber Modified Bitumen: Soxhlet MethodLa FoliakNoch keine Bewertungen

- C 11 - R0 Sand Equivalent Value - Barka Batching PlantDokument1 SeiteC 11 - R0 Sand Equivalent Value - Barka Batching PlantUtpal Mondal100% (1)

- Letter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatDokument4 SeitenLetter To Highway Colleagues in India On Use of "Third Class" Bitumen Emulsion For Prime CoatProf. Prithvi Singh Kandhal100% (1)

- Astm D3740-11 PDFDokument7 SeitenAstm D3740-11 PDFrokealphaNoch keine Bewertungen

- Astm D 6910/D 6910M 19 Standard Test Method For Marsh Funnel Viscosity of Construction SlurriesDokument1 SeiteAstm D 6910/D 6910M 19 Standard Test Method For Marsh Funnel Viscosity of Construction SlurriesAbhinav KumarNoch keine Bewertungen

- ASTM 2493 Viscosidad - TemperaturaDokument5 SeitenASTM 2493 Viscosidad - TemperaturaDiana Moscoso100% (1)

- Worktips 31 Asphalt Paving Speed PDFDokument2 SeitenWorktips 31 Asphalt Paving Speed PDFvamshi100% (1)

- Marshall Mix Design - Current PracticesDokument20 SeitenMarshall Mix Design - Current PracticesProf. Prithvi Singh Kandhal100% (1)

- Asphalt Concrete With Encapsulated CbsDokument13 SeitenAsphalt Concrete With Encapsulated CbsMariaNilaZaragozaPalacioNoch keine Bewertungen

- Elastic RecoveryDokument4 SeitenElastic RecoverypdbNoch keine Bewertungen

- Mix Design of Semi Dense Bituminous ConcreteDokument18 SeitenMix Design of Semi Dense Bituminous ConcreteRahul GoyalNoch keine Bewertungen

- Water Bound Macadam-WbmDokument11 SeitenWater Bound Macadam-WbmCheng EngiNoch keine Bewertungen

- Shear Susceptibility of Asphalts in Relation To Pavement PerformanceDokument27 SeitenShear Susceptibility of Asphalts in Relation To Pavement PerformanceProf. Prithvi Singh Kandhal100% (1)

- Los Angeles Abrasion TestDokument2 SeitenLos Angeles Abrasion TestyattapuNoch keine Bewertungen

- Mix Design Using RAPDokument3 SeitenMix Design Using RAPRaghav100% (1)

- Astm Ac20Dokument3 SeitenAstm Ac20Juan QuiñonesNoch keine Bewertungen

- Is 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)Dokument17 SeitenIs 8887 (2004) - Bitumen Emulsion For Roads (Cationic Type)arjun kumar50% (2)

- Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) TestDokument8 SeitenPerformance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Testmohammed karasnehNoch keine Bewertungen

- ASTM For OGFC PDFDokument7 SeitenASTM For OGFC PDFSri RamyaNoch keine Bewertungen

- D 4867 - D 4867M - 04Dokument5 SeitenD 4867 - D 4867M - 04Luisinho Alvarez ChávezNoch keine Bewertungen

- Utilization of Copper Slag in Bituminous MixDokument12 SeitenUtilization of Copper Slag in Bituminous MixMuktipada DasNoch keine Bewertungen

- Rap GSB and WMM PDFDokument4 SeitenRap GSB and WMM PDFvenkateswara rao PothinaNoch keine Bewertungen

- Copy of Aggregate Gradation-06-09-2022Dokument8 SeitenCopy of Aggregate Gradation-06-09-2022Bagish Upadhyay UpadhyayNoch keine Bewertungen

- SBS BinderDokument11 SeitenSBS Binderprabin kumar ashishNoch keine Bewertungen

- UserManual SuperpaveDokument19 SeitenUserManual Superpavericardogr_2005100% (1)

- Stabilization of Soil Using AdmixtureDokument17 SeitenStabilization of Soil Using AdmixtureVarun Singh ChandelNoch keine Bewertungen

- Sampling Bituminous Paving Mixtures: Standard Practice ForDokument4 SeitenSampling Bituminous Paving Mixtures: Standard Practice ForAnonymous x7VY8VF7Noch keine Bewertungen

- Worksheet For Superpave Asphalt Concrete Mix Design Aashto R 35Dokument4 SeitenWorksheet For Superpave Asphalt Concrete Mix Design Aashto R 35deenhanifah695Noch keine Bewertungen

- 25.00mm Class B Mix Design Submittal 2022 1622 - v13Dokument4 Seiten25.00mm Class B Mix Design Submittal 2022 1622 - v13Don PopinoNoch keine Bewertungen

- Kingdom of Saudi Arabia: Marshall Asphalt Mix Design DataDokument1 SeiteKingdom of Saudi Arabia: Marshall Asphalt Mix Design DataHamza AldaeefNoch keine Bewertungen

- NCHRP Synthesis 432Dokument59 SeitenNCHRP Synthesis 432Moslem AghapourNoch keine Bewertungen

- Paper No. 03-3554 Paper Unavailable For CD-ROMDokument1 SeitePaper No. 03-3554 Paper Unavailable For CD-ROMMoslem AghapourNoch keine Bewertungen

- Sciencedirect3d4b5162 fd47 20130418072036Dokument10 SeitenSciencedirect3d4b5162 fd47 20130418072036Moslem AghapourNoch keine Bewertungen

- Paper No. 03-2345 Paper Unavailable For CD-ROMDokument1 SeitePaper No. 03-2345 Paper Unavailable For CD-ROMMoslem AghapourNoch keine Bewertungen

- Paper No. 03-2118 Paper Unavailable For CD-ROM: Title: Traffic Flow On Freeway Upgrades Author: Brilon, WernerDokument1 SeitePaper No. 03-2118 Paper Unavailable For CD-ROM: Title: Traffic Flow On Freeway Upgrades Author: Brilon, WernerMoslem AghapourNoch keine Bewertungen

- Paper No. 03-2243 Paper Unavailable For CD-ROM: Title: Public Awareness and Highway Safety Author: Tignor, Samuel CDokument1 SeitePaper No. 03-2243 Paper Unavailable For CD-ROM: Title: Public Awareness and Highway Safety Author: Tignor, Samuel CMoslem AghapourNoch keine Bewertungen

- Paper No. 03-2107 Paper Unavailable For CD-ROMDokument1 SeitePaper No. 03-2107 Paper Unavailable For CD-ROMMoslem AghapourNoch keine Bewertungen

- Estimation of Asphalt Concrete Fatigue Curves - A Damage Theory Approach 2008 Construction and Building MaterialsDokument7 SeitenEstimation of Asphalt Concrete Fatigue Curves - A Damage Theory Approach 2008 Construction and Building MaterialsMoslem AghapourNoch keine Bewertungen

- Investigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsDokument5 SeitenInvestigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsMoslem AghapourNoch keine Bewertungen

- Laboratory Study of Fatigue Characteristics of HMA Surface Mixtures Containing RAPDokument11 SeitenLaboratory Study of Fatigue Characteristics of HMA Surface Mixtures Containing RAPMoslem AghapourNoch keine Bewertungen

- Esearch Esults Igest: National Cooperative Highway Research ProgramDokument17 SeitenEsearch Esults Igest: National Cooperative Highway Research ProgramMoslem AghapourNoch keine Bewertungen

- D75 PDFDokument5 SeitenD75 PDFMoslem AghapourNoch keine Bewertungen

- Midterm Fin Oo4Dokument82 SeitenMidterm Fin Oo4patricia gunio100% (1)

- Train TicketDokument2 SeitenTrain TicketGautam KumarNoch keine Bewertungen

- Cronbach's AlphaDokument4 SeitenCronbach's AlphaHeide Orevillo Apa-apNoch keine Bewertungen

- Small Roller Granulator NPK Compound Fertilizer Production ProcessDokument3 SeitenSmall Roller Granulator NPK Compound Fertilizer Production Processluna leNoch keine Bewertungen

- TUF-2000M User Manual PDFDokument56 SeitenTUF-2000M User Manual PDFreinaldoNoch keine Bewertungen

- Thermo King CG 2000Dokument155 SeitenThermo King CG 2000Connie TaibaNoch keine Bewertungen

- Lynette Hawkins, BMG Awesome InsightDokument2 SeitenLynette Hawkins, BMG Awesome Insightawesomei100% (1)

- Motorola Droid 2Dokument11 SeitenMotorola Droid 2Likith MNoch keine Bewertungen

- ADMS 2510 Week 13 SolutionsDokument20 SeitenADMS 2510 Week 13 Solutionsadms examzNoch keine Bewertungen

- Flexi Multiradio Introduction - Sharing SessionDokument96 SeitenFlexi Multiradio Introduction - Sharing SessionRobby MiloNoch keine Bewertungen

- I-Lt-Cyclomax 3.7-3Dokument10 SeitenI-Lt-Cyclomax 3.7-3Luis Fernando OrtigozaNoch keine Bewertungen

- FEDokument20 SeitenFEKenadid Ahmed OsmanNoch keine Bewertungen

- 1.3.2 SIC/XE Machine Architecture: 1 Megabytes (1024 KB) in Memory 3 Additional Registers, 24 Bits in LengthDokument8 Seiten1.3.2 SIC/XE Machine Architecture: 1 Megabytes (1024 KB) in Memory 3 Additional Registers, 24 Bits in LengthSENTHILKUMAR PNoch keine Bewertungen

- Add MITx Credentials To Resume and LinkedIn PDFDokument5 SeitenAdd MITx Credentials To Resume and LinkedIn PDFRizwanNoch keine Bewertungen

- SRB 301 Ma Operating Instructions Safety-Monitoring ModulesDokument6 SeitenSRB 301 Ma Operating Instructions Safety-Monitoring ModulesMustafa EranpurwalaNoch keine Bewertungen

- Cost Estimate, RevisedDokument6 SeitenCost Estimate, RevisedUdit AmatNoch keine Bewertungen

- Slid e 4-1Dokument67 SeitenSlid e 4-1Rashe FasiNoch keine Bewertungen

- Daily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationDokument2 SeitenDaily Activities List - TCF3 (Safety Aramco) : Work Description Date LocationSheri DiĺlNoch keine Bewertungen

- Vbulletin 5 Connect: Quick Start Guide (Ver 1.0)Dokument21 SeitenVbulletin 5 Connect: Quick Start Guide (Ver 1.0)dantevasquezNoch keine Bewertungen

- BS en 12285-1-2003 (2006)Dokument162 SeitenBS en 12285-1-2003 (2006)dahzahNoch keine Bewertungen

- Oil and Gas Reloaded: Offshore ArgentinaDokument9 SeitenOil and Gas Reloaded: Offshore ArgentinaMuhammad Fahmi AnbNoch keine Bewertungen

- RODEL LUZ y ONG, Petitioner, People of The Philippines, Respondent. FactsDokument1 SeiteRODEL LUZ y ONG, Petitioner, People of The Philippines, Respondent. FactsBee Raagas100% (1)

- FII Ordering SuppliesDokument9 SeitenFII Ordering SuppliesO GamezNoch keine Bewertungen

- Media DRIVEON Vol25 No2Dokument21 SeitenMedia DRIVEON Vol25 No2Nagenthara PoobathyNoch keine Bewertungen

- Cash Management Bank of IndiaDokument52 SeitenCash Management Bank of Indiaakalque shaikhNoch keine Bewertungen

- Notes in Judicial AffidavitDokument11 SeitenNotes in Judicial AffidavitguibonganNoch keine Bewertungen

- Ped Med HandbookDokument27 SeitenPed Med HandbookSoad Shedeed0% (1)

- IEC947-5-1 Contactor Relay Utilization CategoryDokument1 SeiteIEC947-5-1 Contactor Relay Utilization CategoryipitwowoNoch keine Bewertungen

- Unilift de DGDDokument36 SeitenUnilift de DGDLove SemsemNoch keine Bewertungen

- ChinatownDokument1 SeiteChinatownAiken KomensenNoch keine Bewertungen